JP2006249602A - Connection part of fabric, clothes and method for producing clothes - Google Patents

Connection part of fabric, clothes and method for producing clothes Download PDFInfo

- Publication number

- JP2006249602A JP2006249602A JP2005066332A JP2005066332A JP2006249602A JP 2006249602 A JP2006249602 A JP 2006249602A JP 2005066332 A JP2005066332 A JP 2005066332A JP 2005066332 A JP2005066332 A JP 2005066332A JP 2006249602 A JP2006249602 A JP 2006249602A

- Authority

- JP

- Japan

- Prior art keywords

- fabric

- sheet

- folded

- main body

- folded portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Details Of Garments (AREA)

Abstract

Description

本発明は、布帛の結合部分、衣料、又は衣料の製造方法に関する。より詳しくは、縫合による布帛の結合部分又は布地を縫合して衣料を製造する方法に係る。ここでいう衣料には、シャツ等の完成品のみならず、半製品も含まれる。 The present invention relates to a bonded portion of fabric, clothing, or a method for manufacturing clothing. More specifically, the present invention relates to a method for manufacturing a garment by sewing a stitched portion of fabric or a fabric. The clothing here includes not only finished products such as shirts but also semi-finished products.

従来、衣料において、洗濯を繰り返すと縫合部位に縮みによるしわが生じやすかった。特に、ワイシャツ等において、外部から見える箇所にこのようなしわが生じると、外観を大いに損なっていた。 Conventionally, when clothes are repeatedly washed, wrinkles due to shrinkage are likely to occur at the stitched portion. In particular, in a shirt or the like, when such a wrinkle is generated at a place visible from the outside, the appearance is greatly impaired.

このような縮み及びしわが生じるのは、主として、洗濯による縫糸の縮小が布地の縮小よりも大きいことによると考えられる。 Such shrinkage and wrinkle are considered to be mainly due to the fact that the reduction of the sewing thread by washing is larger than the reduction of the fabric.

このような縮み及びしわを防止するための衣料の製造方法に関する発明がすでに知られている(例えば、特許文献1,2,3参照)。

Inventions relating to a method of manufacturing a garment for preventing such shrinkage and wrinkle are already known (see, for example,

特許文献1,2,3には、衣料構成要素(布地)を適宜折り返して熱接着性物質からなる結合要素とともに縫い合わせた後、加熱と加圧により熱接着性物質を溶融させることにより、衣料構成要素を強固に結合し、縫合せ部分の縮みを防止し、しわを防止する旨が開示されている。

In

しかし、これら従来技術における衣料の製造方法は、手間がかかり、製造コストが高くなりがちで、十分実用化するに至っていない。 However, these garment manufacturing methods in the prior art are time consuming and tend to be expensive to manufacture, and have not been fully put into practical use.

すなわち、特開平7−310276号公報(特許文献1)記載の発明では、その図3,図4に示されているように、まず第1衣料構成要素20、第2衣料構成要素22、結合要素32の三者を互いにずらして重ね、縫合するが、実際にはこれらの間の位置ぎめが難しく、手間がかかり、製造コストが高くなる。

That is, in the invention described in Japanese Patent Laid-Open No. 7-310276 (Patent Document 1), as shown in FIGS. 3 and 4, first, the

特開平10−280215号公報(特許文献2)記載の発明は、ポケットの取付けに関するものであるが、第1衣類構成要素20の縁部で結合ストリップ34を包むようにして第2衣類構成要素40上で位置ぎめするためには、第1衣類構成要素20と結合ストリップ34を一旦仮留め又は縫合する必要があり、手間がかかる。

The invention described in Japanese Patent Laid-Open No. 10-280215 (Patent Document 2) relates to the attachment of a pocket, but on the second garment component 40 so as to wrap the coupling strip 34 at the edge of the

特開平11−200127号公報(特許文献3)記載の発明において、第1衣類構成要素18と第2衣類構成要素20を折り畳んでからステッチ40,42を入れるが、これも実際には位置決めが難しく、仮留め又は縫合の必要があり、手間がかかる。

In the invention described in Japanese Patent Laid-Open No. 11-200237 (Patent Document 3), the first garment component 18 and the

本発明は、このような問題点に対し、洗濯を繰り返しても縫合部位に縮みによるしわが生じがたいのみならず、手間がかからず、結合方法が簡易でコストが低い、衣料の製造方法及び布帛の結合部分を提供することを、解決すべき課題とする。 The present invention provides a method for manufacturing a garment that is not only difficult to cause wrinkles due to shrinkage in the sutured part even when washing is repeated, but also does not take time, is simple in the joining method, and is low in cost. And providing a bonded portion of the fabric is a problem to be solved.

上記の課題を解決するため、請求項1記載の本発明の布帛の結合部分は、第一の布地と、第二の布地と、少なくとも一方の表面が熱接着性物質層を有する熱接着面であるシート状部材を少なくとも備える布帛の結合部分であって、

第一の布地と第二の布地は、それぞれ折り畳まれて本体部と折り重ね部を形成し、

第一の布地及び第二の布地の一方の表面をそれぞれ第一表面、他方の表面をそれぞれ第二表面として、

第一の布地は、第一表面を内側として折り畳まれており、

第一の布地の本体部の第一表面は、第二の布地の折り重ね部の第一表面と接し、

第二の布地の本体部と折り重ね部の間にはシート状部材が挟持され、

第一の布地の本体部と第二の布地の折り重ね部は縫合されており、この縫合はシート状部材に及ばず、

第二の布地の本体部、シート状部材、第一の布地の折り重ね部、及び第一の布地の本体部は縫合されており、

第二の布地の本体部の第二表面がシート状部材の熱接着面と熱接着されていることを特徴とする布帛の結合部分である。

In order to solve the above-mentioned problem, the bonded portion of the fabric of the present invention according to

The first fabric and the second fabric are folded to form a main body portion and a folded portion,

One surface of each of the first fabric and the second fabric is a first surface, and the other surface is a second surface.

The first fabric is folded with the first surface inside,

The first surface of the body portion of the first fabric is in contact with the first surface of the folded portion of the second fabric,

A sheet-like member is sandwiched between the main body portion and the folded portion of the second fabric,

The body portion of the first fabric and the folded portion of the second fabric are stitched, and this stitching does not reach the sheet-like member,

The body part of the second fabric, the sheet-like member, the folded part of the first fabric, and the body part of the first fabric are stitched,

The second portion of the main body portion of the second fabric is a bonded portion of the fabric, wherein the second surface is thermally bonded to the heat bonding surface of the sheet-like member.

以下、請求項1の用語等について説明する。これらの説明は、特記しないかぎり、他の請求項についても同様である。

Hereinafter, terms and the like of

「熱接着性物質」とは、加熱により溶融し、布地同士を接着し得る物質であり、例えば、熱溶融性樹脂である。熱溶融性樹脂としては、ポリアミド系、ポリエステル系、ポリエチレン系、ポリウレタン系、ポリ塩化ビニル系、ポリ酢酸ビニル系、アクリル系等の低融点合成樹脂が使用できるが、接着性、耐久性、取扱い性や風合いのソフト化等の面から、ポリエチレン系が好ましい。熱接着性物質の融点は140℃〜160℃が適当である。 “Thermo-adhesive substance” is a substance that can be melted by heating and adhere fabrics, and is, for example, a thermo-meltable resin. Low melting point synthetic resins such as polyamide-based, polyester-based, polyethylene-based, polyurethane-based, polyvinyl chloride-based, polyvinyl acetate-based, and acrylic-based resins can be used as heat-meltable resins. From the viewpoint of softening the texture and the like, polyethylene is preferred. The melting point of the thermoadhesive material is suitably 140 ° C to 160 ° C.

この熱接着性物質を用いる結合媒体である「シート状部材」として、布帛状のものを用いてもよいし、薄肉プラスチックシート状のものを用いてもよい。布帛の材質は、綿、ポリエステル、綿とポリエステルの混紡、ナイロン、レーヨン等から適宜選択すればよい。シート状部材の形状はテープ状が好ましい。衣料製造装置へのシート状部材の供給や、シート状部材の保持、位置合わせ等が容易になるからである。 As the “sheet-like member” that is a binding medium using this heat-adhesive substance, a cloth-like member or a thin plastic sheet-like member may be used. The material of the fabric may be appropriately selected from cotton, polyester, cotton / polyester blend, nylon, rayon, and the like. The shape of the sheet-like member is preferably a tape shape. This is because the supply of the sheet-like member to the clothing manufacturing apparatus, the holding of the sheet-like member, the alignment and the like are facilitated.

シート状部材は、布帛又は薄肉プラスチックシートの一表面又は両表面に塗布又は含浸により熱接着性物質層が設けられたものであることが望ましい。

熱接着性物質層を両表面に設ければ結合はより強固となり、皺も生じにくいが、結合部が固くなりすぎて着用感が悪くなることがある。

一方、熱接着性物質層を一表面のみに設ける構成は、製作が簡易であり、結合部が固くなりすぎず、また、皺を防止する効果も、一般には十分である。外部から見える布地の皺を防止すれば足りるからである。

The sheet-like member is preferably one in which a thermal adhesive material layer is provided on one or both surfaces of a fabric or a thin plastic sheet by coating or impregnation.

If the heat-adhesive material layers are provided on both surfaces, the bond becomes stronger and wrinkles are less likely to occur, but the bonded part may become too hard and the feeling of wear may worsen.

On the other hand, the configuration in which the heat-adhesive material layer is provided on only one surface is easy to manufacture, the joint portion does not become too hard, and the effect of preventing wrinkles is generally sufficient. This is because it is sufficient to prevent wrinkles of the fabric visible from the outside.

「本体部」、「折り重ね部」とは、布地等の折り重ねの状態を表すためのもので、布地の折り目を境界として、末端側の小部分を「折り重ね部」、他の部分を「本体部」という。 “Main part” and “folding part” are used to indicate the state of folding the fabric, etc., with the fold of the fabric as the boundary, the small part on the end side is the “folding part”, and the other part is It is called “main part”.

「第一表面」、「第二表面」とは、表面を特定するための便宜的な呼称である。第一表面側を衣服の表側として実施するのが一般には好都合であるが、逆に第一表面側を衣服の裏側として実施してもよい。 “First surface” and “second surface” are convenient names for specifying a surface. Although it is generally convenient to implement the first surface side as the front side of the garment, conversely, the first surface side may be implemented as the back side of the garment.

布地等を縫合する方法としては、ミシンによる錠縫い(ロックステッチ)、環縫い(チェーンステッチ)、かがり縫い等を適宜選択して用いればよく、手縫いでもよいが、ミシンによる錠縫い、単環縫い等が強度上望ましい。 As a method for sewing fabrics, etc., lock sewing with a sewing machine (lock stitch), chain sewing, chain stitching, etc. may be selected as appropriate, and hand sewing may be used. Etc. are desirable in terms of strength.

熱溶融性樹脂を溶融させて熱接着を行うための加熱手段としては、アイロン、プレス機、コテ、ローラ加熱圧着機、高周波溶着機、超音波溶着機、ヒートシーラ等などの加熱圧着装置を適宜選択して用いることができる。 As a heating means for melting the heat-meltable resin and performing thermal bonding, a thermo-compression bonding device such as an iron, a press, a trowel, a roller heat-bonding machine, a high-frequency welding machine, an ultrasonic welding machine, a heat sealer, etc. is appropriately selected. Can be used.

請求項1記載の本発明の布帛の結合部分によれば、第一の布地と第二の布地をまず縫合し、次にシート状部材を挿入することができるので、位置ぎめが容易であり、手間がかからず、低コストとなる。

また、熱接着性物質を溶融させることにより、第二の布地の本体部とシート状部材は、固化した熱接着性物質により強固に固定され、相対移動できないので、縫糸の縮小によって縫合部位に縮みが生じがたい。

この発明は、例えばシャツのアームホール縫合せ部分のように、2枚の布地を比較的幅の狭い重合部を設けて結合する場合に適する。

According to the joint portion of the fabric of the present invention according to

Also, by melting the heat-adhesive substance, the main body portion of the second fabric and the sheet-like member are firmly fixed by the solidified heat-adhesive substance and cannot move relative to each other. Is difficult to occur.

The present invention is suitable for the case where two fabrics are joined by providing a relatively narrow overlapping portion, for example, an armhole stitched portion of a shirt.

請求項2記載の本発明の布帛の結合部分は、シート状部材は、第二の布地の本体部の第二表面とのみ熱接着されていることを特徴とする請求項1記載の布帛の結合部分である。 In the joint portion of the fabric of the present invention according to claim 2, the sheet-like member is thermally bonded only to the second surface of the main body portion of the second fabric. Part.

この布帛の結合部分によれば、例えば、第二の布地を、アームホール縫合せ部分における前身頃や後身頃といった縫合せ部分における外部に表れる部位に用いた場合、外部から視認される縫合部位に縮みによるしわが生じがたい。その一方で、着用者の身体に接触する第一の布地(例えば袖用布地)には熱接着性物質が用いられていないので、着用時にゴワゴワ感がなく、着用者にとって快適である。 According to this joint portion of the fabric, for example, when the second fabric is used in a portion appearing outside in the stitched portion such as the front body and the back body in the armhole stitched portion, the second fabric shrinks to the stitched site visually recognized from the outside. It is difficult to cause wrinkles. On the other hand, since the heat-adhesive substance is not used for the first fabric that contacts the wearer's body (for example, the fabric for sleeves), there is no feeling of tingling at the time of wearing, and the wearer is comfortable.

請求項3記載の本発明の衣料は、複数のパーツを構成する布地が縫製によって結合されて成形された衣料において、請求項1又は2記載の布帛の結合部分を有する衣料である。

The apparel of the present invention according to claim 3 is an apparel having the joint portion of the fabric according to

この衣料によれば、第一の布地と第二の布地をまず縫合し、次にシート状部材を挿入するので、位置ぎめが容易であり、手間がかからず、低コストとなる。

また、第二の布地の本体部とシート状部材は、固化した熱接着性物質により強固に固定され、相対移動できないので、縫糸の縮小によって縫合部位に縮みが生じがたい。

According to this garment, the first fabric and the second fabric are stitched first, and then the sheet-like member is inserted. Therefore, the positioning is easy, labor is not required, and the cost is low.

In addition, since the main body portion and the sheet-like member of the second fabric are firmly fixed by the solidified heat-adhesive substance and cannot move relative to each other, it is difficult for the sutured portion to shrink due to the reduction of the sewing thread.

請求項4記載の本発明の衣料は、第一の布地は袖用布地であり、第二の布地は身頃であることを特徴とする請求項3記載の衣料である。ここで、身頃は前身頃でも後身頃でもよい。 The clothing of the present invention according to claim 4 is the clothing according to claim 3, wherein the first fabric is a sleeve fabric and the second fabric is a body. Here, the body may be the front body or the back body.

この衣料によれば、第二の布地が外部に表れる部位(身頃)に用いられており、外部から視認される縫合部位に縮みによるしわが生じがたい。その一方で、着用者の身体に接触する第一の布地(袖用布地)には熱接着性物質が用いられていないので、着用時にゴワゴワ感がなく、着用者にとって快適である。 According to this garment, the second fabric is used in a part (body) that appears to the outside, and it is difficult for wrinkles due to shrinkage to occur in the stitched part that is visible from the outside. On the other hand, since the heat-adhesive substance is not used for the first fabric (sleeve fabric) that comes into contact with the wearer's body, the wearer does not feel awkward at the time of wearing and is comfortable for the wearer.

請求項5記載の本発明の衣料の製造方法は、複数の布地を接合して衣料を製造する方法であって、少なくとも一部の接合部においては、第一の布地及び第二の布地を、少なくとも一方の表面が熱接着性物質層を有する熱接着面であるシート状部材を用いて結合する衣料の製造方法において、第一の布地及び第二の布地の一方の表面をそれぞれ第一表面、他方の表面をそれぞれ第二表面として、

第一の布地と第二の布地を、互いの第一表面同士が接し、かつ、第二の布地の端が第一の布地の端より後退した位置となるように重ね合わせる工程と、

第二の布地の端より一定距離内側で第一の布地と第二の布地を縫合する工程と、

第二の布地を当該縫合の縫い目から第一の布地の上記端側へ折り返し、第二の布地の折り返された部分の第二表面と折り返されていない部分の第二表面とを対向させる工程と、

第二の布地の折り返された部分と折り返されていない部分との間に、少なくとも第一表面は熱接着面であるシート状部材を、上記折り返された部分側へ第一表面を向けて挿入する工程と、

第一の布地の上記端側の部分を、第一表面を内側として折り、第一の布地の折り重ね部の第二表面がシート状部材と接するようにする工程と、

第二の布地の折り返された部分、シート状部材、第一の布地の折り返されていない部分、及び第一の布地の折り返されていない部分を縫合する工程と、

加熱によりシート状部材の熱接着性物質を溶融させる工程とを有することを特徴とする衣料の製造方法である。

The method for producing a garment of the present invention according to claim 5 is a method of producing a garment by joining a plurality of fabrics, wherein at least a part of the joint portions includes the first fabric and the second fabric, In the method of manufacturing a garment in which at least one surface is bonded using a sheet-like member that is a heat-bonding surface having a heat-adhesive substance layer, one surface of each of the first fabric and the second fabric is the first surface, The other surface as the second surface,

Superimposing the first fabric and the second fabric so that the first surfaces of each other are in contact with each other and the end of the second fabric is in a position retracted from the end of the first fabric;

Stitching the first fabric and the second fabric a certain distance inside the edge of the second fabric;

Folding back the second fabric from the stitching seam to the end side of the first fabric and making the second surface of the folded portion of the second fabric face the second surface of the unfolded portion; ,

A sheet-like member having at least a first surface as a heat bonding surface is inserted between the folded portion and the unfolded portion of the second fabric with the first surface facing the folded portion side. Process,

Folding the end side portion of the first fabric with the first surface as the inner side, the second surface of the folded portion of the first fabric in contact with the sheet-like member,

Sewing the folded portion of the second fabric, the sheet-like member, the unfolded portion of the first fabric, and the unfolded portion of the first fabric;

And a step of melting the heat-adhesive substance of the sheet-like member by heating.

ここで、シート状部材を挿入する工程と、第一の布地の上記端側の部分を折る工程とは、いずれを先に実施してもよいし、同時に実施してもよい。 Here, any of the step of inserting the sheet-like member and the step of folding the end-side portion of the first fabric may be performed first or simultaneously.

請求項5において、請求項1〜4と同様に、この熱接着性物質を用いる結合媒体である「シート状部材」として、布帛状のものを用いてもよいし、薄肉プラスチックシート状のものを用いてもよいが、加熱時に融ける材質のものをシート状部材として用いてもよい。この場合、完成した衣料においてシート状部材は融けて布地に染み込み、シート形状をとどめていなくてもよい。 In the fifth aspect, as in the first to fourth aspects, as the “sheet-like member” which is a binding medium using the heat-adhesive substance, a cloth-like one or a thin plastic sheet-like one may be used. Although it may be used, a material that melts when heated may be used as the sheet-like member. In this case, in the completed clothing, the sheet-like member may melt and soak into the fabric, and the sheet shape does not have to remain.

請求項5の方法によれば、第一の布地と第二の布地をまず縫合し、次にシート状部材を挿入するので、位置ぎめが容易であり、手間がかからず、低コストとなる。

また、シート状部材の熱接着性物質を溶融させることにより、第二の布地とシート状部材は、固化した熱接着性物質により強固に固定され、相対移動できないので、縫糸の縮小によって縫合部位に縮みが生じがたい。

According to the method of claim 5, since the first fabric and the second fabric are stitched first, and then the sheet-like member is inserted, positioning is easy, labor is not required, and the cost is low. .

In addition, by melting the heat-adhesive substance of the sheet-like member, the second fabric and the sheet-like member are firmly fixed by the solidified heat-adhesive substance and cannot move relative to each other. It is hard for shrinkage to occur.

なお、加熱により熱接着性物質を溶融させる工程に加えて、加圧により定着させる工程を有することが好ましい。 In addition to the step of melting the heat-adhesive substance by heating, it is preferable to have a step of fixing by pressing.

この方法によれば、加圧により、折り目等が定着し、結合部分の厚みが減少する。また、第一の布地、第二の布地、及び折り返された第二の布地が緊密に接触し、さらに、シート状部材が圧迫されるため、溶融した熱接着性物質が各布地によく浸透する。したがって、緊密な結合が得られる。

ここで、「加圧により折り目を定着させる工程」を「加熱により熱接着性物質を溶融させる工程」と同時に実施して一工程化するのが、作業の迅速・簡易化のために好ましいが、「加熱により熱接着性物質を溶融させる工程」の後に「加圧により折り目を定着させる工程」を実施してもよい。

According to this method, the crease or the like is fixed by pressurization, and the thickness of the joint portion is reduced. Further, since the first fabric, the second fabric, and the folded second fabric are in close contact with each other, and the sheet-like member is pressed, the molten heat-adhesive substance penetrates well into each fabric. . Thus, a tight bond is obtained.

Here, it is preferable to carry out the “step of fixing the crease by pressurization” simultaneously with the “step of melting the heat-adhesive substance by heating” to make it one step, for the speed and simplification of the work, After the “step of melting the heat-adhesive substance by heating”, the “step of fixing the crease by pressing” may be performed.

本発明の方法により製造された衣料又は本発明による布帛の結合部分は、結合時の位置ぎめが容易であって作業しやすく、結合方法が簡易で手間がかからず、低コストでありながら、縫合部位(結合部分)が強固である。また、外観がよく、風合いにすぐれている。さらに、縫合部位の耐久性が向上し、洗濯を繰り返しても縫合部位に縮みによるしわが生じがたいので、ワイシャツ等のノーアイロン化に役立つ。 The garment manufactured by the method of the present invention or the bonded portion of the fabric according to the present invention is easy to position and work at the time of bonding, the bonding method is simple, hassle-free, and low cost, The suture site (bonding portion) is strong. In addition, the appearance is good and the texture is excellent. Furthermore, the durability of the stitched area is improved, and wrinkles due to shrinkage are less likely to occur at the stitched area even after repeated washing.

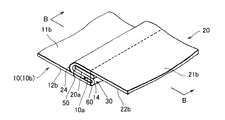

以下、本発明のさらに具体的な実施形態を、図面を参照しつつ説明する。

図1乃至図11は、本発明の実施形態に係るものである。

本実施形態は、本発明をワイシャツに適用したものである。本実施形態のワイシャツ70(図10)は、前身頃71、後身頃72、袖73、襟74、ヨーク75といった所定形状に裁断されたパーツを縫製によって結合して作られたものである。

そして、袖73と前身頃71又は後身頃72との合わせ部分81、82に本発明の特徴的構造が採用されている。

Hereinafter, more specific embodiments of the present invention will be described with reference to the drawings.

1 to 11 relate to an embodiment of the present invention.

In this embodiment, the present invention is applied to a shirt. The shirt 70 (FIG. 10) of this embodiment is made by joining parts cut into a predetermined shape such as a

And the characteristic structure of this invention is employ | adopted for the joining

以下、説明を簡単にするために、第一の布地10及び第二の布地20を接合するものとして特徴的構造部分を説明する。すなわち、袖73と前身頃71又は後身頃72との合わせ部分に本発明を適用する場合においては、袖73が第一の布地10であり、前身頃71又は後身頃72が第二の布地20に相当する。もっとも、袖73を第二の布地20とし、前身頃71又は後身頃72を第一の布地10として実施することもできる。

Hereinafter, in order to simplify the description, the characteristic structural portion will be described as joining the

第一の布地10及び第二の布地20として、綿とポリエステルの混紡によって製造した布地を用いた。

シート状部材として、布帛35の一方の表面(熱接着面31)に塗布又は接着により熱接着性物質の層Mを設けたテープ部材30を用いた(図10)。ここで布帛35の材質として、ポリエステルを用い、熱接着性物質としては、ポリエチレン系のものを用いた。テープ部材(シート状部材)30のうち布帛35は、加熱の後も結合部に残り、結合部を補強する役割を果たす。

As the

As the sheet-like member, a

なお、テープ部材は、熱接着性物質を層状に設けず、散点状に設けてもよい。

また、テープ部材は、熱接着性物質を含有する布帛であってもよい。このようなテープ部材を製造する手段としては、例えば、布帛に熱接着性物質を含浸させる、又は、軟化点の低い熱可塑性の化学繊維と綿、ポリエステル等を混紡又は交織する等が挙げられる。

The tape member may be provided in the form of dots instead of providing the heat-adhesive substance in a layer form.

The tape member may be a fabric containing a heat-adhesive substance. Examples of means for producing such a tape member include impregnating a fabric with a thermal adhesive substance, or blending or interweaving thermoplastic chemical fibers having a low softening point with cotton, polyester, or the like.

以下、縫製工程を説明する。 Hereinafter, the sewing process will be described.

図1に示すように、第一の布地10と第二の布地20を、互いの第一表面11,21同士が接し、かつ、第二の布地の端23が第一の布地の端13より後退した位置となるようにずらして重ね合わせる。

As shown in FIG. 1, the

次に、第二の布地20の端23より一定距離d内側で第一の布地10と第二の布地20をステッチ50(地縫い)により縫合する(図2)。なお、布地の重ね方およびステッチ50の位置は、「第一の布地10の端13からステッチ50までの長さD」と「第二の布地20の端からステッチ50までの長さd」の和「D+d」が、縫い合わせ部の所望の幅の1.5〜2.5倍、さらに好ましくは1.7〜2.0倍となるように定める。

Next, the

次いで、第二の布地20のうち当該縫合の縫い目50を基準として上記端13から遠い部分(広い方の部分)を、図3の矢印のように当該縫合の縫い目50から第一の布地10の上記端13側(第二の布地20の上記端23側)へ折り返し、第二の布地20の折り返された部分20bの第二表面22bと折り返されていない部分20aの第二表面22aとを対向させる(図4)。

Next, the portion of the

次いで、第二の布地20の折り返された部分20bと折り返されていない部分20aとの間に、熱接着面を有する細長いテープ部材(シート状部材)30を、上記折り返された部分20b側へ熱接着面である第一表面31を向けて挿入する。

Next, an elongated tape member (sheet-like member) 30 having a heat-bonding surface is heated between the folded

第一の布地10のうち縫い目50よりも上記端13側の部分を、第一表面11を内側として折り込んで、折り目14を形成し、また、折り重ね部10aと本体部10bを形成する。この折り込みにより、第一の布地10の折り重ね部10aの第二表面12aがシート状部材30の第2表面32と接するようにし、かつ、第一の布地10の折り重ね部10aの端13を第二の布地20の端23と突き合わせる(図5)。このときの折り目とステッチ50との距離aが、ほぼ縫い合わせ部の幅となる。この工程は、所定の設備を用いて、上記のシート状部材30の挿入と同時並行で行う。

A portion of the

なお、上記のごとく、本明細書において布地等の折り重ねの形状を表すために、折り目を境界として、末端側の小部分を「折り重ね部」、他の部分を「本体部」というが、折り重ね部関係の符号にはa、本体部関係の符号にはbを付している。

この表記は形状のみによるもので、実際の製作方法によらないので、第二の布地20については、上記の「折り返された部分20b」が「本体部」、「折り返されていない部分20a」が「折り重ね部」に相当する。

In addition, as described above, in this specification, in order to represent the shape of the folded fabric or the like, the small portion on the terminal side is referred to as the “folded portion” and the other portion is referred to as the “main body portion” with the fold as a boundary. The reference sign for the folded part is a, and the reference sign for the body part is b.

Since this notation is based only on the shape and not on the actual manufacturing method, the “folded

次いで、第二の布地20の折り返された部分(本体部)20b、テープ部材30、第一の布地10の折り返された部分(折り重ね部)20a、及び第一の布地10の折り返されていない部分(本体部)を縫合する縫い目60(袖伏せステッチ)を入れる(図6)。

Next, the folded portion (main body portion) 20b of the

さらに、加熱しつつ加圧してテープ部材30の熱接着性物質を溶融させて、テープ部材30の第一表面31と第二の布地20を熱接着して、結合を完成する(図7)。

Further, the heat adhesive material of the

こうして結合された第一の布地10、第二の布地20、及びテープ部材30の重なり方を説明する(図8)。

An overlapping method of the

図8において、布地等は、図における下方からいえば、第一の布地10の本体部10b、第二の布地20の折り重ね部20aおよび第一の布地10の折り重ね部10a、テープ部材30、第二の布地20の本体部20bの順に重なっている。(なお、第二の布地20の折り重ね部20aと第一の布地10の折り重ね部10aは図7のように重なってもよい。その場合、第一の布地10の折り重ね部10aは第二の布地20の折り重ね部20aとテープ部材30との間に入る。)

In FIG. 8, the fabric and the like are, from the lower side in the figure, the

第二の布地20の本体部第二表面22bはテープ部材30の第一表面(熱接着面)31と接し、テープ部材30の第二表面32は第一の布地10の折り重ね部第二表面12aおよび第二の布地20の折り重ね部第二表面22aと接し、第一の布地10の折り重ね部第一表面11aおよび第二の布地20の折り重ね部第一表面21aは第一の布地10の本体部第一表面11bと接する。

The main body portion

第二の布地20の本体部第二表面22bとテープ部材30の第一表面31が熱接着され、一体化されている。テープ部材30のうち布帛35は融けないで残る。テープ部材30の第二表面32は、第一の布地10の表面12aと熱接着されない。他の布地間でも、熱接着による結合は生じない。

The main body portion

こうして結合された第一の布地10及び第二の布地20を表側(第一表面側)から見れば、図8のように折り目24と縫い目60が見えるだけであり、シンプルな外観が得られ、風合いにすぐれている。

When the

このような布地の結合を、図10に示すワイシャツ70のアームホール縫合せ部分81,82に用いたところ、外観、気心地、耐久性とも良好であった。

When such a fabric bond was used for the armhole stitched

10 第一の布地

11 第一の布地の第一表面

12 第一の布地の第二表面

20 第二の布地

21 第二の布地の第一表面

22 第二の布地の第二表面

30 テープ部材(シート状部材)

31 テープ部材(シート状部材)の第一表面

32 テープ部材(シート状部材)の第二表面

50,60 縫い目

DESCRIPTION OF

31 First surface of tape member (sheet-like member) 32 Second surface of tape member (sheet-like member) 50, 60 Seam

Claims (5)

第一の布地と第二の布地は、それぞれ折り畳まれて本体部と折り重ね部を形成し、

第一の布地及び第二の布地の一方の表面をそれぞれ第一表面、他方の表面をそれぞれ第二表面として、

第一の布地は、第一表面を内側として折り畳まれており、

第一の布地の本体部の第一表面は、第二の布地の折り重ね部の第一表面と接し、

第二の布地の本体部と折り重ね部の間にはシート状部材が挟持され、

第一の布地の本体部と第二の布地の折り重ね部は縫合されており、この縫合はシート状部材に及ばず、

第二の布地の本体部、シート状部材、第一の布地の折り重ね部、及び第一の布地の本体部は縫合されており、

第二の布地の本体部の第二表面がシート状部材の熱接着面と熱接着されていることを特徴とする布帛の結合部分。 A bonded portion of a fabric comprising at least a first fabric, a second fabric, and a sheet-like member having at least one surface of which is a thermal adhesive surface having a thermal adhesive substance layer,

The first fabric and the second fabric are folded to form a main body portion and a folded portion,

One surface of each of the first fabric and the second fabric is a first surface, and the other surface is a second surface.

The first fabric is folded with the first surface inside,

The first surface of the body portion of the first fabric is in contact with the first surface of the folded portion of the second fabric,

A sheet-like member is sandwiched between the main body portion and the folded portion of the second fabric,

The body portion of the first fabric and the folded portion of the second fabric are stitched, and this stitching does not reach the sheet-like member,

The body part of the second fabric, the sheet-like member, the folded part of the first fabric, and the body part of the first fabric are stitched,

A joint portion of a fabric, wherein the second surface of the main body portion of the second fabric is thermally bonded to the thermal bonding surface of the sheet-like member.

第一の布地と第二の布地を、互いの第一表面同士が接し、かつ、第二の布地の端が第一の布地の端より後退した位置となるように重ね合わせる工程と、

第二の布地の端より一定距離内側で第一の布地と第二の布地を縫合する工程と、

第二の布地を当該縫合の縫い目から第一の布地の上記端側へ折り返し、第二の布地の折り返された部分の第二表面と折り返されていない部分の第二表面とを対向させる工程と、

第二の布地の折り返された部分と折り返されていない部分との間に、少なくとも第一表面は熱接着面であるシート状部材を、上記折り返された部分側へ第一表面を向けて挿入する工程と、

第一の布地の上記端側の部分を、第一表面を内側として折り、第一の布地の折り重ね部の第二表面がシート状部材と接するようにする工程と、

第二の布地の折り返された部分、シート状部材、第一の布地の折り返されていない部分、及び第一の布地の折り返されていない部分を縫合する工程と、

加熱によりシート状部材の熱接着性物質を溶融させる工程とを有することを特徴とする衣料の製造方法。 A method of manufacturing a garment by joining a plurality of fabrics, wherein at least some of the joints are bonded to the first fabric and the second fabric at least one surface of which has a heat-adhesive substance layer. In the manufacturing method of the clothing combined using the sheet-like member that is a surface, one surface of each of the first fabric and the second fabric is a first surface, and the other surface is a second surface,

Superimposing the first fabric and the second fabric so that the first surfaces of each other are in contact with each other and the end of the second fabric is in a position retracted from the end of the first fabric;

Stitching the first fabric and the second fabric a certain distance inside the edge of the second fabric;

Folding back the second fabric from the stitching seam to the end side of the first fabric and making the second surface of the folded portion of the second fabric face the second surface of the unfolded portion; ,

A sheet-like member having at least a first surface as a heat bonding surface is inserted between the folded portion and the unfolded portion of the second fabric with the first surface facing the folded portion side. Process,

Folding the end side portion of the first fabric with the first surface as the inner side, the second surface of the folded portion of the first fabric in contact with the sheet-like member,

Sewing the folded portion of the second fabric, the sheet-like member, the unfolded portion of the first fabric, and the unfolded portion of the first fabric;

And a step of melting the heat-adhesive substance of the sheet-like member by heating.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005066332A JP2006249602A (en) | 2005-03-09 | 2005-03-09 | Connection part of fabric, clothes and method for producing clothes |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005066332A JP2006249602A (en) | 2005-03-09 | 2005-03-09 | Connection part of fabric, clothes and method for producing clothes |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2006249602A true JP2006249602A (en) | 2006-09-21 |

Family

ID=37090387

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005066332A Pending JP2006249602A (en) | 2005-03-09 | 2005-03-09 | Connection part of fabric, clothes and method for producing clothes |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006249602A (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011500982A (en) * | 2007-10-19 | 2011-01-06 | ダブリュ.エル.ゴア アンド アソシエーツ,ゲゼルシャフト ミット ベシュレンクテル ハフツング | Seam joint structure, garment having seam joint structure, and method of manufacturing seam joint structure |

| JP2012500344A (en) * | 2009-10-15 | 2012-01-05 | 魯泰紡績股▲ふん▼有限公司 | No-stitch shirt with wrinkle-proof and no-iron functions and method for manufacturing the same |

| WO2012026029A1 (en) * | 2010-08-26 | 2012-03-01 | 株式会社重松製作所 | Method for joining cloth pieces for chemical protective clothing |

| US9155921B2 (en) | 2010-08-26 | 2015-10-13 | Shigemtsu Works Co., Ltd. | Chemical protective suit |

| JP2018003208A (en) * | 2016-07-05 | 2018-01-11 | フレックスジャパン株式会社 | Shirt |

| JP6886066B1 (en) * | 2020-10-26 | 2021-06-16 | グンゼ株式会社 | mask |

| CN115079645A (en) * | 2022-05-12 | 2022-09-20 | 雅莹集团股份有限公司 | Flexible intelligent garment production method and system based on digital management |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06280103A (en) * | 1993-03-23 | 1994-10-04 | Asahi Chem Ind Co Ltd | Production of dust-free clothing |

| JPH07310276A (en) * | 1994-05-17 | 1995-11-28 | Tal Apparel Ltd | Method for preparing smooth seam on clothes |

| JPH0892868A (en) * | 1994-09-27 | 1996-04-09 | Asahi Chem Ind Co Ltd | Water-proofing cloth having water-proofing sewing structure and its production |

| JPH10280215A (en) * | 1997-01-06 | 1998-10-20 | Tal Apparel Ltd | Clothing having smooth pocket seam and its formation |

| JPH10280217A (en) * | 1997-01-06 | 1998-10-20 | Tal Apparel Ltd | Clothing with smooth seam and its formation |

| JPH11200127A (en) * | 1998-01-06 | 1999-07-27 | Tal Apparel Ltd | Wear having smooth side seam and its formation |

| JP2004522011A (en) * | 2001-10-18 | 2004-07-22 | ガンドン エスケル テキスタイルス カンパニー リミテッド | Wrinkle-free clothes and method of manufacturing wrinkle-free clothes |

-

2005

- 2005-03-09 JP JP2005066332A patent/JP2006249602A/en active Pending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06280103A (en) * | 1993-03-23 | 1994-10-04 | Asahi Chem Ind Co Ltd | Production of dust-free clothing |

| JPH07310276A (en) * | 1994-05-17 | 1995-11-28 | Tal Apparel Ltd | Method for preparing smooth seam on clothes |

| JPH0892868A (en) * | 1994-09-27 | 1996-04-09 | Asahi Chem Ind Co Ltd | Water-proofing cloth having water-proofing sewing structure and its production |

| JPH10280215A (en) * | 1997-01-06 | 1998-10-20 | Tal Apparel Ltd | Clothing having smooth pocket seam and its formation |

| JPH10280217A (en) * | 1997-01-06 | 1998-10-20 | Tal Apparel Ltd | Clothing with smooth seam and its formation |

| JPH11200127A (en) * | 1998-01-06 | 1999-07-27 | Tal Apparel Ltd | Wear having smooth side seam and its formation |

| JP2004522011A (en) * | 2001-10-18 | 2004-07-22 | ガンドン エスケル テキスタイルス カンパニー リミテッド | Wrinkle-free clothes and method of manufacturing wrinkle-free clothes |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2011500982A (en) * | 2007-10-19 | 2011-01-06 | ダブリュ.エル.ゴア アンド アソシエーツ,ゲゼルシャフト ミット ベシュレンクテル ハフツング | Seam joint structure, garment having seam joint structure, and method of manufacturing seam joint structure |

| JP2012500344A (en) * | 2009-10-15 | 2012-01-05 | 魯泰紡績股▲ふん▼有限公司 | No-stitch shirt with wrinkle-proof and no-iron functions and method for manufacturing the same |

| WO2012026029A1 (en) * | 2010-08-26 | 2012-03-01 | 株式会社重松製作所 | Method for joining cloth pieces for chemical protective clothing |

| US9107463B2 (en) | 2010-08-26 | 2015-08-18 | Shigematsu Works Co., Ltd. | Method for integrating multi-layer sheet fabric pieces for use in a chemical protective suit |

| US9155921B2 (en) | 2010-08-26 | 2015-10-13 | Shigemtsu Works Co., Ltd. | Chemical protective suit |

| JP2018003208A (en) * | 2016-07-05 | 2018-01-11 | フレックスジャパン株式会社 | Shirt |

| JP6886066B1 (en) * | 2020-10-26 | 2021-06-16 | グンゼ株式会社 | mask |

| JP2022069959A (en) * | 2020-10-26 | 2022-05-12 | グンゼ株式会社 | mask |

| CN115079645A (en) * | 2022-05-12 | 2022-09-20 | 雅莹集团股份有限公司 | Flexible intelligent garment production method and system based on digital management |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0861605B1 (en) | Pucker free garment side seam and method for production | |

| US8336474B2 (en) | Wrinkle free garment and method of manufacture | |

| US7013818B2 (en) | Wrinkle free garment and method of manufacture | |

| EP0855150B1 (en) | Pucker free seam for a garment hem and method for production | |

| JP2859137B2 (en) | Clothing having stitched non-shrinkable portion and method of manufacturing the same | |

| US7828925B2 (en) | Method for the butt joining of two textile pieces | |

| CN101273804B (en) | Slopwork seam crease-shedding method with special composite adhesive lining belt | |

| US6070542A (en) | Pucker free collar seam and method of manufacture | |

| US20110281499A1 (en) | Ultrasonic cut and bonded elastic material | |

| EP0855147B1 (en) | Pucker free yoke-to-front yoke-to-back garment seam and method for production | |

| US5713292A (en) | Pucker free pocket garment seam and method for production | |

| JP2006249602A (en) | Connection part of fabric, clothes and method for producing clothes | |

| CN100515247C (en) | Dress material and method for producing dress material | |

| JPH10280214A (en) | Clothing having smooth seam with open sleeve and its formation | |

| JP2011047066A (en) | Method for producing seamless garment, and seamless garment produced by the method | |

| JP4533194B2 (en) | Fabric binding portion, apparel, and apparel manufacturing method | |

| US20050196585A1 (en) | Seam | |

| JP2005105475A (en) | Clothing, method for producing the same and bonded part of fabric | |

| Hayes | Joining techniques for high-performance apparel | |

| JP3434810B1 (en) | How to sew sewing products | |

| CN114098202B (en) | Manufacturing process of non-ironing clothing bidirectional seamless edge structure | |

| JPH11200127A (en) | Wear having smooth side seam and its formation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071113 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20091126 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100603 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20101104 |