JP2014020456A - Thrust roller bearing - Google Patents

Thrust roller bearing Download PDFInfo

- Publication number

- JP2014020456A JP2014020456A JP2012159336A JP2012159336A JP2014020456A JP 2014020456 A JP2014020456 A JP 2014020456A JP 2012159336 A JP2012159336 A JP 2012159336A JP 2012159336 A JP2012159336 A JP 2012159336A JP 2014020456 A JP2014020456 A JP 2014020456A

- Authority

- JP

- Japan

- Prior art keywords

- negative pressure

- roller bearing

- ring member

- thrust roller

- cage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Rolling Contact Bearings (AREA)

Abstract

Description

この発明はスラストころ軸受に関する。 The present invention relates to a thrust roller bearing.

従来、例えば、遊星歯車機構のキャリアに配設される軸方向に所定間隔を隔てる両支持部の間に、遊星歯車がラジアルころ軸受を介しかつ中心軸を中心として回転可能に組み付けたものが知られている。

このような遊星歯車機構において、キャリアの両支持部と遊星歯車の両端面との間にワッシャ(例えば、銅ワッシャ)が介在され、遊星歯車のスラスト荷重をワッシャで受けるように構成したものがある。

また、遊星歯車のスラスト荷重による摩擦損失を軽減するために、図10に示すように、キャリア105の両支持部106と、遊星歯車110の両端面との間に、ワッシャに代えて、軌道輪部材140と、この軌道輪部材140の一側面の軌道面に転動可能に配設される複数のころ121と、これら複数のころ121を保持する保持器150とを備えたスラストころ軸受が配設されたものがある。

また、スラストころ軸受において、例えば、特許文献1に開示されているように、保持器の柱部に潤滑油を保持する凹部が設けられたものがある。

また、スラストころ軸受において、例えば、特許文献2に開示されているように、遊星歯車の端面と軌道輪部材とがテーパ嵌合によって密着させたものがある。

Conventionally, for example, it is known that a planetary gear is assembled via a radial roller bearing and rotatable about a central axis between both support portions arranged at a predetermined interval in the axial direction disposed on the carrier of the planetary gear mechanism. It has been.

In such a planetary gear mechanism, there is a configuration in which a washer (for example, a copper washer) is interposed between both support portions of the carrier and both end faces of the planetary gear, and the thrust load of the planetary gear is received by the washer. .

Further, in order to reduce the friction loss due to the thrust load of the planetary gear, as shown in FIG. 10, a raceway ring is used instead of the washer between both the

In addition, as disclosed in Patent Document 1, for example, there are thrust roller bearings in which a concave portion for holding lubricating oil is provided in a pillar portion of a cage.

In addition, as disclosed in

ところで、図10に示すスラストころ軸受においては、キャリア105の両支持部106と遊星歯車110の両端面との間に、ワッシャに代えて、軌道輪部材140と、複数のころ121を保持した保持器150とがそれぞれ個別に組み付けられるため、組付工数が多くなり、組付性が悪化する。

By the way, in the thrust roller bearing shown in FIG. 10, a

この発明の目的は、前記問題点に鑑み、組付性の向上を図ることができるスラストころ軸受を提供することである。 In view of the above problems, an object of the present invention is to provide a thrust roller bearing capable of improving assemblability.

前記課題を解決するために、この発明の請求項1に係るスラストころ軸受は、軌道輪部材と、この軌道輪部材の一側面の軌道面に転動可能に配設される複数のころと、これら複数のころを保持する保持器とを備えたスラストころ軸受であって、

前記軌道輪部材と前記保持器との対向する両側面うち、少なくとも一方の部材の側面には、他方部材の側面に負圧によって吸着する単数又は複数の負圧発生用凹部が形成されていることを特徴とする。

In order to solve the above-mentioned problem, a thrust roller bearing according to claim 1 of the present invention includes a bearing ring member, and a plurality of rollers arranged to roll on a raceway surface of one side surface of the bearing ring member, A thrust roller bearing comprising a cage for holding the plurality of rollers,

Of the opposite side surfaces of the race ring member and the cage, at least one member side surface is formed with one or a plurality of negative pressure generating recesses that are attracted to the side surface of the other member by negative pressure. It is characterized by.

前記構成によると、スラストころ軸受を組み付ける前の状態において、負圧発生用凹部が負圧にされることで、その負圧による吸着力で軌道輪部材と、複数のころを保持した保持器とが一体化される。

軌道輪部材と保持器とが一体化された状態で、例えば、キャリアの支持部と遊星歯車の端面との間に配置されて組み付けられる。

このため、軌道輪部材と保持器とがそれぞれ個別に配置されて組み付ける場合と比べ、組付性の向上を図ることができる。

According to the above-described configuration, in the state before the thrust roller bearing is assembled, the negative pressure generating recess is made negative pressure, so that the bearing ring member and the cage that holds the plurality of rollers by the suction force by the negative pressure, Are integrated.

In a state where the bearing ring member and the cage are integrated, for example, the bearing ring member and the cage are arranged and assembled between the support portion of the carrier and the end face of the planetary gear.

For this reason, compared with the case where a bearing ring member and a holder | retainer are each arrange | positioned separately and assembled | attached, the improvement of an assembly | attachment property can be aimed at.

請求項2に係るスラストころ軸受は、請求項1に記載のスラストころ軸受であって、軌道輪部材と保持器との対向する両側面うち、負圧発生用凹部が形成された一方の部材の側面に対向する他方部材の側面には、前記軌道輪部材と前記保持器とが設定角度相対回転したときに、前記負圧発生用凹部に重なって負圧を解放する負圧解放部が形成されていることを特徴とする。 A thrust roller bearing according to a second aspect is the thrust roller bearing according to the first aspect, wherein one of the opposite side surfaces of the race ring member and the cage is formed with a negative pressure generating recess. On the side surface of the other member facing the side surface, a negative pressure release portion is formed that releases the negative pressure overlapping the negative pressure generating recess when the raceway ring member and the cage rotate relative to each other by a set angle. It is characterized by.

前記構成によると、軌道輪部材と保持器とが設定角度相対回転したときには、負圧解放部が負圧発生用凹部に重なって負圧を解放する。このため、軌道輪部材と保持器とが相対的に回転自在となる。 According to the above configuration, when the race ring member and the cage rotate relative to each other at a set angle, the negative pressure release portion overlaps the negative pressure generating recess to release the negative pressure. For this reason, the bearing ring member and the cage are relatively rotatable.

請求項3に係るスラストころ軸受は、請求項1に記載のスラストころ軸受であって、

負圧発生用凹部は、保持器の側面に形成され、負圧解放部は、軌道輪部材の側面に形成され、かつ前記軌道輪部材の中心孔の外周から径方向外方へ延びる溝状又は切欠状の負圧解放溝によって構成されていることを特徴とする。

The thrust roller bearing according to

The negative pressure generating recess is formed on the side surface of the cage, and the negative pressure releasing portion is formed on the side surface of the race ring member, and is a groove-like shape extending radially outward from the outer periphery of the center hole of the race ring member. It is characterized by comprising a notch-shaped negative pressure release groove.

前記構成によると、保持器が鋼鉄板のプレス加工や合成樹脂材によって成形すると同時に、保持器の側面に負圧発生用凹部を容易に形成することができる。

また、軌道輪部材の側面に対し同軌道輪部材の中心孔の外周から径方向外方へ延びる溝状又は切欠状の負圧解放溝を形成することで負圧解放部を容易に形成することができる。

According to the said structure, the recessed part for negative pressure generation | occurrence | production can be easily formed in the side surface of a holder | retainer simultaneously with a cage | basket | molding by the press work of a steel plate or a synthetic resin material.

Further, the negative pressure release portion can be easily formed by forming a groove-like or notched negative pressure release groove extending radially outward from the outer periphery of the center hole of the race ring member on the side surface of the race ring member. Can do.

請求項4に係るスラストころ軸受は、請求項1に記載のスラストころ軸受であって、

負圧発生用凹部は、保持器の側面に形成され、負圧解放部は、軌道輪部材の側面から反対側側面にわたって貫通する負圧解放孔によって構成されていることを特徴とする。

The thrust roller bearing according to claim 4 is the thrust roller bearing according to claim 1,

The negative pressure generating recess is formed on the side surface of the cage, and the negative pressure release portion is configured by a negative pressure release hole penetrating from the side surface of the bearing ring member to the opposite side surface.

前記構成によると、軌道輪部材の側面から反対側側面にわたって負圧解放孔を形成することで負圧解放部を容易に形成することができる。 According to the said structure, a negative pressure release part can be easily formed by forming a negative pressure release hole from the side surface of a bearing ring member to an opposite side surface.

この発明を実施するための形態について実施例にしたがって説明する。 A mode for carrying out the present invention will be described in accordance with an embodiment.

この発明の実施例1を図面にしたがって説明する。

図1と図2に示すように、この実施例1に係るスラストころ軸受は、自動車のオートマチックトランスミッション等に配設される遊星歯車機構1に採用される場合を例示するものであり、周知のように、遊星歯車機構1は、太陽歯車2と、リングギヤ3と、複数(図1では3つ)の遊星歯車10と、キャリア5とを備えている。

図2に示すように、キャリア5には、軸方向に所定間隔を保って支持部6が配設され、これら両支持部6の間に、遊星歯車10が中心軸8を中心として回転可能に組み付けられている。

A first embodiment of the present invention will be described with reference to the drawings.

As shown in FIGS. 1 and 2, the thrust roller bearing according to the first embodiment exemplifies a case where it is employed in a planetary gear mechanism 1 disposed in an automatic transmission or the like of an automobile. In addition, the planetary gear mechanism 1 includes a

As shown in FIG. 2, the

図2に示すように、遊星歯車10の中心孔11と、中心軸8の外周面との間には、ラジアルころ軸受20が配設されている。

このラジアルころ軸受20は、遊星歯車10の中心孔11の内径面を外輪軌道面とし、中心軸8の外周面を内輪軌道として、これら両者間の環状の隙間に組み込まれた複数のころ(針状ころも含む)21と、これら複数のころ21を転動可能に保持する保持器22とを備えている。

As shown in FIG. 2, a radial roller bearing 20 is disposed between the

The radial roller bearing 20 includes a plurality of rollers (needle) incorporated in an annular clearance between the

図2と図3に示すように、キャリア5の両支持部6と、遊星歯車10の両端面との間には、スラストころ軸受30がそれぞれ配設されている。

スラストころ軸受30は、支持部6側に配設された軌道輪部材40と、遊星歯車10の端面を軌道面12とし、この軌道面12と、これに対向する軌道輪部材40の一側面の軌道面41との間に転動可能に配設される複数のころ31と、これら複数のころ31を保持する保持器50とを備えている。

As shown in FIGS. 2 and 3,

The thrust roller bearing 30 has a

図3に示すように、軌道輪部材40は、炭素鋼板がプレス加工されることによって形成されており、その軌道輪部材40の中心部には、中心軸8の外周面に僅かな隙間をもって嵌挿される中心孔42が形成される。

As shown in FIG. 3, the

図3と図4に示すように、スラストころ軸受30の保持器50は、径方向に所定間隔を隔てる内径側環状部51及び外径側環状部52と、これら内・外径の両環状部51、52を連結すると共に、複数のころ(針状ころも含む)31に対応する複数のポケット53を区画形成する複数の柱部54とを一体に備えている。

なお、保持器50は、鋼鉄板のプレス加工品や耐熱性及び耐摩耗性を有する合成樹脂製成形品等によって形成され、その各ポケット53には、ころ31を抜け止めする爪(図示しない)が形成されている。

As shown in FIGS. 3 and 4, the

The

図3と図4に示すように、軌道輪部材40と保持器50との対向する両側面うち、少なくとも一方の部材の側面には、他方部材の側面に負圧によって吸着する単数又は複数の負圧発生用凹部60が形成されている。

一方、他方部材の側面には、軌道輪部材40と保持器50とが設定角度相対回転したときに、負圧発生用凹部60に重なって負圧を解放する負圧解放部61が形成されている。

As shown in FIG. 3 and FIG. 4, of the opposing side surfaces of the

On the other hand, a negative

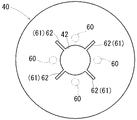

この実施例1において、図3と図4に示すように、保持器50の一側面(軌道輪部材40と対向する側面)の内径側環状部51に、複数(図では四つ)の円形状をなす負圧発生用凹部60が所定の配設ピッチ円上に等間隔で形成されている。

一方、図3と図7に示すように、軌道輪部材40の一側面(保持器50と対向する側面)には、軌道輪部材40と保持器50とが設定角度(この実施例1では45度)相対回転したときに、負圧発生用凹部60に重なって負圧を解放する負圧解放部61を構成する複数の溝状又は切欠状の負圧解放溝62が軌道輪部材40の中心孔42の外周から径方向外方へ放射状に延びて形成されている。

In the first embodiment, as shown in FIGS. 3 and 4, a plurality (four in the figure) of circular shapes are formed on the inner diameter side

On the other hand, as shown in FIG. 3 and FIG. 7, the

この実施例1に係るスラストころ軸受は上述したように構成される。

したがって、キャリア5の両支持部6と、遊星歯車10の両端面との間にスラストころ軸受30をそれぞれ配設して組み付ける前の状態において、軌道輪部材40と、複数のころ31が組み付けられた保持器50とを重ね合わせる。

The thrust roller bearing according to the first embodiment is configured as described above.

Accordingly, the

この状態において、図5に示すように、保持器50の負圧発生用凹部60の開口側と反対側(底部側)を押圧し弾性変形させることで負圧発生用凹部60内の空気を排出した後、押圧を解除する。

すると、図6に示すように、負圧発生用凹部60の底部が元の状態に弾性復帰し、これによって負圧発生用凹部60が負圧となり、その負圧による吸着力で軌道輪部材40と、複数のころ31を保持した保持器50とが一体化される。

なお、軌道輪部材40と、複数のころ31が組み付けられた保持器50とを重ね合わせる際に、これら軌道輪部材40と、保持器50との対向する両側面に潤滑オイル等の潤滑材が塗布されることが望ましい。この場合には、軌道輪部材40と保持器50との密着が良好に確保される。

In this state, as shown in FIG. 5, the air in the negative

Then, as shown in FIG. 6, the bottom of the negative

Note that when the

その後、図9に示すように、キャリア5の両支持部6の間に、ラジアルころ軸受20が組み付けられた遊星歯車10が配置され、キャリア5の両支持部6と遊星歯車10の両端面の間に、前記したように一体化されたスラストころ軸受30の軌道輪部材40と保持器50とが配置される。

そして、図9に示すように、中心軸8が、キャリア5の一方の支持部6側から一方のスラストころ軸受30の軌道輪部材40と、保持器50と、ラジアルころ軸受20と、他方のスラストころ軸受30の保持器50と、軌道輪部材40と、キャリア5の他方の支持部6にわたって挿通される。そして、中心軸8の両端部がキャリア5の両支持部6に対し、かしめポンチ等によってかしめられることで、図2に示すように、前記各部材が一体状に組み付けられる。

After that, as shown in FIG. 9, the

And as shown in FIG. 9, the center axis |

遊星歯車機構1の作動時において、スラストころ軸受30の軌道輪部材40と保持器50とが、相互の摩擦抵抗によって設定角度(この実施例1では45度程度)相対回転したときには、負圧解放部61としての負圧解放溝62が負圧発生用凹部60に重なって負圧を解放する。このため、軌道輪部材40と保持器50とが相対的に回転自在となる。

When the planetary gear mechanism 1 is in operation, when the

前記したように、キャリア5の支持部6と遊星歯車10の端面の間に、スラストころ軸受30の軌道輪部材40と保持器50とが一体化されて配置され、組み付けられる。

このため、軌道輪部材40と保持器50とがそれぞれ個別に配置されて組み付ける場合と比べ、組付性の向上を図ることができる。

また、スラストころ軸受30の保持器50が鋼鉄板のプレス加工や合成樹脂材によって成形されると同時に、保持器50の側面に単数又は複数の負圧発生用凹部60が容易に形成される。

また、軌道輪部材40の側面に対し同軌道輪部材40の中心孔42の外周から径方向外方へ延びる溝状又は切欠状の負圧解放溝62が形成されることで負圧解放部61が容易に形成される。

As described above, the

For this reason, compared with the case where the

In addition, the

Further, the negative

なお、この発明は前記実施例1に限定するものではなく、この発明の要旨を逸脱しない範囲内において、種々なる形態で実施することもできる。

例えば、前記実施例1においては、図7に示すように、負圧解放部61を構成する複数の溝状又は切欠状の負圧解放溝62が軌道輪部材40の中心孔42の外周から径方向外方へ放射状に延びて形成される場合を例示したが、図8に示すように、軌道輪部材40の側面から反対側側面にわたって貫通する単数又は複数の負圧解放孔63を形成して負圧解放部61を構成することも可能である。

また、前記実施例1においては、保持器50の一側面に負圧発生用凹部60が形成され、軌道輪部材40の一側面に負圧解放部61が形成される場合を例示したが、軌道輪部材40の一側面に負圧発生用凹部60が形成され、保持器50の一側面に負圧解放部61が形成されてもこの発明を実施することができる。

また、前記実施例1においては、スラストころ軸受30が遊星歯車機構1に採用される場合を例示したが、遊星歯車機構1以外の歯車機構や回転機構に対してもこの発明のスラストころ軸受を採用することが可能である。

In addition, this invention is not limited to the said Example 1, In the range which does not deviate from the summary of this invention, it can also be implemented with a various form.

For example, in the first embodiment, as shown in FIG. 7, a plurality of groove-shaped or notched negative-

In the first embodiment, the case where the negative

In the first embodiment, the case where the

1 遊星歯車機構(歯車機構)

5 キャリア

6 支持部

10 遊星歯車

30 スラストころ軸受

31 ころ

40 軌道輪部材

41 軌道面

60 負圧発生用凹部

61 負圧解放部

1 Planetary gear mechanism (gear mechanism)

DESCRIPTION OF

Claims (4)

前記軌道輪部材と前記保持器との対向する両側面うち、少なくとも一方の部材の側面には、他方部材の側面に負圧によって吸着する単数又は複数の負圧発生用凹部が形成されていることを特徴とするスラストころ軸受。 A thrust roller bearing comprising a bearing ring member, a plurality of rollers arranged to be rollable on a raceway surface of one side of the bearing ring member, and a cage for holding the plurality of rollers,

Of the opposite side surfaces of the race ring member and the cage, at least one member side surface is formed with one or a plurality of negative pressure generating recesses that are attracted to the side surface of the other member by negative pressure. Thrust roller bearing characterized by.

軌道輪部材と保持器との対向する両側面うち、負圧発生用凹部が形成された一方の部材の側面に対向する他方部材の側面には、前記軌道輪部材と前記保持器とが設定角度相対回転したときに、前記負圧発生用凹部に重なって負圧を解放する負圧解放部が形成されていることを特徴とするスラストころ軸受。 The thrust roller bearing according to claim 1,

Of the opposite side surfaces of the race ring member and the cage, the race ring member and the cage are set at a set angle on the side surface of the other member facing the side surface of the one member where the negative pressure generating recess is formed. A thrust roller bearing, wherein a negative pressure release portion is formed to release the negative pressure by overlapping with the negative pressure generating recess when relatively rotated.

負圧発生用凹部は、保持器の側面に形成され、

負圧解放部は、軌道輪部材の側面に形成され、かつ前記軌道輪部材の中心孔の外周から径方向外方へ延びる溝状又は切欠状の負圧解放溝によって構成されていることを特徴とするスラストころ軸受。 The thrust roller bearing according to claim 2,

The negative pressure generating recess is formed on the side surface of the cage,

The negative pressure release portion is formed by a groove-shaped or notched negative pressure release groove formed on a side surface of the race ring member and extending radially outward from the outer periphery of the center hole of the race ring member. And thrust roller bearing.

負圧発生用凹部は、保持器の側面に形成され、

負圧解放部は、軌道輪部材の側面から反対側側面にわたって貫通する負圧解放孔によって構成されていることを特徴とするスラストころ軸受。 The thrust roller bearing according to claim 2,

The negative pressure generating recess is formed on the side surface of the cage,

The thrust roller bearing, wherein the negative pressure release portion is constituted by a negative pressure release hole penetrating from the side surface of the bearing ring member to the opposite side surface.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012159336A JP2014020456A (en) | 2012-07-18 | 2012-07-18 | Thrust roller bearing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012159336A JP2014020456A (en) | 2012-07-18 | 2012-07-18 | Thrust roller bearing |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2014020456A true JP2014020456A (en) | 2014-02-03 |

Family

ID=50195610

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012159336A Pending JP2014020456A (en) | 2012-07-18 | 2012-07-18 | Thrust roller bearing |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2014020456A (en) |

-

2012

- 2012-07-18 JP JP2012159336A patent/JP2014020456A/en active Pending

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2013053734A (en) | Cage for rolling bearing and rolling bearing | |

| JP2009236314A5 (en) | ||

| WO2016080186A1 (en) | Electric linear actuator and electric brake device | |

| JP5630159B2 (en) | Combined radial and thrust needle bearings | |

| JP2013231448A (en) | One-way clutch and power generating device | |

| JP6047999B2 (en) | Rotating support device | |

| KR20100084474A (en) | Combined radial-axial rolling bearing | |

| CN102235446A (en) | One way clutch and stator assembly including one way clutch | |

| JP2013015200A (en) | Conical roller bearing | |

| JP6618757B2 (en) | Fluid dynamic bearing | |

| JP2010255778A (en) | Radial needle bearing | |

| JP2012036990A (en) | Clutch release bearing device | |

| JP2013061023A (en) | Thrust rolling bearing | |

| JP2014185649A (en) | Rolling bearing device and vehicular pinion shaft supporting device | |

| JP2014020456A (en) | Thrust roller bearing | |

| JP2012246972A (en) | Roller thrust bearing | |

| JP6211260B2 (en) | Crown cage and ball bearing | |

| JP5083056B2 (en) | Thrust roller bearing race mounting device and mounting method | |

| JP5909918B2 (en) | Roller bearing cage | |

| JP6217366B2 (en) | One-way clutch | |

| JP6064783B2 (en) | Rolling bearing | |

| KR20140112487A (en) | Rolling bearing with reduced friction torque | |

| JP2016098873A (en) | Electrically-driven direct acting actuator and electrically-driven brake device | |

| JP2012145134A (en) | Bearing device | |

| JP2018071720A (en) | Corrugated holder and ball bearing |