EP3670778B1 - Prefabricated frame - Google Patents

Prefabricated frame Download PDFInfo

- Publication number

- EP3670778B1 EP3670778B1 EP19172996.1A EP19172996A EP3670778B1 EP 3670778 B1 EP3670778 B1 EP 3670778B1 EP 19172996 A EP19172996 A EP 19172996A EP 3670778 B1 EP3670778 B1 EP 3670778B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- column

- prefabricated

- cast

- reinforcing bars

- main beam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000003014 reinforcing effect Effects 0.000 claims description 70

- 238000011065 in-situ storage Methods 0.000 claims description 46

- 239000004567 concrete Substances 0.000 claims description 35

- 238000005266 casting Methods 0.000 claims description 8

- 239000011083 cement mortar Substances 0.000 claims description 3

- 238000010276 construction Methods 0.000 description 31

- 239000011150 reinforced concrete Substances 0.000 description 10

- 230000002787 reinforcement Effects 0.000 description 7

- 235000012773 waffles Nutrition 0.000 description 6

- 239000011440 grout Substances 0.000 description 5

- 238000009417 prefabrication Methods 0.000 description 5

- 208000037805 labour Diseases 0.000 description 4

- 239000010410 layer Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 239000002699 waste material Substances 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000004904 shortening Methods 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 230000003749 cleanliness Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000009415 formwork Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000005498 polishing Methods 0.000 description 1

- 239000011178 precast concrete Substances 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B5/00—Floors; Floor construction with regard to insulation; Connections specially adapted therefor

- E04B5/43—Floor structures of extraordinary design; Features relating to the elastic stability; Floor structures specially designed for resting on columns only, e.g. mushroom floors

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C1/00—Building elements of block or other shape for the construction of parts of buildings

- E04C1/24—Elements for building-up floors, ceilings, roofs, arches, or beams

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/20—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons the supporting parts consisting of concrete, e.g. reinforced concrete, or other stonelike material

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/30—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons the supporting parts being composed of two or more materials; Composite steel and concrete constructions

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B5/00—Floors; Floor construction with regard to insulation; Connections specially adapted therefor

- E04B5/16—Load-carrying floor structures wholly or partly cast or similarly formed in situ

- E04B5/32—Floor structures wholly cast in situ with or without form units or reinforcements

- E04B5/36—Floor structures wholly cast in situ with or without form units or reinforcements with form units as part of the floor

- E04B5/38—Floor structures wholly cast in situ with or without form units or reinforcements with form units as part of the floor with slab-shaped form units acting simultaneously as reinforcement; Form slabs with reinforcements extending laterally outside the element

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/30—Columns; Pillars; Struts

- E04C3/34—Columns; Pillars; Struts of concrete other stone-like material, with or without permanent form elements, with or without internal or external reinforcement, e.g. metal coverings

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04G—SCAFFOLDING; FORMS; SHUTTERING; BUILDING IMPLEMENTS OR AIDS, OR THEIR USE; HANDLING BUILDING MATERIALS ON THE SITE; REPAIRING, BREAKING-UP OR OTHER WORK ON EXISTING BUILDINGS

- E04G21/00—Preparing, conveying, or working-up building materials or building elements in situ; Other devices or measures for constructional work

- E04G21/14—Conveying or assembling building elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/24—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons the supporting parts consisting of metal

- E04B1/2403—Connection details of the elongated load-supporting parts

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B2/00—Walls, e.g. partitions, for buildings; Wall construction with regard to insulation; Connections specially adapted to walls

- E04B2/74—Removable non-load-bearing partitions; Partitions with a free upper edge

- E04B2/7407—Removable non-load-bearing partitions; Partitions with a free upper edge assembled using frames with infill panels or coverings only; made-up of panels and a support structure incorporating posts

- E04B2/7416—Removable non-load-bearing partitions; Partitions with a free upper edge assembled using frames with infill panels or coverings only; made-up of panels and a support structure incorporating posts with free upper edge, e.g. for use as office space dividers

- E04B2/7422—Removable non-load-bearing partitions; Partitions with a free upper edge assembled using frames with infill panels or coverings only; made-up of panels and a support structure incorporating posts with free upper edge, e.g. for use as office space dividers with separate framed panels without intermediary support posts

- E04B2/7425—Details of connection of panels

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B1/1903—Connecting nodes specially adapted therefor

- E04B2001/1918—Connecting nodes specially adapted therefor with connecting nodes having flat radial connecting surfaces

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1924—Struts specially adapted therefor

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/18—Structures comprising elongated load-supporting parts, e.g. columns, girders, skeletons

- E04B1/19—Three-dimensional framework structures

- E04B2001/1975—Frameworks where the struts are directly connected to each other, i.e. without interposed connecting nodes or plates

Definitions

- CN 108 678 445 A discloses a multi-floor factory building comprising a roof, a waffle floor and a plurality of ribbed floors, wherein the plurality of ribbed floors are upper and lower structural buildings, the waffle floor being located on an upper floor of the top ribbed floor, the roof being constructed on the waffle floor. Furthermore, the frame main beam, the waffle plate and the ribbed plate are prefabricated components.

- US 2014/060721 A1 discloses a grout-filled reinforcement joint that is buried in reinforced concrete and is used for joining reinforcing bars in the reinforced concrete. It is proposed to provide a grout inlet being a protruding opening protruding outward, wherein said protruding opening is fitted with a cylindrical sealing body constituted of an elastic body including a check valve provided at one end. Since an outlet of the reinforcement joint is fitted with a removable sealing plug which, when the grout is filled, closes the outlet automatically after the paste components are discharged, an invisible filling state of the grout inside the reinforcement joint can be confirmed from outside, and, at the same time, the grout can be prevented from flowing outside through the outlet.

- the technical problem to be solved by the present invention is to provide a prefabricated frame, in which the prefabricated members account for a large proportion of all structural members used, thus significantly reducing the amount of on-site construction work.

- the column is recessed inwardly at one or more lower sidewalls thereof to form the to-be-cast structure.

- the exposed reinforcing bars of the lower building structure are overlapped and bundled with the reserve connecting bars of the to-be-cast structure, so that the column and the lower building structure are connected with each other through establishing a template outside of the to-be-cast structure and pouring concrete therewith.

- the cast-in-situ portion at one end of the main beam is provided with upper and lower connecting bars, each of the connecting bars being bent at a free end thereof.

- the novel prefabricated frame according to the present invention has the following advantages.

- a novel prefabricated frame includes at least one column 1, at least one main beam 2 connected to the column 1, at least one secondary beam 3 connected to the main beam 2, and a floor 5.

- the present invention is characterized in that the column 1, the main beam 2 and the secondary beam 3 are all prefabricated members, and the floor 5 is a laminated plate, wherein a lower part of the floor 5 is a prefabricated slab 51 while an upper part thereof is a cast-in-situ concrete layer 52.

- the main beam 2, the secondary beam 3, and the prefabricated slab 51 are all provided with exposed reserve reinforcing bars at respective top portions thereof, and provided in advance with reinforcing bars for cast-in-situ parts, all the reinforcing bars being temporarily fixed.

- the reinforcing bars for cast-in-situ parts that are arranged in recesses are pulled or inserted into their respective designated positions, bundled in series, and then fixed.

- the reinforcing bars for cast-in-situ parts are connected to the exposed reserve reinforcing bars of the prefabricated members.

- the prefabricated slab 51, the prefabricated main beam 2, and the prefabricated secondary beam 3 are used as a bottom mold, and connected together through in-situ casting concrete on the bottom mold.

- the column 1 is a prefabricated column having exposed reserve reinforcing bars at a top thereof and a to-be-cast structure at a bottom thereof.

- the to-be-cast structure is provided therein with reserve connecting bars for connection with a lower building structure. Exposed reinforcing bars of the lower building structure, which are located under the column, are inserted into the to-be-cast structure.

- the connection between the column 1 and the lower building structure is achieved through in-situ casting concrete in the to-be-cast structure.

- the main beam 2 may be configured in either of the following two structural modes.

- the width of the main beam 2 at two end portions 22 thereof is larger than that at a middle portion 21 thereof, so that the middle portion 21 is connected to each of the end portions 22 through a step part.

- the middle portion 21 and the two end portions 22 of the main beam 2 are provided, on their top portions, with recesses 23 and 24, respectively, wherein the recess 23 of the middle portion 21 is relatively shallow, and the recesses 24 of the end portions 22 are relatively deep and open to respective end faces of the main beam 2.

- Two sides of the middle portion 21 and two sides of each of the end portions 22 are equally high. Concrete, while being cast in-situ on the floor, is also cast in-situ in the recesses 23 and 24 on the top portion of the main beam 2, thus forming the cast-in-situ parts of the main beam 2.

- the secondary beam 3 may also be configured according to the following two structural mode.

- the width at two end portions 32 of the secondary beam 3 is larger than that at a middle portion 31 of the secondary beam 3, so that the middle portion 31 is connected to each of the end portions 32 through a step part.

- the middle portion 31 and the two end portions 32 of the secondary beam 3 are provided, on their top portions, with recesses 33 and 34, respectively, wherein the recess 33 of the middle portion 31 is relatively shallow, and the recesses 34 of the end portions 32 are relatively deep and open to end faces of the secondary beam 3.

- Two sides of the middle portion 31 and two sides of the end portions 32 are equally high. Concrete, while being cast in-situ on the floor, is also cast in-situ in the recesses 33 and 34 on the top portions of the secondary beam 3, thus forming the cast-in-situ parts of the secondary beam 3.

- Main reinforcing bars for cast-in-situ parts of the main beam 2 and the secondary beam 3 can be respectively provided in advance in the recesses 23 and 24 at the top portion of the main beam 2, and in the recesses 31 and 34 at the top portion of the secondary beam 3, and then transported together with the prefabricated members to the construction site. After the main beam 2 and the secondary beam 3 are mounted through hoist, the above main reinforcing bars are separately pulled or inserted into corresponding positions, bundled in series, and then fixed.

- the main beam 2 is mounted between two adjacent columns 1, and the end portions of the main beam 2 are disposed on top edges of the columns 1 in a specific floor.

- the secondary beam 3 is mounted between two adjacent main beams 2. The end faces of the secondary beam 3 abut against sidewalls of the main beams 2. At a position where the sidewall of the main beam 2 connects the secondary beam 3 is provided with an opening 25, so that the reinforcing bars at the top portion of the secondary beam 3 can conveniently pass therethrough.

- a reinforcing bar connector 78 is provided in advance at a lower position of a junction between the main beam 2 and each of the secondary beams 3 located at left and right sides of the main beam 2, and is connected to a reinforcing bar 77 provided in a prefabricated part of the main beam 2.

- a reinforcing bar 93 provided in the recess 34 at the end portion of the secondary beam 3 is connected to a corresponding reinforcing bar connector 78, thereby achieving connection between the reinforcing bar 77 provided in the prefabricated part of the main beam 2 and the reinforcing bar 93 for the cast-in-situ part at the end portion of the secondary beam 3.

- a connecting bar 79 is provided at a top portion of the cast-in-situ part at the end portion of the secondary beam 3 located at one side of the main beam 2, passes along a bottom portion of a reinforcing bar provided at the top portion of the main beam 2, and extends to the secondary beam 3 located at the other side of the main beam 2.

- Two ends of the connecting bar 79 partially overlap reinforcing bars 92 provided at the top portions of the cast-in-situ parts of the left and right secondary beams 3, respectively.

- the end portions of the secondary beams 3 are provided with exposed reserve stirrups 94, which extend from the prefabricated parts of the secondary beams 3.

- connecting bars 74 and 73 are respectively provided at an upper portion and a lower portion of the cast-in-situ part at the end portion of the main beam 2.

- the lower connecting bar 73 has one end extending into the column 1 connected thereto and being bent upwardly.

- the upper connecting bar 74 has one end extending similarly into the column 1 connected thereto and being bent downwardly, and another end partially overlapping a reinforcing bar 72 provided at a cast-in-situ concrete part at an upper portion of the main beam 2.

- the end portion of the main beam 2 is provided with exposed reserve stirrups 75, which extend from the prefabricated part of the main beam 2.

- stirrups 75 connect the reinforcing bar 71 provided in the prefabricated part of the main beam 2 with the reinforcing bars 74 and 72 provided at the cast-in-situ part of the main beam 2, and enclose them.

- the reinforcing bars 72, 73, and 74 may be arranged in the recesses of the main beam 2 at a prefabrication factory in advance, and directly pulled or inserted, after the main beam 2 is mounted at the construction site, into the corresponding positions, bundled in series, and then fixed.

- connecting bars 81 and 82 are respectively provided at upper and lower positions of the cast-in-situ part at the end portion of the main beam 2 located at one side of the column 1, pass through the column 1, and extend to the main beam 2 located at the other side of the column 1.

- Two ends of the upper connecting 81 partially overlap the reinforcing bars 72 provided at the top portions of the cast-in-situ parts of the left and right main beams 2, respectively.

- the end portions of each of the main beams 2 located at both sides of the column 1 are provided with exposed reserve stirrups 76, which extend from the prefabricated part thereof.

- stirrups 76 connect the reinforcing bars 71 provided in the prefabricated parts of the main beams 2 with the reinforcing bars 72 and 81 provided in the cast-in-situ parts thereof, and enclose them.

- the reinforcing bars 72, 81, and 82 may be arranged in the recesses of the main beam 2 at a prefabrication factory in advance, and directly pulled or inserted, after the main beam 2 is mounted at the construction site, into the corresponding positions, bundled in series, and then fixed.

- the reinforcing bars inside the column 1 may be exposed to a certain length from the top of the column 1.

- the exposed portions, referred to as exposed reinforcing bars 11, are used for connection with an upper building structure.

- the bottom of the column 1 is provided with a to-be-cast structure 12, which is provided therein with reserve connecting bars 13.

- the sidewalls of the column 1 are inwardly recessed at the lower end thereof, so that the recessed portion forms the to-be-cast structure 12.

- the recessed portion may be formed such that four sidewalls of the column 1 are all recessed inwardly to a certain depth at a region of the lower end of the column 1, or only part of them is recessed inwardly to a certain depth.

- the depth of the recessed portion is preferably selected to expose the reinforcing bars inside the column 1.

- the exposed reinforcing bars in the to-be-cast structure 12 are called as reserve connecting bars, for connection with a lower building structure.

- the to-be-cast structure 12 can be cast in-situ with concrete, so as to achieve the connection to the lower building structure.

- the inner wall of the to-be-cast structure 12 is beveled, thus increasing the contact area between the prefabricated concrete and the in-situ-cast concrete. In this manner, the bonding force therebetween can be further improved.

- This to-be-cast structure facilitates the pouring of concrete and the integrated production of the prefabricated column at the factory, improves the overall prefabrication rate, and thus is advantageous for production and transportation.

- the reserve connecting bars 13 in the to-be-cast structure 12 include vertical reinforcing bars 131 and transverse stirrups 132.

- the vertical reinforcing bars 131 and the exposed reserve reinforcing bars 11 may be formed by exposed ends of the reinforcing bars inside the column 1, respectively.

- the reserve connecting bars 13 in the to-be-cast structure 12 are firstly connected with the exposed reinforcing bars 141 on the top of the lower building structure 14, and fixed therewith by stirrups. Then, a template is established at the to-be-cast structure 12 and concrete is poured, thus connecting the prefabricated column with the lower building structure 14.

- a cement mortar layer may be disposed between a bottom surface of the column 1 and a top surface of the lower building structure 14, thus realizing a close connection between the column 1 and the lower building structure 14.

- the exposed reserve reinforcing bars 11 on the top of the column 1 are inserted into the upper building structure 15, with top ends thereof being exposed from the top of the upper building structure 15.

- the exposed portions of the reinforcing bars 11 are used as exposed reinforcing bars 151 at the top of the upper building structure 15. In this manner, a firm connection between the prefabricated column and the building structures can be achieved.

- one or more sidewalls of the column 1 may be provided in advance with a decorative surface layer, so as to reduce the workload of subsequent on-site construction.

- the member to be cast at the bottom of the prefabricated column can be formed as a toothed joint.

- the top and bottom of the prefabricated column are both provided with exposed reinforcing bars.

- the top of a lower prefabricated column can be formed into one piece with the cast-in-situ beam.

- the exposed steel bars at the top of the lower prefabricated column can be connected with the reserve connecting bars at the bottom of the upper prefabricated column, tied together by wires, and then fixed by stirrups.

- the upper and lower prefabricated columns can be connected with each other into one piece by establishing a template on the outer part of the prefabricated columns and then casting concrete therewith.

- the prefabricated column, the prefabricated main beam, the prefabricated secondary beam, and the prefabricated floor slab are used, thereby remarkably reducing the amount of construction work on site, reducing pollution and waste, and saving labor forces significantly.

- the construction efficiency can be effectively improved, and the duration can thus be shortened.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Mechanical Engineering (AREA)

- Joining Of Building Structures In Genera (AREA)

Description

- The invention relates to a building structure, in particular to a novel prefabricated frame, which is particularly suitable for all buildings with frame structures or frame-shear wall structures.

- A conventional frame structure building, established through assembling prefabricated members, mainly uses prefabricated members such as prefabricated secondary beams, prefabricated slabs, or the like. During construction, a column should be cast in-situ first, followed by mounting of the prefabricated secondary beam and the prefabricated slab, and then in-situ casting of main beam reinforcing bars. Finally, concrete is cast in-situ on the prefabricated slab, so as to connect the main beam, the prefabricated secondary beam, and the prefabricated slab together. The use of prefabricated members can reduce on-site construction work, save labors, and improve construction efficiency.

-

CN 108 678 445 A discloses a multi-floor factory building comprising a roof, a waffle floor and a plurality of ribbed floors, wherein the plurality of ribbed floors are upper and lower structural buildings, the waffle floor being located on an upper floor of the top ribbed floor, the roof being constructed on the waffle floor. Furthermore, the frame main beam, the waffle plate and the ribbed plate are prefabricated components. Both ends of the first prefabricated frame main beam are built on the top of the first support column, and two or more of the first support columns support the first prefabricated frame main beam, The construction process is performed by connecting reinforcing bars of the first prefabricated frame main beam and connecting reinforcing bars of the first supporting column, so that the first prefabricated frame main beam and the first supporting column form a connection node of the first prefabricated frame main beam, the first support column and the ribbed plate. The frame main beam, the ribbed plate and the waffle plate can be produced in the prefabricated factory, and the cast-in-place concrete can be reliably connected on site. By installing the waffle plate as a top floor, it meets the cleanliness requirements of a general electronic factory. Compared with the traditional cast-in-place concrete construction process, this concept adopts a prefabricated construction method to improve the quality and construction efficiency and reduce the dependence on labor. -

CN105421632A relates to a stalwart floor covering system comprising a cast-in-place concrete column, wherein the upper and lower layer columns of the cast-in-place concrete column form a step. Prefabricated concrete main beams are placed between the steps. Concrete beams are connected by a number of prefabricated steel secondary beams, and prefabricated reinforcement templates are laid on all prefabricated components. The prefabricated reinforcement formwork is integrally formed with the slab thickness portion reserved for all prefabricated beams and the lower portion of the upper column. Said nodes are simple in construction and can be used as a fixed connection for simple earthquake resistance. All precast beams can be used as continuous beams, and the prestressing can be applied in the precast concrete beams, which makes the construction more economical. -

US 2014/060721 A1 discloses a grout-filled reinforcement joint that is buried in reinforced concrete and is used for joining reinforcing bars in the reinforced concrete. It is proposed to provide a grout inlet being a protruding opening protruding outward, wherein said protruding opening is fitted with a cylindrical sealing body constituted of an elastic body including a check valve provided at one end. Since an outlet of the reinforcement joint is fitted with a removable sealing plug which, when the grout is filled, closes the outlet automatically after the paste components are discharged, an invisible filling state of the grout inside the reinforcement joint can be confirmed from outside, and, at the same time, the grout can be prevented from flowing outside through the outlet. -

CN 108 035 438 A discloses a concrete assembled frame structure system comprising prefabricated reinforced concrete columns, reinforced concrete beams, reinforced concrete columns and joints of reinforced concrete beams on both sides thereof to form a node core region. The prefabricated reinforced concrete columns include concrete prefabricated columns, column longitudinal bars, and column stirrups formed on the upper and lower ends of the concrete prefabricated column. The upper and lower ends of the reserved column longitudinal bars and the lower reserved column bars are respectively formed and exposed in the core area of the node. Column stirrups are reserved on the outside of the longitudinal bars. There are prefabricated beam supports at the top of the prefabricated reinforced concrete columns in the core area of the nodes, and the prefabricated reinforced concrete beams are placed on the prefabricated beam supports. - However, the prefabricated members used in the existing building structures are limited, and a large number of structures still need to be formed by cast-in-situ concrete. Therefore, the amount of on-site construction workload is still heavy, and the construction period cannot be further shortened.

- The technical problem to be solved by the present invention is to provide a prefabricated frame, in which the prefabricated members account for a large proportion of all structural members used, thus significantly reducing the amount of on-site construction work.

- The present invention is defined by

Claim 1. Specific embodiments are defined with the dependent claims. - A prefabricated frame is proposed, comprising at least one column, at least one main beam connected to the column, at least one secondary beam connected to the main beam, and a floor. The column, the main beam and the secondary beam are all prefabricated members, and the main beam and the secondary beam are both provided with, on respective top portions thereof, exposed reserve reinforcing bars, and reinforcing bars for cast-in-situ parts. The floor is a laminated plate having a prefabricated slab at a lower portion thereof, and the prefabricated slab, the main beam, and the secondary beam are connected together by means of in-situ casting concrete on respective top portions thereof. The column is a prefabricated column having exposed reserve reinforcing bars at a top thereof and a to-be-cast structure at a bottom thereof, the to-be-cast structure being provided therein with reserve connecting bars. The to-be-cast structure is used for connection with a lower building structure, which has exposed reinforcing bars that are located under the column and inserted into the to-be-cast structure, the connection between the column and the lower building structure being achieved by casting in-situ concrete in the to-be-cast structure.

- The column is recessed inwardly at one or more lower sidewalls thereof to form the to-be-cast structure.

- The exposed reinforcing bars of the lower building structure are overlapped and bundled with the reserve connecting bars of the to-be-cast structure, so that the column and the lower building structure are connected with each other through establishing a template outside of the to-be-cast structure and pouring concrete therewith.

- Optionally, the exposed reserve reinforcing bars on the top of the column are higher than the main beam and the floor.

- Optionally, at a connection node between the main beam and a column located at one end of the frame, the cast-in-situ portion at one end of the main beam is provided with upper and lower connecting bars, each of the connecting bars being bent at a free end thereof.

- Optionally, at connection nodes between the column and two main beams to a right side and to a left side thereof, the cast-in-situ parts at one end of one of said two main beams is provided with upper and lower connecting bars, which pass above the column and extend to the other of said two main beams, and both ends of the upper connecting bars are connected to reinforcing bars arranged on top of the cast-in-situ parts of said two main beams, respectively.

- Optionally, a cement mortar layer is disposed between a bottom surface of the column and the lower building structure.

- Compared with the prior arts, the novel prefabricated frame according to the present invention has the following advantages.

- First, the conventional cast-in-situ main beam is replaced with the prefabricated main beam, and the reinforcing bars for cast-in-situ parts of the prefabricated main beam and the prefabricated secondary beam have been prepared in advance and fixed on the prefabricated members. This will save a lot of construction work on site, and reduce investment in the human resources for on-site reinforcement breaking and reinforcement fixing.

- Second, the column is a prefabricated column having exposed reserve reinforcing bars at a top thereof and a to-be-cast structure at a bottom thereof, the to-be-cast structure being used for connection with a lower building structure. With the prefabricated column, the construction can be performed more rapidly and conveniently, and the construction quality can be consistently ensured. Therefore, the on-site workload can be significantly reduced, thus greatly shortening the construction duration. Moreover, construction can be performed in the middle area and in the side areas of the building in parallel, thus reducing labor cost, construction waste, and noise and sand pollution. In this manner, the influence of the construction on surrounding residents can be avoided to a maximum extent.

- Third, construction progress can be accelerated, thereby improving construction efficiency and shortening an overall project duration.

- Fourth, as a result of increase in factory production of the prefabricated members, the quality of products can be more effectively guaranteed. And as the prefabricated members can be favorably completed, on-site polishing and secondary repair procedures can be directly saved.

- Finally, the column, the main beam, the secondary beam, and the floor are all in the form of prefabricated members, which can reduce the use of a large number of wood plate molds. Only a few gaps between members are necessary to be blocked with plate molds. This also remarkably reduces construction waste on site, and thus is more environmentally friendly.

-

-

Fig. 1 schematically shows the structure of a novel prefabricated frame of the present invention; -

Fig. 2 schematically shows a main structural diagram of a prefabricated main beam according toEmbodiment 1 thereof, wherein its exposed reserve reinforcing bars are not shown; -

Fig. 3 schematically shows a main structural diagram of a prefabricated secondary beam according toEmbodiment 1 thereof, wherein its exposed reserve reinforcing bars are not shown; -

Fig. 4 schematically shows a temporary support for the main beam, the secondary beam, and a prefabricated slab during construction; -

Fig. 5 is a detail view showing an end node at a junction between a cast-in-situ column and the main beam; -

Fig. 6 is a detail view showing a central node at a junction between the cast-in-situ column and each of the main beams located at right and left sides of the column; and -

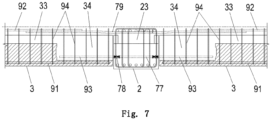

Fig. 7 is a detail view showing a node at a junction between the main beam and each of the secondary beams located at left and right sides of the main beam. -

Figs. 8 to 10 schematically show a main structural diagram of a column according to a first example. - The present invention will be described in further detail with reference to preferred embodiments shown in the accompanying drawings.

- As shown in

Figs. 1 and4 , a novel prefabricated frame according to the present invention includes at least onecolumn 1, at least onemain beam 2 connected to thecolumn 1, at least onesecondary beam 3 connected to themain beam 2, and afloor 5. The present invention is characterized in that thecolumn 1, themain beam 2 and thesecondary beam 3 are all prefabricated members, and thefloor 5 is a laminated plate, wherein a lower part of thefloor 5 is aprefabricated slab 51 while an upper part thereof is a cast-in-situ concrete layer 52. Themain beam 2, thesecondary beam 3, and theprefabricated slab 51 are all provided with exposed reserve reinforcing bars at respective top portions thereof, and provided in advance with reinforcing bars for cast-in-situ parts, all the reinforcing bars being temporarily fixed. During construction, after the prefabricated main beam, the prefabricated secondary beam, and the floor are mounted through hoist, the reinforcing bars for cast-in-situ parts that are arranged in recesses are pulled or inserted into their respective designated positions, bundled in series, and then fixed. The reinforcing bars for cast-in-situ parts are connected to the exposed reserve reinforcing bars of the prefabricated members. Theprefabricated slab 51, the prefabricatedmain beam 2, and the prefabricatedsecondary beam 3 are used as a bottom mold, and connected together through in-situ casting concrete on the bottom mold. In addition, thecolumn 1 is a prefabricated column having exposed reserve reinforcing bars at a top thereof and a to-be-cast structure at a bottom thereof. The to-be-cast structure is provided therein with reserve connecting bars for connection with a lower building structure. Exposed reinforcing bars of the lower building structure, which are located under the column, are inserted into the to-be-cast structure. The connection between thecolumn 1 and the lower building structure is achieved through in-situ casting concrete in the to-be-cast structure. - According to the present invention, the

main beam 2 may be configured in either of the following two structural modes. - In

Embodiment 1 of themain beam 2 as shown inFig. 2 , the width of themain beam 2 at twoend portions 22 thereof is larger than that at amiddle portion 21 thereof, so that themiddle portion 21 is connected to each of theend portions 22 through a step part. Themiddle portion 21 and the twoend portions 22 of themain beam 2 are provided, on their top portions, withrecesses recess 23 of themiddle portion 21 is relatively shallow, and therecesses 24 of theend portions 22 are relatively deep and open to respective end faces of themain beam 2. Two sides of themiddle portion 21 and two sides of each of theend portions 22 are equally high. Concrete, while being cast in-situ on the floor, is also cast in-situ in therecesses main beam 2, thus forming the cast-in-situ parts of themain beam 2. - The

secondary beam 3 may also be configured according to the following two structural mode. - In

Embodiment 1 of thesecondary beam 3 as shown inFig. 3 , the width at twoend portions 32 of thesecondary beam 3 is larger than that at amiddle portion 31 of thesecondary beam 3, so that themiddle portion 31 is connected to each of theend portions 32 through a step part. Themiddle portion 31 and the twoend portions 32 of thesecondary beam 3 are provided, on their top portions, withrecesses recess 33 of themiddle portion 31 is relatively shallow, and therecesses 34 of theend portions 32 are relatively deep and open to end faces of thesecondary beam 3. Two sides of themiddle portion 31 and two sides of theend portions 32 are equally high. Concrete, while being cast in-situ on the floor, is also cast in-situ in therecesses secondary beam 3, thus forming the cast-in-situ parts of thesecondary beam 3. - Main reinforcing bars for cast-in-situ parts of the

main beam 2 and thesecondary beam 3 can be respectively provided in advance in therecesses main beam 2, and in therecesses secondary beam 3, and then transported together with the prefabricated members to the construction site. After themain beam 2 and thesecondary beam 3 are mounted through hoist, the above main reinforcing bars are separately pulled or inserted into corresponding positions, bundled in series, and then fixed. - As shown in

Fig. 1 , themain beam 2 is mounted between twoadjacent columns 1, and the end portions of themain beam 2 are disposed on top edges of thecolumns 1 in a specific floor. Thesecondary beam 3 is mounted between two adjacentmain beams 2. The end faces of thesecondary beam 3 abut against sidewalls of themain beams 2. At a position where the sidewall of themain beam 2 connects thesecondary beam 3 is provided with an opening 25, so that the reinforcing bars at the top portion of thesecondary beam 3 can conveniently pass therethrough. - As shown in

Fig. 7 , a reinforcingbar connector 78 is provided in advance at a lower position of a junction between themain beam 2 and each of thesecondary beams 3 located at left and right sides of themain beam 2, and is connected to a reinforcingbar 77 provided in a prefabricated part of themain beam 2. Before concrete is cast in-situ, a reinforcingbar 93 provided in therecess 34 at the end portion of thesecondary beam 3 is connected to a corresponding reinforcingbar connector 78, thereby achieving connection between the reinforcingbar 77 provided in the prefabricated part of themain beam 2 and the reinforcingbar 93 for the cast-in-situ part at the end portion of thesecondary beam 3. And a connectingbar 79 is provided at a top portion of the cast-in-situ part at the end portion of thesecondary beam 3 located at one side of themain beam 2, passes along a bottom portion of a reinforcing bar provided at the top portion of themain beam 2, and extends to thesecondary beam 3 located at the other side of themain beam 2. Two ends of the connectingbar 79 partially overlap reinforcingbars 92 provided at the top portions of the cast-in-situ parts of the left and rightsecondary beams 3, respectively. The end portions of thesecondary beams 3 are provided with exposedreserve stirrups 94, which extend from the prefabricated parts of thesecondary beams 3. Thesestirrups 94connect reinforcing bars 91 provided in the prefabricated part of thesecondary beam 3 with the reinforcingbars secondary beam 3, and enclose them. The reinforcing bars 93, 79, and 92 may be arranged in the recesses of thesecondary beams 3 at a prefabrication factory in advance, then directly pulled or inserted, after the main beams and secondary beams are mounted at the construction site, into corresponding positions, bundled in series, and then fixed. - As shown in

Fig. 5 , at a connecting node between themain beam 2 and anend column 1, connectingbars main beam 2. The lower connectingbar 73 has one end extending into thecolumn 1 connected thereto and being bent upwardly. The upper connectingbar 74 has one end extending similarly into thecolumn 1 connected thereto and being bent downwardly, and another end partially overlapping a reinforcingbar 72 provided at a cast-in-situ concrete part at an upper portion of themain beam 2. The end portion of themain beam 2 is provided with exposedreserve stirrups 75, which extend from the prefabricated part of themain beam 2. Thesestirrups 75 connect the reinforcingbar 71 provided in the prefabricated part of themain beam 2 with the reinforcingbars main beam 2, and enclose them. The reinforcing bars 72, 73, and 74 may be arranged in the recesses of themain beam 2 at a prefabrication factory in advance, and directly pulled or inserted, after themain beam 2 is mounted at the construction site, into the corresponding positions, bundled in series, and then fixed. - As shown in

Fig. 6 , at connecting nodes between thecolumn 1 and themain beams 2 located at left and right sides of thecolumn 1, connectingbars main beam 2 located at one side of thecolumn 1, pass through thecolumn 1, and extend to themain beam 2 located at the other side of thecolumn 1. Two ends of the upper connecting 81 partially overlap the reinforcingbars 72 provided at the top portions of the cast-in-situ parts of the left and rightmain beams 2, respectively. The end portions of each of themain beams 2 located at both sides of thecolumn 1 are provided with exposedreserve stirrups 76, which extend from the prefabricated part thereof. Thesestirrups 76 connect the reinforcingbars 71 provided in the prefabricated parts of themain beams 2 with the reinforcingbars main beam 2 at a prefabrication factory in advance, and directly pulled or inserted, after themain beam 2 is mounted at the construction site, into the corresponding positions, bundled in series, and then fixed. -

Figs. 8-10 schematically show the structure of thecolumn 1 according to examples of the present invention. - In a first example, as shown in

Fig. 8 , thecolumn 1 of this example is a prefabricated column having a reinforced concrete structure made by one-piece prefabrication, comprising prefabricated concrete and reinforcing bars arranged therein. - The reinforcing bars inside the

column 1 may be exposed to a certain length from the top of thecolumn 1. The exposed portions, referred to as exposed reinforcingbars 11, are used for connection with an upper building structure. - The bottom of the

column 1 is provided with a to-be-cast structure 12, which is provided therein with reserve connecting bars 13. Optionally, the sidewalls of thecolumn 1 are inwardly recessed at the lower end thereof, so that the recessed portion forms the to-be-cast structure 12. The recessed portion may be formed such that four sidewalls of thecolumn 1 are all recessed inwardly to a certain depth at a region of the lower end of thecolumn 1, or only part of them is recessed inwardly to a certain depth. The depth of the recessed portion is preferably selected to expose the reinforcing bars inside thecolumn 1. The exposed reinforcing bars in the to-be-cast structure 12 are called as reserve connecting bars, for connection with a lower building structure. The to-be-cast structure 12 can be cast in-situ with concrete, so as to achieve the connection to the lower building structure. - In order to increase the bonding force between the prefabricated concrete and the in-situ-cast concrete, in a preferred embodiment, the inner wall of the to-

be-cast structure 12 is beveled, thus increasing the contact area between the prefabricated concrete and the in-situ-cast concrete. In this manner, the bonding force therebetween can be further improved. - The use of this to-be-cast structure facilitates the pouring of concrete and the integrated production of the prefabricated column at the factory, improves the overall prefabrication rate, and thus is advantageous for production and transportation.

- Optionally, the

reserve connecting bars 13 in the to-be-cast structure 12 include vertical reinforcingbars 131 andtransverse stirrups 132. The vertical reinforcingbars 131 and the exposedreserve reinforcing bars 11 may be formed by exposed ends of the reinforcing bars inside thecolumn 1, respectively. - Referring to

Fig. 9 , when thecolumn 1 is installed on thelower building structure 14, the exposed reinforcingbars 141 on the top of thelower building structure 14 are inserted into the to-be-cast structure 12, which is poured with concrete to achieve the connection between thecolumn 1 and thelower building structure 14. - Optionally, before the concrete is poured, the

reserve connecting bars 13 in the to-be-cast structure 12 are firstly connected with the exposed reinforcingbars 141 on the top of thelower building structure 14, and fixed therewith by stirrups. Then, a template is established at the to-be-cast structure 12 and concrete is poured, thus connecting the prefabricated column with thelower building structure 14. - Optionally, before the

column 1 is installed on thelower building structure 14, a cement mortar layer may be disposed between a bottom surface of thecolumn 1 and a top surface of thelower building structure 14, thus realizing a close connection between thecolumn 1 and thelower building structure 14. - Referring to

Fig. 10 , when theupper building structure 15 is formed or mounted on thecolumn 1, the exposedreserve reinforcing bars 11 on the top of thecolumn 1 are inserted into theupper building structure 15, with top ends thereof being exposed from the top of theupper building structure 15. The exposed portions of the reinforcingbars 11 are used as exposed reinforcingbars 151 at the top of theupper building structure 15. In this manner, a firm connection between the prefabricated column and the building structures can be achieved. - In addition, optionally, one or more sidewalls of the

column 1 may be provided in advance with a decorative surface layer, so as to reduce the workload of subsequent on-site construction. - As described above, the member to be cast at the bottom of the prefabricated column can be formed as a toothed joint. The top and bottom of the prefabricated column are both provided with exposed reinforcing bars. The top of a lower prefabricated column can be formed into one piece with the cast-in-situ beam. In addition, the exposed steel bars at the top of the lower prefabricated column can be connected with the reserve connecting bars at the bottom of the upper prefabricated column, tied together by wires, and then fixed by stirrups. The upper and lower prefabricated columns can be connected with each other into one piece by establishing a template on the outer part of the prefabricated columns and then casting concrete therewith.

- According to the novel prefabricated frame of the present invention, the prefabricated column, the prefabricated main beam, the prefabricated secondary beam, and the prefabricated floor slab are used, thereby remarkably reducing the amount of construction work on site, reducing pollution and waste, and saving labor forces significantly. Thus the construction efficiency can be effectively improved, and the duration can thus be shortened.

- The foregoing is merely preferred embodiments of the present invention, but is not intended to be limitation of the present invention. It will be apparent to those skilled in the art that various changes and modifications can be made to the present invention..

Claims (6)

- A prefabricated frame, comprising at least one column (1), at least one main beam (2) connected to the column (1), at least one secondary beam (3) connected to the main beam (2), and a floor (5),wherein the column (1), the main beam (2) and the secondary beam (3) are all prefabricated members, and the main beam (2) and the secondary beam (3) are both provided with, on respective top portions thereof, exposed reserve reinforcing bars, and reinforcing bars for cast-in-situ parts,wherein the floor (5) is a laminated plate having a prefabricated slab (51) at a lower portion thereof, and the prefabricated slab (51), the main beam (2), and the secondary beam (3) are connected together by means of in-situ casting concrete on respective top portions thereof,wherein the column (1) is a prefabricated column having exposed reserve reinforcing bars (11) at a top thereof and a to-be-cast structure (12) at a bottom thereof, the to-be-cast structure (12) being provided therein with reserve connecting bars (13), which include vertical reinforcing bars (131) and transverse stirrups (132),wherein the to-be-cast structure (12) is used for connection with a lower building structure (14), which has exposed reinforcing bars (141) that are located under the column and inserted into the to-be-cast structure (12), a connection between the column (1) and the lower building structure (14) being achieved by casting in-situ concrete in the to-be-cast structure (12),characterized in thatthe exposed reinforcing bars (141) of the lower building structure are overlapped and bundled with the reserve connecting bars of the to-be-cast structure (12), whereby the vertical reinforcing bars (131) are connected with the exposed reinforcing bars (141), and fixed therewith by the transverse stirrups (132), so that the column (1) and the lower building structure (14) are connected with each other through establishing a template outside of the to-be-cast structure (12) and pouring concrete therewith, andwherein the column (1) is recessed inwardly at one or more lower sidewalls thereof to form the to-be-cast structure (12).

- The prefabricated frame according to claim 1, wherein inner wall of the to-be-cast structure is beveled.

- The prefabricated frame according to claim 1, wherein the exposed reserve reinforcing bars on the top of the column (1) are higher than the main beam (2) and the floor (5).

- The prefabricated frame according to claim 1, wherein at a connection node between the main beam (2) and a column (1) located at one end of the frame, the cast-in-situ portion at one end of the main beam (2) is provided with upper and lower connecting bars, each of the connecting bars being bent at a free end thereof.

- The prefabricated frame according to claim 1, wherein at connection nodes between the column (1) and two main beams (2) to a right side and to a left side thereof, the cast-in-situ parts at one end of one of said two main beams (2) is provided with upper and lower connecting bars, which pass above the column (1) and extend to the other of said two main beams (2), and both ends of the upper connecting bars are connected to reinforcing bars arranged on top of the cast-in-situ parts of said two main beams (2), respectively.

- The prefabricated frame according to claim 1, wherein a cement mortar layer is disposed between a bottom surface of the column (1) and the lower building structure.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811551493.2A CN109403458A (en) | 2018-12-18 | 2018-12-18 | Novel pre-fabricated one |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3670778A1 EP3670778A1 (en) | 2020-06-24 |

| EP3670778C0 EP3670778C0 (en) | 2024-07-03 |

| EP3670778B1 true EP3670778B1 (en) | 2024-07-03 |

Family

ID=65459988

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19172996.1A Active EP3670778B1 (en) | 2018-12-18 | 2019-05-07 | Prefabricated frame |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20200190799A1 (en) |

| EP (1) | EP3670778B1 (en) |

| CN (1) | CN109403458A (en) |

| AU (1) | AU2019203356A1 (en) |

| SG (1) | SG10201902337QA (en) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109853739B (en) * | 2019-02-27 | 2020-06-23 | 青岛理工大学 | Assembled steel-wood combined node |

| CN110616808B (en) * | 2019-09-04 | 2020-07-14 | 青岛理工大学 | Assembled floor type steel-wood combined node and assembling method thereof |

| CN110644619B (en) * | 2019-09-21 | 2020-10-09 | 青岛理工大学 | Assembly type limiting reinforced steel-wood frosted sleeve combined node |

| CN113863574A (en) * | 2020-06-30 | 2021-12-31 | 振中建设集团有限公司 | Assembly type bearing beam structure and construction method |

| CN111927090B (en) * | 2020-08-10 | 2021-10-22 | 湖南省第六工程有限公司 | Steel pipe support construction structure of beam type conversion layer of high-rise building and construction method thereof |

| CN112049245A (en) * | 2020-08-26 | 2020-12-08 | 广东九万里建设集团有限公司 | Fully-assembled prestressed concrete frame and construction method |

| CN112081308A (en) * | 2020-09-30 | 2020-12-15 | 中国电建集团贵阳勘测设计研究院有限公司 | Detachable self-locking connecting structure for assembly type building and using method thereof |

| CN114319677A (en) * | 2020-09-30 | 2022-04-12 | 王皇凰 | Building structure capable of increasing building use clear height and facilitating pipeline installation |

| CN112095780A (en) * | 2020-10-22 | 2020-12-18 | 中铁上海设计院集团有限公司 | Upper cover structure system applied to track operation line and implementation method thereof |

| CN112593632A (en) * | 2020-12-04 | 2021-04-02 | 中天建设集团有限公司 | Fabricated beam-slab structure suitable for large-span high-clearance building and construction method thereof |

| CN112878511B (en) * | 2021-04-02 | 2022-07-08 | 陕西建工集团股份有限公司 | Special-shaped assembled frame beam column node connecting system |

| CN113152762B (en) * | 2021-04-06 | 2022-05-20 | 江苏华源建筑设计研究院股份有限公司 | Connecting structure of assembled building laminated slab and cast-in-place slab and construction process of connecting structure |

| CN113293871A (en) * | 2021-05-14 | 2021-08-24 | 广东省建科建筑设计院有限公司 | Assembled concrete beam column joint with concrete prefabricated rectangular pipe pile as upper column |

| CN113653177A (en) * | 2021-08-26 | 2021-11-16 | 刘钦 | Building preassembling structure and mounting method thereof |

| CN113700194A (en) * | 2021-09-07 | 2021-11-26 | 天津一冶建设工程有限公司 | Assembly type beam-slab connecting structure and construction method thereof |

| CN114475964B (en) * | 2021-12-13 | 2024-10-01 | 海洋石油工程(青岛)有限公司 | Rapid assembling leveling device for deck sheet steel of marine structure |

| CN114000708A (en) * | 2021-12-21 | 2022-02-01 | 中建八局第二建设有限公司 | Installation method and installation support frame of truss composite slab |

| CN114278019B (en) * | 2021-12-30 | 2023-07-07 | 中建八局第一建设有限公司 | Assembled roof frame and preparation process and construction method thereof |

| CN114908794B (en) * | 2022-04-12 | 2023-05-16 | 中铁二院工程集团有限责任公司 | Assembled building method of subway station |

| CN114922428A (en) * | 2022-05-16 | 2022-08-19 | 吉林省新生建筑工程有限公司 | Wall module pre-assembly method assembly type building construction method |

| CN114991301B (en) * | 2022-05-17 | 2023-11-28 | 中建科技集团有限公司 | Mould-free and support-free assembled reinforced concrete structure system and assembling method thereof |

| CN115012444B (en) * | 2022-06-06 | 2024-04-12 | 中国铁路设计集团有限公司 | Cross beam-free through high V-shaped column node structure and construction method |

| CN115233811B (en) * | 2022-07-12 | 2024-08-30 | 中冶赛迪工程技术股份有限公司 | Building frame |

| CN115233814B (en) * | 2022-07-12 | 2024-08-30 | 中冶赛迪工程技术股份有限公司 | Fastening connection structure for building |

| CN115370198A (en) * | 2022-09-23 | 2022-11-22 | 中铁建工集团有限公司 | Construction method and structure of assembled canopy |

| CN115781888B (en) * | 2022-11-24 | 2024-02-20 | 黄骅市华悦商砼有限公司 | Splicing structure of concrete prefabricated parts and construction method |

| CN117803075B (en) * | 2024-02-29 | 2024-05-10 | 河南幻彩机电工程有限公司 | Assembled steel construction building structure system |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108035438A (en) * | 2018-01-24 | 2018-05-15 | 西安建筑科技大学 | A kind of concrete assembled frame structure system of high-strength high ductility and connection method |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101660327B (en) * | 2008-08-29 | 2011-07-20 | 万科企业股份有限公司 | Connecting structure of precast concrete secondary beam and main beam, construction method and building |

| JP2014051798A (en) * | 2012-09-06 | 2014-03-20 | Splice Sleeve Japan Ltd | Joint construction method of reinforcing-bar |

| CN203174770U (en) * | 2013-04-19 | 2013-09-04 | 深圳海龙建筑制品有限公司 | Connection structure of prefabricated column and construction site base and building |

| CN104452961A (en) * | 2014-12-08 | 2015-03-25 | 上海应用技术学院 | Rural low-rise assembled damping building structure system |

| CN104563299B (en) * | 2015-01-15 | 2017-10-24 | 建研科技股份有限公司 | Reinforced concrete prefabricated component and mounting method |

| CN204940527U (en) * | 2015-04-23 | 2016-01-06 | 普瑞康建筑材料(临沂)有限公司 | With the precast member for reinforcing bar concrete that indeterminate node connects |

| CN105350641B (en) * | 2015-11-20 | 2017-12-22 | 上海建工五建集团有限公司 | Suitable for the framework column connected node and its construction technology of prefabrication and assembly construction building |

| CN105421632B (en) * | 2015-12-23 | 2018-02-06 | 上海欧本钢结构有限公司 | Prompt about floor system and its construction method |

| CN106638947A (en) * | 2016-12-20 | 2017-05-10 | 有利华建材(惠州)有限公司 | Prefabricated frame structure and cascaded prefabrication construction method thereof |

| CN206737141U (en) * | 2017-04-14 | 2017-12-12 | 李凯伦 | A kind of bolt connection assembled integral node |

| CN107227870B (en) * | 2017-07-25 | 2024-01-09 | 深圳供电局有限公司 | Substation building spliced by prefabricated parts |

| CN207919746U (en) * | 2018-01-24 | 2018-09-28 | 西安建筑科技大学 | A kind of prefabricated node of high-strength high concrete assembled frame of ductility |

| CN108331158B (en) * | 2018-01-25 | 2020-05-08 | 浙江大学建筑设计研究院有限公司 | On-site connection method of prefabricated reinforced concrete beam column |

| CN108930360A (en) * | 2018-04-29 | 2018-12-04 | 山东德建集团有限公司 | Exposed inversion reinforcing bar grout sleeve precast concrete column and construction method |

| CN108678445A (en) * | 2018-07-06 | 2018-10-19 | 上海天华建筑设计有限公司 | A kind of structure of workshop |

| CN209397710U (en) * | 2018-12-18 | 2019-09-17 | 有利华建材(惠州)有限公司 | Novel pre-fabricated one |

-

2018

- 2018-12-18 CN CN201811551493.2A patent/CN109403458A/en active Pending

-

2019

- 2019-03-15 SG SG10201902337QA patent/SG10201902337QA/en unknown

- 2019-05-07 EP EP19172996.1A patent/EP3670778B1/en active Active

- 2019-05-14 AU AU2019203356A patent/AU2019203356A1/en not_active Abandoned

- 2019-06-27 US US16/455,418 patent/US20200190799A1/en not_active Abandoned

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108035438A (en) * | 2018-01-24 | 2018-05-15 | 西安建筑科技大学 | A kind of concrete assembled frame structure system of high-strength high ductility and connection method |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3670778C0 (en) | 2024-07-03 |

| US20200190799A1 (en) | 2020-06-18 |

| CN109403458A (en) | 2019-03-01 |

| AU2019203356A1 (en) | 2020-07-02 |

| EP3670778A1 (en) | 2020-06-24 |

| SG10201902337QA (en) | 2020-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3670778B1 (en) | Prefabricated frame | |

| CN102808465B (en) | Assembly connecting structure and assembly connecting method of assembled concrete frame and shear wall combination | |

| CN105442727A (en) | Compound type connection shear wall structure and assembling method thereof | |

| CN108678220B (en) | Concrete shear wall with integrally installed reinforcing steel bar templates | |

| CN113529956A (en) | Shear wall box type assembly type building structure and construction method thereof | |

| CN107313507B (en) | Construction method for node structure of fabricated concrete frame overhead core column | |

| KR20140110490A (en) | Half precast concrete column manufacturing method using prefabricated PC panels and constructing method using the same | |

| CN113374171B (en) | Recycled block concrete prefabricated assembled ring beam structure and construction method thereof | |

| KR102484159B1 (en) | Rapid Construction Structure of Core Part Using Multi-Story Precast Wall | |

| CN212453065U (en) | Assembled building frame structure member | |

| KR20140110491A (en) | Half precast concrete column manufacturing method using saddle-type ties and dual hoops and constructing method using the same | |

| KR100226168B1 (en) | Architecture and method for making a stair using a precast concrete | |

| CN105952044B (en) | Fully-prefabricated prestressed concrete floor structure and prestressed assembly method | |

| CN211312950U (en) | Assembled integral elevator shaft prefabricated part | |

| CN210031897U (en) | Fan foundation and wind generating set | |

| CN111877626A (en) | Overhead laminated slab construction structure and construction method | |

| CN216239326U (en) | Vertical half grout sleeve grout connects full assembled RC wallboard structure | |

| KR101324884B1 (en) | Hybrid building construction method combining dry type and wet type | |

| CN215716062U (en) | Connection node of assembled concrete shear wall edge member | |

| CN210597875U (en) | Cross beam | |

| CN110778011B (en) | Concrete precast slab, connecting structure and construction method thereof | |

| CN210421625U (en) | Cast-in-place combination beam structure of assembled | |

| JP2959325B2 (en) | Construction method of steel frame reinforced concrete structure | |

| CN115419196B (en) | UHPC wet joint prefabricated double-sided superimposed shear wall for nuclear power plant and method | |

| JPH1113189A (en) | Half-precast floor slab and floor structure using the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20201118 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20221107 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20240131 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602019054461 Country of ref document: DE |

|

| U01 | Request for unitary effect filed |

Effective date: 20240801 |

|

| U07 | Unitary effect registered |

Designated state(s): AT BE BG DE DK EE FI FR IT LT LU LV MT NL PT SE SI Effective date: 20240816 |