JP2006242464A - Refrigerator - Google Patents

Refrigerator Download PDFInfo

- Publication number

- JP2006242464A JP2006242464A JP2005058557A JP2005058557A JP2006242464A JP 2006242464 A JP2006242464 A JP 2006242464A JP 2005058557 A JP2005058557 A JP 2005058557A JP 2005058557 A JP2005058557 A JP 2005058557A JP 2006242464 A JP2006242464 A JP 2006242464A

- Authority

- JP

- Japan

- Prior art keywords

- chamber

- refrigerator

- temperature zone

- ice making

- storage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Devices That Are Associated With Refrigeration Equipment (AREA)

- Cold Air Circulating Systems And Constructional Details In Refrigerators (AREA)

Abstract

Description

本発明は、冷蔵庫の冷却構造に関するものである。 The present invention relates to a refrigerator cooling structure.

従来、左右に分割された貯蔵室を区画している冷蔵庫において、片側が上から下まで全て引出し扉で構成されているものが提案されている(例えば、特許文献1参照)。 Conventionally, in a refrigerator that divides a storage room divided into left and right, a structure in which one side is entirely constituted by drawer doors from top to bottom has been proposed (for example, see Patent Document 1).

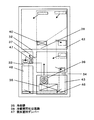

図5、図6は特許文献1に記載された従来の冷蔵庫を示すものである。図5は従来の冷蔵庫の正面図、図6は従来の冷蔵庫の扉を開けた状態の斜視図である。 5 and 6 show a conventional refrigerator described in Patent Document 1. FIG. FIG. 5 is a front view of a conventional refrigerator, and FIG. 6 is a perspective view of the conventional refrigerator with the door opened.

図5、図6に示すように2は冷蔵庫本体1内を上下に区画する断熱区画壁であり、上部に上部区画3、下部に下部区画4を形成している。5は上部区画3内を左右に区画する第1の区画壁であり、6は下部区画4内を左右に区画する第2の区画壁である。7は第1の区画壁5により一側に形成された冷蔵室、8は冷蔵室7の下部に区画壁9を挟んで形成された野菜室である。10は第1の区画壁5により他側に形成されたボトル収納室である。11は第2の区画壁6により一側に形成された冷凍室、12は他側に形成された製氷室である。

As shown in FIGS. 5 and 6,

冷蔵室7の開口面には開閉自在に取り付けられたヒンジ開閉式扉13が設けられている。野菜室8は開口面に開閉自在に取り付けられた引出し式扉14を設けており、室内側の収納容器(図示せず)を一体に引き出せるように構成されている。

On the opening surface of the

ボトル収納室10は開口面に開閉自在に取り付けられた引出し式扉16を設けており、室内側の収納容器17、18、19、20を一体に引き出せるように構成されている。また、冷凍室11は開口面に開閉自在に取り付けられた引出し式扉21を設けており、室内側の収納容器(図示せず)を一体に引き出せるよう構成されている。製氷室12は開口面に開閉自在に取り付けられた引出し式扉22を設けており、室内側の収納容器(図示せず)を一体に引き出せるように構成されている。

しかしながら、上記従来の構成では、上方に位置するボトル収納を目的にしたボトル収納室の上下方向の高さに占める割合が大きく、下方に位置する製氷室の位置が低くなるため、製氷室から生成した氷を取り出す際に、腰をかがめたり、しゃがんだりする必要があるという課題を有していた。また冷蔵室にも冷却器と送風機を設置している為、冷蔵室の奥行きが少なくなるという課題も有していた。 However, in the above-described conventional configuration, the ratio of the bottle storage chamber for the purpose of storing the bottle located above to the height in the vertical direction is large, and the position of the ice making chamber located below is low, so that it is generated from the ice making chamber. When taking out the frozen ice, it was necessary to bend or squat down. Moreover, since the refrigerator and the air blower are also installed in the refrigerator compartment, there is a problem that the depth of the refrigerator compartment is reduced.

本発明は、上記従来の課題を解決するもので、収納食品の種類に応じて適切な貯蔵環境を提供し、各貯蔵室の使い勝手を同時に改善、そして、容積効率を高めた冷蔵庫を提供することを目的とする。 The present invention solves the above-mentioned conventional problems, and provides a storage environment suitable for the type of stored food, simultaneously improving the convenience of each storage room, and providing a refrigerator with improved volumetric efficiency. With the goal.

上記従来の課題を解決するために、冷蔵庫の前面開口部を塞ぐ扉が、前記冷蔵庫の上下方向の全高にて左右に分断され、分断された左右区画のいずれか一方をすべて引き出し扉にて構成し、高さ方向の中央付近で独立した製氷室を配置し製氷室の上方の引き出し区画を冷蔵温度帯の貯蔵室、下方引き出し区画には冷凍温度帯の貯蔵室を有し、冷蔵温度帯の貯蔵室の側方に隣接する区画に回転扉を有する第二の冷蔵温度帯の貯蔵室を配置し、第二の冷蔵温度帯の貯蔵室の下方には野菜室を配置し、野菜室の下方には第二の冷凍温度帯の貯蔵室を配置し、冷却器は、冷凍温度帯の第二の冷凍温度帯の貯蔵室の背面のみに配置したものである。 In order to solve the above-mentioned conventional problems, the door that closes the front opening of the refrigerator is divided into left and right at the total height in the vertical direction of the refrigerator, and any one of the divided right and left sections is constituted by a drawer door An independent ice making chamber is arranged near the center in the height direction, and the drawer compartment above the ice making chamber has a storage compartment in the refrigeration temperature zone, and the lower drawer compartment has a storage compartment in the refrigeration temperature zone. A storage room of the second refrigeration temperature zone having a revolving door is arranged in a section adjacent to the side of the storage room, a vegetable room is arranged below the storage room of the second refrigeration temperature zone, and below the vegetable room Is provided with a storage room in the second freezing temperature zone, and the cooler is arranged only on the back surface of the storage room in the second freezing temperature zone.

これによって、使いやすい引出し扉を冷蔵庫本体の片側サイドに構成し、上方に目線に位置する引出し扉と、独立した製氷室を氷が取り出しやすい位置に配置することが可能となる。また冷蔵庫全体を冷却する冷却器は冷凍室内に収納することにより、複雑なシール構造が不要となり、冷蔵室には冷却器を設置しないので奥行きを深くすることが可能になる。 Accordingly, an easy-to-use drawer door is configured on one side of the refrigerator main body, and the drawer door positioned above the line of sight and the independent ice making chamber can be arranged at positions where ice can be easily taken out. The cooler that cools the entire refrigerator is housed in the freezer compartment, so that a complicated seal structure is not necessary, and the refrigerator is not installed in the refrigerator compartment, so that the depth can be increased.

本発明の冷蔵庫は、冷蔵庫本体の片側サイドを全て引出し扉で構成することで、冷蔵温度帯の引出しはもちろんのこと冷凍温度帯の引出しにも比較的背の高いペットボトル、ビン類を収納しやすくし、また奥に収納している収納物をも手前に簡単に引き出すことができるため、収納物が取り出しやすい構造にすることができる。また、扉を引き出した時に左右両側から収納物を取り出せるという利点も有する。また、独立した製氷室を冷蔵庫本体の中央付近に位置させることで、夏場に使用頻度が高い氷を、腰をかがめることなく、立ったままの姿勢で楽に取り出しができるという使い勝手のよさを提供することができる。さらに他の部屋と独立させることで、冷凍収納物と氷の使い分けができ、臭い移りを防止したキレイな氷を提供するとともに、必要に応じた扉開閉による温度上昇の低減が図れ、省エネにも繋がる。また、1つの冷却器で冷蔵庫全体を冷却し、その冷却器を冷凍室内に収納することで、冷凍室風路カバーが簡素化でき、庫内の容積効率も向上する。 The refrigerator of the present invention comprises all the one side of the refrigerator body with drawer doors, and stores relatively tall plastic bottles and bottles not only in the refrigerator temperature zone but also in the refrigerator temperature zone. In addition, since the stored item stored in the back can be easily pulled out to the front, the structure can be easily taken out. Further, there is an advantage that the stored item can be taken out from both the left and right sides when the door is pulled out. In addition, by positioning an independent ice making room near the center of the refrigerator body, it provides ease of use, allowing you to easily take out ice that is frequently used in summer without standing down, while standing up. be able to. Furthermore, by making it independent from other rooms, it is possible to use frozen storage and ice separately, providing clean ice that prevents odors from moving, and reducing temperature rise by opening and closing the door as necessary, saving energy Connected. Moreover, by cooling the whole refrigerator with one cooler and storing the cooler in the freezer compartment, the freezer compartment air passage cover can be simplified, and the volumetric efficiency in the cabinet is improved.

請求項1に記載の発明は、冷蔵庫の前面開口部を塞ぐ扉が、前記冷蔵庫の上下方向の全高にて左右に分断され、分断された左右区画のいずれか一方をすべて引き出し扉にて構成し、高さ方向の中央付近で独立した製氷室を配置し製氷室の上方の引き出し区画を冷蔵温度帯の貯蔵室、下方引き出し区画には冷凍温度帯の貯蔵室を有し、前記冷蔵温度帯の貯蔵室の側方に隣接する区画に回転扉を有する第二の冷蔵温度帯の貯蔵室を配置し、前記第二の冷蔵温度帯の貯蔵室の下方には野菜室を配置し、前記野菜室の下方には第二の冷凍温度帯の貯蔵室を配置し、冷却器は、前記冷凍温度帯の第二の冷凍温度帯の貯蔵室の背面のみに配置したことにより、使いやすい引出し扉を片側サイドに集約し、独立した製氷室を氷が取り出しやすい位置に配置することができ、使用頻度の高いペットボトルやビン類を区画収納することができ、楽な出し入れが実現できるとともに、収納物を奥まで収納しても引き出せて簡単に取り出すことができる。また、製氷室の位置を冷蔵庫本体の中央付近に位置させることで、腰をかがめることなく楽な姿勢で取り出すことができとともに、他の部屋と独立させることで、冷凍収納物と氷の使い分けができ、臭い移りを防止したキレイな氷を提供するとともに、必要に応じた扉開閉による温度上昇の低減が図れ、省エネにも繋がる。また、冷凍室風路カバーが簡素化でき、庫内の容積効率も向上する。 In the first aspect of the present invention, the door that closes the front opening of the refrigerator is divided into left and right parts at the overall height in the vertical direction of the refrigerator, and any one of the divided right and left sections is constituted by a drawer door. An independent ice making chamber is arranged near the center of the height direction, the drawer compartment above the ice making chamber has a storage room in a refrigerated temperature zone, and the lower drawer compartment has a storage room in a refrigeration temperature zone, A storage room of a second refrigeration temperature zone having a revolving door is arranged in a section adjacent to the side of the storage room, a vegetable room is arranged below the storage room of the second refrigeration temperature zone, and the vegetable room A storage room for the second refrigeration temperature zone is disposed below the cooler, and the cooler is arranged only on the back surface of the storage room for the second refrigeration temperature zone. Concentrate on the side and place an independent ice making room where ice can be easily removed It can be, a high bottles and bottles that are frequently used can be partitioned storage, with an easy loading and unloading can be achieved, storage was can be retrieved easily drawn out be accommodated as far as it will go. In addition, by positioning the ice making room near the center of the refrigerator body, it can be taken out in an easy posture without bending down, and by making it independent of other rooms, it is possible to use frozen storage items and ice properly. In addition to providing clean ice that prevents odors from shifting, the temperature rise can be reduced by opening and closing the door as needed, leading to energy savings. Moreover, the freezer compartment air channel cover can be simplified, and the volumetric efficiency in the cabinet is improved.

請求項2に記載の発明は、請求項1に記載の発明において、前記野菜室は、前記第二の冷蔵温度帯の貯蔵室を冷却した戻り空気で冷却するものであり、いかなる使用条件においても吐出口付近の野菜の凍結を防止することができる。

The invention according to

請求項3に記載の発明は、請求項1または2に記載の発明において、冷蔵温度帯の貯蔵室を冷却する空気を吐出する冷蔵室用吐出風路は、前記回転扉を有する第二の冷蔵温度帯の貯蔵室奥面のみに配置したものであり、引き出し区画の冷蔵温度帯の貯蔵室の奥行きを最大限に利用できる。

The invention according to

請求項4に記載の発明は、請求項1から3のいずれか一項に記載の発明において、前記引き出し区画の冷凍温度帯の貯蔵室は、前記製氷室の戻り冷気のみで冷却するものであり、奥面に冷却風路が必要なく、奥行きを最大限に利用できる。 According to a fourth aspect of the present invention, in the invention according to any one of the first to third aspects, the storage room in the freezing temperature zone of the drawer section is cooled only by the return cold air of the ice making room. , No cooling air path is required on the back, and the maximum depth can be used.

請求項5に記載の発明は、請求項1から4のいずれか一項に記載の発明において、前記製氷室を冷却する空気は、空気調整手段で調整するものであり、製氷室で製氷を行わない場合には冷気量を低減することで、省エネとなる。また、冷却器の除霜時には暖湿気が製氷室内に流入しないので着霜が防止できる。

The invention according to

以下、本発明の実施の形態について、図面を参照しながら説明する。なお、この実施の形態によってこの発明が限定されるものではない。 Hereinafter, embodiments of the present invention will be described with reference to the drawings. The present invention is not limited to the embodiments.

(実施の形態1)

図1は本発明の実施の形態1における冷蔵庫の正面図である。図2は本発明の実施の形態1における冷蔵庫の風路を示す正面図である。図3は本発明の実施の形態1における冷蔵庫の断面図である。

(Embodiment 1)

FIG. 1 is a front view of the refrigerator according to Embodiment 1 of the present invention. FIG. 2 is a front view showing the air path of the refrigerator in the first embodiment of the present invention. FIG. 3 is a cross-sectional view of the refrigerator according to Embodiment 1 of the present invention.

図1に示すように、冷蔵庫本体23は、上下方向の全高で左右に分断された左区画24と、右区画25に区画されている。左区画24は中央付近に製氷室26が配置され、製氷室26の上方には引出し扉で構成された冷蔵スライド室27を、製氷室26の下方には引出し扉で構成された冷凍スライド室28が配置されている。

As shown in FIG. 1, the refrigerator

一方、右区画25には、上から冷蔵室29、野菜室30、冷凍室31が配置されていて、それぞれの部屋の前面開口は扉により塞がれている。なお、冷蔵スライド室27と冷蔵室29は上下方向の同一線上で区画されているが、冷蔵スライド室27の高さと、冷蔵室29の高さが違う、すなわち段差がつくよう構成されていても構わない。

On the other hand, in the

図2、3において、第1の仕切り壁32は、冷蔵スライド室27及び冷蔵室29と製氷室26及び野菜室30を仕切っている。第2の仕切り壁33は、製氷室26と冷凍スライド室28を仕切っている。第3の仕切り壁34は、野菜室30と冷凍室31を仕切っている。冷却器35と冷却ファン36は冷凍室31の背面に設置される。冷却ファン36から吐出された冷気は冷凍室31内と製氷室用吐出風路37及び冷蔵室用吐出風路38に分岐している。冷蔵室用吐出風路38は、冷蔵室29奥面に配置し、冷蔵室ダンパー40を介して冷蔵室29及び冷蔵スライド室27に冷気を吐出する。

2 and 3, the

製氷室用吐出風路37を吐出した製氷室を冷却した冷気は、製氷室戻り風路41から冷凍スライド室28に流入し、冷凍スライド室を冷却した後冷却器吸込口46に戻る。野菜室30は、冷蔵室戻り風路から吐出された冷気により冷却され、野菜室戻り風路43から冷却器吸込口46に戻る。

The cold air that has cooled the ice making chamber discharged from the ice making chamber

以上のように構成された冷蔵庫について、以下その動作について説明する。 About the refrigerator comprised as mentioned above, the operation | movement is demonstrated below.

使用頻度の高い冷蔵スライド室27を冷蔵庫本体23の上部に配置することで、従来冷蔵室29の扉棚に収納されていたペットボトル、ビン類、牛乳パックなどの収納物を取り込むことができ、更に大量に収納することができるとともに、目線から若干した側に位置する重量物のペットボトルの出し入れ性を向上することができる。また、使用頻度の高い製氷室26を冷蔵庫本体23の中央付近に配置したことで、氷の取り出しを立ったままの楽な姿勢で行うことができる。下方に設置した冷凍スライド室28も奥の収納物が引き出せて簡単に取り出せることができるように、使用頻度に応じて使い勝手の向上が図れるレイアウトを提供することが可能となる。また、冷却器35は、冷凍室31の奥面のみに設置しているので、冷凍室風路カバーが簡素化でき、庫内の容積効率も向上する。

By placing the frequently used

さらに、野菜室30は冷蔵室29を冷却した戻り空気で冷却するので、冷気温度は高く、いかなる使用条件においても吐出口付近の野菜の凍結の危険がない。

Furthermore, since the

さらに、冷蔵室用吐出風路38は、冷蔵室29奥面のみに配置するので、冷蔵スライド室27の奥行きを最大限に利用できる。

Further, since the

さらに、冷凍スライド室28は、製氷室26の戻り冷気で冷却するので、奥面に冷凍スライド室用の吐出風路が必要なく、奥行きを最大限に利用でき、使い勝手の向上が図れる。

Furthermore, since the freezing

(実施の形態2)

図4は本発明の実施の形態2における冷蔵庫の風路を示す正面図である。図4において、製氷室用ダンパー47は製氷室用吐出風路37内に設置し、製氷室26を冷却した冷気は、製氷室戻り風路41から冷却器吸込口46に戻る。

(Embodiment 2)

FIG. 4 is a front view showing the air path of the refrigerator in the second embodiment of the present invention. In FIG. 4, the ice

以上のように構成された冷蔵庫について、以下その動作について説明する。 About the refrigerator comprised as mentioned above, the operation | movement is demonstrated below.

冷却ファン36から吐出された冷気は冷凍室31内と冷凍スライド室28内及び製氷室用吐出風路37及び冷蔵室用吐出風路38に分岐している。製氷室吐出風路37から吐出される冷気は、製氷室用ダンパー47により、製氷室で製氷を行わない場合には冷気量を低減するように調整されることで、省エネとなる。また、冷却器35の除霜時には製氷室用ダンパー47を閉じることで暖湿気が製氷室内への流入がなく着霜が防止できる。

The cold air discharged from the cooling

以上のように、本発明にかかる冷蔵庫は、冷却器を冷凍室の奥面に配置する事により、食品を貯蔵するための容積を十分確保することができると共に、お客様の使い勝手を向上させることができるので、冷凍機器全般の冷却方法の用途にも適用できる。 As described above, the refrigerator according to the present invention can secure a sufficient volume for storing food by arranging the cooler on the back surface of the freezer compartment, and can improve the convenience for customers. Therefore, it can be applied to the use of cooling methods for refrigeration equipment in general.

26 製氷室

27 冷蔵スライド室

28 冷凍スライド室

29 冷蔵室

30 野菜室

31 冷凍室

35 冷却器

38 冷蔵室用吐出風路

47 製氷室用ダンパー

26

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005058557A JP2006242464A (en) | 2005-03-03 | 2005-03-03 | Refrigerator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005058557A JP2006242464A (en) | 2005-03-03 | 2005-03-03 | Refrigerator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2006242464A true JP2006242464A (en) | 2006-09-14 |

Family

ID=37049059

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005058557A Pending JP2006242464A (en) | 2005-03-03 | 2005-03-03 | Refrigerator |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006242464A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008304074A (en) * | 2007-06-05 | 2008-12-18 | Panasonic Corp | Refrigerator |

| CN102840734A (en) * | 2011-06-20 | 2012-12-26 | 日立空调·家用电器株式会社 | Refrigerator |

| JP2016017683A (en) * | 2014-07-08 | 2016-02-01 | シャープ株式会社 | refrigerator |

-

2005

- 2005-03-03 JP JP2005058557A patent/JP2006242464A/en active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008304074A (en) * | 2007-06-05 | 2008-12-18 | Panasonic Corp | Refrigerator |

| CN102840734A (en) * | 2011-06-20 | 2012-12-26 | 日立空调·家用电器株式会社 | Refrigerator |

| JP2016017683A (en) * | 2014-07-08 | 2016-02-01 | シャープ株式会社 | refrigerator |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101437170B1 (en) | Refrigerator | |

| TWI363861B (en) | ||

| JP2009222342A (en) | Refrigerator | |

| JP2008106993A (en) | Refrigerator | |

| JP2003075055A (en) | Refrigerator | |

| JP2006090686A (en) | Refrigerator | |

| US10605516B2 (en) | Refrigerator appliance | |

| JP2007071465A (en) | Refrigerator | |

| US20100139307A1 (en) | Refrigerator with an improved air handler for quickly chilling a bin | |

| WO2007010267A2 (en) | Improvements in or relating to cold storage | |

| JP2007187362A (en) | Refrigerator | |

| JP4672506B2 (en) | refrigerator | |

| JP4820787B2 (en) | refrigerator | |

| JP2006242464A (en) | Refrigerator | |

| JP2007071429A (en) | Refrigerator | |

| JP4764383B2 (en) | refrigerator | |

| JP7390178B2 (en) | refrigerator | |

| US10928122B2 (en) | Dual asymmetrical and symmetrical architecture cantilever positioning | |

| JP2006250465A (en) | Refrigerator | |

| JP4250664B2 (en) | refrigerator | |

| KR100614315B1 (en) | A refrigerator | |

| JP2001349668A (en) | Refrigerator | |

| JP2007147224A (en) | Refrigerator | |

| JP7430524B2 (en) | refrigerator | |

| JP7056199B2 (en) | refrigerator |