EP2765356B1 - Portable lighting device - Google Patents

Portable lighting device Download PDFInfo

- Publication number

- EP2765356B1 EP2765356B1 EP14000275.9A EP14000275A EP2765356B1 EP 2765356 B1 EP2765356 B1 EP 2765356B1 EP 14000275 A EP14000275 A EP 14000275A EP 2765356 B1 EP2765356 B1 EP 2765356B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ballast

- lighting apparatus

- column

- portable lighting

- holding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000000725 suspension Substances 0.000 claims description 7

- 230000005484 gravity Effects 0.000 description 10

- 238000010276 construction Methods 0.000 description 5

- 238000003780 insertion Methods 0.000 description 5

- 230000037431 insertion Effects 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 238000005286 illumination Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 229910001507 metal halide Inorganic materials 0.000 description 2

- 150000005309 metal halides Chemical class 0.000 description 2

- 239000010426 asphalt Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 150000004820 halides Chemical class 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000002689 soil Substances 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V23/00—Arrangement of electric circuit elements in or on lighting devices

- F21V23/02—Arrangement of electric circuit elements in or on lighting devices the elements being transformers, impedances or power supply units, e.g. a transformer with a rectifier

- F21V23/026—Fastening of transformers or ballasts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21L—LIGHTING DEVICES OR SYSTEMS THEREOF, BEING PORTABLE OR SPECIALLY ADAPTED FOR TRANSPORTATION

- F21L14/00—Electric lighting devices without a self-contained power source, e.g. for mains connection

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V11/00—Screens not covered by groups F21V1/00, F21V3/00, F21V7/00 or F21V9/00

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V17/00—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages

- F21V17/04—Fastening of component parts of lighting devices, e.g. shades, globes, refractors, reflectors, filters, screens, grids or protective cages the fastening being onto or by the light source

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V21/00—Supporting, suspending, or attaching arrangements for lighting devices; Hand grips

- F21V21/06—Bases for movable standing lamps; Fixing standards to the bases

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V21/00—Supporting, suspending, or attaching arrangements for lighting devices; Hand grips

- F21V21/14—Adjustable mountings

- F21V21/22—Adjustable mountings telescopic

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21W—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES F21K, F21L, F21S and F21V, RELATING TO USES OR APPLICATIONS OF LIGHTING DEVICES OR SYSTEMS

- F21W2131/00—Use or application of lighting devices or systems not provided for in codes F21W2102/00-F21W2121/00

- F21W2131/10—Outdoor lighting

- F21W2131/1005—Outdoor lighting of working places, building sites or the like

Definitions

- the invention relates to a portable lighting device.

- Transportable lighting devices are known as floor lights and are used, for example, for temporary illumination of a construction site, an accident site or a work area.

- the EP 1 059 483 A2 shows such a transportable lighting device.

- the lighting device consists essentially of a light balloon with a light source, such as a metal halide lamp, and a tripod with retractable telescope, with the aid of the height of the light balloon can be adjusted with the light source. So it is possible to extend the telescope so far that the light source reaches a height of 4 to 5 m, in order to achieve a uniform illumination of the job.

- ballast is usually provided, which is required for providing an electric current and thus for the operation of the metal halide lamp.

- the components are designed in terms of their dimensions and their weight so that they can be easily carried by a person. In this way, the lighting device can be easily moved from one place to another.

- the light balloon with the lighting device is placed on the tripod and electrically connected to the ballast.

- the ballast in turn is connected to the existing at the work or construction site electrical power supply and usually placed next to the tripod on the floor.

- a light point height of 4 to 5 m is usually achieved in known lighting devices.

- the light bulb surrounding the actual light source (lamp) has a good wind attack surface due to its dimensions.

- the light balloon which consists for example of a fabric encloses the light source and thus causes a uniform, glare-free light distribution and a lower luminance of the lamp. Thereby the quality of the illumination can be improved considerably.

- Such a light balloon is in the EP 1 059 483 A2 shown.

- the lighting device has a relatively high center of gravity due to the additional weight of the light balloon, which likewise encloses the lamp at a considerable height.

- the large wind attack surface of the light balloon in conjunction with the high center of gravity and the large leverage effect when the telescopic elements are extended require additional safety measures in windy working conditions, such as roping with ropes. In this way it should be prevented that the tripod or the entire lighting device can easily fall over.

- the ropes for example, three ropes

- the ropes extend from the vertical telescopic column and must be secured to the ground by means of pegs. Although this prevents the light device from falling over under the influence of wind.

- the ropes are tripod sleepers and thus a risk of accidents for persons working in the vicinity of the lighting device.

- a portable lighting device with a tripod known.

- a lighting device is supported by a longitudinally extending column device.

- a battery is mounted to shift the center of gravity of the device downwards, thereby increasing stability.

- the invention has for its object to provide a lighting device having an increased stability, without the device must be secured by means of guy ropes.

- a mobile or portable lighting device has a lighting device, a lighting device carrying, extending in a longitudinal direction column device, a pillar device supporting tripod device and a ballast for providing an electrical current for the lighting device.

- the lighting device is characterized in that the ballast is arranged in the longitudinal direction below the column device on the column device.

- the invention provides that the ballast not - as in the prior art - placed next to the lighting device on the ground, but is arranged below the pillar device at this. Due to its structural design, for example as a magnetic ballast transformer, the ballast has a not inconsiderable weight, for example between 8 and 15 kg. Added to this is the weight of the housing of the ballast, which is suitable for construction sites and therefore robust and heavy. Overall, the ballast is a not inconsiderable weight, the fact that it is located below the pillar device at this significantly reduces the center of gravity and thus increases the stability of the lighting device against falling over. The overall center of gravity of the lighting device can thus be shifted downwards.

- the ballast may be attached to the pillar device.

- the ballast is releasably attached to the column device, so that the ballast and the column device or the ballast and the tripod device when not in use of the lighting device can be separated again, so that the individual components are again comfortably worn by a person can.

- the lighting device may comprise at least one lamp and at least a part of the lamp surrounding at least partially translucent lampshade.

- the lighting device may be formed as a so-called Lichtballön, as he also for example from the EP 1 059 483 A2 is known.

- the lampshade may consist of an elliptical or spherical balloon envelope which completely surrounds the illuminant, for example a metal vapor halide lamp. It is also possible that the lampshade or the balloon envelope consists of two halves, of which, for example, the upper half consists of a reflective textile material and the lower half of a translucent material. The light emitted by the light source then becomes reflected by the reflective material of the upper half downwards and thus amplifies the already directly exiting through the lower half of light.

- the lighting device may comprise clamping means, wherein the clamping means are fixable in a state of stress, in which the clamping means clamp the lampshade, for holding the lampshade in an open and usable state, and wherein the clamping means are movable to a relaxation state in which the clamping means the lampshade do not cock.

- the clamping means With the help of the clamping means thus the lampshade can be spanned balloon-like, so that the screen material does not come into contact with the very hot expectant lamp during operation. Rather, the lampshade surrounds bulbs at a certain distance in the voltage state, so that a uniform light emission can be achieved.

- the column device may be a telescopic device, with at least two telescopically linearly displaceable telescopic elements.

- a satisfactory luminous level can be achieved.

- the column device can be constructed relatively compact and thereby easily transported. The desired working height of the lighting device is then achieved by extending the telescopic elements.

- the stand means may comprise an upper support, which is arranged axially displaceable on the column means, and a lower support, which is arranged in the region of a lower end of the column means, at least three tripod legs, one end of which is pivotally attached to the upper support, and for Each of the tripod legs a strut, one end of which is pivotable on the lower bracket and the other end is pivotable on the associated tripod leg.

- the tripod device ensured by the at least three tripod legs a secure state, so that the supported by the tripod pillar device can also be kept safe and upright when the column device or the telescopic elements of the column device are extended to full working height.

- the arrangement of the upper bracket, the lower bracket, the three tripod legs and the associated struts each a robust structure is built, which can reliably hold the lighting device even with greater weight.

- the lower holder can be arranged displaceably on the column device.

- a stop may be provided for at least one of the tripod legs to limit a pivoting movement of the tripod leg away from the longitudinal axis.

- the tripod leg can then only be pivoted so far that it strikes against the stop. This position should then correspond to the desired end position, which is to take the tripod leg for safe support of the column device.

- a stop may be provided for at least one of the struts to limit a pivoting movement of the strut.

- the strut or - if all struts are provided with stops - all struts can be limited in this way with respect to their pivoting, so that in the operating state all struts and all tripod legs abut their respective stops and can not be pivoted further. As a result, the entire structure is additionally stabilized.

- the ballast has a suspension device, wherein the retaining device can be connected to the suspension device in order to hold the ballast.

- the suspension device has a grip device for supporting the ballast, wherein the retaining device is designed to hold the grip device.

- the gripping device which is usually provided on a ballast in order to facilitate the transport of the heavy ballast, can also be coupled to the holding device, so that the holding device holds the ballast on its grip device. In this way, the ballast or the housing of the ballast must not be modified in a special way.

- the holding device has a suspension device for suspending the gripping device of the ballast or a guide device for the linear insertion of the gripping device.

- a suspension device for suspending the gripping device of the ballast or a guide device for the linear insertion of the gripping device.

- the hanging device may be provided, for example, a suitably trained hook on which the handle device is suspended.

- the guide device allows the insertion or insertion of the handle device.

- the guide means may be in the form of a dovetail guide extending transverse to the longitudinal axis of the column means. Accordingly, the gripping device can then be inserted laterally, that is perpendicular to the longitudinal axis of the column device in the guide.

- the guide device enables rapid attachment of the ballast to the column device. At the same time, however, the ballast can remain reliably and permanently attached to the column device.

- a locking device may be provided for locking the handle device in the guide device in a predetermined holding position on the holding device.

- the locking device is thus able to lock the gripping device in such a way that unintentional disconnection of the ballast from the holding device or the column device is prevented in any case. Only by releasing the locking device, it is possible to push the handle device from the guide device and remove the ballast.

- the locking device may, for example, have a latching device, so that upon insertion of the grip device into the guide device, the locking device engages upon reaching a certain position, whereupon the grip device with the ballast is positively secured to the column device. By releasing the latching device, the ballast can then be pushed out of the guide device again.

- the holding device may be formed in one embodiment below the lower support of the tripod device. In this way it is possible to provide the holding device and thus - in the intended construction - the ballast at a low-lying as possible.

- the holding device and the lower holder are integrally formed. As a result, a very compact structure can be achieved and overall the structural complexity can be reduced.

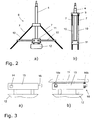

- Fig. 1 shows a portable lighting device in the operating state.

- the lighting device can be easily carried by a user - possibly disassembled into a few components - to the place of use or to different locations.

- a lighting device 1 designed as a light balloon is shown.

- the lighting device has in its interior an unillustrated light source, which is almost completely surrounded by a lampshade 2.

- the lampshade 2 is not shown by clamping means in the in Fig. 1 Spanned voltage state shown so that it assumes an ellipse-like outer contour.

- the lampshade 2 has an upper half 3a a reflective fabric and a lower half 3b of a translucent material.

- the light generated in the interior of the lighting device 1 by the lamp or the lamp thus radiates almost completely down and illuminates the underlying work area.

- the lighting device 1 is supported on its underside by a column device 4.

- the column device 4 may be formed as a telescopic device and have a plurality of telescoping elements telescoping.

- three telescopic elements 5a, 5b, 5c are provided, which can be displaced linearly into one another and locked in their respective relative positions.

- Corresponding telescopic devices are known, so that at this point a more detailed description is unnecessary.

- the column device 4 is supported by a tripod device 6 and in particular prevented from falling over.

- the tripod device 6 has three tripod legs 7, which are arranged offset by 120 ° on the circumference. In this way, the tripod device 6 is supported with three provided at the ends of the tripod legs 7 tripod feet 8 on the ground, which allows a safe and defined state in terms of a tripod.

- tripod feet 8 opposite ends of the tripod legs 7 are hinged to an upper bracket 9 pivotally.

- a strut 10 is pivoted at one end pivotally, the other end extends to a lower bracket 11 respectively.

- the lower bracket 11 is fixedly secured to the lower end of the column device 4, while the upper bracket 9 encloses the column device 4 and is axially movable on the latter in the longitudinal direction of the column device 4 back and forth.

- the tripod device 6 between the in Fig. 1 shown operating position and a transport position in which the tripod device 6 is folded together to be changed.

- the upper bracket 9 is moved to the column device 4 upwards, whereupon the tripod legs 7 are applied by the leadership of the struts 10 to the column device 4.

- the tripod legs 7 may be formed as a square tube, while the struts 10 are formed in the form of U-profiles. This makes it possible that in the folded transport state, the tripod legs 7 come to rest between the legs of the U-shaped profile of the struts 10, whereby the structure in the collapsed state can be even more compact.

- ballast 12 serves as a transformer for providing a corresponding current to the lighting device 1. It is connected to the construction site network, a public grid or a power generator, and converts the power in an appropriate manner. In addition, it serves to ignite the light source in the lighting device. 1

- the ballast 12 has a considerable weight. The fact that it is attached to the lower end of the column device 4, the overall center of gravity of the lighting device is moved downward, whereby the stability of the stand and thus for example the stability against wind influences is significantly increased.

- the ballast 12 has a handle 13 serving as a handle, on which the ballast 12 can be comfortably worn. At the same time the handle 13 is used to attach the ballast 12 to the column device 4, such as Fig. 1 shows.

- Fig. 2 schematically shows the column device 4 with the tripod device 6 in the Fig. 1 corresponding operating state ( Fig. 2a ) and in the merged transport state ( Fig. 2b ). Since the principle of opening and closing the tripod device 6 has already been explained above, a new description is unnecessary at this point.

- the ballast 12 in the open operating state of the tripod device 6, the ballast 12 is attached to the lower bracket 11. To achieve the transport state, the ballast 12 must be removed in advance from the lower bracket 11. In this way, the tripod device 6 can then be conveniently transported with the column device 4.

- Fig. 3 schematically shows an example of the attachment of the ballast 12 to the lower bracket 11th

- Fig. 3a It can be seen that the handle 13 is formed on the upper side of the ballast 12.

- the handle 13 has an opening 14 and a hook member 15.

- a holding device 16 is formed, with a hook 16a and an eyelet 16b.

- the opening 14 of the handle 13 can be hung for attaching the ballast 12 to the lower bracket 11 on the hook 16a, while the hook member 15 of the handle 13 is inserted into the eyelet 16b and also hooked there.

- Fig. 4 shows a variant of the attachment of the handle 13 of the ballast 12 to the lower bracket 11 in a schematic representation.

- Fig. 5 a partial section through the handle 13 is shown.

- the lower region of the lower holder 11 is designed as a holding device 17.

- a holding device 17 serving as a guide device dovetail groove 18 is formed, in which the handle 13 can be inserted from the side.

- the handle 13 has a cross-sectional profile adapted to allow a dovetail effect to be achieved between the handle 13 and the dovetail groove 18, such as Fig. 5 shows.

- the ballast 12 is already positively secured to the bracket 11 and thus to the column device 4.

- locking device 19 is provided which has a spring-loaded pin 20, the end of which engages in a recess 21 in the handle 13 when the handle 13 (in Fig. 4 from right to left) is inserted into the dovetail groove 18.

- the center of gravity of the ballast 12 is not arranged vertically below the column device 4, but laterally offset somewhat, so that the center of gravity of the ballast 12 is arranged eccentrically to the column device 4. Also in this way, the overall center of gravity can be reduced and the stability of the lighting device can be increased.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

Description

Die Erfindung betrifft eine transportable Leuchtvorrichtung.The invention relates to a portable lighting device.

Transportable Leuchtvorrichtungen sind als Standleuchten bekannt und werden zum Beispiel zur zeitweiligen Ausleuchtung einer Baustelle, einer Unfallstelle oder eines Arbeitsbereichs eingesetzt.Transportable lighting devices are known as floor lights and are used, for example, for temporary illumination of a construction site, an accident site or a work area.

Die

Weiterhin ist üblicherweise ein Vorschaltgerät vorgesehen, das zum Bereitstellen eines elektrischen Stroms und damit zum Betrieb der Metalldampfhalogen-Lampe benötigt wird.Furthermore, a ballast is usually provided, which is required for providing an electric current and thus for the operation of the metal halide lamp.

Die Komponenten sind hinsichtlich ihrer Abmessungen und ihres Gewichts derart gestaltet, dass sie problemlos von einer Person getragen werden können. Auf diese Weise kann die Leuchtvorrichtung bequem von einem zum anderen Ort verbracht werden.The components are designed in terms of their dimensions and their weight so that they can be easily carried by a person. In this way, the lighting device can be easily moved from one place to another.

Bei bekannten Leuchtvorrichtungen wird der Lichtballon mit der Leuchteinrichtung auf das Stativ gesteckt und an das Vorschaltgerät elektrisch angeschlossen. Das Vorschaltgerät wiederum wird mit der an der Arbeits- bzw. Baustelle vorhandenen elektrischen Spannungsversorgung angeschlossen und meist neben das Stativ auf den Boden gestellt.In known lighting devices, the light balloon with the lighting device is placed on the tripod and electrically connected to the ballast. The ballast in turn is connected to the existing at the work or construction site electrical power supply and usually placed next to the tripod on the floor.

Im voll ausgefahrenen Zustand des Stativs bzw. des Teleskops wird bei bekannten Leuchtvorrichtungen meist eine Lichtpunkthöhe von 4 bis 5 m erreicht. Der die eigentliche Lichtquelle (Lampe) umgebende Lichtballon weist durch seine Abmessungen eine gute Windangriffsfläche auf. Der zum Beispiel aus einem Gewebe bestehende Lichtballon umschließt die Lichtquelle und bewirkt so eine gleichmäßige, blendfreie Lichtverteilung sowie eine geringere Leuchtdichte der Leuchte. Dadurch kann die Qualität der Ausleuchtung erheblich verbessert werden. Ein derartiger Lichtballon ist in der

Die Leuchtvorrichtung weist durch das zusätzliche Gewicht des ebenfalls in erheblicher Höhe die Lampe umschließenden Lichtballons einen relativ hohen Schwerpunkt auf. Die große Windangriffsfläche des Lichtballons in Verbindung mit der hohen Schwerpunktslage und der bei ausgefahrenen Teleskopelementen großen Hebelwirkung erfordert bei windigen Arbeitsverhältnissen zusätzliche Sicherungsmaßnahmen, wie zum Beispiel das Abspannen mit Seilen. Auf diese Weise soll verhindert werden, dass das Stativ bzw. die komplette Leuchtvorrichtung leicht umfallen kann. Beim Abspannen der Leuchtvorrichtung mit Seilen erstrecken sich die Seile (zum Beispiel drei Seile) von der vertikalen Teleskopsäule und müssen am Boden mit Hilfe von Heringen befestigt werden. Dadurch wird zwar ein Umfallen der Leuchtvorrichtung unter Windeinfluss verhindert. Jedoch bilden die Seile Stolperschwellen und insoweit eine Unfallgefahr für Personen, die in der Nähe der Leuchtvorrichtung arbeiten. Zudem ist es bei bestimmten Böden, zum Beispiel bei Asphalt oder Beton, nicht möglich, ohne weiteres Heringe in den Boden einzuschlagen.The lighting device has a relatively high center of gravity due to the additional weight of the light balloon, which likewise encloses the lamp at a considerable height. The large wind attack surface of the light balloon in conjunction with the high center of gravity and the large leverage effect when the telescopic elements are extended require additional safety measures in windy working conditions, such as roping with ropes. In this way it should be prevented that the tripod or the entire lighting device can easily fall over. When unstrapping the lighting device with ropes, the ropes (for example, three ropes) extend from the vertical telescopic column and must be secured to the ground by means of pegs. Although this prevents the light device from falling over under the influence of wind. However, the ropes are tripod sleepers and thus a risk of accidents for persons working in the vicinity of the lighting device. In addition, it is not possible for certain types of soil, for example asphalt or concrete, to hammer pegs into the ground without further ado.

Wenn jedoch die Leuchtvorrichtung nicht durch das Abspannen von Seilen gegen Umfallen gesichert wird, besteht die Gefahr, dass die Vorrichtung bereits bei leichteren Windstößen umkippen kann.However, if the light fixture is not secured from tipping over by roping cables, there is a risk that the device may tip over even in lighter gusts of wind.

Aus der

Der Erfindung liegt die Aufgabe zugrunde, eine Leuchtvorrichtung anzugeben, die eine erhöhte Standfestigkeit aufweist, ohne dass die Vorrichtung mit Hilfe von Abspannseilen gesichert werden muss.The invention has for its object to provide a lighting device having an increased stability, without the device must be secured by means of guy ropes.

Die Aufgabe wird erfindungsgemäß durch eine transportable Leuchtvorrichtung mit den Merkmalen von Anspruch 1 gelöst. Vorteilhafte Ausgestaltungen sind in den abhängigen Ansprüchen angegeben.The object is achieved by a portable lighting device with the features of

Eine mobile bzw. transportable Leuchtvorrichtung weist eine Leuchteinrichtung eine die Leuchteinrichtung tragende, sich in einer Längsrichtung erstreckende Säuleneinrichtung, eine die Säuleneinrichtung tragende Stativeinrichtung und ein Vorschaltgerät zum Bereitstellen eines elektrischen Stroms für die Leuchteinrichtung auf. Die Leuchtvorrichtung ist dadurch gekennzeichnet, dass das Vorschaltgerät in der Längsrichtung unterhalb der Säuleneinrichtung an der Säuleneinrichtung angeordnet ist.A mobile or portable lighting device has a lighting device, a lighting device carrying, extending in a longitudinal direction column device, a pillar device supporting tripod device and a ballast for providing an electrical current for the lighting device. The lighting device is characterized in that the ballast is arranged in the longitudinal direction below the column device on the column device.

Somit wird erfindungsgemäß vorgesehen, dass das Vorschaltgerät nicht - wie beim Stand der Technik - neben die Leuchtvorrichtung auf den Boden gestellt, sondern unterhalb der Säuleneinrichtung an dieser angeordnet wird. Das Vorschaltgerät weist aufgrund seines konstruktiven Aufbaus, zum Beispiel als magnetischer Vorschalttransformator, ein nicht unerhebliches Gewicht, zum Beispiel zwischen 8 und 15 kg auf. Hinzu kommt das Gewicht des Gehäuses des Vorschaltgeräts, das baustellengerecht und damit robust und schwer ausgeführt ist. Insgesamt stellt das Vorschaltgerät ein nicht unerhebliches Gewicht dar, das dadurch, dass es unterhalb der Säuleneinrichtung an dieser angeordnet wird, den Schwerpunkt deutlich herabsetzt und so die Stabilität der Leuchtvorrichtung gegen Umfallen erhöht. Der Gesamtschwerpunkt der Leuchtvorrichtung kann somit nach unten verlagert werden.Thus, the invention provides that the ballast not - as in the prior art - placed next to the lighting device on the ground, but is arranged below the pillar device at this. Due to its structural design, for example as a magnetic ballast transformer, the ballast has a not inconsiderable weight, for example between 8 and 15 kg. Added to this is the weight of the housing of the ballast, which is suitable for construction sites and therefore robust and heavy. Overall, the ballast is a not inconsiderable weight, the fact that it is located below the pillar device at this significantly reduces the center of gravity and thus increases the stability of the lighting device against falling over. The overall center of gravity of the lighting device can thus be shifted downwards.

Das Vorschaltgerät kann an der Säuleneinrichtung befestigt sein. Insbesondere ist es möglich, dass das Vorschaltgerät an der Säuleneinrichtung lösbar befestigt ist, so dass das Vorschaltgerät und die Säuleneinrichtung bzw. das Vorschaltgerät und die Stativeinrichtung bei Nichtgebrauch der Leuchtvorrichtung wieder voneinander getrennt werden können, damit die einzelnen Komponenten wieder bequem von einer Person getragen werden können.The ballast may be attached to the pillar device. In particular, it is possible that the ballast is releasably attached to the column device, so that the ballast and the column device or the ballast and the tripod device when not in use of the lighting device can be separated again, so that the individual components are again comfortably worn by a person can.

Die Leuchteinrichtung kann wenigstens ein Leuchtmittel und einen wenigstens einen Teil des Leuchtmittels umgebenden, zumindest teilweise lichtdurchlässigen Leuchtenschirm aufweisen. Auf diese Weise kann die Leuchteinrichtung als sogenannter Lichtballön ausgebildet sein, wie er zum Beispiel auch aus der

Der Leuchtenschirm kann aus einer ellipsen- oder kugelförmigen Ballonhülle bestehen, die das Leuchtmittel, zum Beispiel eine Metalldampfhalogen-Lampe, vollständig umgibt. Ebenso ist es möglich, dass der Leuchtenschirm bzw. die Ballonhülle aus zwei Hälften besteht, von denen zum Beispiel die obere Hälfte aus einem reflektierenden textilen Material und die untere Hälfte aus einem lichtdurchlässigen Material besteht. Das von dem Leuchtmittel abgegebene Licht wird dann durch das reflektierende Material der oberen Hälfte nach unten reflektiert und verstärkt so das ohnehin durch die untere Hälfte direkt austretende Licht.The lampshade may consist of an elliptical or spherical balloon envelope which completely surrounds the illuminant, for example a metal vapor halide lamp. It is also possible that the lampshade or the balloon envelope consists of two halves, of which, for example, the upper half consists of a reflective textile material and the lower half of a translucent material. The light emitted by the light source then becomes reflected by the reflective material of the upper half downwards and thus amplifies the already directly exiting through the lower half of light.

Die Leuchteinrichtung kann Spannmittel aufweisen, wobei die Spannmittel in einem Spannungszustand fixierbar sind, in dem die Spannmittel den Leuchtenschirm spannen, zum Halten des Leuchtenschirms in einem geöffneten und gebrauchsfähigen Zustand, und wobei die Spannmittel in einen Entspannungszustand bewegbar sind, in dem die Spannmittel den Leuchtenschirm nicht spannen. Mit Hilfe der Spannmittel kann somit der Leuchtenschirm ballonähnlich aufgespannt werden, so dass das Schirmmaterial nicht in Kontakt mit dem im Betrieb sehr heiß werdenden Leuchtmittel gelangt. Vielmehr umgibt der Leuchtenschirm im Spannungszustand Leuchtmittel mit einem gewissen Abstand, so dass ein gleichmäßiger Lichtaustritt erreicht werden kann.The lighting device may comprise clamping means, wherein the clamping means are fixable in a state of stress, in which the clamping means clamp the lampshade, for holding the lampshade in an open and usable state, and wherein the clamping means are movable to a relaxation state in which the clamping means the lampshade do not cock. With the help of the clamping means thus the lampshade can be spanned balloon-like, so that the screen material does not come into contact with the very hot expectant lamp during operation. Rather, the lampshade surrounds bulbs at a certain distance in the voltage state, so that a uniform light emission can be achieved.

Die Säuleneinrichtung kann eine Teleskopeinrichtung sein, mit wenigstens zwei ineinander linear verschiebbaren Teleskopelementen. In der Praxis hat es sich erwiesen, dass mit Hilfe von drei Teleskopelementen eine zufriedenstellende Leuchthöhe erreicht werden kann. Durch das Ineinanderverschieben der Teleskopelemente kann die Säuleneinrichtung relativ kompakt aufgebaut sein und dadurch leicht transportiert werden. Die gewünschte Arbeitshöhe der Leuchteinrichtung wird dann durch Ausfahren der Teleskopelemente erreicht.The column device may be a telescopic device, with at least two telescopically linearly displaceable telescopic elements. In practice, it has been found that with the help of three telescopic elements a satisfactory luminous level can be achieved. By telescoping the telescopic elements, the column device can be constructed relatively compact and thereby easily transported. The desired working height of the lighting device is then achieved by extending the telescopic elements.

Die Stativeinrichtung kann eine obere Halterung aufweisen, die an der Säuleneinrichtung axial verschiebbar angeordnet ist, sowie eine untere Halterung, die im Bereich eines unteren Endes der Säuleneinrichtung angeordnet ist, wenigstens drei Stativbeine, deren eines Ende an der oberen Halterung verschwenkbar befestigt ist, und für Jedes der Stativbeine eine Strebe, deren eines Ende an der unteren Halterung verschwenkbar ist und deren anderes Ende an dem zugeordneten Stativbein verschwenkbar ist.The stand means may comprise an upper support, which is arranged axially displaceable on the column means, and a lower support, which is arranged in the region of a lower end of the column means, at least three tripod legs, one end of which is pivotally attached to the upper support, and for Each of the tripod legs a strut, one end of which is pivotable on the lower bracket and the other end is pivotable on the associated tripod leg.

Die Stativeinrichtung gewährleistet durch die wenigstens drei Stativbeine einen sicheren Stand, so dass die von der Stativeinrichtung getragene Säuleneinrichtung auch dann sicher und aufrecht gehalten werden kann, wenn die Säuleneinrichtung bzw. die Teleskopelemente der Säuleneinrichtung in die volle Arbeitshöhe ausgefahren sind. Durch die Anordnung der oberen Halterung, der unteren Halterung, der drei Stativbeine und der jeweils zugeordneten Streben wird ein robustes Tragwerk errichtet, das die Leuchtvorrichtung auch bei größerem Gewicht zuverlässig aufrecht halten kann. Darüber hinaus ist durch die Verschwenkbarkeit der Stativbeine und der Streben gewährleistet, dass bei einem Anheben bzw. axialen Verschieben der oberen Halterung nach oben die Stativeinrichtung zusammengeklappt werden kann. Dadurch wird der Transport der Leuchtvorrichtung erleichtert.The tripod device ensured by the at least three tripod legs a secure state, so that the supported by the tripod pillar device can also be kept safe and upright when the column device or the telescopic elements of the column device are extended to full working height. The arrangement of the upper bracket, the lower bracket, the three tripod legs and the associated struts each a robust structure is built, which can reliably hold the lighting device even with greater weight. In addition, it is ensured by the pivotability of the tripod legs and the struts that when lifting or axial Move the upper bracket up the tripod device can be folded. As a result, the transport of the lighting device is facilitated.

Bei einer Variante kann auch die untere Halterung an der Säuleneinrichtung verschiebbar angeordnet werden.In a variant, the lower holder can be arranged displaceably on the column device.

An der oberen Halterung kann für wenigstens eines der Stativbeine ein Anschlag vorgesehen sein, um eine Verschwenkbewegung des Stativbeins weg von der Längsachse zu begrenzen. Das Stativbein kann dann nur so weit verschwenkt werden, bis es an den Anschlag anschlägt. Diese Stellung sollte dann der gewünschten Endstellung entsprechen, die das Stativbein zum sicheren Abstützen der Säuleneinrichtung einnehmen soll.At the upper support a stop may be provided for at least one of the tripod legs to limit a pivoting movement of the tripod leg away from the longitudinal axis. The tripod leg can then only be pivoted so far that it strikes against the stop. This position should then correspond to the desired end position, which is to take the tripod leg for safe support of the column device.

An der unteren Halterung kann für wenigstens eine der Streben ein Anschlag vorgesehen sein, um eine Verschwenkbewegung der Strebe zu begrenzen. Auch die Strebe bzw. - wenn alle Streben mit Anschlägen versehen sind - sämtliche Streben können auf diese Weise hinsichtlich ihrer Verschwenkbewegung begrenzt werden, so dass im Betriebszustand alle Streben und alle Stativbeine an ihren jeweiligen Anschlägen anliegen und nicht mehr weiter verschwenkt werden können. Dadurch wird das gesamte Tragwerk zusätzlich stabilisiert.At the lower bracket, a stop may be provided for at least one of the struts to limit a pivoting movement of the strut. Also, the strut or - if all struts are provided with stops - all struts can be limited in this way with respect to their pivoting, so that in the operating state all struts and all tripod legs abut their respective stops and can not be pivoted further. As a result, the entire structure is additionally stabilized.

Erfindungsgemäß weist das Vorschaltgerät eine Einhängeeinrichtung auf, wobei die Halteeinrichtung mit der Einhängeeinrichtung verbindbar ist, um das Vorschaltgerät zu halten.According to the invention, the ballast has a suspension device, wherein the retaining device can be connected to the suspension device in order to hold the ballast.

Die Einhängeeinrichtung weist eine Griffeinrichtung zum Tragen des Vorschaltgeräts auf, wobei die Halteeinrichtung zum Halten der Griffeinrichtung ausgebildet ist. Das bedeutet, dass die Griffeinrichtung, die ohnehin üblicherweise an einem Vorschaltgerät vorgesehen ist, um den Transport des schweren Vorschaltgeräts zu erleichtern, auch mit der Halteeinrichtung gekoppelt werden kann, so dass die Halteeinrichtung das Vorschaltgerät an seiner Griffeinrichtung hält. Auf diese Weise muss das Vorschaltgerät bzw. das Gehäuse des Vorschaltgeräts nicht in besonderer Weise modifiziert werden.The suspension device has a grip device for supporting the ballast, wherein the retaining device is designed to hold the grip device. This means that the gripping device, which is usually provided on a ballast in order to facilitate the transport of the heavy ballast, can also be coupled to the holding device, so that the holding device holds the ballast on its grip device. In this way, the ballast or the housing of the ballast must not be modified in a special way.

Die Halteeinrichtung weist eine Hängeeinrichtung zum Einhängen der Griffeinrichtung des Vorschaltgeräts oder eine Führungseinrichtung zum linearen Einschieben der Griffeinrichtung auf. Bei der Hängeeinrichtung kann zum Beispiel ein entsprechend ausgebildeter Haken vorgesehen sein, auf den die Griffeinrichtung aufgehängt wird. Die Führungseinrichtung hingegen ermöglicht das Einschieben bzw. Einführen der Griffeinrichtung. Zum Beispiel kann die Führungseinrichtung in Form einer Schwalbenschwanzführung ausgebildet sein, die sich quer zur Längsachse der Säuleneinrichtung erstreckt. Entsprechend kann die Griffeinrichtung dann seitlich, also senkrecht zur Längsachse der Säuleneinrichtung in die Führung eingeschoben werden. Die Führungseinrichtung ermöglicht ein rasches Befestigen des Vorschaltgeräts an der Säuleneinrichtung. Gleichzeitig kann aber das Vorschaltgerät zuverlässig und dauerhaft an der Säuleneinrichtung befestigt bleiben.The holding device has a suspension device for suspending the gripping device of the ballast or a guide device for the linear insertion of the gripping device. In the hanging device may be provided, for example, a suitably trained hook on which the handle device is suspended. The guide device, however, allows the insertion or insertion of the handle device. For example, the guide means may be in the form of a dovetail guide extending transverse to the longitudinal axis of the column means. Accordingly, the gripping device can then be inserted laterally, that is perpendicular to the longitudinal axis of the column device in the guide. The guide device enables rapid attachment of the ballast to the column device. At the same time, however, the ballast can remain reliably and permanently attached to the column device.

An der Halteeinrichtung kann eine Verriegelungseinrichtung vorgesehen sein, zum Verriegeln der Griffeinrichtung in der Führungseinrichtung in einer vorgegebenen Halteposition an der Halteeinrichtung. Die Verriegelungseinrichtung ist somit in der Lage, die Griffeinrichtung derart zu verriegeln, dass ein ungewolltes Trennen des Vorschaltgeräts von der Halteeinrichtung bzw. der Säuleneinrichtung in jedem Fall verhindert wird. Nur durch Lösen der Verriegelungseinrichtung ist es möglich, die Griffeinrichtung aus der Führungseinrichtung zu schieben und das Vorschaltgerät zu entnehmen. Die Verriegelungseinrichtung kann zum Beispiel eine Rasteinrichtung aufweisen, so dass bei einem Einschieben der Griffeinrichtung in die Führungseinrichtung die Verriegelungseinrichtung bei Erreichen einer bestimmten Position einrastet, woraufhin die Griffeinrichtung mit dem Vorschaltgerät formschlüssig an der Säuleneinrichtung gesichert ist. Durch Lösen der Rasteinrichtung kann das Vorschaltgerät dann aus der Führungseinrichtung wieder herausgeschoben werden.On the holding device, a locking device may be provided for locking the handle device in the guide device in a predetermined holding position on the holding device. The locking device is thus able to lock the gripping device in such a way that unintentional disconnection of the ballast from the holding device or the column device is prevented in any case. Only by releasing the locking device, it is possible to push the handle device from the guide device and remove the ballast. The locking device may, for example, have a latching device, so that upon insertion of the grip device into the guide device, the locking device engages upon reaching a certain position, whereupon the grip device with the ballast is positively secured to the column device. By releasing the latching device, the ballast can then be pushed out of the guide device again.

Die Halteeinrichtung kann bei einer Ausführungsform unterhalb der unteren Halterung der Stativeinrichtung ausgebildet sein. Auf diese Weise ist es möglich, die Halteeinrichtung und damit - bei bestimmungsgemäßem Aufbau - auch das Vorschaltgerät an einer möglichst tiefliegenden Stelle vorzusehen.The holding device may be formed in one embodiment below the lower support of the tripod device. In this way it is possible to provide the holding device and thus - in the intended construction - the ballast at a low-lying as possible.

Bei einer Ausführungsform sind die Halteeinrichtung und die untere Halterung einstückig ausgebildet. Dadurch kann ein sehr kompakter Aufbau erreicht und insgesamt der bauliche Aufwand vermindert werden.In one embodiment, the holding device and the lower holder are integrally formed. As a result, a very compact structure can be achieved and overall the structural complexity can be reduced.

Diese und weitere Vorteile und Merkmale werden nachfolgend anhand von Beispielen unter Zuhilfenahme der begleitenden Figuren näher erläutert. Es zeigen:

- Fig. 1

- eine seitliche Perspektivansicht einer mobilen bzw. transportablen Leuchtvorrichtung;

- Fig. 2

- eine Säuleneinrichtung und eine Stativeinrichtung im Betriebszustand (a) und im zusammengelegten Zustand (b);

- Fig. 3

- eine Griffeinrichtung eines Vorschaltgeräts im getrennten Zustand (a) und im eingehängten Zustand (b);

- Fig. 4

- eine Griffeinrichtung im gehaltenen Zustand; und

- Fig. 5

- einen Teilschnitt durch eine Griffeinrichtung.

- Fig. 1

- a side perspective view of a mobile or portable lighting device;

- Fig. 2

- a column device and a tripod device in the operating state (a) and in the collapsed state (b);

- Fig. 3

- a gripping device of a ballast in the disconnected state (a) and in the suspended state (b);

- Fig. 4

- a grip device in the held state; and

- Fig. 5

- a partial section through a handle device.

Die Leuchtvorrichtung kann von einem Benutzer - gegebenenfalls zerlegt in einige wenige Komponenten - bequem zum Einsatzort bzw. zu verschiedenen Standorten getragen werden.The lighting device can be easily carried by a user - possibly disassembled into a few components - to the place of use or to different locations.

Im oberen Bildteil ist eine als Lichtballon ausgeführte Leuchteinrichtung 1 dargstellt. Die Leuchteinrichtung weist in ihrem Inneren ein nicht dargestelltes Leuchtmittel auf, das fast vollständig von einem Leuchtenschirm 2 umgeben ist.In the upper part of the picture a

Der Leuchtenschirm 2 wird durch ebenfalls nicht dargestellte Spannmittel in den in

Das im Inneren der Leuchteinrichtung 1 durch das Leuchtmittel bzw. die Lampe erzeugte Licht strahlt somit fast vollständig nach unten ab und beleuchtet den unterhalb liegenden Arbeitsbereich.The light generated in the interior of the

Die Leuchteinrichtung 1 wird an ihrer Unterseite von einer Säuleneinrichtung 4 getragen. Die Säuleneinrichtung 4 kann als Teleskopeinrichtung ausgebildet sein und mehrere ineinander verschiebbare Teleskopelemente aufweisen. Bei dem gezeigten Beispiel sind drei Teleskopelemente 5a, 5b, 5c vorgesehen, die linear ineinander verschiebbar und in ihren jeweiligen Relativstellungen verriegelbar sind. Entsprechende Teleskopeinrichtungen sind bekannt, so dass sich an dieser Stelle eine nähere Beschreibung erübrigt.The

Die Säuleneinrichtung 4 wird durch eine Stativeinrichtung 6 getragen und insbesondere am Umfallen gehindert.The

Die Stativeinrichtung 6 weist drei Stativbeine 7 auf, die am Umfang um 120° versetzt angeordnet sind. Auf diese Weise stützt sich die Stativeinrichtung 6 mit drei an den Enden der Stativbeine 7 vorgesehenen Stativfüßen 8 am Boden ab, was einen sicheren und definierten Stand im Sinne eines Dreibeins ermöglicht.The

Die den Stativfüßen 8 gegenüberliegenden Enden der Stativbeine 7 sind an einer oberen Halterung 9 verschwenkbar angelenkt. Etwa in der Mitte der Stativbeine 7 ist jeweils eine Strebe 10 mit ihrem einen Ende verschwenkbar angelenkt, deren anderes Ende sich zu einer unteren Halterung 11 erstreckt.The

Durch das Zusammenwirken der oberen Halterung 9, der unteren Halterung 11, der Stativbeine 7 und der Streben 10 wird ein stabiles Tragwerk gebildet, das zuverlässig die senkrecht stehende Säuleneinrichtung 4 hält.Due to the interaction of the

Die untere Halterung 11 ist am unteren Ende der Säuleneinrichtung 4 ortsfest befestigt, während die obere Halterung 9 die Säuleneinrichtung 4 umschließt und auf dieser axial in Längsrichtung der Säuleneinrichtung 4 hin und her bewegbar ist. Auf diese Weise kann die Stativeinrichtung 6 zwischen der in

Die Stativbeine 7 können als Vierkantrohr ausgebildet sein, während die Streben 10 in Form von U-Profilen ausgebildet sind. Dadurch ist es möglich, dass im zusammengelegten Transportzustand die Stativbeine 7 zwischen die Schenkel des U-förmigen Profils der Streben 10 zu liegen kommen, wodurch der Aufbau im zusammengelegten Zustand noch kompakter sein kann.The

An der unteren Halterung 11, genauer gesagt unterhalb der unteren Halterung 11 ist ein Vorschaltgerät 12 angehängt. Das Vorschaltgerät 12 dient als Transformator zum Bereitstellen eines entsprechenden Stroms für die Leuchteinrichtung 1. Es wird mit dem Baustellennetz, einem öffentlichen Netz oder einem Stromgenerator verbunden und wandelt den Strom in geeigneter Weise. Zudem dient es zum Zünden des Leuchtmittels in der Leuchteinrichtung 1.At the

Das Vorschaltgerät 12 weist ein erhebliches Gewicht auf. Dadurch, dass es am unteren Ende der Säuleneinrichtung 4 befestigt ist, wird der Gesamtschwerpunkt der Leuchtvorrichtung nach unten verschoben, wodurch die Standstabilität und damit zum Beispiel die Stabilität gegen Windeinflüsse deutlich erhöht wird.The

Das Vorschaltgerät 12 weist einen als Griffeinrichtung dienenden Handgriff 13 auf, an dem das Vorschaltgerät 12 bequem getragen werden kann. Gleichzeitig dient der Handgriff 13 zur Befestigung des Vorschaltgeräts 12 an der Säuleneinrichtung 4, wie

Zu beachten ist jedoch, dass im geöffneten Betriebszustand der Stativeinrichtung 6 das Vorschaltgerät 12 an der unteren Halterung 11 befestigt ist. Zum Erreichen des Transportzustands muss das Vorschaltgerät 12 vorher von der unteren Halterung 11 entfernt werden. Auf diese Weise lässt sich dann die Stativeinrichtung 6 mit der Säuleneinrichtung 4 bequem transportieren.It should be noted, however, that in the open operating state of the

In

Entsprechend ist an der unteren Halterung 11 (

Im Zusammenwirken der Öffnung 14 und des Hakenelements 15 einerseits sowie des Hakens 16a und der Öse 16b andererseits wird eine formschlüssige Verbindung zwischen dem Vorschaltgerät 12 bzw. dessen Handgriff 13 und der unteren Halterung 11 erreicht.In cooperation of the

Der untere Bereich der unteren Halterung 11 ist als Halteeinrichtung 17 ausgebildet. In der Halteeinrichtung 17 ist eine als Führungseinrichtung dienende Schwalbenschwanznut 18 ausgebildet, in die der Handgriff 13 von der Seite her eingeschoben werden kann. Der Handgriff 13 weist ein Querschnittsprofil auf, das derart angepasst ist, dass zwischen dem Handgriff 13 und der Schwalbenschwanznut 18 eine Schwalbenschwanzwirkung erzielt werden kann, wie

Nach Einschieben des Handgriffs 13 in die Schwalbenschwanznut 18 ist das Vorschaltgerät 12 bereits formschlüssig an der Halterung 11 und damit an der Säuleneinrichtung 4 befestigt.After insertion of the

Zur weiteren Absicherung ist eine in

Zum Lösen wird der federbelastete Stift 20 angehoben, so dass er aus der Ausnehmung 21 bewegt wird. Daraufhin kann der Handgriff 13 mit dem Vorschaltgerät 12 wieder aus der Schwalbenschwanznut 18 geschoben werden.To release the spring-loaded

Bei einer weiteren Variante ist es möglich, dass der Schwerpunkt des Vorschaltgeräts 12 nicht vertikal unterhalb der Säuleneinrichtung 4 angeordnet, sondern seitlich etwas versetzt ist, so dass der Schwerpunkt des Vorschaltgeräts 12 exzentrisch zu der Säuleneinrichtung 4 angeordnet ist. Auch auf diese Weise kann der Gesamtschwerpunkt herabgesetzt und die Stabilität der Leuchtvorrichtung erhöht werden.In a further variant, it is possible that the center of gravity of the

All diesen Varianten ist gemeinsam, dass mit Hilfe der Masse des Vorschaltgeräts der Gesamtschwerpunkt der Leuchtvorrichtung nach unten verlagert werden kann.All these variants have in common that with the help of the mass of the ballast, the overall center of gravity of the lighting device can be moved down.

Claims (12)

- Portable lighting apparatus, comprising- a lighting device (1);- a column device (4) which carries the lighting device (1) and extends in a longitudinal direction;- a stand device (6) which carries the column device (4); and comprising- a ballast (12) for providing electrical power for the lighting device (1);wherein- the ballast (12) is arranged on the column device (4) in the longitudinal direction below the column device (4);- the ballast (12) is held by a holding device (16, 17) on the column device (4);- the ballast (12) comprises a suspension device (13);- the holding device (16, 17) can be connected to the suspension device (13) in order to hold the ballast (12);- the suspension device comprises a handle device (13) for carrying the ballast (12); and wherein- the holding device (16, 17) is formed to hold the handle device (13).

- Portable lighting apparatus as claimed in claim 1, characterised in that the ballast (12) is attached, more particularly detachably attached, to the column device (4).

- Portable lighting apparatus as claimed in claim 1 or 2, characterised in that the lighting device (1) comprises- at least one lighting means; and- an at least partially translucent light screen surrounding at least part of the lighting means.

- Portable lighting apparatus as claimed in claim 3, characterised in that- the lighting device (1) comprises clamping means;- the clamping means can be fixed in a clamping state in which the clamping means clamp the light screen in order to hold the light screen in an open state ready for use; and in that- the clamping means can be moved into a non-clamping state in which the clamping means do not clamp the light screen.

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that the column device (4) is a telescopic device having at least two telescopic elements (5a, 5b, 5c) which can be linearly slid one inside the other.

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that the stand device (6) comprises:- an upper holder (9) which is arranged to be axially displaceable on the column device (4);- a lower holder (11) which is arranged in the region of a lower end of the column device (4);- at least three stand legs (7), one end of which is pivotably attached to the upper holder (9); and- a cross-piece (10) for each of the stand legs (7), one end of which is pivotably attached to the lower holder (11) and the other end of which is pivotably attached to the associated stand leg (7).

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that a stop is provided on the upper holder (9) for at least one of the stand legs (7) in order to delimit a pivoting movement of the stand leg (7) away from the longitudinal axis.

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that a stop is provided on the lower holder (11) for at least one of the cross-pieces (10) in order to delimit a pivoting movement of the cross-piece (10).

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that the holding device (16, 17) comprises:- a hanging device (16a, 16b) for suspending the handle device (13) of the ballast (12); or- a guide device (18) for linearly sliding-in the handle device (13).

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that a locking device (19) is provided on the holding device (17) for locking the handle device (13) in the guide device (18) in a predetermined holding position on the holding device (17).

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that the holding device (17) is formed below the lower holder (11).

- Portable lighting apparatus as claimed in any one of the preceding claims, characterised in that the holding device (17) and the lower holder (11) are formed in one piece.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013002202.9A DE102013002202A1 (en) | 2013-02-07 | 2013-02-07 | Portable lighting device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2765356A1 EP2765356A1 (en) | 2014-08-13 |

| EP2765356B1 true EP2765356B1 (en) | 2016-08-17 |

Family

ID=50031124

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14000275.9A Not-in-force EP2765356B1 (en) | 2013-02-07 | 2014-01-27 | Portable lighting device |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20140218936A1 (en) |

| EP (1) | EP2765356B1 (en) |

| DE (1) | DE102013002202A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11287103B2 (en) | 2019-04-22 | 2022-03-29 | Ism Lighting, Llc. | Low wattage balloon work light |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101674262B1 (en) * | 2014-11-05 | 2016-11-08 | 박성진 | Lighting device |

| AU2016215219B2 (en) | 2015-02-04 | 2018-12-13 | Milwaukee Electric Tool Corporation | Light |

| US10378739B2 (en) | 2015-04-24 | 2019-08-13 | Milwaukee Electric Tool Corporation | Stand light |

| DE202015103384U1 (en) | 2015-06-26 | 2015-08-04 | Gerhard Heubacher | Holding device for a load |

| US10775032B2 (en) | 2015-07-01 | 2020-09-15 | Milwaukee Electric Tool Corporation | Area light |

| US20170003574A1 (en) * | 2015-07-02 | 2017-01-05 | Hanel CHOI | Systems and devices for modular portable lighting |

| US10323831B2 (en) | 2015-11-13 | 2019-06-18 | Milwaukee Electric Tool Corporation | Utility mount light |

| USD816252S1 (en) | 2016-05-16 | 2018-04-24 | Milwaukee Electric Tool Corporation | Light |

| EP4249801A3 (en) | 2017-10-06 | 2023-12-06 | Milwaukee Electric Tool Corporation | Stand light |

| US11262020B2 (en) | 2018-08-02 | 2022-03-01 | Milwaukee Electric Tool Corporation | Standing tool with telescopic arm having a guide rod |

| JP7323431B2 (en) * | 2019-11-07 | 2023-08-08 | 株式会社マキタ | portable light |

| DE102019135534B4 (en) * | 2019-12-20 | 2024-05-23 | Hans-Werner Friedrich Briese | Luminaire unit, lighting device with a luminaire unit and reflector arrangement with a lighting device |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29910204U1 (en) | 1999-06-11 | 2000-03-23 | Nölle, Jürgen, Dipl.-Ing., 47495 Rheinberg | Spring lamp |

| US6350046B1 (en) * | 1999-07-22 | 2002-02-26 | Kenneth Lau | Light fixture |

| US6902294B2 (en) * | 2003-08-13 | 2005-06-07 | Michael N. Wright | Light stand |

| DE202004004984U1 (en) * | 2004-03-26 | 2004-06-03 | Nölle, Jürgen, Dipl.-Ing. | Transportable light |

| US7195377B2 (en) * | 2005-06-09 | 2007-03-27 | Peter Tsai | Worklight support with stand |

| CA2884517C (en) * | 2006-12-24 | 2017-01-24 | Brasscorp Limited | Led lamps including led work lights |

| US7824079B2 (en) * | 2008-12-08 | 2010-11-02 | Multiquip, Inc. | Light tower diffuser |

| US7997753B2 (en) * | 2009-03-19 | 2011-08-16 | Phillip Walesa | Dual mode portable lighting system |

| US9103495B2 (en) * | 2009-06-03 | 2015-08-11 | Air Systems, Inc. | Integrated portable stand, power supply, and control panel |

| US8201979B2 (en) * | 2009-11-20 | 2012-06-19 | Pelican Products, Inc. | Collapsible light |

-

2013

- 2013-02-07 DE DE102013002202.9A patent/DE102013002202A1/en not_active Ceased

-

2014

- 2014-01-27 EP EP14000275.9A patent/EP2765356B1/en not_active Not-in-force

- 2014-01-28 US US14/165,811 patent/US20140218936A1/en not_active Abandoned

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11287103B2 (en) | 2019-04-22 | 2022-03-29 | Ism Lighting, Llc. | Low wattage balloon work light |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2765356A1 (en) | 2014-08-13 |

| US20140218936A1 (en) | 2014-08-07 |

| DE102013002202A1 (en) | 2014-08-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2765356B1 (en) | Portable lighting device | |

| EP1059483B1 (en) | Portable lamp | |

| DE2618160A1 (en) | Lounger | |

| DE102017101113B3 (en) | Telescopic boom with pole tensioning system for a mobile crane and guying method | |

| DE102015108034A1 (en) | Device for securing cargo | |

| EP1610639A1 (en) | Unfoldable and foldable or fixed protective canopy structure | |

| DE102008061334B4 (en) | Device for handling heavy objects | |

| DE102010014989B4 (en) | Stand for masts | |

| EP2789904B1 (en) | Portable lighting device with bending rods | |

| EP3399517A1 (en) | Lighting box | |

| DE102013005987A1 (en) | Portable lighting device with lamp holder | |

| DE4445165C2 (en) | Method and stick tree for erecting lattice masts | |

| DE2709652A1 (en) | Sun shade stand with pole and pointed bottom end - has at least three radially positioned rods fixed to it with holes for tent pegs | |

| DE2260465C3 (en) | Collapsible rod | |

| DE102019103982B3 (en) | Storage devices for use with a standing clothes dryer | |

| AT511737B1 (en) | Start assist device | |

| DE102010044103A1 (en) | Working table, especially for the workshop area | |

| CH700853A1 (en) | Strassensignalisations- or Strassenabsperrmittel. | |

| DE4227322C1 (en) | Tent rapidly erectable frame with linkage coupled to central suspension - comprises rods secured in releasable holders by distal ends,and tensioning spokes coupled to clamping head | |

| DE2233342A1 (en) | TELESCOPIC MAST | |

| DE102014006823A1 (en) | Portable lighting device | |

| DE4315287A1 (en) | Illuminated traffic sign | |

| DE2540400C2 (en) | Rack winch | |

| DE102016104422A1 (en) | Luminaire with roll-up carrier | |

| DE102015002727A1 (en) | Device for raising people lying on the ground |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20140127 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| R17P | Request for examination filed (corrected) |

Effective date: 20150211 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F21L 14/00 20060101ALI20160118BHEP Ipc: F21V 21/06 20060101AFI20160118BHEP Ipc: F21W 131/10 20060101ALN20160118BHEP Ipc: F21V 23/02 20060101ALN20160118BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F21V 21/06 20060101AFI20160216BHEP Ipc: F21W 131/10 20060101ALN20160216BHEP Ipc: F21L 14/00 20060101ALI20160216BHEP Ipc: F21V 23/02 20060101ALN20160216BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20160308 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 821468 Country of ref document: AT Kind code of ref document: T Effective date: 20160915 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502014001226 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20160817 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161117 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161219 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161118 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502014001226 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161117 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170131 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170929 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170131 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170131 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170127 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170127 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 821468 Country of ref document: AT Kind code of ref document: T Effective date: 20190127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160817 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190127 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20200123 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502014001226 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210803 |