JP2005125757A - Method for producing tube resin joint and tube resin joint produced by the method - Google Patents

Method for producing tube resin joint and tube resin joint produced by the method Download PDFInfo

- Publication number

- JP2005125757A JP2005125757A JP2004279385A JP2004279385A JP2005125757A JP 2005125757 A JP2005125757 A JP 2005125757A JP 2004279385 A JP2004279385 A JP 2004279385A JP 2004279385 A JP2004279385 A JP 2004279385A JP 2005125757 A JP2005125757 A JP 2005125757A

- Authority

- JP

- Japan

- Prior art keywords

- tube

- joint

- resin

- mold

- resin material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Branch Pipes, Bends, And The Like (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Abstract

Description

この発明は、チューブ樹脂継手の製造方法及びその製造方法により製造されたチューブ樹脂継手に係わり、更に詳しくは樹脂チューブの継手側端末部と樹脂製の継手部材との成形部の融着を均一に行ってシール性を向上させ、更にチューブ及び継手部の形状や肉厚の設計に自由度を持たせることを可能としたチューブ樹脂継手の製造方法及びその製造方法により製造されたチューブ樹脂継手に関するものである。 TECHNICAL FIELD The present invention relates to a tube resin joint manufacturing method and a tube resin joint manufactured by the manufacturing method, and more specifically, uniform bonding of a molded portion between a joint side end portion of a resin tube and a resin joint member. The present invention relates to a tube resin joint manufacturing method and a tube resin joint manufactured by the manufacturing method capable of improving sealing performance and allowing flexibility in designing the shape and thickness of the tube and the joint portion. It is.

従来、管継手の構造としては、例えば、継手本体と筒状体(チューブ等)との接続は、筒状体に挿通された押し込み筒体のネジ部と継手本体に形成されたネジ部とを螺嵌させた構造のものや、接続部にネジ部を締め付けのためのナット部が設けてある(例えば、特許文献1参照)。 Conventionally, as a structure of a pipe joint, for example, a connection between a joint body and a tubular body (tube or the like) includes a threaded portion of a push-in tubular body inserted through the tubular body and a threaded portion formed in the joint body. A screwed structure or a nut portion for tightening the screw portion at the connection portion is provided (for example, see Patent Document 1).

また、他の接続管の構造としては、フッ素系樹脂から成る管体とフッ素系樹脂から成る筒状の継手部材とを熱融着により一体的に形成したものが提案されている(例えば、特許文献2参照)。 As another connecting pipe structure, a structure in which a tubular body made of a fluorine-based resin and a cylindrical joint member made of a fluorine-based resin are integrally formed by heat fusion has been proposed (for example, a patent) Reference 2).

然しながら、前者の管継手の構造の場合、継手本体と筒状体との接続部におけるシール性が悪く、締め付けのためのナット部を設けたものは、継手全体が大型化し、コストアップとなる問題があった。従って、このような継手構造を使用した配管を含む装置全体は、漏れに関する信頼性が低く、大型化し、高コスト化する問題があった。 However, in the case of the former pipe joint structure, the sealing performance at the connection part between the joint body and the cylindrical body is poor, and the nut part for tightening has a problem that the whole joint becomes large and the cost increases. was there. Therefore, the entire apparatus including the pipe using such a joint structure has a problem of low reliability related to leakage, large size, and high cost.

また、後者の接続管の構造は、管体と筒状の継手部材とを溶融して融着させる必要があるが、管体と継手部材との接触部のみを溶融して融着させることが難しく、融着が不十分で管体内を流動する流体の漏れが発生すると言う問題があった。このため、このような継手を使用した配管を含む装置全体は、漏れに関する信頼性が低いと言う問題があった。

この発明はかかる従来の問題点に着目し、チューブの継手側端末部と樹脂製の継手部材との成形部の融着を均一に行ってシール性を向上させ、更に加熱チューブ及び継手部の形状や肉厚の設計に自由度を持たせることを可能とし、大量生産した場合、継手部材の成形と同時にチューブとの一体化が出来るため低コストに生産することが出来るチューブ樹脂継手の製造方法及びその製造方法により製造されたチューブ樹脂継手を提供することを目的とするものである。 This invention pays attention to such conventional problems, and improves the sealing performance by uniformly fusing the molded portion of the tube joint side end portion and the resin joint member, and further, the shape of the heating tube and the joint portion. The tube resin joint manufacturing method that can be manufactured at low cost because it can be integrated with the tube at the same time as the molding of the joint member when mass production is possible. An object of the present invention is to provide a tube resin joint manufactured by the manufacturing method.

この発明は上記目的を達成するため、この発明のチューブ樹脂継手の製造方法は、チューブ本体の継手側端末部に芯金を挿入し、このチューブ本体の継手側端末部近傍を分割金型内に配設して型締めした後、前記チューブ本体の継手側端末部及び芯金と分割金型との空間部に溶融した樹脂材料を射出成形し、樹脂材料が硬化した後、脱型させてチューブ本体と継手部材とを一体的に成形することを要旨とするものである。 In order to achieve the above object, the present invention provides a tube resin joint manufacturing method in which a metal core is inserted into a joint-side end portion of a tube body, and the vicinity of the joint-side end portion of the tube body is placed in a split mold. After disposing and clamping, the molten resin material is injection-molded into the joint-side end portion of the tube main body and the space between the core metal and the split mold, and after the resin material is cured, it is demolded and the tube The gist is to integrally form the main body and the joint member.

また、この発明の他のチューブ樹脂継手の製造方法は、チューブ本体の継手側端末部を予め拡管し、この状態でチューブ本体の拡管した継手側端末部から芯金を挿入し、このチューブ本体の継手側端末部近傍を分割金型内に配設して型締めした後、前記チューブ本体の継手側端末部の分割金型の内面と芯金との空間部に溶融した樹脂材料を射出成形し、チューブ本体に対して樹脂材料が硬化した後、脱型させてチューブ本体と継手部材とを一体的に成形することを要旨とするものである。 Further, another method of manufacturing the tube resin joint of the present invention is to expand the joint side end portion of the tube body in advance, and insert a cored bar from the joint side end portion of the tube body expanded in this state, After the vicinity of the joint-side end portion is placed in the split mold and clamped, the molten resin material is injection-molded in the space between the inner surface of the split mold and the core metal of the joint-side end portion of the tube body. Then, after the resin material is cured with respect to the tube main body, it is demolded to integrally form the tube main body and the joint member.

ここで、前記チューブ本体の継手側端末部の内面または外面、または内外面と樹脂製の継手部材とを一体的に成形するものである。 Here, the inner surface or outer surface of the joint-side end portion of the tube main body, or the inner and outer surfaces and the resin-made joint member are integrally formed.

更に、前記チューブ本体と継手部材とを、四フッ化エチレン−パーフルオロビニルエーテル共重合体(PFA)、四フッ化エチレン−六フッ化プロピレン共重合体(FEP)、四フッ化エチレン−エチレン共重合体(ETFE)、ポリビニリデンフルオライド(PVDF)等の熱可塑性のフッ素樹脂を使用する。 Further, the tube body and the joint member are made of tetrafluoroethylene-perfluorovinylether copolymer (PFA), tetrafluoroethylene-hexafluoropropylene copolymer (FEP), tetrafluoroethylene-ethylene copolymer. A thermoplastic fluororesin such as coalescence (ETFE) or polyvinylidene fluoride (PVDF) is used.

また、この発明のチューブ樹脂継手は、チューブ本体の継手側端末部に樹脂製の継手部材を射出成形により一体的に成形したことを要旨とするものである。 Further, the gist of the tube resin joint of the present invention is that a joint member made of resin is integrally formed by injection molding at the joint side end portion of the tube main body.

前記チューブ本体は、内面層及び外面層に樹脂材料を使用して複層構造にしたり、また樹脂製の内面層と外面層との間にガスバリア層を介在させて複層構造にすることも可能である。更に、前記チューブ本体と一体的に成形した継手部材は、相手機器と締結部材を介して固定するためのフランジ部を一体的に形成し、該フランジ部の相手機器との当接部にシール部材を設けるものである。 The tube body can be made into a multilayer structure by using a resin material for the inner surface layer and the outer surface layer, or a multilayer structure by interposing a gas barrier layer between the resin inner surface layer and the outer surface layer. It is. Further, the joint member formed integrally with the tube main body integrally forms a flange portion for fixing with the counterpart device via the fastening member, and a seal member is provided at the contact portion of the flange portion with the counterpart device. Is provided.

この発明は、上記のように構成することで、以下のような優れた効果を奏するものである。

(a).射出成形により一体的に成形されるので、成形時に適度な圧力を加えることが可能となり、融着部の温度が均一に出来るため、チューブ本体の継手側端末部と樹脂製の継手部材との成形部の融着を均一に行うことが出来、シール性を向上させることが出来る。

(b).射出成形により一体的に成形されるので、チューブ本体の継手側端末部と樹脂製の継手部材との接続部を外部から加熱する制約がなく、接続部の形状や、チューブの肉厚をコンパクトに、かつ自由に設計出来る。

(c).大量生産した場合、継手部材の成形と同時にチューブとの一体化が出来るため低コストに生産することが出来る。

The present invention has the following excellent effects by being configured as described above.

(a) Since it is molded integrally by injection molding, it is possible to apply appropriate pressure during molding, and the temperature of the fused part can be made uniform, so the joint side end of the tube body and the resin joint The molded part can be fused uniformly with the member, and the sealing performance can be improved.

(b) Since it is integrally molded by injection molding, there is no restriction to heat the connection part between the joint side end part of the tube body and the resin joint member from the outside, and the shape of the connection part and the thickness of the tube The thickness can be designed compactly and freely.

(c) When mass-produced, it can be produced at low cost because it can be integrated with the tube simultaneously with the formation of the joint member.

以下、添付図面に基づき、この発明の実施形態を説明する。 Embodiments of the present invention will be described below with reference to the accompanying drawings.

図1は、この発明の第1実施形態を示すチューブ樹脂継手の断面図を示し、1はチューブ本体、2はチューブ本体1の継手側端末部1aに射出成形により一体的に成形された継手部材を示している。

FIG. 1 is a cross-sectional view of a tube resin joint showing a first embodiment of the present invention. 1 is a tube body, 2 is a joint member integrally formed by injection molding on a joint-

前記チューブ本体1は、樹脂材料との溶融可能なゴム材料または樹脂材料により構成され、継手部材2は、接続部2aとネジ連結部2bとが樹脂材料により一体的に成形されている。この発明の実施形態としては、チューブ本体1と継手部材2とを、四フッ化エチレン−パーフルオロビニルエーテル共重合体(PFA)、四フッ化エチレン−六フッ化プロピレン共重合体(FEP)、四フッ化エチレン−エチレン共重合体(ETFE)、ポリビニリデンフルオライド(PVDF)等の熱可塑性のフッ素樹脂を使用する。

The

また、チューブ本体1は、一層構造に限定されず、内面層にフッ素樹脂、外面層にナイロン等の樹脂材料を使用して複層構造にしたり、または内面層と外面層との間にエチレンビニルアルコール共重合体(EVOH)等の樹脂材料から成るガスバリア層を介在させて複層構造にすることも可能である。

The

更に、前記チューブ本体1と継手部材2とを、同一樹脂材料または継手部材2の樹脂材料がチューブ本体1の樹脂材料より融点の高い材料を使用することが望ましい。

Furthermore, it is desirable that the

また、内面層をフッ素系樹脂とし外面層をナイロン等の汎用樹脂としたチューブを使用し、継手をフッ素樹脂で成形した場合に、この実施形態ではチューブの内面層と継手の樹脂材料が溶着するため、配管の内部に流れるチューブの外面層に接することが無くなり、腐食性流体を使用した際にもチューブの外面層を侵すことが無く、純水を流体とした際には外面層材からの不純物の溶出等が無い配管を得ることが出来る。 In addition, when a tube having an inner surface layer made of a fluorine-based resin and an outer surface layer made of a general-purpose resin such as nylon is used and the joint is formed of a fluororesin, the inner surface layer of the tube and the resin material of the joint are welded in this embodiment Therefore, it does not come into contact with the outer surface layer of the tube that flows inside the piping, and does not attack the outer surface layer of the tube even when a corrosive fluid is used. Piping without impurity elution can be obtained.

また、中間層にエチレンビニルアルコール共重合体(EVOH)等の耐水性の劣る材料を使用した場合に、この実施形態では、配管の内部に流れる流体が中間層に接することが無いため、水分を含む流体を流しても性能低下を無くすことが出来る。 In addition, when a material having poor water resistance such as ethylene vinyl alcohol copolymer (EVOH) is used for the intermediate layer, in this embodiment, since the fluid flowing inside the pipe does not contact the intermediate layer, Even if the fluid containing it is made to flow, performance degradation can be eliminated.

次に、チューブ樹脂継手の製造方法を、図2〜図7を参照しながら説明する。

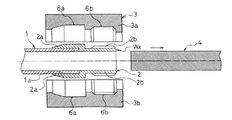

図2及び図3は、チューブ本体1と継手部材2とを一体的に成形する射出成形用の分割金型3と同一径の芯金4の側面図とA−A矢視断面図とを示し、前記分割金型3は、上型3aと下型3bとの二分割で構成され、分割面Sの一部には射出穴5が形成され、また上型3aと下型3bとの内面には、継手部材2の接続部2aとネジ連結部2bとを成形するための成形凹部6a,6bが形成されている。

Next, a method for manufacturing a tube resin joint will be described with reference to FIGS.

2 and 3 show a side view and a cross-sectional view taken along the line AA of the

この発明では、図4に示すように、先ずチューブ本体1の継手側端末部1aに同一径の芯金4を所定の長さ挿入し、このチューブ本体1の継手側端末部1aの近傍を分割金型3の上型3aと下型3bとの略中央部に配設して型締めする。

In this invention, as shown in FIG. 4, first, a

その後、図5に示すように前記チューブ本体1の継手側端末部1a及び芯金4と分割金型3との空間部X、即ち、継手部材2の接続部2aとネジ連結部2bとを成形するための成形凹部6a,6bに前記射出穴5から溶融した樹脂材料Wを射出し、樹脂材料Wが硬化した後、図6に示すように分割金型3を分割して状態で開放し、チューブ本体1と継手部材2とが一体化された製品Wxを分割金型3から脱型させる。そして、図7に示すように、チューブ本体1の継手側端末部1aから芯金4を引き抜き、成形作業を完了させる。

After that, as shown in FIG. 5, the joint-

なお、成形時にはチューブ本体1の継手側端末部1aに芯金4を所定の長さ挿入した状態で所定温度に加温された分割金型3内に一定時間保持しておくことで、チューブ本体1の温度を高くしておき、この状態で射出成形によって溶融した樹脂材料Wをチューブ本体1と接触させると同時に継手部材2を成形する。

At the time of molding, the tube

このようにチューブ樹脂継手を射出成形により一体的に成形するので、成形時に適度な圧力を加えることが可能となり、融着部の温度が均一に出来るため、チューブ本体1の継手側端末部1aと樹脂製の継手部材2の接続部2aとの成形部の融着を均一に行うことが出来、シール性を向上させることが出来る。またチューブ本体1の継手側端末部1aと樹脂製の継手部材2との接続部2aを外部から加熱する制約がなく、接続部2a及びネジ連結部2bの形状や、チューブ本体1の肉厚をコンパクトに、かつ自由に設計出来る。

Since the tube resin joint is integrally formed by injection molding in this way, it is possible to apply an appropriate pressure at the time of molding, and the temperature of the fused portion can be made uniform. It is possible to uniformly fuse the molded portion with the connecting

次に、図8〜図14は、この発明の第2実施形態を示し、この実施形態は、チューブ本体1の継手側端末部1aの内外面と継手部材2の接続部2aとを一体的に成形したものである。

Next, FIGS. 8-14 shows 2nd Embodiment of this invention, and this embodiment integrally connects the inner and outer surface of the joint

即ち、この実施形態では、芯金4として一部に小径部4aを形成したものを使用し、溶融した樹脂材料Wをチューブ本体1の継手側端末部1aの内面側と外面側とで覆うように一体的に成形するように構成したものである。

That is, in this embodiment, the

なお、以下の説明で第1実施形態と同一構成要素は、同一符号を付して製造方法について省略する。 In the following description, the same components as those in the first embodiment are denoted by the same reference numerals, and the manufacturing method is omitted.

この第2実施形態の製造方法としては、図9〜図11に示すように、チューブ本体1の継手側端末部1aに一部に小径部4aを形成した芯金4の一端を所定の長さ挿入し、このチューブ本体1の継手側端末部1aの近傍を分割金型3の上型3aと下型3bとの略中央部に配設して型締めする。

As a manufacturing method of the second embodiment, as shown in FIGS. 9 to 11, one end of a cored

その後、図12に示すように前記チューブ本体1の継手側端末部1a及び芯金4と分割金型3との空間部X、即ち、継手部材2の接続部2aとネジ連結部2bとを成形するための成形凹部6a,6bに前記射出穴5から溶融した樹脂材料Wを射出する。すると、溶融した樹脂材料Wは、芯金4の小径部4aによりチューブ本体1の継手側端末部1aの内面側と外面側とで覆うように流れ込み、更に分割金型3の空間部X全体に充填される。

After that, as shown in FIG. 12, the joint-

そして、樹脂材料Wが硬化した後は、図13に示すように分割金型3を分割して状態で開放し、チューブ本体1と継手部材2とが一体化された製品Wxを分割金型3から脱型させ、更に図14に示すように、チューブ本体1の継手側端末部1aから芯金4を引き抜き、成形作業を完了させる。

And after the resin material W hardens | cures, as shown in FIG. 13, the division | segmentation metal mold | die 3 is divided | segmented and it open | releases in the state, The product Wx with which the tube

なお、その他の構成及び作用は上記第1実施形態と同様なので同一符号を付して説明は省略する。 Since other configurations and operations are the same as those in the first embodiment, the same reference numerals are given and description thereof is omitted.

次に、図15〜図21は、この発明の第3実施形態を示し、この実施形態は、第2実施形態の変形例を示し、芯金4を段付きのないストレート状のものを使用することで、チューブ本体1の内面と継手部材2の接続部2aとの内面を面一にして一体的に成形したものである。

Next, FIG. 15 to FIG. 21 show a third embodiment of the present invention. This embodiment shows a modification of the second embodiment, and uses a straight cored

即ち、この実施形態では、芯金4としてストレート状のものを使用することで、射出成形後に芯金4を容易に抜くことが出来、またチューブ本体1の継手側端末部1aの内径を狭めることなく、流体の流れ抵抗を小さく出来る上、複層チューブにも対応させることが出来るようにしたものである。

That is, in this embodiment, by using a straight cored

なお、以下の説明で第2実施形態と同一構成要素は、同一符号を付して製造方法について省略する。 In the following description, the same constituent elements as those in the second embodiment are denoted by the same reference numerals, and the manufacturing method is omitted.

この第3実施形態の製造方法としては、図18に示すように、チューブ本体1の継手側端末部1aを予め拡管し、この状態でチューブ本体1の拡管した継手側端末部1aから芯金4の一端を所定の長さ挿入し、このチューブ本体1の継手側端末部1aの近傍を分割金型3の上型3aと下型3bとの略中央部に配設して型締めする。なお、分割金型3は温度調節装置を使用して所定温度に加熱しておくことが望ましく、また継手側端末部1aの拡管の寸法は、分割金型3を閉じた時に、拡管した部分の外径が分割金型3の内面に接触することが望ましい。

As shown in FIG. 18, in the manufacturing method of the third embodiment, the joint-

その後、図19に示すように前記チューブ本体1の継手側端末部1aの分割金型3の内面と芯金4との空間部X、即ち、継手部材2の接続部2aとネジ連結部2bとを成形するための成形凹部6a,6bに前記射出穴5から溶融した樹脂材料Wを射出する。すると、溶融した樹脂材料Wは、芯金4の表面に沿ってチューブ本体1の継手側端末部1aの内面側に流れ込み、予め温度調節装置により温度調節された分割金型3からの熱伝導により加熱されたチューブ本体1の継手側端末部1aの拡管した部分は、溶融した樹脂材料Wの温度によって更に加熱されると共に射出された樹脂材料Wの圧力により拡がって、分割金型3の上型3aと下型3bとの形態に沿った形態まで変形して圧着する。

Thereafter, as shown in FIG. 19, the space X between the inner surface of the

このような状態で樹脂材料Wは分割金型3の空間部X全体に充填され、内表面が溶融または溶融に近い状態となったチューブ本体1の内表面と射出された樹脂材料Wとが一体的に溶着するものである。

In such a state, the resin material W is filled in the entire space portion X of the

なお、第2実施形態のように、射出された樹脂材料Wがチューブ本体1の内面に薄く広がる場合は、射出された樹脂材料Wの容積が小さく、熱容量が小さいために、広がる過程で温度が下がり、チューブ本体1を十分に加熱できず溶着が十分に出来ない場合も考えられるが、この発明の実施形態ではチューブ本体1の継手側端末部1aを予め拡管するので、射出された樹脂材料Wは大量にチューブ本体1の内面に廻るので、熱容量があり溶着が十分に起こる。

In addition, when the injected resin material W spreads thinly on the inner surface of the

このようにして、充填された樹脂材料Wが硬化した後は、図20に示すようにチューブ本体1の継手側端末部1aから芯金4を引き抜き成形作業を完了させる。この場合、上述したように、芯金4としてストレート状のものを使用することで、射出成形後に芯金4を容易に抜くことが出来るものである。

Thus, after the filled resin material W is hardened, the cored

そして、図21に示すように分割金型3の上型3aと下型3bとを分割した状態で開放し、チューブ本体1と継手部材2とが一体化された製品Wxを分割金型3から脱型させて成形作業を完了させる。なお、その他の構成及び作用は上記第2実施形態と同様なので同一符号を付して説明は省略する。

Then, as shown in FIG. 21, the divided

なお、この発明の実施形態を複層チューブの内面に使用する樹脂材料と射出成形する樹脂材料を両方ともフッ素樹脂にする等、近い特性の樹脂を用いることにより、流体に接触する面の樹脂材料の特性を揃えることも可能である。 In addition, the resin material of the surface which contacts fluid by using resin of the near characteristic, such as making the resin material used for the inner surface of a multilayer tube, and the resin material to be injection-molded into fluororesin into the embodiment of this invention. It is also possible to have the same characteristics.

また、分割金型3を予め加熱しているので、樹脂材料Wの射出成形後に早期に硬化しない場合も考えられるが、この場合には樹脂材料Wをチューブ本体1の樹脂材料よりも融点の高い材料を使用することにより、チューブ本体1の内表面の溶融または溶融に近い状態まで加熱しながら、射出樹脂材料が速やかに硬化するので成形速度を速くすることが出来るものである。

In addition, since the divided

上記のような第3実施形態によれば、芯金4としてストレート状のものを使用することで、射出成形後に芯金4を容易に抜くことが出来、またチューブ本体1の継手側端末部1aの内径を狭めることなく、流体の流れ抵抗を小さく出来る上、複層チューブにも対応させることが出来る。またチューブ本体1の継手側端末部1aを予め拡管してあるので、十分な容積の樹脂材料Wをチューブ本体1の内面に廻すことが出来、溶着を安定して行うことが出来る。また、多層チューブを使用した場合は、特に内面をフッ素樹脂のみで構成することが出来るので、流体に対する特性を揃えることも可能である。

According to the third embodiment as described above, by using a straight cored

次に、図22〜図28は、この発明の第4実施形態を示し、この実施形態は、図22及び図23に示すように、継手部材2の一端に図示しない相手機器と固定するためのフランジ部2cを一体的に形成し、このフランジ部2cの側面には、ボルト等の締結部材を挿通するための貫通穴7a,7bを形成し、更にフランジ部2cの相手機器との当接部8には、Oリング等のシール部材9が設けてある。

Next, FIGS. 22 to 28 show a fourth embodiment of the present invention. This embodiment is for fixing a mating device (not shown) to one end of the

また、この実施形態のチューブ樹脂継手を成形する金型10は、互いに係合可能な上下に二分割された第一金型10aと第2金型10bとで構成され、分割面Sの一部には射出穴5が形成され、また二分割された第一金型10aの内部には、チューブ本体1の継手側端末部1aを挿通するための貫通穴11aと、前記フランジ部2cを成形するための凹部11bとが形成され、また第2金型10bの内面には、チューブ本体1の継手側端末部1aに嵌合する芯金12が中心部に形成され、またその周囲には、前記貫通穴7a,7bを形成するための突起13a,13bが一体的形成されている。更に第2金型10bの内面には、前記シール部材9を嵌合させるための凹部13を形成するための突起14が形成されている。

The

この第4実施形態の製造方法としては、図25〜図28に示すように、先ずチューブ本体1の継手側端末部1aを二分割された第一金型10aの貫通穴11aから挿通すると共に、チューブ本体1の継手側端末部1aに第2金型10bの内面に形成した芯金12を所定の長さ挿入して図26に示すように第一金型10aと第2金型10bとを型締めする。

As a manufacturing method of this fourth embodiment, as shown in FIGS. 25 to 28, first, the joint

その後、図27に示すように前記チューブ本体1の継手側端末部1a及び芯金12と金型10との空間部Xに前記射出穴5から溶融した樹脂材料Wを射出する。すると、溶融した樹脂材料Wは図27に示すように、空間部Xの全体に充填される。

Thereafter, as shown in FIG. 27, the molten resin material W is injected from the

そして、樹脂材料Wが硬化した後は、図28に示すように二分割された第一金型10aと第2金型10bとをそれぞれ分割した状態で開放すると共に、チューブ本体1の継手側端末部1aから芯金12を引き抜き、チューブ本体1とフランジ部2cを備えた継手部材2とが一体化された製品Wxを分割金型3から脱型させ成形作業を完了させる。

Then, after the resin material W is cured, as shown in FIG. 28, the

なお、その他の構成及び作用は上記第1実施形態と同様なので同一符号を付して説明は省略する。 Since other configurations and operations are the same as those in the first embodiment, the same reference numerals are given and description thereof is omitted.

1 チューブ本体 1a 継手側端末部

2 継手部材 2a 接続部

2b ネジ連結部 2c フランジ部

3 分割金型 3a 上型

3b 下型 4 芯金

4a 小径部

5 射出穴 6a,6b 成形凹部

7a,7b 貫通穴 8 当接部

9 シール部材

10 金型 10a 第一金型

10b 第2金型 11a 貫通穴

11b 凹部 12 芯金

13a,13b 突起 13 凹部

14 突起 S 分割面 X 空間部 W 樹脂材料

Wx 製品

DESCRIPTION OF

Claims (8)

The joint member formed integrally with the tube main body integrally forms a flange portion for fixing with a counterpart device via a fastening member, and a seal member is provided at a contact portion of the flange portion with the counterpart device. The tube resin joint according to claim 5, 6 or 7.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004279385A JP4424137B2 (en) | 2003-10-01 | 2004-09-27 | Manufacturing method of tube resin joint |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003343326 | 2003-10-01 | ||

| JP2004279385A JP4424137B2 (en) | 2003-10-01 | 2004-09-27 | Manufacturing method of tube resin joint |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005125757A true JP2005125757A (en) | 2005-05-19 |

| JP4424137B2 JP4424137B2 (en) | 2010-03-03 |

Family

ID=34655781

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004279385A Expired - Fee Related JP4424137B2 (en) | 2003-10-01 | 2004-09-27 | Manufacturing method of tube resin joint |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4424137B2 (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100633009B1 (en) | 2005-08-11 | 2006-10-12 | 최해권 | Manufacturing method of drainpipe joint and drainpipe joint manufactued by the same |

| WO2011010837A2 (en) * | 2009-07-22 | 2011-01-27 | Kim Jeong Hwa | Blade socket for an air conditioner built into the ceiling, and method for manufacturing same |

| JP2012002348A (en) * | 2010-05-18 | 2012-01-05 | Sekisui Chem Co Ltd | Piping material and method of manufacturing the same |

| KR101103467B1 (en) | 2009-07-22 | 2012-01-09 | 김정화 | The wings socket which is used at the system air conditioner making method besides |

| KR101196699B1 (en) * | 2010-05-28 | 2012-11-07 | 김정화 | System airconditioner wing socket and its product method |

| JP2013152004A (en) * | 2012-01-26 | 2013-08-08 | Sekisui Chem Co Ltd | Piping material and method of manufacturing the same |

| JP2017106575A (en) * | 2015-12-10 | 2017-06-15 | 淀川ヒューテック株式会社 | Tube with joint |

| CN107297857A (en) * | 2017-08-11 | 2017-10-27 | 西安奥若特材料技术有限公司 | A kind of thermoplastic material pipe connection method |

| JP2018096482A (en) * | 2016-12-14 | 2018-06-21 | 株式会社イノアック住環境 | Pipe and manufacturing method thereof |

| JP7492728B2 (en) | 2020-04-23 | 2024-05-30 | 株式会社ニチリン | Method for molding accessories onto rubber or plastic hoses |

-

2004

- 2004-09-27 JP JP2004279385A patent/JP4424137B2/en not_active Expired - Fee Related

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100633009B1 (en) | 2005-08-11 | 2006-10-12 | 최해권 | Manufacturing method of drainpipe joint and drainpipe joint manufactued by the same |

| WO2011010837A2 (en) * | 2009-07-22 | 2011-01-27 | Kim Jeong Hwa | Blade socket for an air conditioner built into the ceiling, and method for manufacturing same |

| WO2011010837A3 (en) * | 2009-07-22 | 2011-08-25 | Kim Jeong Hwa | Blade socket for an air conditioner built into the ceiling, and method for manufacturing same |

| KR101103467B1 (en) | 2009-07-22 | 2012-01-09 | 김정화 | The wings socket which is used at the system air conditioner making method besides |

| JP2012002348A (en) * | 2010-05-18 | 2012-01-05 | Sekisui Chem Co Ltd | Piping material and method of manufacturing the same |

| KR101196699B1 (en) * | 2010-05-28 | 2012-11-07 | 김정화 | System airconditioner wing socket and its product method |

| JP2013152004A (en) * | 2012-01-26 | 2013-08-08 | Sekisui Chem Co Ltd | Piping material and method of manufacturing the same |

| CN106870831A (en) * | 2015-12-10 | 2017-06-20 | 淀川惠德株式会社 | The pipe of belt lacing |

| JP2017106575A (en) * | 2015-12-10 | 2017-06-15 | 淀川ヒューテック株式会社 | Tube with joint |

| KR20170069157A (en) * | 2015-12-10 | 2017-06-20 | 요도가와 휴텍 가부시키가이샤 | Tube with coupling |

| US10094497B2 (en) | 2015-12-10 | 2018-10-09 | Yodogawa Hu-Tech Co., Ltd. | Tube with coupling |

| TWI709708B (en) * | 2015-12-10 | 2020-11-11 | 日商淀川惠德股份有限公司 | Tube with coupling |

| KR102631753B1 (en) * | 2015-12-10 | 2024-01-31 | 요도가와 휴텍 가부시키가이샤 | Tube with coupling |

| JP2018096482A (en) * | 2016-12-14 | 2018-06-21 | 株式会社イノアック住環境 | Pipe and manufacturing method thereof |

| CN107297857A (en) * | 2017-08-11 | 2017-10-27 | 西安奥若特材料技术有限公司 | A kind of thermoplastic material pipe connection method |

| JP7492728B2 (en) | 2020-04-23 | 2024-05-30 | 株式会社ニチリン | Method for molding accessories onto rubber or plastic hoses |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4424137B2 (en) | 2010-03-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4508368A (en) | Plastic pipe joint | |

| US8966757B2 (en) | Plastic heat exchanger and method of manufacturing the same | |

| JP4424137B2 (en) | Manufacturing method of tube resin joint | |

| JP2008155587A (en) | Manufacturing method of hollow resin molded product | |

| JP2002240096A (en) | Method for manufacturing pipe joint made of resin | |

| FI112337B (en) | A method of making a plastic tube | |

| JP7147514B2 (en) | Method for manufacturing resin pipe | |

| AU683986B2 (en) | Method of fabricating a tank and method of fabricating a tank connector therefore | |

| JP3327442B2 (en) | Manufacturing method of fuel filler pipe | |

| JP2003194273A (en) | Flexible hose coupling pipe provided with connecting fitting | |

| JPH0885154A (en) | Electric fusion bonded joint, manufacture thereof and injection mold thereof | |

| JP2002160292A (en) | Connecting terminal of plastic tube and its manufacturing method | |

| JPH06123393A (en) | Manufacture of electric fusing joint | |

| JP4011763B2 (en) | Hose flange forming method | |

| JPH07132555A (en) | Preparation of resin lining steel pipe with flange | |

| KR100546995B1 (en) | The plastics pipe which has the Connection tool | |

| JPH09277313A (en) | Mold for tubular molded article and molding method thereof | |

| JP2004181702A (en) | Method for multi-layer injection molding | |

| JPS62151689A (en) | Manufacture of pipe joint made of resin | |

| JP2000015700A (en) | Manufacture of fluororesin tube | |

| JPH09170685A (en) | Tube joint and its forming method | |

| JPH09187840A (en) | Manufacture of flanged resin lining steel pipe | |

| JPH06286013A (en) | Production of resin lining flanged steel pipe | |

| JPH0780933A (en) | Production of flanged resin lining steel pipe | |

| JP2005113988A (en) | Bent hose |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070607 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090731 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090818 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091014 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091117 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20091130 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121218 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121218 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121218 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |