JP2005307454A - Plug device and piping member for drainage - Google Patents

Plug device and piping member for drainage Download PDFInfo

- Publication number

- JP2005307454A JP2005307454A JP2004122148A JP2004122148A JP2005307454A JP 2005307454 A JP2005307454 A JP 2005307454A JP 2004122148 A JP2004122148 A JP 2004122148A JP 2004122148 A JP2004122148 A JP 2004122148A JP 2005307454 A JP2005307454 A JP 2005307454A

- Authority

- JP

- Japan

- Prior art keywords

- opening

- back pressure

- cover plate

- water stop

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L55/00—Devices or appurtenances for use in, or in connection with, pipes or pipe systems

- F16L55/10—Means for stopping flow from or in pipes or hoses

- F16L55/12—Means for stopping flow from or in pipes or hoses by introducing into the pipe a member expandable in situ

- F16L55/128—Means for stopping flow from or in pipes or hoses by introducing into the pipe a member expandable in situ introduced axially into the pipe or hose

- F16L55/132—Means for stopping flow from or in pipes or hoses by introducing into the pipe a member expandable in situ introduced axially into the pipe or hose the closure device being a plug fixed by radially deforming the packing

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Sink And Installation For Waste Water (AREA)

- Branch Pipes, Bends, And The Like (AREA)

Abstract

Description

本発明は、栓装置及びこの栓装置を具備する排水用配管部材に関するものである。 The present invention relates to a plug device and a drainage piping member including the plug device.

排水管システムに使用される集合管などの配管部材では、管内の点検や清掃をするために点検口が設けられたものがあった。この種の配管部材では、点検口を使用しないときにはこれを閉鎖して水漏れが起こらないようにする必要がある。

従来、この点検口を閉鎖するための構造としては、点検口内周面に雌ねじを刻設すると共にこれに螺合可能な雄ねじを有する盲栓を、点検口へねじ嵌合させる構造(特許文献1等参照)や、点検口の開口周部に複数箇所のネジ孔を設けると共に点検口を閉鎖可能な蓋板にネジ孔に対応したネジ通孔を設けて、点検口に蓋板を被せた状態でネジ通孔からネジ孔へネジを止め付ける構造(特許文献2等参照)が知られている。

Some piping members such as collecting pipes used in drainage pipe systems are provided with an inspection port in order to inspect and clean the inside of the pipe. In this type of piping member, when the inspection port is not used, it is necessary to close the inspection port to prevent water leakage.

Conventionally, as a structure for closing the inspection port, a female screw is engraved on the inner peripheral surface of the inspection port and a blind plug having a male screw that can be screwed to the internal screw is screwed into the inspection port (Patent Document 1). Etc.), and a screw plate with a screw hole corresponding to the screw hole is provided on the cover plate that can close the inspection port, and the inspection plate is covered with the cover plate. There is known a structure in which a screw is fastened from a screw hole to a screw hole (see

なお、なかには、配管部材の管内に垂れ壁状のストッパー部を設け、点検口を閉鎖可能な蓋板には回動によってストッパー部と係合したり外れたりする鉤部を設けて、この鉤部を蓋の外部から回動操作できるようにした構造も提案されている(特許文献3参照)。

盲栓を点検口へねじ嵌合させる構造(特許文献1等参照)では、点検口内周面に雌ねじを刻設したり盲栓に雄ねじを刻設したりする加工で高コストになる。また腐食や取り扱いの不手際からネジ山を潰しやすいということもあった。点検口に蓋板を被せて複数本のネジでネジ止めする構造(特許文献2等参照)では、点検口の開口周部にネジ孔を設ける加工で高コストになる。また、蓋板の開閉を繰り返すうちに、ネジの紛失やネジ孔のネジ山潰し等の事故が起こりやすいということもあった。

蓋板に回動操作可能な鉤部を設けて配管部材内のストッパー部へ係合させる構造(特許文献3参照)では、配管部材自体にストッパー部を設けるという複雑な専用構造が必要であるために汎用性に欠け、やはり高コストになる問題があった。

In the structure in which the blind plug is screw-fitted into the inspection port (see

In the structure (refer to Patent Document 3) in which a lid that can be rotated is provided on the cover plate and engaged with the stopper in the piping member (see Patent Document 3), a complicated dedicated structure in which the stopper is provided on the piping member itself is required. However, there was a problem that it lacked versatility and was also expensive.

更に、これら従来公知の各種構造では、いずれも、点検口はあくまでも点検のためのものであり、例えばこの点検口を利用して他の管材を接続するといったことは不可能であるか、又は可能であったとしても接続構造が特別なもの(ねじ嵌合など)に限定されてしまうということがあった。

本発明は、上記事情に鑑みてなされたものであって、低コスト化、取り扱いの容易化、汎用性の拡大等を可能とした栓装置及び排水用配管部材を提供することを目的とする。

Further, in each of these conventionally known various structures, the inspection port is only for inspection, and for example, it is impossible or possible to connect other pipes using this inspection port. Even in such a case, the connection structure may be limited to a special one (screw fitting or the like).

This invention is made | formed in view of the said situation, Comprising: It aims at providing the plug apparatus and drainage piping member which enabled cost reduction, easy handling, expansion of versatility, etc.

前記目的を達成するために、本発明は次の手段を講じた。

即ち、本発明に係る栓装置は、所定の奥行きを有して形成された開口部に対してその開口端に当接してこれを閉鎖可能にする蓋板と、開口部内に嵌る大きさに形成されて上記蓋板の裏側でこれと重合状に保持される背圧負荷部材と、蓋板を貫通してその表側へ操作部を露出させた状態でこの操作部の操作によって上記背圧負荷部材を蓋板に接離動作可能にする止栓手段と、蓋板と背圧負荷部材との間に挟持された状態で全周面を背圧負荷部材の回りへ露出させた止水部材とを有し、上記止水部材は肉厚方向の圧縮を受けることで開口部の内径以上に拡径可能となる弾性材により形成されている。

In order to achieve the above object, the present invention has taken the following measures.

That is, the stopper device according to the present invention is formed with a lid plate that contacts the opening end of the opening formed with a predetermined depth so that the opening can be closed, and a size that fits in the opening. A back pressure load member which is held in a superposed manner on the back side of the lid plate, and the back pressure load member is operated by operating the operation portion in a state where the operation portion is exposed to the front side through the lid plate. A stopper member that allows the lid plate to be moved toward and away from the lid plate, and a water stop member that is sandwiched between the lid plate and the back pressure load member so that the entire circumferential surface is exposed around the back pressure load member. The water stop member is formed of an elastic material that can be expanded beyond the inner diameter of the opening by receiving compression in the thickness direction.

このような構成の栓装置では、背圧負荷部材及び止水部材を開口部内へ嵌め入れるようにしてこの開口部の開口端へ蓋板を押し付けておき、止栓手段の操作部を操作する。すると、背圧負荷部材が蓋板に近接するようになって止水部材に対する挟持圧が高まり、止水部材は肉厚方向で圧縮されることになる。そのため、止水部材は拡径してその外周面全周が開口部の内周面に押し付けられることになり、止水作用が生起する。なお、止栓手段の操作部を上記と逆向きに操作すれば、止水部材の肉厚方向圧縮を解除して拡径を元に戻せるので、開口部から止水部材及び背圧負荷部材を引き出すことができ、結果、この栓装置を開口部から取り外すことができる。 In the plug device having such a configuration, the back pressure load member and the water stop member are fitted into the opening, the cover plate is pressed against the opening end of the opening, and the operation portion of the stopper means is operated. Then, the back pressure load member comes close to the cover plate, and the clamping pressure with respect to the water stop member increases, and the water stop member is compressed in the thickness direction. Therefore, the diameter of the water stop member is increased, and the entire outer periphery of the water stop member is pressed against the inner peripheral surface of the opening, thereby causing a water stop effect. In addition, if the operation part of the stopper means is operated in the opposite direction to the above, the compression in the thickness direction of the water stop member can be released and the expanded diameter can be restored. Can be withdrawn, so that the plug device can be removed from the opening.

このように、栓装置は、蓋板と背圧負荷部材とで止水部材を挟持するだけの構造であり、部品点数が少なく、また各部品形状も簡潔であり、構造簡潔と言える。また開口部に対して装着したり外したりするための操作も至極簡単である。開口部に対しては何ら特別な構造が必要ないという利点もある。

なお、蓋体は必ずしも開口部の開口端に当接するような大きさにしなくてもよく、開口部に嵌る大きさとしてもよい。このようにすると、蓋体と背圧負荷部材とについて、部品の共通化ができることになり、コストダウンに繋がる。

As described above, the stopper device has a structure in which the water stop member is simply sandwiched between the lid plate and the back pressure load member, has a small number of parts, and each part has a simple shape, which can be said to have a simple structure. In addition, the operation for mounting and removing the opening is extremely simple. There is also an advantage that no special structure is required for the opening.

Note that the lid does not necessarily have to be sized to contact the opening end of the opening, but may be sized to fit into the opening. If it does in this way, about a lid and a back pressure load member, parts can be made common and it leads to a cost reduction.

止水部材はリング形に形成されたものとし、蓋板及び背圧負荷部材の各外周部には、互いに共同して止水部材のリング内周面をV溝で挟持しつつ径方向外方へ押し広げ可能にする傾斜面を形成させておくのが好適である。

このようにすると、止水部材においてはその材料コストを低廉化できるという利点がある。また蓋板に背圧負荷部材を近接させればさせるほど止水部材に対して径方向外方へ押し広げる作用を高められるので、肉厚方向の圧縮作用と相まって止水部材を迅速且つ効率よく径大化できるものとなる。

The water-stop member is formed in a ring shape, and the outer peripheral portions of the lid plate and the back pressure load member are radially outward while holding the ring inner peripheral surface of the water-stop member in a V-groove together. It is preferable to form an inclined surface that can be spread out.

If it does in this way, there exists an advantage that the material cost can be reduced in a water stop member. In addition, the closer the back pressure load member is to the lid plate, the higher the action of pushing the water stop member radially outward, so the water stop member can be quickly and efficiently coupled with the compression action in the thickness direction. The diameter can be increased.

なお、止水部材と蓋板との接触間、及び止水部材と背圧負荷部材との接触間には、潤滑剤を塗布しておくのが好適である。

止栓手段は、蓋板に背圧負荷部材が到達する前に止水部材の外周面が開口部の内周面に水密当接可能にしておくのが好適である。

このようにすることで止水部材の径大化に余力を残した状態に維持でき、もって止水作用を高めることができる。

止栓手段は、背圧負荷部材から蓋板を貫通して突設されるネジ軸と、蓋板を貫通したネジ軸に螺合されるナット部材とを有したものとすればよい。このような構造は簡潔であり、低コスト化に有益となる。

Note that it is preferable to apply a lubricant between the water stop member and the cover plate and between the water stop member and the back pressure load member.

It is preferable that the stopper means is configured such that the outer peripheral surface of the water-stopping member can be brought into watertight contact with the inner peripheral surface of the opening before the back pressure load member reaches the cover plate.

By doing in this way, it can maintain in the state which left the surplus power for diameter enlargement of a water stop member, and can improve a water stop effect | action.

The stopper means may have a screw shaft protruding from the back pressure load member through the cover plate and a nut member screwed to the screw shaft passing through the cover plate. Such a structure is simple and is useful for cost reduction.

一方、本発明に係る排水用配管部材は、排水流れの入口及び出口に用いられる少なくとも2つの管接続部が設けられこれら管接続部の相互間に管壁を貫通する開口部が設けられた管本体と、この管本体に対して上記開口部を閉鎖すべく着脱自在に設けられる栓装置とを有したものであって、上記管本体には、開口部の開口周部を取り囲んでこの開口部内に所定の奥行きを形成させる口枠が設けられており、栓装置として本発明のものが採用されて、上記口枠を介して開口部へ装着される。

このように管本体として開口部まわりに口枠を設けることで、この開口部内に所定の奥行きを持たせられるようになり、ここに栓装置の装着スペースを確保できるものである。この栓装置を着脱自在にさせる方式であれば、仮に栓装置側で止栓手段(ネジ軸やナット部材など)等が破損したとしても、この栓装置自体を交換するだけでよい。すなわち、従来における点検口内周面に雌ねじを刻設した配管部材(特許文献1等参照)や点検口の開口周部にネジ孔を設けた配管部材(特許文献2等参照)とは異なって、管本体としての交換や修理などは全く不要であり、メンテナンスが極めて容易且つ低コストで行える利点がある。

On the other hand, the pipe member for drainage according to the present invention is a pipe provided with at least two pipe connecting parts used for the inlet and outlet of the drainage flow, and provided with an opening penetrating the pipe wall between these pipe connecting parts. A main body and a plug device that is detachably provided so as to close the opening with respect to the tube main body, and the tube main body surrounds the opening periphery of the opening. A mouth frame for forming a predetermined depth is provided, and the stopper device of the present invention is adopted, and is attached to the opening through the mouth frame.

By providing the mouth frame around the opening as the tube main body in this way, a predetermined depth can be provided in the opening, and a mounting space for the stopper device can be secured here. If the stopper device is detachable, even if the stopper means (screw shaft, nut member, etc.) or the like is damaged on the stopper device side, it is only necessary to replace the stopper device itself. That is, unlike a conventional piping member in which a female screw is engraved on the inner peripheral surface of the inspection port (see

管本体に設けられた開口部はその内周面を平滑面に形成しておけばよい。すなわち、いちいち雌ねじを刻設する等の手間は不要になる。それだけ低コスト化にとって有益である。

管本体の口枠は、この管本体の管壁に干渉することなく他の管材を接続できる突出長さに形成しておくのが好適である。このようにすることで、開口部は点検口として使用するだけでなく、必要に応じて他の管材との接続(要は流体の流通孔)に利用できるようになる。

The opening provided in the tube body may be formed with a smooth inner surface. That is, the trouble of engraving the female screw one by one is unnecessary. It is beneficial for cost reduction.

It is preferable that the mouth frame of the tube main body is formed to have a protruding length that allows other pipe materials to be connected without interfering with the tube wall of the tube main body. In this way, the opening can be used not only as an inspection port but also for connection with other pipe materials (essentially, a fluid circulation hole) as necessary.

口枠の開口端寄りの内周面には、栓装置における止水部材の抜けだしを防止する突起を設けておくのが好適である。

管本体の口枠と栓装置の蓋板との相互間に、互いに凹凸係合する回り止め手段を設けておくのが好適である。

このような回り止め手段を採用することで、栓装置に設けられる止水手段の操作部を簡単且つ確実に操作できる利点がある。また管本体(開口部)に対する栓装置の位置決めが確実にできるので、栓装置の装着が簡単になり、また止水作用も確実に得られるようになる。

It is preferable to provide a protrusion on the inner peripheral surface near the opening end of the mouth frame to prevent the water stop member from coming off in the stopper device.

It is preferable to provide anti-rotation means for engaging with each other between the mouth frame of the tube main body and the lid plate of the stopper device.

By employing such a detent means, there is an advantage that the operation portion of the water stop means provided in the stopper device can be easily and reliably operated. Further, since the plug device can be reliably positioned with respect to the tube main body (opening), it is easy to mount the plug device, and a water-stopping action can be obtained with certainty.

本発明に係る栓装置及び排水用配管部材では、低コスト化が図れ、取り扱いが容易になり、汎用性の拡大等が図れるものとなっている。 In the plug device and drain piping member according to the present invention, the cost can be reduced, the handling becomes easy, and the versatility can be expanded.

以下、本発明の実施の形態を、図面に基づき説明する。

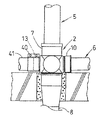

図1乃至図7は、本発明に係る栓装置および排水用配管部材1の第1実施形態を示している。この配管部材1は管本体2と栓装置3とを有している。図2、図3及び図6から明らかなように、管本体2は、例えば立主管5に横枝管6を接続させるための排水集合管などであって、立主管5を流れる排水流れの入口用とされる上部の管接続部7と、排水流れの出口用とされる下部の管接続部8とを有している。また横枝管6から流入する排水流れの入口用とされる中間の管接続部10を有している。なお本第1実施形態における管本体2では、この中間の管接続部10は一方(一つ)だけのものを示している。

Hereinafter, embodiments of the present invention will be described with reference to the drawings.

1 to 7 show a first embodiment of a plug device and a

この管本体2において、上下の管接続部7,8の相互間には、丁度、中間の管接続部10とは反対向きになる管壁から短円筒状に突出する部分が設けられている。図1及び図5に示すようにこの突出部分は内部が中空に形成されており、この中空内部が、管本体2の管壁を貫通する開口部12として設けられていると共に、突出部分の外周壁が、開口部12の開口周部を取り囲む口枠13として設けられている。この口枠13の開口端13aは円環状に形成されている。

開口部12は、口枠13が設けられることによりその内周面12aに所定の奥行きを持ったものとして形成されていることになる。この開口部12の内周面12aは平滑面に形成されており、雌ねじや、その他、排水流を流す目的以外では不必要となるようなもの(例えば垂れ壁状のものなど)は、何ら設けられていない。

In the

The

開口部12の内径及び口枠13の内径は、管本体2の内部を点検したり清掃したりするうえで適するように所定の開口径(例えば75mm)に形成されている。

なお、口枠13が管本体2の管壁から突出する長さを、この管壁との干渉が無い状態で他の管材との接続が可能となる寸法(最も管壁に近い部分でも20mm程度)として形成しておけば、開口部12や口枠13の内径が所定の開口径に形成されていることとも相まって、この開口部12を他の管材との接続(要は流体の流通孔)に利用できるようになる。メカニカル式の管継ぎ手との接続をも可能にするため、口枠13が管本体2の管壁から突出する長さを更に大きく(例えば50mm程度)してもよい。

The inner diameter of the

It should be noted that the length by which the

開口部12を他の管材との接続に利用するうえでは、接続の方法をはじめ、接続しようとする管材の内外径などとの相対関係も考慮に入れる。例えば、口枠13と接続対象管材とを突き合わせてこれらをバンド等で外巻き状にして結合する接続方法では、口枠13の外径と接続対象管材との外径を合わせる。また口枠13を差し口で接続対象管材を受け口とする接続方法では口枠13の外径を接続対象管材(管継ぎ手部)の内径に合わせ、反対に口枠13を受け口で接続対象管材を差し口とする接続方法では口枠13の内径を接続対象管材の外径に合わせる。本実施形態では口枠13の外径を89mmとした。

When the

栓装置3は、管本体2に対しその開口部12を閉鎖すべく着脱自在となったものである。この栓装置3は、図1及び図4から明らかなように、蓋板16とその裏側でこれと重合状に保持されるようになった背圧負荷部材17とを有し、これらの間で止水部材18を挟持する構造になっている。また蓋板16と背圧負荷部材17との間に止栓手段19が設けられている。

蓋板16及び背圧負荷部材17はいずれも円板状に形成されている。蓋板16の方が背圧負荷部材17よりも径大に形成されている。蓋板16は、管本体2に設けられた開口部12の口枠13に対してその開口端13aの外径と略同径になっており、この開口端13aに当接させれば開口部12を閉鎖することが可能になっている。また背圧負荷部材17は、開口部12内に嵌る大きさに形成されている。

The

Both the

これら蓋板16及び背圧負荷部材17は、いずれも板金製(ステンレス板等)とされ、板面中央がすり鉢形に凹む形状にプレス加工されて板面強度が高められている。なお、樹脂などによる成形品としても可能である。蓋板16の方は、すり鉢形に凹んだ部分の外周側に平坦な鍔部16aが形成されるようにしてあり、この鍔部16aで上記開口端13aとの当接ができるようになっている。

そしてこれら蓋板16及び背圧負荷部材17は、互いにすり鉢形状に凹んだ部分同士が背合わせになるようにして重合されている。このことにより、蓋板16の外周部で形成される傾斜面16bと背圧負荷部材17の外周部で形成される傾斜面17bとが、互いに向き合ってV溝状の周溝を形成させるようになっている。

Both the

The

蓋板16の中心部には円形開口のネジ通孔20が形成され、背圧負荷部材17の中心部には正方形開口の回り止め孔21が形成されている。これらネジ通孔20や回り止め孔21は止栓手段19の装着用の孔として使用される。

止栓手段19は蓋体16に対して背圧負荷部材17を接離動作させるためのものであって、蓋板16の表側で露出する操作部25を有している。本第1実施形態ではネジ軸26とナット部材27とを有したものを示してある。

ネジ軸26は、ネジ頭26aに回り止め用の角軸26bを介して雄ねじ端部26cが突設されたもので、この雄ねじ端部26cを背圧負荷部材17におけるすり鉢形の内側から回り止め孔21へ差し込んで設けられる。

A

The stopper means 19 is for moving the back

The

栓装置本体の止水性を保持するために、ネジ頭26aと蓋板16との間に挟持された弾性体の止水手段28を有する。すなわち、角軸26bまわりには止水手段28が嵌められて、回り止め孔21とネジ頭26aとの間の防水性が高められている。この止水手段28にはゴムや樹脂などの弾性材をはじめ、その他、漏水を防止可能な適宜の材料を使用できる。このネジ軸26は蓋板16のネジ通孔20を貫通して、この蓋体16におけるすり鉢形の内側へと突出される。

このようなネジ頭26aと蓋板16との間に挟持された弾性体の止水手段28を設けることにより、止水手段28の操作部25を背圧負荷部材17が蓋板16に近接する方向に操作すると、前記止水手段28が背圧負荷部材17に密着し、栓装置本体の止水機能を合わせ持つことができる。

In order to maintain the water-stopping property of the stopper device main body, an elastic body water-stopping

By providing the elastic water stop means 28 sandwiched between the

ナット部材27は、蓋板16を貫通したネジ軸26の雄ねじ端部26cに螺合される。要するに、ネジ軸26の雄ねじ端部26cに対してナット部材27を緩めたり締め込んだりする操作で、蓋体16に対する背圧負荷部材17の接離動作が可能になるわけで、これによって操作部25が形成されていることになる。図例ではナット部材27として蝶ナットを用いてある。そのため、殊更工具を使わずとも手で操作が可能になる。この他、外周面にローレットを施した円盤形のナットや、汎用性の高い一般型の六角ナットをナット部材27として使用することも勿論可能である。

The

なお、雄ねじ端部26cにはワッシャ29が嵌められている。このワッシャ29にはナイロンなどの滑り性を良くした材料を用いておくと、ナット部材27を蓋体16側へ締め付けるときの回転を円滑にできるだけでなく、ナット部材27を緩めておいたときのガタツキでナット部材27が蓋体16と衝突したり擦れたりするのを防止できる利点がある。このワッシャ29には、硬質樹脂やステンレスなどの金属を用いたりすることもできる。

止水部材18は上記したように蓋板16と背圧負荷部材17との間に挟持されるが、本第1実施形態ではリング形に形成されたものとすることにより、蓋板16の外周部傾斜面16bと背圧負荷部材17の外周部傾斜面17bとの間で形成されるV溝状の周溝に嵌め付けられたものを示してある。そのため、この止水部材18の内周面側の断面形状も、蓋板16の外周部傾斜面16b及び背圧負荷部材17の外周部傾斜面17bに沿って面接触可能な傾斜面を有したものとして形成されている。

A

The

この止水部材18はゴムや樹脂等の弾性材によって形成されている。そのため、蓋板16に対して背圧負荷部材17を近接させ、止水部材18の肉厚方向を圧縮させると、この止水部材18は径方向の内外へ膨張するようになる。このときの止水部材18における径方向の膨張は、止水部材18の内周面が蓋板16の外周部傾斜面16b及び背圧負荷部材17の外周部傾斜面17bと面接触するようになっていることから、径方向外方へ押し広げられる方向、即ち、拡径方向に向けられる。

止水部材18の内周面は、上記のように蓋板16の外周部傾斜面16b及び背圧負荷部材17の外周部傾斜面17bと面接触した状態で強く押圧されるようになるので、これらの面接触間には、押圧時の潤滑性を高め、且つ止水部材18の拡径が周方向で均等に行われることを目的として、シリコングリースなどの潤滑剤を塗布しておくのが好適である。

The

Since the inner peripheral surface of the

止水部材18は、拡径前の状態では全周面を背圧負荷部材17の回りへ露出させる程度のものとなっている。そして拡径により、管本体2の開口部12に対し、その内径(口枠13の内径)以上となるように、その寸法や硬度などが設定されている。

なお、この止水部材18の寸法や硬度との関係を含め、止栓手段19全体として、蓋板16に背圧負荷部材17が到達する前に止水部材18の外周面が開口部12の内周面に水密当接するようになっている。すなわち、この水密当接の状態でも、蓋板16と背圧負荷部材17との間には隙間が残っている。そのため、止栓手段19を一杯一杯まで操作しても、止水部材18はまだその径大化に余力を残した状態になり、それだけ止水作用は高められるものである。

The water-

In addition, before the back

ここにおいて管本体2には、図8に示すように、口枠13の開口端寄りの内周面に対して突起13bを設けておくのが好適となる。この突起13bは、口枠13における内周面の周方向に沿って連続した円環状に形成されているものでも、その周方向一部に切欠が設けられたものでも、或いは周方向の複数箇所に等配状又は点在状に設けられたものでもよい。このような突起13bを設けておくことで、栓装置3における止水部材18の抜けだしを防止することができる。

なお、突起13bの突出高さは1mm程度としておけばよい。これより小さいと、止水部材18の抜けだしを防止する効果が乏しく、反対に突出高さが大きすぎると、栓装置3の着脱する際に、止水部材18が、拡径前の状態にあるとしても突起13bに干渉して出し入れし難くなるおそれがある。

Here, as shown in FIG. 8, the

Note that the protrusion height of the

ところで、管本体2の口枠13と、この栓装置3の蓋板16との相互間には回り止め手段30が設けられている。この回り止め手段30は、口枠13又は蓋板16の一方に凹部31が設けられ、同他方に凸部32が設けられて、これら凹部31と凸部32とが係合することで、蓋板16が、止栓手段19の操作部25の操作で連れ回りしないようにしたものである。本第1実施形態では、管本体2の口枠13に対し、開口端13aにおける円周上の対向位置に2個一組の凸部32が設けられ、栓装置3の蓋板16に対し、鍔部16aにおける円周上の対向位置に2個一組の凹部31が設けられたものを示してある。

By the way, an anti-rotation means 30 is provided between the

このような管本体2及び栓装置3を有して成る配管部材1では、背圧負荷部材17及び止水部材18を開口部12(口枠13)内へ嵌め入れるようにして、この開口部12の開口端13aへ蓋板16の鍔部16aを押し付ける。

そして止栓手段19の操作部25を操作する。具体的にはナット部材27を締め込み方向へ回転操作する。すると、背圧負荷部材17が蓋板16に近接するようになって止水部材18に対する挟持圧が高まる。これを受けて止水部材18は肉厚方向で圧縮され、結果、拡径することになり、止水部材18の外周面全周が開口部12の内周面12aに押し付けられる。そのため止水作用が生起し、開口部12が閉鎖される。

In the piping

Then, the

このような栓装置3を管本体2へ装着後、即ち、配管部材1とさせた後、この配管部材1内では、立主管5内を流下する排水を上部の入口用管接続部7から下部の出口用管接続部8へと通し、また横枝管6から流入する排水を中間の入口用管接続部10から下部の出口用接続管8へと通すといった具合に、日常の使用状態におく。

定期的又は配管部材1内で不具合が起こったときには、栓装置3において、止栓手段19の操作部25を上記と逆向きに操作する。すなわち、ナット部材27を緩め方向へ回転操作する。すると、背圧負荷部材17が蓋板16から離反するようになって止水部材18に対する挟持圧が弱められ又は解除される。これを受けて止水部材18は肉厚方向圧縮が解除され、結果、拡径状態が元に戻ることになり、止水部材18の外周面が開口部12の内周面12aから離反する。

After such a

When trouble occurs regularly or in the piping

そのため、開口部12から止水部材18及び背圧負荷部材17を引き出すことができ、結果、この栓装置3を開口部12から取り外すことができる。このようにして、開口部12から管本体2内を点検したり清掃したりすればよい。

なお管本体2において、口枠13の突出長さを他の管材との接続可能な寸法に形成してあるので、図7に示すようにこの開口部12(口枠13)に適宜継ぎ手40を用いて管材41を接続させるといった使い方もできる。

ところで、本発明は、上記した実施形態に限定されるものではなく、実施の形態に応じて適宜変更可能である。

Therefore, the

In the

By the way, the present invention is not limited to the above-described embodiment, and can be appropriately changed according to the embodiment.

例えば、管本体2の形態は限定されず、図9及び図10に示す第2実施形態のように中間の管接続部10が三方(三つ)のものや、図11及び図12に示す第3実施形態のように中間の管接続部10が無いものなどでもよい。勿論、この管本体2の材質は樹脂でも金属でもよい。

栓装置3において、止水部材18はリング形に限定されず、円盤形でもよい。止栓手段19の細部構造(操作部25等)は適宜変更可能である。

図13に示すように、蓋体16は必ずしも開口部12の開口端13aに当接するような大きさにしなくてもよく、開口部12に嵌る大きさとしてもよい。このようにすると、蓋体16と背圧負荷部材17とについて、部品の共通化ができることになり、コストダウンに繋がる。蓋体16や背圧負荷部材17はすり鉢形とせず、平板状にしてもよい。

For example, the form of the

In the

As shown in FIG. 13, the

1 配管部材

2 管本体

3 栓装置

7 管接続部

8 管接続部

12 開口部

12a 内周面

13 口枠

13a 開口端

13b 突起

16 蓋板

16b 傾斜面

17 背圧負荷部材

17b 傾斜面

18 止水部材

19 止栓手段

25 操作部

26 ネジ軸

27 ナット部材

30 回り止め手段

41 他の管材

DESCRIPTION OF

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004122148A JP2005307454A (en) | 2004-04-16 | 2004-04-16 | Plug device and piping member for drainage |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004122148A JP2005307454A (en) | 2004-04-16 | 2004-04-16 | Plug device and piping member for drainage |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2005307454A true JP2005307454A (en) | 2005-11-04 |

Family

ID=35436537

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004122148A Pending JP2005307454A (en) | 2004-04-16 | 2004-04-16 | Plug device and piping member for drainage |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2005307454A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009121186A (en) * | 2007-11-16 | 2009-06-04 | Noriatsu Kojima | Closing plug |

| DE102008022583A1 (en) * | 2008-05-07 | 2009-11-12 | Schulte & Todt Systemtechnik Gmbh & Co.Kg | Pipeline closing device for use in e.g. ceiling of room, has disk-shaped part fixed to another disk-shaped part by bolted connection such that parts are not moved or only insignificantly moved relative to each other in case of fire |

| DE102009043734A1 (en) * | 2009-10-01 | 2011-04-07 | Josef Zimmermann | tube plugs |

-

2004

- 2004-04-16 JP JP2004122148A patent/JP2005307454A/en active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009121186A (en) * | 2007-11-16 | 2009-06-04 | Noriatsu Kojima | Closing plug |

| DE102008022583A1 (en) * | 2008-05-07 | 2009-11-12 | Schulte & Todt Systemtechnik Gmbh & Co.Kg | Pipeline closing device for use in e.g. ceiling of room, has disk-shaped part fixed to another disk-shaped part by bolted connection such that parts are not moved or only insignificantly moved relative to each other in case of fire |

| DE102009043734A1 (en) * | 2009-10-01 | 2011-04-07 | Josef Zimmermann | tube plugs |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4506705A (en) | Pipe closure device | |

| JP6526144B2 (en) | Groove fitting adapter | |

| US20110272888A1 (en) | Slip joint with clamp | |

| JP2011220012A (en) | Attaching/detaching mechanism applied to coupling means of catch basin | |

| US8096590B2 (en) | Connecting structure for piping | |

| CA2990363A1 (en) | Faucet coupling structure | |

| KR20030069089A (en) | Quick-release fitting assembly | |

| KR100989052B1 (en) | Pipe connecting apparatus | |

| JP2002130554A (en) | Thin-wall pipe joint | |

| JP2005307454A (en) | Plug device and piping member for drainage | |

| US3749131A (en) | End plug assembly for pipe | |

| US20100170578A1 (en) | Separable faucet | |

| US20190056050A1 (en) | Connection arrangement for connecting a pipeline | |

| JP6317930B2 (en) | Fluid pipe end face anticorrosion device and fluid pipe end face anticorrosion treatment method | |

| KR200474408Y1 (en) | Jig for hydraulic test | |

| JP2001324069A (en) | Pipe connecting structure for valve system | |

| JP5007200B2 (en) | Test plug | |

| KR200376304Y1 (en) | Pipe closing device for pipe laying | |

| JP4512921B2 (en) | Ball valve | |

| JP2001280569A (en) | Snap tap | |

| US6116262A (en) | Plumbing coupling and method of use | |

| JP2004316789A (en) | Pressure resistant closing device | |

| KR200359206Y1 (en) | Pipe connector | |

| JP2007292534A (en) | Test plug | |

| JP2009133423A (en) | Leakage preventive device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070327 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090708 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090714 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20091110 |