JP2004206987A - Connector - Google Patents

Connector Download PDFInfo

- Publication number

- JP2004206987A JP2004206987A JP2002373404A JP2002373404A JP2004206987A JP 2004206987 A JP2004206987 A JP 2004206987A JP 2002373404 A JP2002373404 A JP 2002373404A JP 2002373404 A JP2002373404 A JP 2002373404A JP 2004206987 A JP2004206987 A JP 2004206987A

- Authority

- JP

- Japan

- Prior art keywords

- contact

- fpc

- contacts

- housing

- slider

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

Abstract

Description

【0001】

【発明の属する技術分野】

本発明は、携帯電話やノートパソコンやデジタルカメラ等に使用されるコネクタに関するもので、特にフレキシブルプリント基板(以下「FPC」という)の表裏両面に接触部がある場合にコネクタの狭小化を図ったものである。

【0002】

【従来の技術】

携帯電話やCCDカメラ等に使用されるコネクタは、狭ピッチで極薄(所謂軽薄短小)であり、主にハウジングとコンタクトとを備え、ハウジングにFPCを挿入し、コンタクトの接触部に接触させう構造のものや主にハウジングとコンタクトとスライダーとを備え、ハウジングとスライダーとでFPCを挟持する構造である。ハウジングとスライダーとでFPCを保持する方法には、色々考えられるが、中でもハウジングにFPCを挿入した後にスライダーを挿入しFPCをコンタクトに押しつける構造のものが多い。また、客先の仕様や狭ピッチを図るためには、前記コンタクトの接続部を前記ハウジングの嵌合口側に配置しなければならないこともある。

ハウジングには、コンタクトが挿入される所要数の挿入孔が設けられるとともにFPCが挿入される嵌合口が設けられている。

コンタクトは主にFPCと接触する接触部と基板等に接続する接続部とハウジングに固定される固定部とから構成されている。このコンタクトは、圧入等によってハウジングに固定されている。

【0003】

【特許文献1】

例えば、ゼロインサーションフォース構造としては、実開平6−60983号がある。実開平6−60983号の要約によると、その目的は、電子機器や通信機器内の狭いスペースに使用されるスライダー付プリント基板用コネクタに関するものであり、その構成は、コネクタのスライダーの両側端部にそのスライダーが挿入されるハウジングへの挿入ガイドとして手前側が固定されたU字形状のアーム部を形成し、そのU字形状のアーム部の開放端側に凸部を設けるとともに、U字形状のアーム部の開放端が挿入方向から目視できるように切欠部を設け、ハウジングの両側端部にはスライダーの凸部が係合する傾斜面を有する突出部を設け、スライダーをフレキシブル・プリント基板の接続端子部とともにハウジングに挿入されるとき、当該スライダーの凸部がハウジングの傾斜面を有する突出部を乗り越えることにより、そのU字形状のアーム部の開放端が一時的に外側に広げられ、かつ挿入完了時にその開放端が正常位置に復帰するようにしたコネクタが開示されている。

【0004】

【特許文献2】

所謂、ピアノタッチ構造としては、特開平13−257020号に、コネクタのコンタクトとFPC叉はFFCのパターンとの位置合わせを確実に行うことを目的とし、FPC叉はFFCが挿入される開口側の、コネクタの端子ブロックの各コンタクト間の稜線上に突起を列設して、端子ブロックにFPC叉はFFCを挿入した後に、スライダを移動させることによってFPC叉はFFCを前記コンタクトに押圧させ、前記スライダでFPC叉はFFCをコンタクトに押しつけ電気接続させる際に、この突起がFPC叉はFFCのパターン間の凹部に入ることにより、コネクタのコンタクトとFPC叉はFFCのパターンとの位置合わせを確実に行うものが開示されている。

【0005】

【特許文献3】

特開平5−326084号の要約によると、回路基板用コネクタに関し、端片に沿う信号入出力用端子の隣接間ピッチや該端子自体が特に狭小化した回路基板でも位置ずれ等を発生させることなく確実に接続させて生産性の向上を図ることを目的とし、文献3には回路基板端辺に数列して形成されている複数の信号入出力用端子と個々に接続するジャック端子が該各信号入出力用端子と対応する位置に植設されている絶縁体の該ジャック端子コンタクト側開口に回路基板をその信号入出力用端子形成辺側から挿入した後、該回路基板をジャック端子のコンタクト側に押圧移動させて対応するコンタクトと信号入出力用端子とを接続させる回路基板用コネクタであって、絶縁体の回路基板が挿入される領域に、所定位置まで挿入したときの回路基板を少なくともその信号入出力用端子形成領域の幅方向側辺で位置決めし得る手段を具えて構成するものが開示されている。

【0006】

【発明が解決しようとする課題】

近年、この種のコネクタでは、電気機器(電子機器)の小型化に伴い、より一層の小型化の要求が強くなり、かつ、狭ピッチ化の要求が強くなると同時に信号密度を高めるためにFPCの両面に接触部を設けることが必要になってきた。

しかしながら、上述した構造のコネクタでは、両面に接触部があるFPCに対応することができなく、狭ピッチ化にも対応することが出来ないといった課題があった。

即ち、文献1のようなZIFタイプのものでは、前記FPCを前記ハウジングに挿入後、前記スライダーにより前記FPCを一方に押しつけて、前記コンタクトに接触させる構造であり、接触部が表裏両面にあるFPCには対応出来ない(一方側の面にしか押しつけられない。)。また、文献2のような前記ハウジングの前記FPC挿入側で前記スライダーを回転させる所謂ピアノタッチタイプでも、ZIFタイプ同様に、前記スライダーにより前記FPCを一方に押しつけて、前記コンタクトに接触させる構造であり、接触部が表裏両面にあるFPCには対応出来ない(一方側の面にしか押しつけられない。)。

【0007】

本発明は、このような従来の問題点に鑑みてなされたもので、ピッチの狭小化に対応でき、接触部が両面にあるFPCにも対応可能なコネクタを提供せんとするものである。

【0008】

【課題を解決するための手段】

上記目的は、FPCと着脱自在に嵌合するコネクタであって、該FPCと接触する接触部を有する所要数のコンタクトと、このコンタクトが保持・固定されるとともに前記FPCが挿入される嵌合口を有するハウジングとを備えるコネクタにおいて、前記FPCの表裏両面に接触部がある時に、2種類のコンタクト用い、一方のコンタクトを前記ハウジングの嵌合口の反対側から挿入するととも該コンタクトの接触部が前記FPCの表面の接触部に接触し、もう一方のコンタクトを前記ハウジングの嵌合口側より挿入するとともに該コンタクトの接触部が前記FPCの裏面の接触部に接触するようにするにより達成できる。

【0009】

2種類のコンタクトを1対とし、1対のコンタクトの接触部を対向するように配置し、前記FPCを1対のコンタクトで挟み込むようにする。このように1対のコンタクトの接触部で前記FPCを挟み込むことで、上側の前記コンタクトの接触部が前記FPCの表面側の接触部に接触し、下側の前記コンタクトの接触部が前記FPCの裏面側の接触部に接触する。

1対のコンタクトの接触部が長手方向で千鳥になるように配置する。このように千鳥に配置することで、より狭小ピッチ化が可能になる。

前記ハウジングには前記嵌合口側に前記フレキシブルプリント基板を誘う凹部を設け、もう一方の前記コンタクトの接続部を前記ハウジングの凹部内から突出しないように配置する。このようにすることで、容易に前記FPCを前記ハウジングの嵌合口内に導くことができる。

【0010】

前記フレキシブルプリント基板を前記ハウジングの嵌合口へ挿入する際に力の掛からないゼロ インサーション フォース(ZIF)構造にするために、前記フレキシブルプリント基板を挿入してから前記コンタクトに押しつけるスライダーを用いる。このようにZIF構造にすることで、容易にFPCを前記ハウジングの嵌合口内に挿入することができ、確実にFPCの表裏両面の接触部に接続することができる。

一方のコンタクトには接触部と接続部との間に弾性部と支点部とを設けるとともに前記接触部と前記弾性部と前記支点部と前記接続部とを略クランク形状に配置し、かつ、前記接続部と対向する位置に前記弾性部から延設された押受部を設け、もう一方のコンタクトは接触部と接続部とを有するとともに該接続部が前記ハウジングの凹部内に入るように配置し、前記スライダーに長手方向に連設した押圧部を設け、該押圧部が一方のコンタクトの接続部と押受部との間で前記押圧部が回動自在に回動するように前記スライダーを前記ハウジングに装着する。このように前記ハウジングの嵌合口側と反対側で前記スライダーを回動することにより、前記FPCに前記コンタクトを押しつけているため、表裏両面に接触部があるFPCにも対応することができ、確実に接触することができる。

【0011】

【作用】

前記FPCが前記ハウジングの嵌合口内に挿入された後に、前記スライダーの押圧部が一方の前記コンタクトの接続部と押受部との間で回動すると、前記押受部が押圧部によって押し上げられることで一方の前記コンタクトの支点部を支点にし、一方の前記コンタクトの弾性部が前記接触部側に傾くことによって、一方の前記コンタクトの前記接触部が前記FPCの表面側に押圧され、前記FPCの裏面側にもう一方の前記コンタクトが押圧されることになる。

【0012】

【発明の実施の形態】

本発明の重要な特徴は、「前記FPCの表裏両面に接触部がある時に、2種類のコンタクト用い、一方のコンタクトを前記ハウジングの嵌合口の反対側から挿入するととも該コンタクトの接触部が前記FPCの表面の接触部に接触し、もう一方のコンタクトを前記ハウジングの嵌合口側より挿入するとともに該コンタクトの接触部が前記FPCの裏面の接触部に接触するようにする」点にある。この特徴を活かした形態には、2つタイプがある。2つのタイプとも、FPCをコンタクトに接触させる構造である点では同じであるが、FPCをコンタクトに接触させる仕方に相違がある。

第一の構造のコネクタは、主にハウジングとコンタクトとスライダーとを備えており、前記スライダーが回動してFPCをコンタクトに押しつけるタイプのものであり、所謂ピアノタッチ方式と称するタイプのコネクタである。前記スライダーを回動させる位置としては、コンタクト接続側(テール側)である。以下の実施例では、このタイプのものを詳細に説明する。

【0013】

第二の構造のコネクタは、主にハウジングとコンタクトとを備えており、前記FPCを前記ハウジングの嵌合口へ挿入して、前記FPCを前記コンタクトに接触させる(押しつける)タイプのものであり、スライダーを使用しない所謂NON ZIFタイプのコネクタと称されるものである。即ち、前記FPCの厚さより狭い、前記コンタクト接触部間や前記コンタクトと前記ハウジングとの間に、前記FPCを無理に挿入して、前記コンタクトに接触させる(押しつける)ものである。

上述した2つの構造とも、2種類のコンタクト用い、一方のコンタクトの接触部が前記FPCの表面の接触部に接触し、もう一方のコンタクトの接触部が前記FPCの裏面の接触部に接触するようにしたことは言うまでもない。

【0014】

【実施例】

図1から図 に基づいて、本発明のコネクタの一実施例について説明する。図1(A)はスライダーが開いた状態の嵌合口側からみた本発明のコネクタの斜視図であり、(B)はFPCが挿入され、スライダーが閉じた状態の嵌合口側からみた本発明のコネクタの斜視図である。図2(A)はスライダーが開いた状態のあるコンタクト部分で切断した本発明のコネクタの斜視図であり、(B)はFPCが挿入されスライダーが閉じた状態のあるコンタクト部分で切断した本発明のコネクタの斜視図である。図3(A)はFPCの接触部が千鳥に配列された場合のスライダーが開いた状態の図2(A)とは別のあるコンタクト部分で切断した本発明のコネクタの斜視図であり、(B)はFPCの接触部が千鳥に配列された場合のFPCが挿入されスライダーが閉じた状態の図2(B)とは別のあるコンタクト部分で切断した本発明のコネクタの斜視図である。図4(A)は一方のコンタクトの斜視図であり、(B)はもう一方のコンタクトの斜視図である。図5は2種類のコンタクトがFPCに接触した状態の斜視図である。図6は部分的なFPCの斜視図であり、図7はスライダーの斜視図である。

一実施例の本発明のコネクタ10は、主にハウジング12とスライダー18とコンタクト14、16とを備えている。該コネクタ10は、2種類のコンタクト14、16をハウジング12への挿入方向を変えて配列しており、挿入方向を変えて配列することによってFPCの表裏両面にある接触部に対応するようにしたものである。また、場合によっては、前記FPCの表裏両面にある接触部が千鳥に配列されている際には、2種類のコンタクト14、16の接触部の位置を変えたものを使用し、接触部が相違する各コンタクトを千鳥に配置している。

【0015】

構成部品を説明する前に、FPC22について説明する。前記FPC22には、主にコンタクト14、16の接触部30と接触する接触部52と該接触部52から回路へ繋がるパターンとを備えている。図6のように、本実施例では前記FPC22の接触部52は表裏両面に配置されている。

【0016】

まず、ハウジング12について説明する。このハウジング12は電気絶縁性のプラスチックであり、公知技術の射出成形によって製作され、この材質としては寸法安定性や加工性やコスト等を考慮して適宜選択するが、一般的にはポリブチレンテレフタレート(PBT)やポリアミド(66PA、46PA)や液晶ポリマー(LCP)やポリカーボネート(PC)やこれらの合成材料を挙げることができる。

【0017】

前記ハウジング12には、所要数のコンタクト14、16が装着される挿入溝28が設けられており、圧入や引っ掛け(ランス)や溶着等によって固定されている。また、前記ハウジング12には前記FPC22が挿入される嵌合口24が設けられ、前記嵌合口24側に前記FPC22を誘う凹部26が設けられている。該凹部26の大きさは、前記ハウジング12の強度や前記コンタクト16の接続性(半田付け性)や前記FPC22の誘い易さを考慮し、前記コンタクト16の接続部34が前記ハウジング12の凹部26内から突出しないように適宜設計されている。前記嵌合口24の大きさは前記FPC22が挿入でき、前記FPC22が挿入された際に前記スライダー18で前記コンタクト14、16に押圧できるように適宜設計されている。前記ハウジング12の長手方向両側には、前記スライダー18の軸46が回動可能に装着される軸受部が設けられている。この軸受部の形状や大きさは、スライダー18の軸46が回動できるように装着されていれば如何なるものでもよく、この役割やハウジング12の強度や大きさ等を考慮して適宜設計する。さらにまた、長手方向両側には、前記スライダー18のロック部に対応した位置に係止部が設けられている。

【0018】

次に、本発明のポイント部分である2種類のコンタクト14、16について説明する。この2種類のコンタクト14、16は金属製であり、公知技術のプレス加工によって製作されている。前記コンタクト14、16の材質としては、バネ性や導電性などが要求されるので、黄銅やベリリウム銅やリン青銅等を挙げることができる。

【0019】

一方の前記コンタクト14は、図4(A)のように倒略h形状をしており、主にFPC22と接触する接触部30と基板に接続する接続部34とハウジング12に固定する固定部36と前記接触部30と前記接続部36との間に設けられた弾性部40及び支点部38と前記接続部36と対向する位置に前記弾性部40から延設された押受部32とを備えている。前記接触部30と前記弾性部40と前記支点部38と前記接続部34とは、略クランク形状に配置されている。前記接触部30は、FPC22と接触し易いように凸部形状にしており、前記接続部34は本実施例では図1のように表面実装タイプ(SMT)にしているが、ディップタイプでも良い。即ち、一方の前記コンタクト14の接触部30は、前記FPC22の表面側の接触部52に接触することになる。

【0020】

前記支点部38と前記弾性部40と前記押受部32とは、前記FPC22が挿入された際に、次のような作用を果たすための部分である。前記FPC22が前記ハウジング12の嵌合口24内に挿入された後に、前記スライダー18の押圧部50が前記コンタクト14の接続部34と押受部32との間で回動すると、前記押受部32が押圧部50によって押し上げられることで前記コンタクト14の支点部38を支点にし、前記コンタクト14の弾性部40が前記接触部30側に傾くことによって、前記接触部30が前記FPC22側に押圧される。前記支点部38と前記弾性部40と前記押受部32の大きさや形状は、このような作用を果たすために、適宜設計されている。また、前記コンタクト14の押受部32の先端に突出部44を設け、スライダー18の押圧部50をコンタクト14の押受部32と接続部34との間で回動させるとき、前記スライダー18の係止孔48に係合させることで、スライダー18の回動に対する強い反発力に対抗し、スライダー18の中央部が図1(A)の矢印「ロ」方向に膨れてしまうことを防ぐようにすることが望ましい。前記突出部44の大きさは、このような役割を果たすことが出来れば如何なる大きさでもよく、スライダー18の係止孔48が引っ掛かる程度に適宜設計する。

【0021】

もう一方のコンタクト16について説明する。もう一方の前記コンタクト16は図4(B)のように倒略I字形状をしており、主にFPC22と接触する接触部20と基板に接続する接続部34とハウジング12に固定する固定部36とを備え、前記接触部20と前記一方のコンタクト14の接触部30とで、前記FPC22を挟持するようにしている。即ち、前記もう一方のコンタクト16の接触部20は、前記FPC22の裏面の接触部52に接触することになる。このように前記一方のコンタクト14と前記もう一方のコンタクト16を配置することにより、前記FPC22の挿入方向に対して、前記FPC22の表裏両面に接触部30、20が配置されることで、前記FPC22を2つの接触部30、20で挟持することになり、確実に前記FPC22の表裏両面の接触部52、52と接触できるようになる。前記接続部34は、一方のコンタクト14と同様に表面実装タイプ(SMT)にしているが、ディップタイプでも良い。

【0022】

上述のように、前記一方のコンタクト14の接触部30は前記FPC22の表面側の接触部52と接触し、前記もう一方のコンタクト16の接触部20は前記FPC22の裏面側の接触部52と接触することになり、2種類のコンタクト14、16を1対とし、1対のコンタクト14、16の接触部30、20を対向するように配置し、前記FPC22を1対のコンタクト14、16で挟み込むようしたもので

あり、2種類の前記コンタクト14、16の接触部30、20は前記FPC22の接触部52、52に対応するように適宜設計される。図6のように前記FPC22の表裏両面に設けられた接触部52、52が長手方向で千鳥に配置されている場合には、図4に示した2種類のコンタクト14、16とは別に接触部30、20の位置を変えたものを用意し、図5のように接触させている。すなわち、接触部30、20の位置を変えるとは、前記一方のコンタクト14においては弾性部40から接触部30までの長さを変えることであり、前記もう一方のコンタクト16においては固定部36から接触部20までの長さを変えることである。

【0023】

最後に、スライダー18について説明する。このスライダー18は電気絶縁性のプラスチックであり、公知技術の射出成形によって製作され、この材質としては寸法安定性や加工性やコスト等を考慮して適宜選択するが、一般的にはポリブチレンテレフタレート(PBT)やポリアミド(66PA、46PA)や液晶ポリマー(LCP)やポリカーボネート(PC)やこれらの合成材料を挙げることができる。該スライダー18は主にハウジング12に回動可能に装着される軸46部分と前記コンタクト14、16の押受部32を押圧する押圧部50と前記コンタクト14、16の突出部44が係合する係止孔48とを備えている。前記軸46は、スライダー18を回動するための支点であり、ハウジング12の長手方向両側にスライダー18が回動可能に適宜装着されている。また、長手方向両側には、前記コンタクト14、16の押受部32を押圧した際にスライダー18が高さ(図面の上)方向に持ち上がらないようにするためにハウジング12と係合するロック部が設けられている。ロック部の形状や大きさ等は、ハウジング12に係合できれば如何なるものでもよく、上述の役割やコネクタ10の大きさや強度等を考慮して適宜設計する。

【0024】

前記スライダー18の前記押圧部50は、コンタクト14、16の押受部32に押し付ける部分であり、その形状としては細長形状にすることが望ましく、本実施例では楕円形状をしている。このように楕円形状にすることによって、図1(A)のようにスライダー18を矢印「イ」方向に回動させ、コンタクト14の押受部32と接続部34との間で回転させることで、押圧部50の大きさの変化によりコンタクト14の押受部32が持ち上げられ、FPC22をコンタクト14の接触部30側に押し付けている。押圧部50の形状としては、コンタクト14の押受部32と接続部34との間で回転でき、長軸と短軸といった大きさの違いによりコンタクト14の押受部32を押し上げられれば、如何なるものでもよい。

また、前記スライダー18を回動した際に、スライダー18の回動に対する反発力が強く、スライダーの中央部が図1(A)の矢印「ロ」方向に膨れてしまうことを防ぐようにする為に、前記コンタクト14の突出部44が係合する係止孔48が別個独立に設けられている。前記係止孔48を別個独立に設けることで、スライダー18の強度アップや回動時の変形を防止している。

上述した前記スライダー18は前記ハウジング12の嵌合口24と反対側(一方のコンタクトの接続部側)に回動自在に装着されている。

【0025】

【発明の効果】

以上の説明から明らかなように、本発明のコネクタ10によると、次のような優れた顕著な効果が得られる。

(1)前記FPC22の表裏両面に接触部52、52がある時に、2種類のコンタクト14、16用い、一方のコンタクト14を前記ハウジング12の嵌合口24の反対側から挿入するととも該コンタクト14の接触部30が前記FPC22の表面の接触部52に接触し、もう一方のコンタクト16を前記ハウジング12の嵌合口24側より挿入するとともに該コンタクト16の接触部20が前記FPC22の裏面の接触部52に接触するようにしているので、表裏両面に接触部52、52を有する前記FPC22にも容易に対応でき、狭小化も図ることができ、信号密度を高めることができる。

(2)2種類のコンタクト14、16を1対とし、1対のコンタクト14、16の接触部30、20を対向するように配置し、前記FPC22を1対のコンタクト14、16で挟み込むようにしているので、一方の前記コンタクト14の接触部30が前記FPC22の表面側の接触部52に接触し、もう一方の前記コンタクト16の接触部20が前記FPC22の裏面側の接触部52に容易に接触できる。

(3)前記FPC22の表裏両面に設けられた接触部52、52が長手方向で千鳥に配置されている場合に、1対のコンタクト14、16の接触部30、20を長手方向で千鳥になるように配置しているので、より狭小ピッチ化が可能になり、信号密度を高めることができ、容易にFPC22の接触部52、52の位置に対応できる。

(4)前記ハウジング12には前記嵌合口24側に前記FPC22を誘う凹部26を設け、もう一方の前記コンタクト16の接続部34を前記ハウジング12の凹部26内から突出しないように配置しているので、確実にFPC22を前記ハウジング12の嵌合口24に案内することができる。

(5)前記FPC22を前記ハウジング12の嵌合口24へ挿入する際に力の掛からないゼロ インサーション フォース(ZIF)構造にするために、前記FPC22を挿入してから前記コンタクト14に押しつけるスライダー18を用いているので、容易に前記FPC22を前記ハウジング12の嵌合口24内に挿入することができ、確実に前記FPC22の表裏両面の接触部52、52に接続することができる。

(6)一方のコンタクト14には接触部30と接続部34との間に弾性部40と支点部38とを設けるとともに前記接触部30と前記弾性部40と前記支点部38と前記接続部34とを略クランク形状に配置し、かつ、前記接続部34と対向する位置に前記弾性部40から延設された押受部32を設け、もう一方のコンタクト16は接触部20と接続部34とを有するとともに該接続部34が前記ハウジング12の凹部26内に入るように配置し、前記スライダー18に長手方向に連設した押圧部50を設け、該押圧部50が一方のコンタクト14の接続部34と押受部32との間で前記押圧部50が回動自在に回動するように前記スライダー18を前記ハウジング12に装着しているので、前記ハウジング12の嵌合口24側と反対側で前記スライダー18を回動することにより、前記FPC22に前記コンタクト14を押しつけているため、表裏両面に接触部52、52があるFPC22にも対応することができ、確実に前記FPC22の接触部52、52に接触することができる。

(7)スライダー18をハウジング12のコンタクト接続部34側で回動させることで、2種類のコンタクト14、16の接触部30、20をFPC22に接触させる構造にしているので、ハウジング12の嵌合口24にスライダー18を挿入することがなく、スライダーの厚み分だけコネクタの低背位化が可能になった。

【図面の簡単な説明】

【図1】(A)スライダーが開いた状態の嵌合口側からみた本発明のコネクタの斜視図である。

(B)FPCが挿入され、スライダーが閉じた状態の嵌合口側からみた本発明のコネクタの斜視図である。

【図2】(A)スライダーが開いた状態のあるコンタクト部分で切断した本発明のコネクタの斜視図である。

(B)FPCが挿入されスライダーが閉じた状態のあるコンタクト部分で切断した本発明のコネクタの斜視図である。

【図3】(A)FPCの接触部が千鳥に配列された場合のスライダーが開いた状態の図2(A)とは別のあるコンタクト部分で切断した本発明のコネクタの斜視図である。

(B)FPCの接触部が千鳥に配列された場合のFPCが挿入されスライダーが閉じた状態の図2(B)とは別のあるコンタクト部分で切断した本発明のコネクタの斜視図である。

【図4】(A)一方のコンタクトの斜視図である。

(B)もう一方のコンタクトの斜視図である。

【図5】2種類のコンタクトがFPCに接触した状態の斜視図である。

【図6】部分的なFPCの斜視図である。

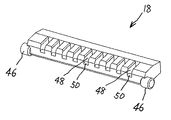

【図7】スライダーの斜視図である。

【符号の説明】

10 コネクタ

12 ハウジング

14、16 コンタクト

18 スライダー

22 FPC

24 嵌合口

26 凹部

28 挿入溝

30、20、52 接触部

32 押受部

34 接続部

36 固定部

38 支点部

40 弾性部

44 突出部

46 軸

48 係止孔

50 押圧部[0001]

TECHNICAL FIELD OF THE INVENTION

The present invention relates to a connector used for a mobile phone, a notebook computer, a digital camera, and the like, and particularly, to reduce the size of a connector when there are contact portions on both sides of a flexible printed circuit board (hereinafter, referred to as “FPC”). Things.

[0002]

[Prior art]

Connectors used in mobile phones, CCD cameras, and the like have a narrow pitch and are extremely thin (so-called light, thin and small), and are mainly provided with a housing and a contact. An FPC is inserted into the housing to make contact with a contact portion of the contact. This is a structure having a structure or mainly including a housing, a contact, and a slider, and holding the FPC between the housing and the slider. There are various methods for holding the FPC between the housing and the slider. Among them, there are many methods of inserting the slider after inserting the FPC into the housing and pressing the FPC against the contact. In addition, in order to achieve customer specifications and a narrow pitch, the connection portion of the contact may need to be arranged on the fitting port side of the housing.

The housing has a required number of insertion holes into which the contacts are inserted, and a fitting opening into which the FPC is inserted.

The contact is mainly composed of a contact portion that contacts the FPC, a connection portion that connects to a substrate or the like, and a fixing portion that is fixed to the housing. This contact is fixed to the housing by press fitting or the like.

[0003]

[Patent Document 1]

For example, Japanese Utility Model Laid-Open No. 6-60983 discloses a zero insertion force structure. According to the summary of Japanese Utility Model Application Laid-Open No. 6-60983, an object thereof is to provide a connector for a printed circuit board with a slider used in a narrow space in an electronic device or a communication device. A U-shaped arm portion having a front side fixed as a guide for insertion into a housing into which the slider is inserted is formed, a convex portion is provided on the open end side of the U-shaped arm portion, and the U-shaped arm portion is provided. A notch is provided so that the open end of the arm can be seen from the insertion direction, and a protrusion having an inclined surface with which the protrusion of the slider engages is provided at both ends of the housing, and the slider is connected to the flexible printed circuit board. When the slider is inserted into the housing together with the terminal portion, the protrusion of the slider gets over the protrusion having the inclined surface of the housing, whereby U-shaped open end of the arm portion of the shape is expanded outwardly temporarily and connector open end upon completion of insertion was made to return to the normal position is disclosed.

[0004]

[Patent Document 2]

A so-called piano touch structure is disclosed in Japanese Patent Application Laid-Open No. Hei 13-257020, which aims to surely align a contact of a connector with a pattern of an FPC or FFC. After arranging the projections on the ridge line between the contacts of the terminal block of the connector, inserting the FPC or FFC into the terminal block, and then moving the slider to press the FPC or FFC against the contacts, When the slider is used to press the FPC or FFC against the contacts for electrical connection, the projections enter the recesses between the FPC or FFC patterns, thereby ensuring the alignment between the connector contacts and the FPC or FFC patterns. What to do is disclosed.

[0005]

[Patent Document 3]

According to the summary of Japanese Patent Application Laid-Open No. Hei 5-326084, regarding a connector for a circuit board, a pitch between adjacent signal input / output terminals along an end piece and a position shift or the like can be prevented even in a circuit board in which the terminal itself is particularly narrowed. For the purpose of improving productivity by securely connecting, the literature 3 discloses a plurality of signal input / output terminals formed in several lines on the edge of the circuit board and jack terminals individually connected thereto. After inserting the circuit board from the signal input / output terminal forming side into the jack terminal contact side opening of the insulator implanted at the position corresponding to the input / output terminal, the circuit board is connected to the contact side of the jack terminal. A connector for connecting a corresponding contact and a signal input / output terminal by pressing and moving the circuit board when the circuit board is inserted up to a predetermined position in a region of the insulator where the circuit board is inserted. What constitutes comprises means capable of positioning at least the width-direction edges of the signal input-output terminal forming region a plate is disclosed.

[0006]

[Problems to be solved by the invention]

In recent years, in this type of connector, with the miniaturization of electric equipment (electronic equipment), the demand for further miniaturization has become stronger, and the demand for narrower pitch has become stronger. It has become necessary to provide contact portions on both sides.

However, the connector having the above-described structure cannot cope with the FPC having the contact portions on both sides and cannot cope with the narrow pitch.

That is, in the case of the ZIF type as described in Document 1, after the FPC is inserted into the housing, the FPC is pressed against one side by the slider to make contact with the contact, and the FPC has contact portions on both front and back surfaces. Cannot be used (it can only be pressed against one side). Also, in a so-called piano touch type in which the slider is rotated on the FPC insertion side of the housing as in Document 2, similarly to the ZIF type, the FPC is pressed to one side by the slider to contact the contact. It cannot be used for FPC with contact portions on both front and back sides (it can only be pressed against one side).

[0007]

The present invention has been made in view of such a conventional problem, and an object of the present invention is to provide a connector which can cope with a narrow pitch and which can cope with an FPC having contact portions on both sides.

[0008]

[Means for Solving the Problems]

An object of the present invention is to provide a connector which is detachably fitted to an FPC, and has a required number of contacts having a contact portion which comes into contact with the FPC, and a fitting opening in which the contact is held and fixed and the FPC is inserted. A connector having a housing having a contact portion on the front and back sides of the FPC, two types of contacts are used, and one contact is inserted from the opposite side of the fitting opening of the housing, and the contact portion of the contact is formed by the FPC. And the other contact is inserted from the fitting opening side of the housing so that the contact portion of the contact contacts the contact portion on the back surface of the FPC.

[0009]

Two types of contacts are paired, and the contact portions of the pair of contacts are arranged so as to face each other, and the FPC is sandwiched between the pair of contacts. In this manner, by sandwiching the FPC between the contact portions of the pair of contacts, the contact portion of the upper contact contacts the contact portion on the front side of the FPC, and the contact portion of the lower contact contacts the contact portion of the FPC. It contacts the contact part on the back side.

The contact portions of the pair of contacts are arranged so as to be staggered in the longitudinal direction. By arranging in a staggered manner in this way, it is possible to further narrow the pitch.

The housing is provided with a concave portion on the side of the fitting port for inviting the flexible printed circuit board, and the connecting portion of the other contact is arranged so as not to protrude from the concave portion of the housing. By doing so, the FPC can be easily guided into the fitting opening of the housing.

[0010]

In order to provide a zero insertion force (ZIF) structure in which no force is applied when the flexible printed circuit board is inserted into the fitting opening of the housing, a slider for inserting the flexible printed circuit board and then pressing the flexible printed circuit board against the contact is used. By adopting the ZIF structure in this manner, the FPC can be easily inserted into the fitting opening of the housing, and can be reliably connected to the contact portions on both the front and back surfaces of the FPC.

One contact is provided with an elastic portion and a fulcrum portion between the contact portion and the connection portion, and the contact portion, the elastic portion, the fulcrum portion, and the connection portion are arranged in a substantially crank shape, and A pressing portion extending from the elastic portion is provided at a position facing the connecting portion, and the other contact has a contact portion and a connecting portion, and is arranged such that the connecting portion enters the recess of the housing. Providing a pressing portion continuously provided in the slider in the longitudinal direction, wherein the pressing portion rotates the slider so that the pressing portion is rotatable between a connection portion of one contact and a pressing portion. Attach to the housing. Since the contact is pressed against the FPC by rotating the slider on the side opposite to the fitting opening side of the housing, it is possible to cope with the FPC having contact portions on both front and back surfaces. Can be contacted.

[0011]

[Action]

When the pressing portion of the slider rotates between the connection portion of one of the contacts and the pressing portion after the FPC is inserted into the fitting opening of the housing, the pressing portion is pushed up by the pressing portion. With the fulcrum portion of one of the contacts as a fulcrum, and the elastic portion of one of the contacts is inclined toward the contact portion, the contact portion of one of the contacts is pressed against the surface of the FPC, and the FPC The other contact is pressed against the rear surface of the contact.

[0012]

BEST MODE FOR CARRYING OUT THE INVENTION

An important feature of the present invention is that, when there are contact portions on both the front and back surfaces of the FPC, two types of contacts are used, and one contact is inserted from the opposite side of the fitting opening of the housing, and the contact portion of the contact becomes the contact portion. The contact portion on the front surface of the FPC, the other contact is inserted from the fitting opening side of the housing, and the contact portion of the contact comes into contact with the contact portion on the back surface of the FPC. There are two types that take advantage of this feature. The two types are the same in that they have a structure in which the FPC is brought into contact with the contact, but differ in the manner in which the FPC is brought into contact with the contact.

The connector having the first structure mainly includes a housing, a contact, and a slider, and is a type in which the slider rotates and presses the FPC against the contact, and is a so-called piano touch type connector. . The position where the slider is rotated is on the contact connection side (tail side). In the following embodiments, this type will be described in detail.

[0013]

The connector of the second structure mainly includes a housing and a contact, and is of a type in which the FPC is inserted into a fitting opening of the housing to contact (press) the FPC with the contact. This is a so-called NON ZIF type connector that does not use a connector. That is, the FPC is forcibly inserted between the contact contact portions or between the contact and the housing, which is smaller than the thickness of the FPC, and is brought into contact with (pressed on) the contact.

In the two structures described above, two types of contacts are used, such that the contact portion of one contact contacts the contact portion on the front surface of the FPC, and the contact portion of the other contact contacts the contact portion on the back surface of the FPC. Needless to say,

[0014]

【Example】

An embodiment of the connector of the present invention will be described with reference to FIGS. FIG. 1A is a perspective view of the connector of the present invention viewed from the fitting port side with the slider opened, and FIG. 1B is a perspective view of the connector of the present invention viewed from the fitting port side with the FPC inserted and the slider closed. It is a perspective view of a connector. FIG. 2A is a perspective view of the connector of the present invention cut at a contact part where the slider is open, and FIG. 2B is a perspective view of the connector cut at a contact part where the FPC is inserted and the slider is closed. It is a perspective view of the connector of FIG. FIG. 3A is a perspective view of the connector of the present invention cut off at a certain contact portion different from FIG. 2A in a state where the slider is opened when the contact portions of the FPC are arranged in a staggered manner. FIG. 2B is a perspective view of the connector of the present invention cut at a certain contact portion different from FIG. 2B in a state where the FPC is inserted and the slider is closed when the contact portions of the FPC are arranged in a staggered manner. FIG. 4A is a perspective view of one contact, and FIG. 4B is a perspective view of the other contact. FIG. 5 is a perspective view showing a state where two types of contacts are in contact with the FPC. FIG. 6 is a partial perspective view of the FPC, and FIG. 7 is a perspective view of the slider.

The

[0015]

Before describing the components, the

[0016]

First, the

[0017]

The

[0018]

Next, two types of

[0019]

The

[0020]

The

[0021]

The

[0022]

As described above, the

[0023]

Finally, the

[0024]

The

Further, when the

The above-described

[0025]

【The invention's effect】

As apparent from the above description, according to the

(1) When there are

(2) The two types of

(3) When the

(4) The

(5) In order to form a zero insertion force (ZIF) structure in which no force is applied when the

(6) One

(7) Since the

[Brief description of the drawings]

FIG. 1A is a perspective view of a connector of the present invention as viewed from a fitting opening side with a slider opened.

(B) It is a perspective view of the connector of the present invention seen from the fitting opening side in the state where the FPC was inserted and the slider was closed.

FIG. 2A is a perspective view of the connector of the present invention cut at a contact portion where a slider is open.

FIG. 2B is a perspective view of the connector of the present invention cut at a contact portion where the FPC is inserted and the slider is closed.

FIG. 3A is a perspective view of the connector of the present invention cut off at a certain contact portion different from FIG. 2A in a state where the slider is opened when the contact portions of the FPC are arranged in a staggered manner.

FIG. 2B is a perspective view of the connector of the present invention cut off at a certain contact portion different from FIG. 2B in a state where the FPC is inserted and the slider is closed when the contact portions of the FPC are arranged in a staggered manner.

FIG. 4A is a perspective view of one contact.

(B) It is a perspective view of the other contact.

FIG. 5 is a perspective view showing a state in which two types of contacts are in contact with the FPC.

FIG. 6 is a perspective view of a partial FPC.

FIG. 7 is a perspective view of a slider.

[Explanation of symbols]

10

24

Claims (6)

前記フレキシブルプリント基板の表裏両面に接触部がある時に、2種類のコンタクト用い、一方のコンタクトを前記ハウジングの嵌合口の反対側から挿入するととも該コンタクトの接触部が前記フレキシブルプリント基板の表面の接触部に接触し、もう一方のコンタクトを前記ハウジングの嵌合口側より挿入するとともに該コンタクトの接触部が前記フレキシブルプリント基板の裏面の接触部に接触するようにしたことを特徴とするコネクタ。A connector detachably fitted to a flexible printed circuit board (FPC), wherein a required number of contacts having a contact portion that contacts the flexible printed circuit board, the contacts are held and fixed, and the flexible printed circuit board is inserted. And a housing having a mating opening,

When there are contact portions on both front and back surfaces of the flexible printed board, two types of contacts are used, and one contact is inserted from the opposite side of the fitting opening of the housing, and the contact portion of the contact contacts the surface of the flexible printed board. A connector, wherein the other contact is inserted from the fitting opening side of the housing, and the contact portion of the contact contacts the contact portion on the back surface of the flexible printed circuit board.

Priority Applications (13)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002373404A JP2004206987A (en) | 2002-12-25 | 2002-12-25 | Connector |

| US10/417,773 US7044773B2 (en) | 2002-08-01 | 2003-04-17 | Connector |

| CN2007101666749A CN101145648B (en) | 2002-08-01 | 2003-05-23 | Connector |

| CN2007101368114A CN101090182B (en) | 2002-08-01 | 2003-05-23 | Connector |

| CNB031365221A CN100345342C (en) | 2002-08-01 | 2003-05-23 | Connector |

| US11/327,901 US20060110974A1 (en) | 2002-08-01 | 2006-01-09 | Connector |

| US11/440,472 US7223110B2 (en) | 2002-08-01 | 2006-05-17 | Connector |

| US11/557,430 US7491088B2 (en) | 2002-08-01 | 2006-11-07 | Connector |

| US11/557,417 US7393239B2 (en) | 2002-08-01 | 2006-11-07 | Electrical connector for flexible printed circuit boards |

| US11/740,751 US7494366B2 (en) | 2002-08-01 | 2007-04-26 | Connector |

| US11/932,004 US7648386B2 (en) | 2002-08-01 | 2007-10-31 | Miniaturized connector for flexible printed circuit board |

| US12/354,443 US7563128B2 (en) | 2002-08-01 | 2009-01-15 | Connector |

| US12/686,880 US20100173518A1 (en) | 2002-08-01 | 2010-01-13 | Connector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002373404A JP2004206987A (en) | 2002-12-25 | 2002-12-25 | Connector |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006186342A Division JP2006261140A (en) | 2006-07-06 | 2006-07-06 | Connector |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2004206987A true JP2004206987A (en) | 2004-07-22 |

Family

ID=32811691

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002373404A Pending JP2004206987A (en) | 2002-08-01 | 2002-12-25 | Connector |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2004206987A (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006261140A (en) * | 2006-07-06 | 2006-09-28 | D D K Ltd | Connector |

| US7306478B2 (en) | 2005-10-26 | 2007-12-11 | Japan Aviation Electronics, Industry, Limited | Connector improved in dust tightness |

| JP2008004340A (en) * | 2006-06-21 | 2008-01-10 | D D K Ltd | Connector |

| JP2008066395A (en) * | 2006-09-05 | 2008-03-21 | D D K Ltd | Both side connectable flexible printed board and connector device for connecting it |

| US7393239B2 (en) | 2002-08-01 | 2008-07-01 | Ddk Ltd. | Electrical connector for flexible printed circuit boards |

| US7435122B2 (en) | 2004-10-18 | 2008-10-14 | Ddk Ltd. | Connector |

| US7540764B2 (en) | 2007-07-13 | 2009-06-02 | Ddk Ltd. | Connector |

| US7766680B2 (en) | 2007-09-07 | 2010-08-03 | Ddk Ltd. | Flexible circuit board connector |

| US9391383B2 (en) | 2014-10-03 | 2016-07-12 | Japan Aviation Electronics Industry, Limited | Connector |

| US9755340B2 (en) | 2015-09-18 | 2017-09-05 | Japan Aviation Electronics Industry, Limited | Connector |

| KR20190079176A (en) * | 2017-12-27 | 2019-07-05 | 엘지디스플레이 주식회사 | Cable, connector, printed circuit board and display device using the same |

| JP7554165B2 (en) | 2021-07-30 | 2024-09-19 | ヒロセ電機株式会社 | Electrical Connectors |

-

2002

- 2002-12-25 JP JP2002373404A patent/JP2004206987A/en active Pending

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7494366B2 (en) | 2002-08-01 | 2009-02-24 | Ddk Ltd. | Connector |

| US7491088B2 (en) | 2002-08-01 | 2009-02-17 | Ddk Ltd. | Connector |

| US7648386B2 (en) | 2002-08-01 | 2010-01-19 | Ddk, Ltd. | Miniaturized connector for flexible printed circuit board |

| US7393239B2 (en) | 2002-08-01 | 2008-07-01 | Ddk Ltd. | Electrical connector for flexible printed circuit boards |

| US7435122B2 (en) | 2004-10-18 | 2008-10-14 | Ddk Ltd. | Connector |

| US7306478B2 (en) | 2005-10-26 | 2007-12-11 | Japan Aviation Electronics, Industry, Limited | Connector improved in dust tightness |

| JP2008004340A (en) * | 2006-06-21 | 2008-01-10 | D D K Ltd | Connector |

| US7448893B2 (en) | 2006-06-21 | 2008-11-11 | Ddk Ltd. | Connector |

| JP2006261140A (en) * | 2006-07-06 | 2006-09-28 | D D K Ltd | Connector |

| JP2008066395A (en) * | 2006-09-05 | 2008-03-21 | D D K Ltd | Both side connectable flexible printed board and connector device for connecting it |

| US7540764B2 (en) | 2007-07-13 | 2009-06-02 | Ddk Ltd. | Connector |

| US7766680B2 (en) | 2007-09-07 | 2010-08-03 | Ddk Ltd. | Flexible circuit board connector |

| US9391383B2 (en) | 2014-10-03 | 2016-07-12 | Japan Aviation Electronics Industry, Limited | Connector |

| US9755340B2 (en) | 2015-09-18 | 2017-09-05 | Japan Aviation Electronics Industry, Limited | Connector |

| KR20190079176A (en) * | 2017-12-27 | 2019-07-05 | 엘지디스플레이 주식회사 | Cable, connector, printed circuit board and display device using the same |

| US10868381B2 (en) | 2017-12-27 | 2020-12-15 | Lg Display Co., Ltd. | Connector and display device including same |

| KR102543054B1 (en) * | 2017-12-27 | 2023-06-14 | 엘지디스플레이 주식회사 | Cable, connector, printed circuit board and display device using the same |

| JP7554165B2 (en) | 2021-07-30 | 2024-09-19 | ヒロセ電機株式会社 | Electrical Connectors |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4280621B2 (en) | connector | |

| JP2004071160A (en) | Connector | |

| JP4073766B2 (en) | connector | |

| JP2004221067A (en) | Connector | |

| JP2004206987A (en) | Connector | |

| JP4927454B2 (en) | connector | |

| JP2004178959A (en) | Connector | |

| JP2020098803A (en) | connector | |

| JP2006261140A (en) | Connector | |

| JP2020191311A (en) | connector | |

| JP2021048143A (en) | connector | |

| JP2021108289A (en) | connector | |

| JP2021036542A (en) | connector | |

| JP2021064624A (en) | connector | |

| JP2021009858A (en) | connector | |

| JP2020205285A (en) | connector | |

| JP2020161502A (en) | connector | |

| JP2021166189A (en) | connector | |

| JP2021192393A (en) | connector | |

| JP2020177927A (en) | connector | |

| JP4644719B2 (en) | connector | |

| JP2020115487A (en) | connector | |

| JP2011023371A (en) | Connector | |

| JP2020109770A (en) | connector | |

| JP2020074336A (en) | connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040621 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20050803 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050816 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051012 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051027 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20060509 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060706 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060818 |

|

| A911 | Transfer of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20060825 |

|

| A912 | Removal of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20070223 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081009 |