EP2976591B1 - Barrel opening mechanism of grenade launcher - Google Patents

Barrel opening mechanism of grenade launcher Download PDFInfo

- Publication number

- EP2976591B1 EP2976591B1 EP14769600.9A EP14769600A EP2976591B1 EP 2976591 B1 EP2976591 B1 EP 2976591B1 EP 14769600 A EP14769600 A EP 14769600A EP 2976591 B1 EP2976591 B1 EP 2976591B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- barrel

- pivot

- grenade launcher

- pin

- latch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 claims description 6

- 230000000994 depressogenic effect Effects 0.000 claims description 3

- 238000013461 design Methods 0.000 description 3

- 210000003811 finger Anatomy 0.000 description 3

- 238000010304 firing Methods 0.000 description 2

- 210000003813 thumb Anatomy 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A9/00—Feeding or loading of ammunition; Magazines; Guiding means for the extracting of cartridges

- F41A9/38—Loading arrangements, i.e. for bringing the ammunition into the firing position

- F41A9/45—Loading arrangements, i.e. for bringing the ammunition into the firing position the cartridge chamber or the barrel as a whole being tiltable or transversely slidable between a loading and a firing position

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A3/00—Breech mechanisms, e.g. locks

- F41A3/02—Block action, i.e. the main breech opening movement being transverse to the barrel axis

- F41A3/04—Block action, i.e. the main breech opening movement being transverse to the barrel axis with pivoting breech-block

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A3/00—Breech mechanisms, e.g. locks

- F41A3/58—Breakdown breech mechanisms, e.g. for shotguns

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A35/00—Accessories or details not otherwise provided for

- F41A35/06—Adaptation of guns to both right and left hand use

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41C—SMALLARMS, e.g. PISTOLS, RIFLES; ACCESSORIES THEREFOR

- F41C27/00—Accessories; Details or attachments not otherwise provided for

- F41C27/06—Adaptations of smallarms for firing grenades, e.g. rifle grenades, or for firing riot-control ammunition; Barrel attachments therefor

Definitions

- the present invention relates to a barrel opening mechanism for loading and unloading of cartridges into a barrel of a grenade launcher.

- a grenade launcher may be a standalone device or detachably mounted below a rifle.

- the grenade launcher uses a spin-stabilised 40 mm cartridge.

- a conventional grenade launcher may employ different methods of opening the barrel: longitudinal sliding opening; lateral swinging to the left hand, to the right hand side, downward or upward; and a combination of longitudinal sliding followed by a lateral swing. These methods of opening the barrel involve many components and often only designed for a right- or left-handed operator; in other words, these conventional grenade launchers are often not ambidextrous.

- US 7,487,612 assigned to FN Herstal S.A., discloses two sliding blocks (13, 14) operable to slide with two longitudinal slides (17) such that the barrel is advanced in a first longitudinal direction and swiveled laterally in the final phase of the longitudinal movement.

- US 3,641,691 assigned to the US Army, discloses a grenade launcher in which the barrel is pivotable downwardly to a 15 degree angle and an ejector rod is used to eject the used cartridge. When the barrel is closed, the firing mechanism is automatically locked in the firing position.

- the present invention seeks to provide a barrel opening mechanism for a grenade launcher that is ambidextrous in operation yet designed with a minimum number of components.

- the Picatinny rail on the top portion of the barrel is configured to transfer recoil forces from the grenade launcher to a supporting rifle it is connected to.

- the present invention provides a receiver body, which is substantially an inverted L-shaped, with a forward pointing arm and a proximal arm, wherein the proximal arm is configured for housing a trigger mechanism; and a barrel connected below the forward pointing receiver arm by a barrel pivot and a latch mechanism; wherein the latch mechanism comprises a latch disposed in the forward receiver arm and is operable to engage with a catch disposed on a top portion of the barrel so that: when the latch is engaged with the catch when the barrel is in a closed position and longitudinal X-axes of both the barrel and the forward receiver arm are substantially parallel, and when the latch is actuated by an appendage of a left or right hand of a user supporting the barrel, the latch becomes released from the catch, thereby allowing the barrel to droop or pivot away from the forward receiver arm about a transverse Y-axis at the barrel pivot and a chamber end of the barrel is operable to be turned laterally to the left or right hand side about a vertical Z-axis

- the present invention provides a method of opening a barrel release and lock mechanism of a grenade launcher.

- This method comprises: supporting a barrel of a grenade launcher with a left or right hand of a user; using an appendage of said left or right hand to push a lever portion that protrudes on each of two sides of a receiver arm to release a barrel latch, thereby allowing a chamber end of the barrel to droop about a transverse Y-axis of a barrel pivot disposed near a distal end of the receiver arm; turning said barrel with said appendage of the left or right hand so that the chamber end of the barrel is turned laterally to the left or right side of the receiver arm about a vertical Z-axis of the barrel pivot to allow the user to load or unload a cartridge into/from the chamber end of the barrel; and laterally turning the barrel back to align the barrel with the receiver arm and then pivoting the barrel back to the receiver arm to release a spring-loaded pin so that the barrel latch is engageable with

- the barrel pivot comprises a substantially cylindrical pivot pin that is journaled in the forward receiver arm to pivot about the Z-axis and a clevis pin pivotable about the Y-axis, with the clevis pin passing through a bore on the pivot pin and the clevis pin being supported by a pair of clevises disposed on a top surface of the barrel.

- the clevis pin allows the barrel to pivot substantially 5 degree angle away from the X-axis whilst the pivot pin allows the barrel to be turned laterally to the left or right hand side of the receiver body by substantially 20 degree.

- the barrel opening mechanism comprises a barrel pivot direction lockout pin or selector.

- the barrel opening mechanism has two notches formed on its cylindrical surface, with the notches being angularly oriented with respect to each other and a paw extending from the pivot pin is restricted to move within a length of the selected notch, so that the direction of swivel of the barrel chamber end is selectable depending on whether the user is right-handed or left-handed.

- the latch mechanism comprises a spring-loaded release pin, which allows the latch to engage with the catch only when the catch is received in the recess and the spring-loaded release pin is depressed.

- the latch also comprises a hook configured integrally on a pivoted lever, such that a lever portion projects out on a left hand side of the forward receiver arm and another lever portion projects out on the right hand side of the forward receiver arm and the hook is engageable with a slot formed on the catch.

- a closed end of a Picatinny rail formed along an upper portion of the forward receiver arm is disposed a stopper plate.

- the stopper plate is located substantially above the barrel pivot and it keeps the pivot pin in position and at the same time transfer recoil forces from the grenade launcher to a supporting rifle mounted at the Picatinny rail.

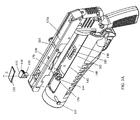

- FIGs. 1A and 1B show a grenade launcher 100 employing a barrel opening mechanism 105 according to the present invention.

- the barrel opening mechanism 105 includes a barrel pivot 150 and a barrel latch mechanism 170.

- the barrel opening mechanism 105 can be used in any single-shot gun, as exemplified by a grenade launcher.

- the grenade launcher 100 includes a receiver body 110, a barrel 130 being connected to the receiver body 110 by the barrel pivot 150 and latch mechanism 170, a barrel sleeve 140 and a lock sleeve 132 to lock the barrel sleeve 140 to the barrel 130.

- the receiver body 110 is substantially inverted L-shaped, with a forward pointing arm 110a provided to support the barrel 130, and the other proximal arm 110b for housing a trigger mechanism, with a portion being shaped for handgrip or as a butt stock.

- the barrel pivot 150 is pivotable about two orthogonal axes, that is, a Y-axis transverse to the receiver arm 110a and a Z-axis perpendicular to the receiver arm 110a, with a longitudinal X-axis along a length of the receiver arm.

- the latch mechanism 170 includes a pivoted lever 172 mounted inside the receiver arm 110a and a catch 180 disposed on a top surface of the barrel. In the normal barrel closed position, the lever 172 engages with the catch 180.

- the lever 172 extends on both sides of the receiver arm 110a (as seen more clearly in FIG. 3B ) so that it can be actuated with a thumb or finger of one's hand supporting the barrel 130.

- a chamber end 134 of the barrel into which a projectile is inserted

- the barrel 130 is supported only at the barrel pivot 150, as seen more clearly in FIG. 2A .

- the drooped barrel is no longer in contact with any part of the receiver body 110 and is free to be turned laterally to the left or right hand side of the receiver body 110 about the Z-axis at the pivot 150.

- the barrel 130 is operable to be turned laterally to the left or right side of the receiver body 110 by substantially 20 degree about the pivot 150 such that the projectile can be loaded or unloaded at the chamber end 134 of the barrel 130 without obstruction by the receiver arm 110b, as seen more clearly in FIGs. 2B , 2C , 2D , 4B and 4C .

- FIG. 3A shows an exploded view of the barrel opening mechanism 105.

- the pivot 150 is made up of a pivot pin 152, a pair of clevises 156 and a clevis pin 157.

- the pivot pin 152 is substantially cylindrical in shape along the Z-axis but has two parallel flat surfaces 153 to cooperate with the pair of clevises 156.

- a top part of the pivot pin 152 has a lateral projection 154 so that the lateral projection 154 is received in the receiver arm 110a for pivotal movement about the Z-axis.

- a stopper plate 122 mounted at the end of a Picatinny rail 120 formed on an upper surface of the receive arm 110a, keeps the pivot pin 152 pivotable in the receiver arm 110a.

- the clevis pin 157 goes through a bore on the clevises 156 and another bore through the pivot pin 152 to allow the barrel to pivot about the Y-axis.

- the pivot 150 allows the barrel 130 to tilt or droop substantially 5 degree from the X-axis and at the same time be pivotable laterally to the left- or right-hand side of the receiver body 110 by substantially 20 degree.

- An advantage of the present invention is that when the barrel 130 is in the open position, the chamber end 134 is unobstructed for loading and unloading of a projectile; this means that the barrel chamber is suitable to receive projectiles of a predetermined design but of varied lengths, thus ensuring the grenade launcher 100 incorporating the barrel opening mechanism 105 is usable with future projectiles that may be longer in lengths.

- the other advantage of the present invention is that the barrel 130 is pivotable to the left- or right-hand side of the receiver body 110, thus making the grenade launcher ambidexterous.

- the barrel sleeve 140 has an open channel 142 formed on the top, longitudinal portion as seen in the figures.

- the open channel 142 is as wide as the distance between the outside faces of the clevises 156 or length of the clevis pin 157.

- the width of the open channel 142 is substantially wider that the distance between the clevises or length of the clevis pin 157 but the edges of the open channel 142 are provided with a pair of projections 144, which are spaced apart to accommodate the distance between the clevises 156 or length of the clevis pin 157.

- tolerance of the width between the pair of projections 144 need only to be controlled instead of along the entire length of the open channel 142.

- the pair of projections 144 locate the clevis pin 157 in the clevises 156; with this arrangement, there is no need to provide any locking mechanism for the clevis pin 157, thus allowing the number of components of the barrel opening mechanism 105 to be reduced and further simplifying this mechanism.

- the latch mechanism 170 includes the lever 172 and the cooperating catch 180 disposed on the top surface of the barrel 130 along the longitudinal X-axis.

- FIG. 3C shows a cut-out portion of the latch mechanism 170 and shows the lever 172 has a portion being formed with a hook 174 to engage with a slot 182 formed on the catch 180.

- the lever 172 is biased in the normal, engaged position by a spring 176.

- the catch 180 extends out of the top surface of the barrel 130 but when the barrel is in the closed position, the catch 180 is received into the receiver arm 110a within a cavity located below the lever 172, as seen more clearly in FIG.

- a spring-loaded pin 178 (not shown in the figures) is extended to prevent the lever 172 from returning to its original position after the latch mechanism 170 is activated and the barrel 130 is released from its connection at the catch 180 with the receiver arm 110a; in other words, the spring-loaded pin 178 is provided to prevent the hook 174 from re-engaging with the slot 182 until the barrel 130 is returned to its closed position, the catch 180 is fully received into its cavity below the receiver arm 110a and the spring loaded pin 178 is depressed.

- the spring-loaded pin 178 serves as a very important safety lock to ensure that the barrel 130 is connected to the receiver arm 110a by the latch mechanism 170 before the grenade launcher 100 is deployed.

- the latch mechanism 170 is spaced apart from the pivot 150.

- the latch mechanism 170 such as the parts of the lever 172 that projects out of the receiver arm 110a are located substantially forward with respect to the trigger guard 136. This allows a user to support the grenade launcher 100 with one hand at a position forward of the trigger guard 136 yet allowing a finger or thumb of the same hand to actuate the latch lever 172, with the other hand on the handgrip and its finger to activate the trigger.

- a transverse lock pin 210 is disposed across the Picatinny rail 120 to lock a matching male component of the Picatinny rail disposed on a rifle 200 (as seen in FIG. 1 C) to which the grenade launcher 100 is to be mounted to.

- the free end of the male component of the rifle's Picatinny rail is in butt contact with a thickness edge of the stopper plate 122 such that locking of the two Picatinny rail components at the lock pin 210 has a clearance fit.

- the lock pin 210 is used to lock together the two components of the Picatinny rail when the grenade launcher 100 is mounted below the rifle 200 but does not take up any recoil forces during deployment. For this reason, the lock pin 210 is relatively small in size of substantially 2 to 3 mm square in cross-section.

- FIGs. 5A and 5B show exploded views of the above grenade launcher 100 incorporating a barrel pivot direction lockout pin or selector 160.

- the pivot direction lockout pin or selector 160 is disposed on the receiver arm 110a parallel to and at a distance aft of the clevis pin 157.

- the direction lockout pin 160 has two notches 162a, 162b formed on the cylindrical surface, with the notches 162a, 162b being angularly oriented with each other; preferably, the notches 162a, 162b are substantially 90 degrees oriented to each other.

- a paw 158 extending laterally from a pivot pin 152a (which is a variation of the above pivot pin 152).

- the direction lockout pin 160 extends out of the width of the receiver arm 110 and each end terminates with a knurled knob 164.

- Each knurled knob 164 may be located on the direction lockout pin 160 by means of a locking pin 166.

- a user By turning the knurled knob 164, a user sets the rotational orientation of the direction lockout pin or selector 160 so that the paw 158 engages with the notch 162a or 162b; in effect, the direction of barrel swivel to the left- or right-hand side of the receiver arm 110a is restricted by the paw 158 moving within a length of the notch 162a or 162b.

- the user selectively determines the direction of swivel of the barrel 130 to the left- or right-hand side of the receiver arm 110a by setting the direction lockout pin or selector 160 in a clockwise or anti-clockwise position 5 depending on whether the user is right-handed or left-handed. For illustration, FIG.

- FIG. 5C shows a left-handed user (ie. left hand on the hand-grip or butt 110b) and the position lockout pin 160 being set so that the paw 158 engages with the notch 162a and the chamber end 134 of the barrel 130 is to the right side of the receiver arm 110a.

- FIG. 5D shows a right-handed user having set the position lockout pin 160 so that the paw 158 engages with the notch 162b and the chamber end 134 of the barrel 130 is swiveled to the left side of the receiver arm 110a.

- the barrel opening 5 mechanism of the present invention is advantageously ambidextrous.

- the grenade launcher incorporating the barrel mechanism has relatively few additional parts, so making the grenade launcher still relatively light.

- Another advantage of the present invention is that no tools are required to dismantle the barrel opening mechanism 105 or the entire barrel 130, for example, for cleaning. For example, by unscrewing the lock sleeve 132 from the barrel 130, the barrel sleeve 140 can be removed from the barrel 130, thereby allowing the clevis pin 157 to be removed and the entire barrel 130 to be dismantled from the receiver body 110. In the same manner, no tools are required to re-assemble the barrel opening mechanism or barrel onto the receiver body.

- the above barrel opening mechanism 105 can be used on any single-shot gun, such as, a shotgun, irrespective of it being single- or double-barrel and its barrel size.

- the spring-loaded pin 178 may be configured as a detent ball.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Toys (AREA)

- Closures For Containers (AREA)

- Aiming, Guidance, Guns With A Light Source, Armor, Camouflage, And Targets (AREA)

Description

- The present invention relates to a barrel opening mechanism for loading and unloading of cartridges into a barrel of a grenade launcher.

- A grenade launcher may be a standalone device or detachably mounted below a rifle. For example, the grenade launcher uses a spin-stabilised 40 mm cartridge. A conventional grenade launcher may employ different methods of opening the barrel: longitudinal sliding opening; lateral swinging to the left hand, to the right hand side, downward or upward; and a combination of longitudinal sliding followed by a lateral swing. These methods of opening the barrel involve many components and often only designed for a right- or left-handed operator; in other words, these conventional grenade launchers are often not ambidextrous. For example,

US 7,487,612 , assigned to FN Herstal S.A., discloses two sliding blocks (13, 14) operable to slide with two longitudinal slides (17) such that the barrel is advanced in a first longitudinal direction and swiveled laterally in the final phase of the longitudinal movement. - In another example,

US 3,641,691 , assigned to the US Army, discloses a grenade launcher in which the barrel is pivotable downwardly to a 15 degree angle and an ejector rod is used to eject the used cartridge. When the barrel is closed, the firing mechanism is automatically locked in the firing position. - Despite development of known grenade launchers, there exists a need for another type of barrel opening mechanism that is ambidextrous yet not complex or heavy in design.

- The following presents a simplified summary to provide a basic understanding of the present invention. This summary is not an extensive overview of the invention, and is not intended to identify key features of the invention. Rather, it is to present some of the embodiments of this invention as defined in the appended independent claim 1 in a generalised form as a prelude to the detailed description that is to follow.

- The present invention seeks to provide a barrel opening mechanism for a grenade launcher that is ambidextrous in operation yet designed with a minimum number of components. In addition, the Picatinny rail on the top portion of the barrel is configured to transfer recoil forces from the grenade launcher to a supporting rifle it is connected to.

- In one embodiment, the present invention provides a receiver body, which is substantially an inverted L-shaped, with a forward pointing arm and a proximal arm, wherein the proximal arm is configured for housing a trigger mechanism; and a barrel connected below the forward pointing receiver arm by a barrel pivot and a latch mechanism; wherein the latch mechanism comprises a latch disposed in the forward receiver arm and is operable to engage with a catch disposed on a top portion of the barrel so that: when the latch is engaged with the catch when the barrel is in a closed position and longitudinal X-axes of both the barrel and the forward receiver arm are substantially parallel, and when the latch is actuated by an appendage of a left or right hand of a user supporting the barrel, the latch becomes released from the catch, thereby allowing the barrel to droop or pivot away from the forward receiver arm about a transverse Y-axis at the barrel pivot and a chamber end of the barrel is operable to be turned laterally to the left or right hand side about a vertical Z-axis at the barrel pivot ambidextrously, so that a cartridge can be loaded into or unloaded from the chamber end without obstruction by the proximal arm.

- In another embodiment, the present invention provides a method of opening a barrel release and lock mechanism of a grenade launcher. This method comprises: supporting a barrel of a grenade launcher with a left or right hand of a user; using an appendage of said left or right hand to push a lever portion that protrudes on each of two sides of a receiver arm to release a barrel latch, thereby allowing a chamber end of the barrel to droop about a transverse Y-axis of a barrel pivot disposed near a distal end of the receiver arm; turning said barrel with said appendage of the left or right hand so that the chamber end of the barrel is turned laterally to the left or right side of the receiver arm about a vertical Z-axis of the barrel pivot to allow the user to load or unload a cartridge into/from the chamber end of the barrel; and laterally turning the barrel back to align the barrel with the receiver arm and then pivoting the barrel back to the receiver arm to release a spring-loaded pin so that the barrel latch is engageable with a cooperating catch disposed on the barrel and the barrel becomes re-connected to the receiver arm at the latch.

- Preferably, the barrel pivot comprises a substantially cylindrical pivot pin that is journaled in the forward receiver arm to pivot about the Z-axis and a clevis pin pivotable about the Y-axis, with the clevis pin passing through a bore on the pivot pin and the clevis pin being supported by a pair of clevises disposed on a top surface of the barrel.

- Preferably, the clevis pin allows the barrel to pivot substantially 5 degree angle away from the X-axis whilst the pivot pin allows the barrel to be turned laterally to the left or right hand side of the receiver body by substantially 20 degree. Preferably, the barrel opening mechanism comprises a barrel pivot direction lockout pin or selector. The barrel opening mechanism has two notches formed on its cylindrical surface, with the notches being angularly oriented with respect to each other and a paw extending from the pivot pin is restricted to move within a length of the selected notch, so that the direction of swivel of the barrel chamber end is selectable depending on whether the user is right-handed or left-handed.

- Preferably, the latch mechanism comprises a spring-loaded release pin, which allows the latch to engage with the catch only when the catch is received in the recess and the spring-loaded release pin is depressed. The latch also comprises a hook configured integrally on a pivoted lever, such that a lever portion projects out on a left hand side of the forward receiver arm and another lever portion projects out on the right hand side of the forward receiver arm and the hook is engageable with a slot formed on the catch.

- Preferably, a closed end of a Picatinny rail formed along an upper portion of the forward receiver arm is disposed a stopper plate. The stopper plate is located substantially above the barrel pivot and it keeps the pivot pin in position and at the same time transfer recoil forces from the grenade launcher to a supporting rifle mounted at the Picatinny rail.

- This invention will be described by way of non-limiting embodiments of the present invention, with reference to the accompanying drawings, in which:

-

FIG. 1A illustrates a grenade launcher (without a barrel guard) with a barrel latch in the locked position according to an embodiment of the present invention, whilstFIG. 1B illustrates the grenade launcher with the barrel disposed partially in a barrel sleeve; -

FIG. 1C illustrates the grenade launcher can be connected to a rifle by means of a Picatinny rail; -

FIG. 2A illustrates the grenade launcher shown inFIG. 1A with the barrel latch in the released position such that the chamber side of the barrel droops downward; -

FIGs. 2B and2C illustrate the chamber side of the barrel being turned to the left hand side of the launcher; whilstFIG. 2D illustrates the chamber side of the barrel being turned to the right hand side; -

FIG. 3A illustrates an exploded view of the barrel from the receiver body showing the pivot and latch mechanism of the present invention; -

FIG. 3B illustrates a plan view of the grenade launcher shown inFIG. 1A ; -

FIG. 3C illustrates a cut-out view showing the latch mechanism, whilstFIG. 3D illustrates a sectional view showing the latch mechanism and barrel pivot; -

FIG. 4A illustrates a sectional view of the grenade launcher shown inFIG. 2A , whilstFIGs. 4B and 4C illustrate the barrel being turned respectively to the right hand and left hand sides; and -

FIGs. 5A and 5B illustrate perspective and exploded views of the grenade launcher incorporating a barrel pivot direction lockout pin or selector, whilstFIGs. 5C and 5D illustrate the chamber end of the barrel being restricted selectively to turn respectively to the right hand and left hand sides. - One or more specific and alternative embodiments of the present invention will now be described with reference to the attached drawings. It shall be apparent to one skilled in the art, however, that this invention may be practised without such specific details. Some of the details may not be described at length so as not to obscure the invention. For ease of reference, common reference numerals or series of numerals will be used throughout the figures when referring to the same or similar features common to the figures.

-

FIGs. 1A and1B show agrenade launcher 100 employing abarrel opening mechanism 105 according to the present invention. Thebarrel opening mechanism 105 includes abarrel pivot 150 and abarrel latch mechanism 170. Thebarrel opening mechanism 105 can be used in any single-shot gun, as exemplified by a grenade launcher. As shown inFIGs. 1A and1B , thegrenade launcher 100 includes areceiver body 110, abarrel 130 being connected to thereceiver body 110 by thebarrel pivot 150 andlatch mechanism 170, abarrel sleeve 140 and alock sleeve 132 to lock thebarrel sleeve 140 to thebarrel 130. Thereceiver body 110 is substantially inverted L-shaped, with aforward pointing arm 110a provided to support thebarrel 130, and the otherproximal arm 110b for housing a trigger mechanism, with a portion being shaped for handgrip or as a butt stock. Thebarrel pivot 150 is pivotable about two orthogonal axes, that is, a Y-axis transverse to thereceiver arm 110a and a Z-axis perpendicular to thereceiver arm 110a, with a longitudinal X-axis along a length of the receiver arm. Thelatch mechanism 170 includes a pivotedlever 172 mounted inside thereceiver arm 110a and acatch 180 disposed on a top surface of the barrel. In the normal barrel closed position, thelever 172 engages with thecatch 180. Thelever 172 extends on both sides of thereceiver arm 110a (as seen more clearly inFIG. 3B ) so that it can be actuated with a thumb or finger of one's hand supporting thebarrel 130. When thelatch mechanism 170 is released by momentarily pressing on thelever 172 on either side of thereceiver arm 110a, achamber end 134 of the barrel (into which a projectile is inserted) is allowed to droop substantially 5 degree from the longitudinal X-axis about the Y-axis at thebarrel pivot 150. In this drooped-down or open pivoted position, thebarrel 130 is supported only at thebarrel pivot 150, as seen more clearly inFIG. 2A . As thepivot 150 is close to the top surface of thebarrel 130 and with a relief angle provided at afront tip 114 of thereceiver arm 110a, the drooped barrel is no longer in contact with any part of thereceiver body 110 and is free to be turned laterally to the left or right hand side of thereceiver body 110 about the Z-axis at thepivot 150. In one embodiment, thebarrel 130 is operable to be turned laterally to the left or right side of thereceiver body 110 by substantially 20 degree about thepivot 150 such that the projectile can be loaded or unloaded at thechamber end 134 of thebarrel 130 without obstruction by thereceiver arm 110b, as seen more clearly inFIGs. 2B ,2C ,2D ,4B and 4C . -

FIG. 3A shows an exploded view of thebarrel opening mechanism 105. As shown inFIG. 3A , thepivot 150 is made up of apivot pin 152, a pair ofclevises 156 and aclevis pin 157. Thepivot pin 152 is substantially cylindrical in shape along the Z-axis but has two parallelflat surfaces 153 to cooperate with the pair ofclevises 156. A top part of thepivot pin 152 has alateral projection 154 so that thelateral projection 154 is received in thereceiver arm 110a for pivotal movement about the Z-axis. Astopper plate 122, mounted at the end of aPicatinny rail 120 formed on an upper surface of the receivearm 110a, keeps thepivot pin 152 pivotable in thereceiver arm 110a. Theclevis pin 157 goes through a bore on theclevises 156 and another bore through thepivot pin 152 to allow the barrel to pivot about the Y-axis. With this pivot design, thepivot 150 allows thebarrel 130 to tilt or droop substantially 5 degree from the X-axis and at the same time be pivotable laterally to the left- or right-hand side of thereceiver body 110 by substantially 20 degree. An advantage of the present invention is that when thebarrel 130 is in the open position, thechamber end 134 is unobstructed for loading and unloading of a projectile; this means that the barrel chamber is suitable to receive projectiles of a predetermined design but of varied lengths, thus ensuring thegrenade launcher 100 incorporating thebarrel opening mechanism 105 is usable with future projectiles that may be longer in lengths. The other advantage of the present invention is that thebarrel 130 is pivotable to the left- or right-hand side of thereceiver body 110, thus making the grenade launcher ambidexterous. - Referring back to

FIGs. 1B and3A , thebarrel sleeve 140 has anopen channel 142 formed on the top, longitudinal portion as seen in the figures. Theopen channel 142 is as wide as the distance between the outside faces of theclevises 156 or length of theclevis pin 157. Preferably, the width of theopen channel 142 is substantially wider that the distance between the clevises or length of theclevis pin 157 but the edges of theopen channel 142 are provided with a pair ofprojections 144, which are spaced apart to accommodate the distance between theclevises 156 or length of theclevis pin 157. In the later embodiment, tolerance of the width between the pair ofprojections 144 need only to be controlled instead of along the entire length of theopen channel 142. In use, when thebarrel sleeve 140 is in place around thebarrel 130, the pair ofprojections 144 locate theclevis pin 157 in theclevises 156; with this arrangement, there is no need to provide any locking mechanism for theclevis pin 157, thus allowing the number of components of thebarrel opening mechanism 105 to be reduced and further simplifying this mechanism. - As can also be seen in

FIG. 3A , thelatch mechanism 170 includes thelever 172 and the cooperatingcatch 180 disposed on the top surface of thebarrel 130 along the longitudinal X-axis.FIG. 3C shows a cut-out portion of thelatch mechanism 170 and shows thelever 172 has a portion being formed with ahook 174 to engage with aslot 182 formed on thecatch 180. Thelever 172 is biased in the normal, engaged position by aspring 176. As seen inFIGs. 2A ,2B or3A , thecatch 180 extends out of the top surface of thebarrel 130 but when the barrel is in the closed position, thecatch 180 is received into thereceiver arm 110a within a cavity located below thelever 172, as seen more clearly inFIG. 3C , so that the longitudinal axes of thebarrel 130 andreceiver arm 110a are substantially parallel. In order to ensure that thelatch mechanism 170 is operable only when thecatch 180 is received in the cavity located below thelever 172, a spring-loaded pin 178 (not shown in the figures) is extended to prevent thelever 172 from returning to its original position after thelatch mechanism 170 is activated and thebarrel 130 is released from its connection at thecatch 180 with thereceiver arm 110a; in other words, the spring-loaded pin 178 is provided to prevent thehook 174 from re-engaging with theslot 182 until thebarrel 130 is returned to its closed position, thecatch 180 is fully received into its cavity below thereceiver arm 110a and the spring loaded pin 178 is depressed. In this way, the spring-loaded pin 178 serves as a very important safety lock to ensure that thebarrel 130 is connected to thereceiver arm 110a by thelatch mechanism 170 before thegrenade launcher 100 is deployed. - In the above

barrel opening mechanism 105, thelatch mechanism 170 is spaced apart from thepivot 150. Preferably, thelatch mechanism 170, such as the parts of thelever 172 that projects out of thereceiver arm 110a are located substantially forward with respect to thetrigger guard 136. This allows a user to support thegrenade launcher 100 with one hand at a position forward of thetrigger guard 136 yet allowing a finger or thumb of the same hand to actuate thelatch lever 172, with the other hand on the handgrip and its finger to activate the trigger. - In a further embodiment, a

transverse lock pin 210 is disposed across thePicatinny rail 120 to lock a matching male component of the Picatinny rail disposed on a rifle 200 (as seen inFIG. 1 C) to which thegrenade launcher 100 is to be mounted to. In use, the free end of the male component of the rifle's Picatinny rail is in butt contact with a thickness edge of thestopper plate 122 such that locking of the two Picatinny rail components at thelock pin 210 has a clearance fit. With clearance fit between thelock pin 210 and the rifle's Picantinny rail component, recoil forces on thereceiver body 100 are transferred to therifle 200 through thestopper plate 122 and Picatinny rail without thelock pin 210 taking up the recoil forces. In other words, in the present invention, thelock pin 210 is used to lock together the two components of the Picatinny rail when thegrenade launcher 100 is mounted below therifle 200 but does not take up any recoil forces during deployment. For this reason, thelock pin 210 is relatively small in size of substantially 2 to 3 mm square in cross-section. By providing thelock pin 210, thegrenade launcher 100 according to the present invention can be deployed as a stand-alone equipment or detachably mounted to a rifle. -

FIGs. 5A and 5B show exploded views of theabove grenade launcher 100 incorporating a barrel pivot direction lockout pin orselector 160. The pivot direction lockout pin orselector 160 is disposed on thereceiver arm 110a parallel to and at a distance aft of theclevis pin 157. As shown inFIGs. 5A and 5B , thedirection lockout pin 160 has twonotches notches notches notch paw 158 extending laterally from apivot pin 152a (which is a variation of the above pivot pin 152). Thedirection lockout pin 160 extends out of the width of thereceiver arm 110 and each end terminates with aknurled knob 164. Eachknurled knob 164 may be located on thedirection lockout pin 160 by means of alocking pin 166. By turning theknurled knob 164, a user sets the rotational orientation of the direction lockout pin orselector 160 so that thepaw 158 engages with thenotch receiver arm 110a is restricted by thepaw 158 moving within a length of thenotch barrel 130 to the left- or right-hand side of thereceiver arm 110a by setting the direction lockout pin orselector 160 in a clockwise or anti-clockwise position 5 depending on whether the user is right-handed or left-handed. For illustration,FIG. 5C shows a left-handed user (ie. left hand on the hand-grip orbutt 110b) and theposition lockout pin 160 being set so that thepaw 158 engages with thenotch 162a and thechamber end 134 of thebarrel 130 is to the right side of thereceiver arm 110a. On the other hand,FIG. 5D shows a right-handed user having set theposition lockout pin 160 so that thepaw 158 engages with thenotch 162b and thechamber end 134 of thebarrel 130 is swiveled to the left side of thereceiver arm 110a. - From the above description, a reader will appreciate that the barrel opening 5 mechanism of the present invention is advantageously ambidextrous. In addition, the grenade launcher incorporating the barrel mechanism has relatively few additional parts, so making the grenade launcher still relatively light. Another advantage of the present invention is that no tools are required to dismantle the

barrel opening mechanism 105 or theentire barrel 130, for example, for cleaning. For example, by unscrewing thelock sleeve 132 from thebarrel 130, thebarrel sleeve 140 can be removed from thebarrel 130, thereby allowing theclevis pin 157 to be removed and theentire barrel 130 to be dismantled from thereceiver body 110. In the same manner, no tools are required to re-assemble the barrel opening mechanism or barrel onto the receiver body. - While specific embodiments have been described and illustrated, it is understood that many changes, modifications, variations and combinations thereof could be made to the present invention without departing from the claimed subject. For example, the above

barrel opening mechanism 105 can be used on any single-shot gun, such as, a shotgun, irrespective of it being single- or double-barrel and its barrel size. In a further example, the spring-loaded pin 178 may be configured as a detent ball.

Claims (15)

- A grenade launcher (100) comprising:a receiver body (110), which is substantially an inverted L-shaped, with a forward pointing arm (110a) and a proximal arm (110b), wherein the proximal arm is configured for housing a trigger mechanism; anda barrel (130) connected below the forward pointing receiver arm (110a) by a barrel pivot (150) and a latch mechanism (170); wherein the latch mechanism comprises a latch (170) disposed in the forward receiver arm and is operable to engage with a catch (180) disposed on a top portion of the barrel so that:when the latch (170) is engaged with the catch (180), the barrel is in a closed position and longitudinal X-axes of both the barrel and the forward receiver arm are substantially parallel, andwhen the latch (170) is actuated by an appendage of a left or right hand of a user supporting the barrel, the latch (170) becomes released from the catch (180), thereby allowing the barrel to droop or pivot away from the forward receiver arm about a transverse Y-axis at the barrel pivot (150)characterised in thata chamber end (134) of the barrel is operable to be turned laterally to the left or right hand side about a vertical Z-axis at the barrel pivot (150) ambidextrously, so that a cartridge can be loaded into or unloaded from the chamber end (134) without obstruction by the proximal arm.

- A grenade launcher (100) according to claim 1, wherein said barrel pivot (150) comprises a substantially cylindrical pivot pin (152) that is journaled in the forward receiver arm to pivot about the Z-axis and a clevis pin (157) pivotable about the Y-axis, with the clevis pin passing through a bore on the pivot pin and the clevis pin being supported by a pair of clevises (156) disposed on a top surface of the barrel.

- A grenade launcher (100) according to claim 2, wherein the clevis pin (157) allows the barrel to pivot substantially 5 degree angle away from the X-axis whilst the pivot pin (152) allows the barrel to be turned laterally to the left or right hand side of the receiver body by substantially 20 degree.

- A grenade launcher (100) according to any one of claims 1-3, wherein the catch (180) is a projected element mounted on the top surface portion of the barrel.

- A grenade launcher (100) according to claim 4, wherein the catch (180) is received in a recess formed in the forward receiver at the position below the latch (170).

- A grenade launcher (100) according to claim 5, wherein said latch mechanism (170) further comprises a spring-loaded release pin (178), which allows the latch (170) to engage with the catch (180) only when the catch is received in the recess and the spring-loaded release pin (178) is depressed.

- A grenade launcher (100) according to any one of claims 1-6, wherein the latch (170) comprises a hook (174) configured integrally on a pivoted lever (172), such that a lever portion (172) projects out on a left hand side of the forward receiver arm and another lever portion projects out on the right hand side of the forward receiver arm and the hook (174) is engageable with a slot (182) formed on the catch (180).

- A grenade launcher (100) according to any one of claims 2-7, further comprising a pivot direction lockout pin (160) disposed on the forward receiver arm (110a) in a position parallel to the clevis pin (157) and at a distance to engage with a paw (158) projecting laterally from the pivot pin (152).

- A grenade launcher (100) according to claim 8, wherein the pivot direction lockout pin (160) has two notches (162a, 162b) formed on a cylindrical surface of the direction lockout pin, with the notches being angularly oriented with respect to each other and the paw (158) is restricted to move within a length of the selected notch depending on whether the user is right-handed or left-handed.

- A grenade launcher (100) according to any one of claims 1-9, further comprising a barrel sleeve (140) to receive the barrel.

- A grenade launcher (100) according to claim 10, wherein the barrel sleeve comprises an open channel (142), with a width of the open channel being controlled only at a pair of projections (144) projecting into the open channel and the pair of projections are configured to locate the clevis pin (157).

- A grenade launcher (100) according to any one of claims 1-11, wherein an upper portion of the forward receiver arm (110a) comprises a female half of a Picatinny rail.

- A grenade launcher (100) according to claim 12, wherein a closed end of the Picatinny rail is oriented in a forward direction with respect to the grenade launcher and a stopper plate (122) is located in the closed end to keep the barrel pivot (150) in place.

- A grenade launcher (100) according to claim 13, further comprising a lock pin (210) disposed transversely through the female half of the Picatinny rail to prevent an external device mounted in the Picatinny rail from dislodgment, wherein the lock pin (210) is disposed a predetermined distance from a contiguous face of the stopper plate (122) so that impulse forces of the grenade launcher are transmitted to the external device directly through the contiguous face of the stopper plate.

- A method of operating a barrel release and lock mechanism (105), said method comprising:supporting a barrel (130) of a grenade launcher (100) according to any of claims 1-14 with a left or right hand of a user;using an appendage of said left or right hand to push a lever portion (172) that protrudes on each of two sides of a receiver arm (110a) to release a barrel latch (170), thereby allowing a chamber end (134) of the barrel to droop about a transverse Y-axis of a barrel pivot (150) disposed near a distal end of the receiver arm;turning said barrel (130) with said appendage of the left or right hand so that the chamber end (134) of the barrel is turned laterally to the left or right side of the receiver arm (110a) about a vertical Z-axis of the barrel pivot (150) to allow the user to load or unload a cartridge into/from the chamber end (134) of the barrel; andlaterally turning the barrel (130) back to align the barrel with the receiver arm (110a) and then pivoting the barrel back to the receiver arm to release a spring-loaded pin (178) so that the barrel latch (170) is engageable with a cooperating catch (180) disposed on the barrel (130) and the barrel (130) becomes re-connected to the receiver arm at the latch (170).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SG2013020433A SG2013020433A (en) | 2013-03-20 | 2013-03-20 | Barrel opening mechanism of grenade launcher |

| PCT/SG2014/000136 WO2014149003A1 (en) | 2013-03-20 | 2014-03-19 | Barrel opening mechanism of grenade launcher |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2976591A1 EP2976591A1 (en) | 2016-01-27 |

| EP2976591A4 EP2976591A4 (en) | 2016-11-02 |

| EP2976591B1 true EP2976591B1 (en) | 2018-05-16 |

Family

ID=55129335

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14769600.9A Active EP2976591B1 (en) | 2013-03-20 | 2014-03-19 | Barrel opening mechanism of grenade launcher |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2976591B1 (en) |

| BR (1) | BR112015024157B1 (en) |

| SG (2) | SG2013020433A (en) |

| TR (1) | TR201811923T4 (en) |

| WO (1) | WO2014149003A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2694383C1 (en) * | 2018-10-05 | 2019-07-12 | Акционерное общество "Концерн "Калашников" | Under-barrel grenade launcher to small arms |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10234222B2 (en) * | 2016-08-09 | 2019-03-19 | Gonzalo Couce | Single 40 mm projectile launcher |

| WO2020027747A1 (en) * | 2018-02-15 | 2020-02-06 | Mertsav Savunma Sistemleri Sanayi Ve Ticaret Limited Sirketi | A barrel tilting mechanism |

| TR201808565A2 (en) | 2018-06-18 | 2018-07-23 | Armsan Silah Sanayi Ve Ticaret Anonim Sirketi | A Modular Bomb Launcher |

| EP3969832A4 (en) * | 2019-05-17 | 2023-01-18 | Armsan Silah Sanayi Ve Ticaret Anonim Sirketi | Safety apparatus for grenade launcher assembly |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3332162A (en) * | 1965-12-22 | 1967-07-25 | Honeywell Inc | Combined rifle and grenade launcher |

| US3641691A (en) * | 1969-05-21 | 1972-02-15 | Us Army | Grenade launcher with pivotally mounted barrel |

| US3967402A (en) * | 1975-01-22 | 1976-07-06 | The United States Of America As Represented By The Scretary Of The Army | Manually-operated firearm with forward-moving barrel and pivoted breech block |

| DE3202806C2 (en) * | 1982-01-28 | 1985-05-30 | Heckler & Koch Gmbh, 7238 Oberndorf | Grenade launcher additional weapon for attachment to automatic fire rifles |

| DE19925864C1 (en) * | 1999-06-07 | 2000-08-10 | Heckler & Koch Gmbh | Grenade launcher for fixture to rifle has launching barrel pivotable around static cross axis near to mouth, with base housing supporting trigger mechanism |

| BE1016610A3 (en) | 2005-05-31 | 2007-02-06 | Fn Herstal Sa | Grenade launcher improved. |

| US7360478B2 (en) * | 2005-09-30 | 2008-04-22 | Colt Canada Corporation | Projectile launcher convertible for left or right hand operation |

-

2013

- 2013-03-20 SG SG2013020433A patent/SG2013020433A/en unknown

-

2014

- 2014-03-19 WO PCT/SG2014/000136 patent/WO2014149003A1/en active Application Filing

- 2014-03-19 BR BR112015024157-3A patent/BR112015024157B1/en active IP Right Grant

- 2014-03-19 TR TR2018/11923T patent/TR201811923T4/en unknown

- 2014-03-19 SG SG11201507699WA patent/SG11201507699WA/en unknown

- 2014-03-19 EP EP14769600.9A patent/EP2976591B1/en active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2694383C1 (en) * | 2018-10-05 | 2019-07-12 | Акционерное общество "Концерн "Калашников" | Under-barrel grenade launcher to small arms |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2976591A4 (en) | 2016-11-02 |

| EP2976591A1 (en) | 2016-01-27 |

| WO2014149003A1 (en) | 2014-09-25 |

| BR112015024157A2 (en) | 2017-07-18 |

| BR112015024157B1 (en) | 2022-05-10 |

| SG11201507699WA (en) | 2015-10-29 |

| SG2013020433A (en) | 2014-10-30 |

| TR201811923T4 (en) | 2018-09-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2976591B1 (en) | Barrel opening mechanism of grenade launcher | |

| EP2721364B1 (en) | Locking front sight for a firearm and firearm with locking front sight | |

| US7810269B2 (en) | Frame-mounted trigger safety and well extension | |

| EP2122291B1 (en) | Lockable safety for firearm | |

| US9222738B2 (en) | Ambidextrous charging handle for firearm | |

| US8567301B1 (en) | Side offset charging handle | |

| US8307747B2 (en) | Self-engaging non-reciprocating charging handle | |

| US8549982B2 (en) | Firearm control devices | |

| US20060254111A1 (en) | Adjustable firearm stock | |

| US3979850A (en) | Safety system for handguns | |

| US8186087B2 (en) | Rifle trigger safety block | |

| US10041751B2 (en) | Rotary lockup action | |

| WO2021040638A1 (en) | Folding stock assembly for firearms | |

| US6360467B1 (en) | Muzzleloading rifle with pivotal bolt action | |

| US6968642B1 (en) | Close combat handguard for rifles | |

| US20150198401A1 (en) | Rotational safety device for firearm | |

| US6405470B1 (en) | Firearm safety lock | |

| US20040211102A1 (en) | Safety device for firearms with a firing pin lock | |

| EP3800423B1 (en) | Carbine with charging handle | |

| US2876576A (en) | Breech release mechanism | |

| WO2023282861A1 (en) | Folding stock structure for firearms |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20151020 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20161006 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F41A 35/06 20060101ALI20160929BHEP Ipc: F41A 3/04 20060101ALI20160929BHEP Ipc: F41A 3/58 20060101ALI20160929BHEP Ipc: F41C 27/06 20060101ALI20160929BHEP Ipc: F41A 9/45 20060101AFI20160929BHEP |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F41C 27/06 20060101ALI20171010BHEP Ipc: F41A 3/58 20060101ALI20171010BHEP Ipc: F41A 3/04 20060101ALI20171010BHEP Ipc: F41A 9/45 20060101AFI20171010BHEP Ipc: F41A 35/06 20060101ALI20171010BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20171120 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: PANG, KHENG HONG SAMUEL Inventor name: HENG, KHEE NGEE Inventor name: TANG, WEI QIANG Inventor name: LI, WEIXIAN WILSON |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014025619 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 999969 Country of ref document: AT Kind code of ref document: T Effective date: 20180615 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180516 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180816 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180816 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180817 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 999969 Country of ref document: AT Kind code of ref document: T Effective date: 20180516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602014025619 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20190219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190319 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190319 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190319 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190319 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180917 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180516 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 602014025619 Country of ref document: DE Owner name: ST ENGINEERING ADVANCED MATERIAL ENGINEERING P, SG Free format text: FORMER OWNER: ADVANCED MATERIAL ENGINEERING PTE. LTD., SINGAPORE, SG |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230522 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240325 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20240311 Year of fee payment: 11 |