JP2009146957A - Solid-state imaging apparatus, and manufacturing method of solid-state imaging apparatus - Google Patents

Solid-state imaging apparatus, and manufacturing method of solid-state imaging apparatus Download PDFInfo

- Publication number

- JP2009146957A JP2009146957A JP2007320267A JP2007320267A JP2009146957A JP 2009146957 A JP2009146957 A JP 2009146957A JP 2007320267 A JP2007320267 A JP 2007320267A JP 2007320267 A JP2007320267 A JP 2007320267A JP 2009146957 A JP2009146957 A JP 2009146957A

- Authority

- JP

- Japan

- Prior art keywords

- light

- pixel region

- film

- interlayer insulating

- solid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000003384 imaging method Methods 0.000 title claims abstract description 45

- 238000004519 manufacturing process Methods 0.000 title claims description 13

- 239000010410 layer Substances 0.000 claims description 69

- 239000011229 interlayer Substances 0.000 claims description 51

- 238000006243 chemical reaction Methods 0.000 claims description 27

- 238000000034 method Methods 0.000 claims description 24

- 239000000758 substrate Substances 0.000 claims description 8

- 239000004065 semiconductor Substances 0.000 claims description 7

- 239000000463 material Substances 0.000 claims description 5

- 230000001681 protective effect Effects 0.000 abstract description 15

- 230000003287 optical effect Effects 0.000 abstract description 11

- 230000002708 enhancing effect Effects 0.000 abstract 1

- 239000002184 metal Substances 0.000 description 32

- 230000015572 biosynthetic process Effects 0.000 description 6

- 238000009413 insulation Methods 0.000 description 4

- 230000035945 sensitivity Effects 0.000 description 4

- 230000000694 effects Effects 0.000 description 2

- 230000000295 complement effect Effects 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

Images

Landscapes

- Solid State Image Pick-Up Elements (AREA)

- Transforming Light Signals Into Electric Signals (AREA)

Abstract

Description

本発明は、光電変換素子を用いて撮像する固体撮像装置及びその製造方法に関するものである。 The present invention relates to a solid-state imaging device that captures an image using a photoelectric conversion element and a manufacturing method thereof.

従来から、CCDイメージセンサまたはCMOSイメージセンサ等の固体撮像装置では、二次元に配列した受光画素領域の光電変換素子で得られた撮像信号の輝度を調整するため、光電変換素子への光を遮る遮光膜を備えた遮光画素領域を設け、その遮光画素領域からの信号を輝度の基準信号として使用している。この基準信号は黒基準を提供するものであり、この受光しないで黒基準信号を生成する遮光画素領域は、オプティカルブラックと呼ばれている。 Conventionally, in a solid-state imaging device such as a CCD image sensor or a CMOS image sensor, light to the photoelectric conversion element is blocked in order to adjust the luminance of the imaging signal obtained by the photoelectric conversion element in the light receiving pixel region arranged in two dimensions. A light-shielded pixel region having a light-shielding film is provided, and a signal from the light-shielded pixel region is used as a luminance reference signal. This reference signal provides a black reference, and the light-shielded pixel region that generates the black reference signal without receiving light is called optical black.

このオプティカルブラックを構成する遮光画素領域の光電変換素子は、受光画素領域の光電変換素子と全く同一の特性を持つことが望ましいため、受光画素領域と遮光画素領域は可能な限り接近させて配置される。 It is desirable that the photoelectric conversion elements in the light-shielding pixel area constituting the optical black have exactly the same characteristics as the photoelectric conversion elements in the light-receiving pixel area. Therefore, the light-receiving pixel area and the light-shielding pixel area are arranged as close as possible. The

また、固体撮像装置においても、更なる小型化等の要求の為に画素領域の微細化も進展し、その結果、光電変換素子の面積の減少による感度低下が生じている。この感度低下に対して、光電変換素子上に設けられた保護膜が平坦化された面上にマイクロレンズを形成し、光電変換素子に集光して感度の低下を抑制する技術が知られているが、更なる集光を図る為にマイクロレンズと光電変換素子との間に、隣接する層と異なる屈折率を有する膜から構成される層内レンズを設ける構造も提案されている。 Also in the solid-state imaging device, the pixel area has been miniaturized due to a demand for further miniaturization and the like, and as a result, the sensitivity is lowered due to the reduction in the area of the photoelectric conversion element. A technology is known in which a microlens is formed on the surface on which the protective film provided on the photoelectric conversion element is flattened, and is focused on the photoelectric conversion element to suppress the decrease in sensitivity. However, a structure in which an in-layer lens composed of a film having a refractive index different from that of an adjacent layer is provided between the microlens and the photoelectric conversion element for further condensing is proposed.

以下、従来のマイクロレンズと凸型層内レンズを有する固体撮像装置の構成について図7を参照して簡単に説明する。図7は従来のマイクロレンズと凸型層内レンズを有する固体撮像装置を示す断面図である。 Hereinafter, the configuration of a conventional solid-state imaging device having a microlens and a convex in-layer lens will be briefly described with reference to FIG. FIG. 7 is a cross-sectional view showing a solid-state imaging device having a conventional microlens and a convex in-layer lens.

図7において、1は遮光画素領域、3は受光画素領域、4は光電変換素子、104は第一メタル配線層、105は第二メタル配線層、106は第三メタル配線層、107は保護膜、108は層内レンズ、109は平坦化膜、110はカラーフィルタ層、111はマイクロレンズである。従来の固体撮像装置は、図7に示すように、遮光画素領域1と受光画素領域3から構成され、それぞれ、マイクロレンズ111,層内レンズ108,光電変換素子及び複数層のメタル配線層を備え、遮光画素領域1の層内レンズ108直下には、保護膜107を介して遮光膜として第三メタル配線層106を形成している。このように層内レンズ108を設けることにより、光電変換素子までの距離を短縮することができ、感度低下をもたらすことなく集光効率を高めることができる(例えば、特許文献1参照)。

しかしながら、図7に示すような受光画素領域3と遮光画素領域1を隣合わせに配置した構造では、遮光画素領域1の遮光膜である第三のメタル配線106の膜厚により生じた段差は平坦化されていないために、段差に隣接して配置された受光画素に設けられる層内レンズ108は、この段差から十分に離れた受光画素に設けられる層内レンズ108に対して、段差による保護膜107の膜厚変動が生じるために、層内レンズ108と保護膜107を合わせた高さが変動したり、層内レンズ108が傾斜したりして、結果的にこの画素の集光率や光学特性が変動し、光電変換素子4への入射光量が変動する。また、第三メタル配線層106の段差部の側面によって反射された入射光が遮光画素領域1に隣接した受光画素領域3へ入射され、不正な反射光を受光することによる感度の変動も加わり、遮光画素領域3に隣接した受光画素からの撮像信号は特性変動を生じる。その結果、受光画素領域3の全画素に渡って均一な撮像特性を得られない装置となる。

However, in the structure in which the light-receiving

また、微細化が進められたCMOSイメージセンサの場合、画素間を接続する配線は多層配線を用いることが多く、層内レンズと光電変換素子の距離は大きくなり、遮光画素に隣接して配置された受光画素に入射した光は、一部が配線膜による回折や反射によって迷光となり、隣接した遮光画素に入射することで、遮光画素によって生成される黒基準信号には不正な光を受けて生成された信号を含むことになる。特に、長波長光の場合、入射深度が大きいため、遮光画素へ到達する割合が多くなる。 In addition, in the case of a CMOS image sensor that has been miniaturized, a multilayer wiring is often used for wiring between pixels, and the distance between the inner lens and the photoelectric conversion element becomes large, and the pixel is disposed adjacent to the light shielding pixel. Part of the light incident on the light-receiving pixels becomes stray light due to diffraction and reflection by the wiring film, and is incident on the adjacent light-shielding pixels, so that the black reference signal generated by the light-shielded pixels receives illegal light and is generated Signal will be included. In particular, in the case of long-wavelength light, since the incident depth is large, the ratio of reaching the light-shielded pixels increases.

そこで本発明は、受光画素領域の各画素への入射光量の均一性を高めながら集光率も向上でき、かつ黒基準信号を生成するオプティカルブラックを構成する遮光画素領域への不正入射光を有効に防止することを目的とする。 Accordingly, the present invention can improve the light collection rate while improving the uniformity of the amount of light incident on each pixel in the light receiving pixel region, and can effectively use the illegal incident light to the light shielding pixel region constituting the optical black that generates the black reference signal. The purpose is to prevent.

上述の目的を達成するために、本発明の固体撮像装置は、主面に光電変換素子が形成され、受光画素領域と境界画素領域と遮光画素領域とを備えた半導体基板と、前記半導体基板上に形成された層間絶縁膜と、前記層間絶縁膜上に形成された配線層と、前記受光画素領域における前記層間絶縁膜上に形成された第1の層内レンズと、前記境界画素領域における前記層間絶縁膜上に形成された第1の入射光制限膜と、前記遮光画素領域における前記層間絶縁膜上に形成された遮光膜とを備え、前記境界画素領域は、受光画素領域と前記遮光画素領域の間に形成されていることを特徴とする。 In order to achieve the above-described object, a solid-state imaging device according to the present invention includes a semiconductor substrate having a photoelectric conversion element formed on a main surface and having a light-receiving pixel region, a boundary pixel region, and a light-shielding pixel region; An interlayer insulating film formed on the interlayer insulating film, a wiring layer formed on the interlayer insulating film, a first intra-layer lens formed on the interlayer insulating film in the light receiving pixel region, and the boundary pixel region A first incident light limiting film formed on the interlayer insulating film; and a light shielding film formed on the interlayer insulating film in the light shielding pixel region, wherein the boundary pixel region includes a light receiving pixel region and the light shielding pixel. It is characterized by being formed between the regions.

また、前記境界画素領域における前記層間絶縁膜上にさらに第2の層内レンズを備えることを特徴とする。

また、前記遮光画素領域における前記層間絶縁膜上にさらに第2の入射光制限膜を備えることを特徴とする。

Further, a second in-layer lens is further provided on the interlayer insulating film in the boundary pixel region.

In addition, a second incident light limiting film is further provided on the interlayer insulating film in the light-shielding pixel region.

また、前記配線層と前記第1の入射光制限膜及び第2の入射光制限膜は同一の材料であることを特徴とする。

また、前記受光画素領域における前記層間絶縁膜上にカラーフィルタを備えることを特徴とする。

Further, the wiring layer, the first incident light limiting film, and the second incident light limiting film are made of the same material.

Further, a color filter is provided on the interlayer insulating film in the light receiving pixel region.

また、前記受光画素領域における前記層間絶縁膜上にマイクロレンズを備えることを特徴とする。

また、外部と接続するためのコンタクトパッドをさらに備え、前記遮光膜と前記コンタクトパッドは同一の材料で形成されていることを特徴とする。

Moreover, a microlens is provided on the interlayer insulating film in the light receiving pixel region.

In addition, a contact pad for connecting to the outside is further provided, and the light shielding film and the contact pad are formed of the same material.

また、前記第1の層内レンズの底面は前記遮光膜の上面よりも低いことを特徴とする。

さらに、受光画素領域と境界画素領域と遮光画素領域とを備えた半導体基板に光電変換素子を形成する工程と、前記半導体基板上に層間絶縁膜を形成する工程と、前記層間絶縁膜上に配線層を形成する工程と、前記境界画素領域における前記層間絶縁膜上に入射光制限膜を形成する工程と、前記遮光画素領域における前記層間絶縁膜上に遮光膜を形成する工程と、前記受光画素領域における前記層間絶縁膜上に層内レンズを形成する工程とからなることを特徴とする。

The bottom surface of the first intra-layer lens is lower than the top surface of the light shielding film.

A step of forming a photoelectric conversion element on a semiconductor substrate having a light-receiving pixel region, a boundary pixel region, and a light-shielding pixel region; a step of forming an interlayer insulating film on the semiconductor substrate; and a wiring on the interlayer insulating film Forming a layer; forming an incident light limiting film on the interlayer insulating film in the boundary pixel region; forming a light shielding film on the interlayer insulating film in the light shielding pixel region; and the light receiving pixel. And forming an intra-layer lens on the interlayer insulating film in the region.

また、前記配線層の形成工程と前記入射光制限膜の形成工程とを同時に行うことを特徴とする。

以上により、受光画素領域の各画素への入射光量の均一性を高めながら集光率も向上でき、かつ黒基準信号を生成するオプティカルブラックを構成する遮光画素領域への不正入射光を防止することができる。

Further, the wiring layer forming step and the incident light limiting film forming step are performed simultaneously.

As described above, it is possible to improve the light collection rate while improving the uniformity of the amount of light incident on each pixel in the light receiving pixel region, and to prevent illegal incident light to the light shielding pixel region constituting the optical black that generates the black reference signal. Can do.

本発明の固体撮像装置によれば、遮光画素領域と受光画素領域の間に境界画素領域を設けることによって、受光画素領域における保護膜の膜厚を一定にすることができるために遮光画素領域に対して最も近傍に配置される受光画素の画素特性を他の受光画素の各画素特性と同一な特性に合わせることが出来ると共に、黒基準となるオプティカルブラック領域を形成する遮光画素領域の光電変換素子への不正入射光を有効に防止することができる。 According to the solid-state imaging device of the present invention, by providing the boundary pixel region between the light-shielding pixel region and the light-receiving pixel region, the thickness of the protective film in the light-receiving pixel region can be made constant. On the other hand, the photoelectric conversion element of the light-shielding pixel region which can match the pixel characteristic of the light receiving pixel arranged closest to the pixel characteristic of each of the other light receiving pixels and forms an optical black region serving as a black reference It is possible to effectively prevent unauthorized incident light on the screen.

以下、添付図面を参照して本発明の実施形態について詳細に説明する。ただし、本実施形態において例示される構成部品の寸法、材質、形状、それらの相対配置などは、本発明が適用される装置の構成や各種条件により適宜変更されるべきものであり、本発明がそれらの例示に限定されるものではない。 Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the dimensions, materials, shapes, relative arrangements, and the like of the components exemplified in the present embodiment should be changed as appropriate according to the configuration of the apparatus to which the present invention is applied and various conditions. It is not limited to those examples.

まず、図1,図2を用いて、本発明の固体撮像装置の構成について説明する。

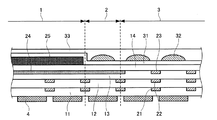

図1は、本発明の固体撮像装置の構成を示す断面図であって、撮像画素を有する固体撮像装置の一部を示しており、1は遮光画素領域、2は境界画素領域、3は受光画素領域、4は入射光を電荷信号に変換する光電変換素子、11は第一層間絶縁膜、12は第二層間絶縁膜、13は第三層間絶縁膜、14は第四層間絶縁膜、21は電荷信号を画像信号として伝達する第一メタル配線層、22は電荷信号を画像信号として伝達する第二メタル配線層、23は電荷信号を画像信号として伝達する第三メタル配線層、24は入射光制限膜、25は遮光膜、31は保護膜、32は層内レンズ,33は第一平坦化膜、34はカラーフィルタ膜、35は第二平坦化膜、36はマイクロレンズである。

First, the configuration of the solid-state imaging device of the present invention will be described with reference to FIGS.

FIG. 1 is a cross-sectional view showing a configuration of a solid-state imaging device according to the present invention, which shows a part of a solid-state imaging device having imaging pixels, where 1 is a light-shielding pixel region, 2 is a boundary pixel region, and 3 is light-receiving Pixel region, 4 is a photoelectric conversion element that converts incident light into a charge signal, 11 is a first interlayer insulating film, 12 is a second interlayer insulating film, 13 is a third interlayer insulating film, 14 is a fourth interlayer insulating film, 21 is a first metal wiring layer that transmits a charge signal as an image signal, 22 is a second metal wiring layer that transmits a charge signal as an image signal, 23 is a third metal wiring layer that transmits a charge signal as an image signal, and 24 An incident light limiting film, 25 is a light shielding film, 31 is a protective film, 32 is an inner lens, 33 is a first planarizing film, 34 is a color filter film, 35 is a second planarizing film, and 36 is a microlens.

図1に示すように、遮光画素領域1の光電変換素子4への入射光を遮光するために遮光膜25が第一層間絶縁膜11、第二層間絶縁膜12、第三層間絶縁膜13及び第四層間絶縁膜14を介して設けられており、第三メタル配線層23の一部が入射光制限膜24として設けられている。境界画素領域2には遮光膜25が形成されておらず、保護膜31上に層内レンズ32が設置されてその下部には入射光を減衰させる入射光制限膜24が設けられている。受光画素領域3には光電変換素子4まで十分な入射光が到達できるように第一層間絶縁膜11、第二層間絶縁膜12、第三層間絶縁膜13、第四層間絶縁膜14及び保護膜25を介して層内レンズ32が設けられている。

As shown in FIG. 1, the

ここで、遮光画素領域1の遮光膜25にはAlを主体とした金属膜が用いられ、第一メタル配線層21、第二メタル配線層22、第三メタル配線層23の配線膜及び入射光制限膜24にはCuを主体とした金属膜が用いられている。また、遮光膜25はここでは図示していないが、外部との接続をするために使用されるAlを主体としたコンタクトパッド膜と同一の金属膜で形成することもでき、同時に形成される。

Here, a metal film mainly composed of Al is used for the

一般にCu膜は大面積で形成された場合、ディッシングと呼ばれる現象で形成領域の中心部では周辺に対して薄膜化するが、遮光画素領域1及び境界画素領域2に、入射光を減衰させる目的で配置されている入射光制限膜24は、境界画素領域2に設定される画素数が1乃至2列のみである為、ディッシングによる薄膜化は殆どなく、十分な入射光を減衰させる効果がある。一方、大きな領域を必要とする遮光画素領域1において生じるディッシングは、上部に遮光膜25が存在するため問題は無い。本実施形態では遮光画素領域1に渡って入射光制限膜24を配置しているが一部隙間を形成することも可能で、また、全くメタル配線層による入射光制限膜24を遮光画素領域1に設けない構成も可能である。

In general, when a Cu film is formed in a large area, it is thinned with respect to the periphery at the center of the formation region due to a phenomenon called dishing. However, for the purpose of attenuating incident light in the light-

また、図2は本発明の固体撮像装置の構成を示す平面図で、遮光膜25と層内レンズ32の構成がわかるようにした平面であり、遮光画素領域1と受光画素領域3の間に設けられた境界画素領域2を示している。遮光画素領域1には遮光膜25が配置されており、受光画素領域3と境界画素領域2には層内レンズ32が設けられている。この実施形態では、境界画素領域2は1画素分を設けているが、2画素以上の画素列を設けることも可能である。遮光画素領域1及び境界画素領域2に入射光を減衰させる目的で配置されている入射光制限膜24は、受光画素領域3の層内レンズ32の端部まで配置させておくことで、遮光画素領域1に対する不正入射光の防止には十分効果がある。また、入射光を減衰させる目的で配置されている入射光制限膜24は、Cu膜にて大面積で形成された場合はディッシングと呼ばれる現象で形成領域の中心部では周辺に対して薄膜化するが、境界画素領域2に設定される画素数は1乃至2列のみである為、ディッシングによる薄膜化は殆どなく十分な入射光を減衰させる効果がある。一方、大きな領域を必要とする遮光画素領域1において生じるディッシングは、上部に遮光膜25が存在するため問題は無い。

FIG. 2 is a plan view showing the configuration of the solid-state imaging device of the present invention, which is a plane in which the configurations of the light-

次に、上述した本発明による固体撮像装置の製造方法について、図3〜図6を用いて説明する。

図3は本発明の固体撮像装置の製造方法における素子領域形成工程を説明する工程断面図、図4は本発明の固体撮像装置の製造方法における遮光膜形成工程を説明する工程断面図、図5は本発明の固体撮像装置の製造方法における層内レンズ形成工程を説明する工程断面図、図6は本発明の固体撮像装置の製造方法におけるカラーフィルタ層形成工程を説明する工程断面図で、図1と対応する部分には同一符号を付す。

Next, the manufacturing method of the solid-state imaging device according to the present invention described above will be described with reference to FIGS.

3 is a process cross-sectional view illustrating a process for forming an element region in the method for manufacturing a solid-state imaging device according to the present invention, FIG. 4 is a process cross-sectional view illustrating a process for forming a light shielding film in the method for manufacturing a solid-state image capturing apparatus according to the present invention. FIG. 6 is a process cross-sectional view illustrating an intra-layer lens forming process in the method for manufacturing a solid-state imaging device of the present invention, and FIG. 6 is a process cross-sectional view illustrating a color filter layer forming process in the method for manufacturing a solid-state image capturing apparatus of the present invention. Parts corresponding to 1 are denoted by the same reference numerals.

まず、図3に示すように、基板上の遮光画素領域1、境界画素領域2及び受光画素領域3に各画素の光電変換素子4が同一に形成され、その上に各画素からの信号電荷を取り出す目的でCu膜を使ったダマシン工法により第一メタル配線層21、第二メタル配線層22及び第三メタル配線層23が第一層間絶縁膜11、第二層間絶縁膜12及び第三層間絶縁膜13を介して形成される。ここで、第三メタル配線層23は受光画素領域3では配線層として形成され、遮光画素領域1及び境界画素領域2では各画素を覆う領域に渡って入射光制限膜24として形成される。

First, as shown in FIG. 3, the

次に、図4に示すように、第三メタル配線層23及び入射光制限膜24の上面に第四層間絶縁膜14を形成した後に、Al膜を使用して遮光膜25を遮光画素領域1を覆う領域に形成すると同時に、外部とのコンタクトパッド電極も形成する。その後、保護膜31を遮光膜25よりも薄い膜厚として形成することにより、受光画素領域1と境界画素領域2の保護膜31の上面を遮光膜25の上面より低い位置とし、入射光の集光特性を高くする。

Next, as shown in FIG. 4, after the fourth

そして、図5に示すように、保護膜31上に層内レンズ32を境界画素領域2及び受光画素領域3の各画素に対して形成する。その後、第一平坦化膜33を形成し、遮光膜25と層内レンズ32の段差等を平坦化する。

Then, as shown in FIG. 5, an

そして、図6に示すようにカラーフィルタ層34を形成し、その平坦化のために第二平坦化膜35を形成する。カラーフィルタとしては、RGBの原色フィルタでも、シアン、マゼンタ、イエロー、グリーンの補色フィルタでも、もしくは、カラーフィルタを備えていなくてもよい。カラーフィルタ層34を備えていない場合は、第二平坦化層35も備える必要はなく、マイクロレンズ35を第一平坦化層33上に形成することができ、固体撮像素子をさらに薄くすることが可能である。

Then, as shown in FIG. 6, a

最後に、第二平坦化膜35上にマイクロレンズ36を形成し、図1に示す本発明の固体撮像装置を得る。

以上のように本発明の固体撮像装置では、遮光画素領域と受光画素領域の間に境界画素領域を設けることによって、遮光画素領域上に形成された遮光膜端部のみに保護膜の厚み差による傾斜が形成されるため、受光画素領域上では保護膜の膜厚が全面的に一定となり、その上に形成する層内レンズと光電変換素子との距離は一定に保たれる。その結果、各画素の層内レンズの集光特性は全受光画素領域に渡って均一となり、受光画素領域の光電変換素子に対して集光効率の向上を図りながら集光特性の均一化が実現できる。また、遮光画素領域と受光画素領域の間に境界画素領域を設けることによって、黒基準信号を生成するオプティカルブラックを構成する遮光画素領域への不正入射光を有効に防止することができる。

Finally, a

As described above, in the solid-state imaging device according to the present invention, by providing the boundary pixel region between the light-shielding pixel region and the light-receiving pixel region, only the edge of the light-shielding film formed on the light-shielding pixel region is caused by the difference in thickness of the protective film. Since the slope is formed, the film thickness of the protective film is entirely constant over the light receiving pixel region, and the distance between the in-layer lens formed thereon and the photoelectric conversion element is kept constant. As a result, the condensing characteristic of the inner lens of each pixel is uniform over the entire light receiving pixel area, and the light condensing characteristic is made uniform while improving the light condensing efficiency with respect to the photoelectric conversion element in the light receiving pixel area. it can. In addition, by providing a boundary pixel region between the light-shielding pixel region and the light-receiving pixel region, it is possible to effectively prevent illegal incident light on the light-shielding pixel region constituting the optical black that generates the black reference signal.

なお、以上の説明では、本発明の固体撮像装置としてMOS型イメージセンサを前提としているが、受光面上に配線層を持たないCCDイメージセンサにも同様に適用することができる。

また、上述のような可視光による固体撮像装置に限らず、例えば赤外線等の不可視光による固体撮像装置に対しても、同様に適用することができる。

In the above description, a MOS image sensor is assumed as the solid-state imaging device of the present invention. However, the present invention can be similarly applied to a CCD image sensor having no wiring layer on the light receiving surface.

Further, the present invention is not limited to the above-described solid-state imaging device using visible light, and can be similarly applied to a solid-state imaging device using invisible light such as infrared rays.

また、上記実施形態は層間絶縁膜およびメタル配線層をそれぞれ3層ずつとしたが、2層ずつとしてもよく、それにより、固体撮像素子の薄型化がさらに可能となる。また、層間絶縁膜およびメタル配線層をそれぞれ4層以上として、集光のための受光画素とマイクロレンズとの距離を広げても構わない。 In the above-described embodiment, three interlayer insulating films and three metal wiring layers are provided, but two layers may be provided, thereby further reducing the thickness of the solid-state imaging device. Further, the interlayer insulating film and the metal wiring layer may each be four or more layers, and the distance between the light receiving pixel for condensing and the microlens may be increased.

さらに、各メタル配線層をダマシン工法によるCu膜としたが、エッチング法によるAl膜で形成してもよい。これにより、入射光制限膜がAlで形成されるため、Cuよりも遮光性を高くすることが可能となる。 Furthermore, although each metal wiring layer is a Cu film by a damascene method, it may be formed by an Al film by an etching method. Thereby, since the incident light limiting film is formed of Al, it is possible to make the light shielding property higher than that of Cu.

本発明は、受光画素領域の各画素への入射光量の均一性を高めながら集光率も向上でき、かつ黒基準信号を生成するオプティカルブラックを構成する遮光画素領域への不正入射光を防止することができ、光電変換素子を用いて撮像する固体撮像装置及びその製造方法等に有用である。 The present invention can improve the light collection rate while improving the uniformity of the amount of light incident on each pixel in the light-receiving pixel region, and prevents illegal incident light on the light-shielding pixel region constituting the optical black that generates the black reference signal. It is useful for a solid-state imaging device that captures an image using a photoelectric conversion element, a manufacturing method thereof, and the like.

1 遮光画素領域

2 境界画素領域

3 受光画素領域

4 光電変換素子

11 第一層間絶縁膜

12 第二層間絶縁膜

13 第三層間絶縁膜

14 第四層間絶縁膜

21 第一メタル配線層

22 第二メタル配線層

23 第三メタル配線層

24 入射光制限膜

25 遮光膜

31 保護膜

32 層内レンズ

33 第一平坦化膜

34 カラーフィルタ膜

35 第二平坦化膜

36 マイクロレンズ

104 第一メタル配線層

105 第二メタル配線層

106 第三メタル配線層

107 保護膜

108 層内レンズ

109 平坦化膜

110 カラーフィルタ層

111 マイクロレンズ

DESCRIPTION OF

Claims (10)

前記半導体基板上に形成された層間絶縁膜と、

前記層間絶縁膜上に形成された配線層と、

前記受光画素領域における前記層間絶縁膜上に形成された第1の層内レンズと、

前記境界画素領域における前記層間絶縁膜上に形成された第1の入射光制限膜と、

前記遮光画素領域における前記層間絶縁膜上に形成された遮光膜とを備え、

前記境界画素領域は、受光画素領域と前記遮光画素領域の間に形成されていることを特徴とする固体撮像装置。 A semiconductor substrate having a photoelectric conversion element formed on a main surface and having a light receiving pixel region, a boundary pixel region, and a light shielding pixel region;

An interlayer insulating film formed on the semiconductor substrate;

A wiring layer formed on the interlayer insulating film;

A first inner lens formed on the interlayer insulating film in the light receiving pixel region;

A first incident light limiting film formed on the interlayer insulating film in the boundary pixel region;

A light shielding film formed on the interlayer insulating film in the light shielding pixel region,

The boundary pixel region is formed between a light-receiving pixel region and the light-shielding pixel region.

前記半導体基板上に層間絶縁膜を形成する工程と、

前記層間絶縁膜上に配線層を形成する工程と、

前記境界画素領域における前記層間絶縁膜上に入射光制限膜を形成する工程と、

前記遮光画素領域における前記層間絶縁膜上に遮光膜を形成する工程と、

前記受光画素領域における前記層間絶縁膜上に層内レンズを形成する工程とからなることを特徴とする固体撮像装置の製造方法。 Forming a photoelectric conversion element on a semiconductor substrate having a light receiving pixel region, a boundary pixel region, and a light shielding pixel region;

Forming an interlayer insulating film on the semiconductor substrate;

Forming a wiring layer on the interlayer insulating film;

Forming an incident light limiting film on the interlayer insulating film in the boundary pixel region;

Forming a light shielding film on the interlayer insulating film in the light shielding pixel region;

And a step of forming an intra-layer lens on the interlayer insulating film in the light-receiving pixel region.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007320267A JP2009146957A (en) | 2007-12-12 | 2007-12-12 | Solid-state imaging apparatus, and manufacturing method of solid-state imaging apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007320267A JP2009146957A (en) | 2007-12-12 | 2007-12-12 | Solid-state imaging apparatus, and manufacturing method of solid-state imaging apparatus |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2009146957A true JP2009146957A (en) | 2009-07-02 |

Family

ID=40917270

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007320267A Pending JP2009146957A (en) | 2007-12-12 | 2007-12-12 | Solid-state imaging apparatus, and manufacturing method of solid-state imaging apparatus |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2009146957A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009252949A (en) * | 2008-04-04 | 2009-10-29 | Canon Inc | Solid-state imaging device and manufacturing method thereof |

| JP2012073167A (en) * | 2010-09-29 | 2012-04-12 | Sharp Corp | Artificial sunlight irradiation apparatus |

| US8633557B2 (en) | 2012-02-29 | 2014-01-21 | Samsung Electronics Co., Ltd. | Image sensors |

| US8659687B2 (en) | 2010-03-17 | 2014-02-25 | Fujifilm Corporation | Photoelectric conversion film stack-type solid-state imaging device and imaging apparatus |

| US8692345B2 (en) | 2011-08-09 | 2014-04-08 | Canon Kabushiki Kaisha | Image sensing device, image sensing system, and method for manufacturing image sensing device |

-

2007

- 2007-12-12 JP JP2007320267A patent/JP2009146957A/en active Pending

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009252949A (en) * | 2008-04-04 | 2009-10-29 | Canon Inc | Solid-state imaging device and manufacturing method thereof |

| US8440493B2 (en) | 2008-04-04 | 2013-05-14 | Canon Kabushiki Kaisha | Solid-state imaging apparatus and manufacturing method thereof |

| US8766340B2 (en) | 2008-04-04 | 2014-07-01 | Canon Kabushiki Kaisha | Solid-state imaging apparatus and manufacturing method thereof |

| US8659687B2 (en) | 2010-03-17 | 2014-02-25 | Fujifilm Corporation | Photoelectric conversion film stack-type solid-state imaging device and imaging apparatus |

| JP2012073167A (en) * | 2010-09-29 | 2012-04-12 | Sharp Corp | Artificial sunlight irradiation apparatus |

| US8692345B2 (en) | 2011-08-09 | 2014-04-08 | Canon Kabushiki Kaisha | Image sensing device, image sensing system, and method for manufacturing image sensing device |

| US8633557B2 (en) | 2012-02-29 | 2014-01-21 | Samsung Electronics Co., Ltd. | Image sensors |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5468133B2 (en) | Solid-state imaging device | |

| KR102499585B1 (en) | Solid-state imaging device, manufacturing method thereof, and electronic apparatus | |

| TWI788994B (en) | Solid-state imaging element, manufacturing method thereof, and electronic device | |

| JP6060851B2 (en) | Method for manufacturing solid-state imaging device | |

| TWI654750B (en) | Solid-state image-capturing device and production method thereof, and electronic appliance | |

| JP5493461B2 (en) | Solid-state imaging device, electronic apparatus, and manufacturing method of solid-state imaging device | |

| US7382011B2 (en) | Solid-state image sensing device equipped with inner lens | |

| KR101358587B1 (en) | Solid-state image sensor and imaging system | |

| JP4939206B2 (en) | Image sensor and manufacturing method thereof | |

| TWI417566B (en) | Method for designing microlens array on pixel array and image sensor device | |

| US8564033B2 (en) | Solid-state imaging device and method for manufacturing the same | |

| JP2009021415A (en) | Solid-state imaging apparatus and manufacturing method thereof | |

| US8866205B2 (en) | Photoelectric conversion device and image sensing | |

| TWI668849B (en) | Solid-state imaging element, imaging device and electronic device | |

| JP2008166677A (en) | Solid-state imaging device, method of manufacturing same, and camera | |

| JP2008091643A (en) | Solid-state image pick-up device | |

| JP2010093081A (en) | Solid-state imaging device and method for manufacturing the same | |

| US7829370B2 (en) | Image sensor and fabricating method thereof | |

| JP2013214616A (en) | Solid-state imaging device, method of manufacturing solid-state imaging device, and electronic device | |

| JP2013207053A (en) | Solid state imaging device and electronic apparatus | |

| JP5298617B2 (en) | SOLID-STATE IMAGING DEVICE, ITS MANUFACTURING METHOD, AND ELECTRONIC DEVICE | |

| KR100720461B1 (en) | Image sensor and method of manufacturing the same | |

| JP2010238726A (en) | Solid-state image pickup device and manufacturing method of the same | |

| JP2009146957A (en) | Solid-state imaging apparatus, and manufacturing method of solid-state imaging apparatus | |

| JP5704811B2 (en) | Method for manufacturing solid-state imaging device |