EP1769131B1 - Drill head for a ground-boring device - Google Patents

Drill head for a ground-boring device Download PDFInfo

- Publication number

- EP1769131B1 EP1769131B1 EP05772195A EP05772195A EP1769131B1 EP 1769131 B1 EP1769131 B1 EP 1769131B1 EP 05772195 A EP05772195 A EP 05772195A EP 05772195 A EP05772195 A EP 05772195A EP 1769131 B1 EP1769131 B1 EP 1769131B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- boring head

- boring

- head section

- section

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000006073 displacement reaction Methods 0.000 claims abstract description 5

- 238000005520 cutting process Methods 0.000 claims description 32

- 238000009527 percussion Methods 0.000 claims description 16

- 239000012530 fluid Substances 0.000 claims description 9

- 230000009471 action Effects 0.000 claims description 3

- 230000000630 rising effect Effects 0.000 claims 2

- 230000005540 biological transmission Effects 0.000 abstract description 2

- 239000002689 soil Substances 0.000 description 32

- 238000010304 firing Methods 0.000 description 12

- 230000008901 benefit Effects 0.000 description 4

- 238000005553 drilling Methods 0.000 description 4

- 238000003466 welding Methods 0.000 description 4

- 239000011435 rock Substances 0.000 description 3

- 230000000454 anti-cipatory effect Effects 0.000 description 2

- 238000013467 fragmentation Methods 0.000 description 2

- 238000006062 fragmentation reaction Methods 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 235000015842 Hesperis Nutrition 0.000 description 1

- 235000012633 Iberis amara Nutrition 0.000 description 1

- 229910000278 bentonite Inorganic materials 0.000 description 1

- 239000000440 bentonite Substances 0.000 description 1

- SVPXDRXYRYOSEX-UHFFFAOYSA-N bentoquatam Chemical compound O.O=[Si]=O.O=[Al]O[Al]=O SVPXDRXYRYOSEX-UHFFFAOYSA-N 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B7/00—Special methods or apparatus for drilling

- E21B7/04—Directional drilling

- E21B7/046—Directional drilling horizontal drilling

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B4/00—Drives for drilling, used in the borehole

- E21B4/06—Down-hole impacting means, e.g. hammers

- E21B4/14—Fluid operated hammers

- E21B4/145—Fluid operated hammers of the self propelled-type, e.g. with a reverse mode to retract the device from the hole

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B7/00—Special methods or apparatus for drilling

- E21B7/26—Drilling without earth removal, e.g. with self-propelled burrowing devices

Definitions

- the invention relates to a drill head for an earth boring device.

- ground rockets For generating wells in the field of horizontal drilling, it is known to use so-called ground rockets, which have a controlled via a drive fluid reciprocating percussion piston. This piston transmits its kinetic energy when hitting a contact surface of the housing or the drill head and drives the auger gradually through the soil.

- the drill head of the device fulfills several tasks. On the one hand this transmits the impact energy of the percussion piston on the ground in front of it and loosens this. Furthermore, the loosened soil should be displaced laterally, so that a borehole with the desired diameter is formed. In addition, the drill head to provide a special shape for a guide and thus for a directional stability of the device.

- drilling heads with a conical base body are known from the prior art (for example DE 21 57 259 C or even out DE 40 14 775 C1 ). These are characterized by the fact that the smoothest, conical jacket has a minimum resistance against the direction of movement.

- these drill heads show a low directional stability, so that the device is deflected out of the desired path by lateral forces, which are caused by hitting obstacles or inhomogeneities within the ground.

- step heads are known (for example DE 101 12 985 A1 ).

- the step heads also have a diameter which increases starting from the tip, but the increase in diameter occurs in steps,

- Im Longitudinal section shows a drill head of this type thus two stairs that meet in the top of the head.

- the drill head consists in the front of a series sternformig arranged cutting.

- the spaces between the cutting serve as Ab technologicalkanale for the removed rock.

- a conical section of the drill joins, which deflects the removed rock in the direction of the borehole wall, where it is blown through an annular gap between the borehole wall and device housing.

- the U.S. Patent 5,467,831 which is provided as the closest prior art discloses a ram boring device with a koniaehieutaufenden Bohrkopt, at the rear end two stabilizers arranged with a triangular cross section on the housing of the drill head, that in the longitudinal direction of the ram boring aligned channels for the supply and discharge be formed by compressed air.

- the present invention seeks to provide a particularly advantageous for use in displaceable soil drill head, the particular advantages of the conical drill head - for example, low resistance to movement - with advantages of the step head - for example, high directional stability - connects.

- the invention provides to carry out the drill head from at least three drill head sections.

- the first drill head section closest to the front end of the device has discharge channels and can be used to loosen the soil or smash obstacles.

- the loosened or crushed soil can be guided through the discharge channels in the first drill head portion to the rear in the direction of the second head portion and depending on the version also to the outside.

- drilling head in the sense of the invention is to be understood in particular as meaning the tool at the head end of an earth boring device, which can serve for producing and widening bores and already laid lines.

- discharge channels are depressions or recessed portions or holes understood that do not extend transversely to the longitudinal direction of the Erdbohr réelles.

- the terms “recess” and “hole” are not manufacturing technology limiting, but to understand geometric, so that wells or holes according to the invention can also be produced by cultivation.

- the discharge channels are arranged at an angle between 0 ° and 45 ° to the longitudinal direction of the Erdbohr réelles.

- the second drill head section with one or more substantially conical sections on the lateral surface can provide for the radial compaction of the loosened soil.

- the effect of the invention can also be achieved with any other geometries.

- a largely conical shape is understood in particular to mean a lateral surface which-at least partially-rises continuously from a small radial extent to a larger radial extent and thus has no sections within the conical region in which the radius is reduced again.

- the third drill head section is designed for attachment of the entire drill head to the housing of an earth boring device.

- This attachment to the housing may be direct or indirect, i. be executed via intermediate elements.

- a particular advantage of the drill head according to the invention is that the loosening work or the work of fragmentation is first carried out by a leading drill head section whose shape has been optimized for this task.

- the preferred combination of the chisel tip with star-shaped blades ensures a high fragmentation performance of the first head section with low resistance to movement. Due to the absence of large, oblique (not vertical) to Moving direction of lying surfaces of the response of the first drill head section on isolated lateral forces due to one-sided obstacles low.

- the second drill head section compacts the loosened and shattered soil which has been passed through the depressions behind the first head section. Due to the largely conical shape (of sections) of the second head section this is particularly well designed for the radial displacement of the soil with low resistance to movement.

- Such a drill head is now used according to the invention for displacement bores in corresponding displaceable soils.

- this can be advantageous when creating horizontal bores.

- Dislacement bore is understood to mean a bore which is essentially based on producing a borehole by radially displacing the environment, whereby the corresponding "displaceable bottom” deforms substantially plastically and the soil structure is substantially deformed by adhesion or other physical effects the deformed structure remains.

- At least two of the drill head sections are longitudinally axially movable (relative to the longitudinal axis of the Erdbohr réelles) to each other.

- An advantageous embodiment provides to perform the first and second drill head portion to each other movable.

- it is preferably provided to execute the second drill head section fixedly - at least longitudinally - to the third drill head section. This can be achieved that first the first head section is driven into the soil. The soil is loosened or smashed and directed backwards. The then driven second head section compresses the loosened soil and thus creates the desired diameter of the borehole. At the same time this is entrained by the fixed connection with the third drill head section or with the housing of Erdbohrvorraum.

- a particular advantage of this embodiment is that, as the first drill head section is propelled, the housing and the second and third head sections are not initially accelerated, so much of the kinetic energy of the percussion piston is transmitted to crush and loosen the soil.

- An alternative embodiment may provide for rigidly connecting the first and second bit sections (at least longitudinally) and for providing that unit movable with the third bit section.

- the functions of the first head section - in particular the loosening, shattering and diverting of the soil - and those of the second head section - in particular the radial compression of the loosened soil - are carried out in a joint operation.

- the entire, transmitted by the percussion piston of the Erdbohr réelles energy can be used.

- the tracking of the auger per se is then only in a second step, when the third connected to the housing Bohrkopfabites is propelled.

- the discharge channels of the first drill head section are dimensioned so that a large number of equally spaced cutting edges are formed with a small wall thickness.

- the thin cutting edges ensure a high cutting action, while a generous dimensioning of the discharge channels ensures a low-resistance removal of the soil.

- the leading edges of the blades are oriented substantially perpendicular to the longitudinal axis of the drill bit.

- the discharge channels it is not necessary for the discharge channels to run constantly from the front of the first drill head section to the rear side thereof. Rather, the discharge channels within the first drill head portion may leak or the first drill head portion may consist of two halves, both of which are provided with Ab technologicalkanälen or cutting, but are rotationally offset from one another. Thus, a cutting edge of the rear half can be arranged behind each discharge channel of the front half of the first drill head section.

- the diameter of the first drill head section substantially corresponds to the diameter of a subsequent housing of the drill. It can thus be achieved that the soil is loosened up by the cutting edges of the first drill head section in a cross-section which substantially corresponds to that of the housing of the drill.

- the housing diameter and thus the loosened diameter corresponds to the nominal diameter of the bore to be created.

- the drill head sections may be dimensioned such that the largest diameter of the first drill head section is greater than the smallest diameter of the second drill head section.

- the largest diameter of the first drill head portion may be made larger than that of the housing. This ensures that a sufficient volume within the soil is relaxed and thus the resistance to movement acting on the housing is reduced.

- the first head portion may include or be connected to a striker.

- the firing pin in turn may have a projecting into the ground chisel tip through which a targeted introduction of the impact energy can be done in the soil located in front of the drill head.

- Obstacles such as stones in the ground, are easily smashed.

- the firing pin penetrates the second and / or third head portion and can thus serve as a guide for a relative movement of these head portions, provided that they are designed to the first head portion lijnsaxial movable.

- the firing pin can also be connected to the second head section.

- the impact energy is transmitted to the third head portion or the associated housing of the device.

- the percussion piston can impinge on a contact surface of the housing or of the second head section after a certain forward movement of the firing pin.

- the firing pin may have a contact surface which, after a certain forward movement of the firing pin, strikes a corresponding contact surface of the housing / of the third head section.

- the three head portions are accordingly sequentially applied by the percussion piston of the drill - directly or indirectly -.

- connection between the third head portion and the housing is designed positively. This is particularly advantageous in terms of ease of maintenance.

- the drill head can be changed quickly and easily. Thread connections and / or bayonet closures are advantageously suitable for this purpose. Any other form-fitting, but also non-positive connection types are possible.

- connection can also be produced by welding, for which the friction welding method is particularly suitable.

- the connection by welding is particularly suitable when the shortest possible length of the device is required.

- connection is not limited.

- the loosened soil behind the first drill head section with oil, bentonite or other fluid is mixed.

- an entry of the fluid can also take place before the first head section.

- bores can be provided in the housing or in one of the head sections, which preferably introduce the fluid used radially into the loosened soil.

- the mixing of the soil with a fluid can serve to reduce the skin friction of the redrawn housing. In addition, it can increase the occurring cohesion of the displaced soil, so that the stability of the well is improved and burglaries of the well occur in reduced numbers.

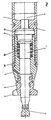

- Fig. 1 shows the front part of a ram boring machine, consisting of a housing 1 and an associated drill head according to the invention in a first embodiment.

- the drill head consists essentially of the components, striker 2, cutting ring 3 and displacer 4.

- striker 2 and cutting ring 3 together form in this embodiment, a first drill head portion, the second head portion, here in the form of the displacer 4 and the third head portion 11 axially is mobile.

- the displacer 4 and the third head section 11 are guided on the firing pin 2.

- the rear end of the firing pin 2 protrudes into a working space 5 of the housing 1, in which a percussion piston (not shown), driven by a pressurized fluid, reciprocates.

- a percussion piston (not shown), driven by a pressurized fluid, reciprocates.

- the percussion piston first strikes the end of the firing pin 2 protruding into the working space 5 and accelerates it in the direction forward.

- the firing pin is driven together with the bit tip 6 and the cutting ring 3 in the soil to loosen this or to smash occurring obstacles.

- the percussion piston hits the housing 1 or the displacer 4 on the contact surface 7 of the housing 1 after a certain relative movement of the striker 2, or the striker 2 with a shoulder 12 strikes the contact surface 8 of the displacer component 4.

- the housing 1 is accelerated together with displacer 4 and follows the movement of the cutting ring 3.

- the displacer 4 compresses the loosened soil and produces a borehole with the diameter of the housing first

- Fig. 2 can be the radial arrangement of the blades 9 recognize that arise by a corresponding dimensioning of the discharge channels 10.

- the drill head according to the invention is designed so that it can be used as a unit from the front into the housing 1 and fixed there. This is particularly advantageous for maintenance work, since the drill head has the most stressed components and consequently is subject to the highest wear during operation. A simple replacement of the drill head is thus possible.

- drill bits with different shapes such as those in the Fig. 3 to 7 are shown, depending on the requirement quickly and easily connected to the housing.

- the Fig. 3 and 4 show an alternative embodiment of the drill head according to the invention.

- the first (cutting ring 3) and second (displacer 4) drill head section are designed as a unit firmly connected to each other.

- This unit is further connected to the firing pin 2, which in turn serves as a guide for the axially movable to the other two head portions third head portion 11.

- the third head portion 11 is connected via the thread 13 with the housing of a drill.

- the displacer 4 differs in particular from that of the first embodiment in that it has only individual conical sections. These are interrupted by further cutting, which are arranged in alignment with a respective discharge channel 10 of the cutting ring 3.

- Fig. 3 and 4 show the same embodiment in different positions.

- Fig. 3 the movable part of the drill head is shown in its retracted position.

- the play between the shoulder 12 of the percussion piston 2 and the striking surface 8 of the third drill head section 11 can clearly be seen.

- the play between the second and third drill head sections is minimal.

- Fig. 4 the movable part of the drill head is shown in an anticipatory position. Accordingly, the clearance between shoulder 12 and face 8 is minimal and maximum between the second and third bits.

- Fig. 5 to 7 show different shapes for the cutting ring 3. These different shapes are in principle for all according to the invention and in particular the two embodiments according to Fig. 1 respectively. Fig. 3 and 4 equally suitable.

- the in the Fig. 5 illustrated embodiment differs from the first embodiment in particular by the shape of the cutting. These are formed substantially trapezoidal. The recesses thus obtain a U-shape in contrast to the V-shaped recesses in the first embodiment.

- the cutting ring consists of two halves, the cutting edges are rotationally offset from one another. In this way, solids that have not been shattered by the front cutting ring half meet the cutting edges of the rear cutting ring half.

- the longitudinal edges of the cutting edges are at an angle of approximately 45 ° to the longitudinal direction of the drill head or the drill.

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mining & Mineral Resources (AREA)

- Physics & Mathematics (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Mechanical Engineering (AREA)

- Earth Drilling (AREA)

Abstract

Description

Die Erfindung betrifft einen Bohrkopf für ein Erdbohrgerät.The invention relates to a drill head for an earth boring device.

Zum Erzeugen von Bohrlöchern im Bereich des Horizontalbohrens ist es bekannt, sogenannte Erdraketen einzusetzen, die einen über ein Antriebsfluid gesteuerten hin- und hergehenden Schlagkolben aufweisen. Dieser Kolben überträgt seine kinetische Energie beim Auftreffen auf eine Kontaktfläche des Gehäuses bzw. des Bohrkopfs und treibt das Erdbohrgerät schrittweise durch das Erdreich.For generating wells in the field of horizontal drilling, it is known to use so-called ground rockets, which have a controlled via a drive fluid reciprocating percussion piston. This piston transmits its kinetic energy when hitting a contact surface of the housing or the drill head and drives the auger gradually through the soil.

Dabei erfüllt der Bohrkopf der Vorrichtung mehrere Aufgaben. Zum einen überträgt dieser die Schlagenergie des Schlagkolbens auf das davor liegende Erdreich und lockert dieses. Weiterhin soll das gelockerte Erdreich seitlich verdrängt werden, so daß ein Bohrloch mit dem gewünschten Durchmesser entsteht. Zusätzlich soll der Bohrkopf durch eine spezielle Formgebung für eine Führung und folglich für eine Richtungsstabilität der Vorrichtung sorgen.The drill head of the device fulfills several tasks. On the one hand this transmits the impact energy of the percussion piston on the ground in front of it and loosens this. Furthermore, the loosened soil should be displaced laterally, so that a borehole with the desired diameter is formed. In addition, the drill head to provide a special shape for a guide and thus for a directional stability of the device.

Zur Erfüllung dieser Aufgaben wurden verschiedene Bohrkopfformen entwickelt.To fulfill these tasks, various drill head shapes have been developed.

Aus dem Stand der Technik sind zum einen Bohrköpfe mit einem konischen Grundkörper bekannt (zum Beispiel aus

Teilweise weisen die konischen Bohrköpfe Vertiefungen in Richtung der Längsachse der Vorrichtung auf. Durch diese Vertiefungen wird das gelockerte Erdreich nach außen transportiert.Some of the conical drill heads on recesses in the direction of the longitudinal axis of the device. Through these depressions, the loosened soil is transported to the outside.

Als Nachteil zeigen diese Bohrköpfe eine geringe Richtungsstabilität, so daß durch Seitenkräfte, die durch das Auftreffen auf Hindernisse oder Inhomogenitäten innerhalb des Erdbodens entstehen, die Vorrichtung aus der gewünschten Bahn abgelenkt wird.As a disadvantage, these drill heads show a low directional stability, so that the device is deflected out of the desired path by lateral forces, which are caused by hitting obstacles or inhomogeneities within the ground.

Neben den konischen Bohrköpfen sind die sogenannten Stufenköpfe bekannt (zum Beispiel aus

Ferner ist aus

Weiterhin ist aus

Die

Ausgehend von diesem Stand der Technik liegt der Erfindung die Aufgabe zugrunde, einen insbesondere für den Einsatz in verdrängbaren Böden vorteilhaften Bohrkopf zu schaffen, der insbesondere Vorteile des konischen Bohrkopfs - zum Beispiel geringer Bewegungswiderstand - mit Vorteilen des Stufenkopfs - zum Beispiel hohe Richtungsstabilität - verbindet.Based on this prior art, the present invention seeks to provide a particularly advantageous for use in displaceable soil drill head, the particular advantages of the conical drill head - for example, low resistance to movement - with advantages of the step head - for example, high directional stability - connects.

Diese Aufgabe wird durch den Gegenstand der nebengeordneten Ansprüche gelöst. Vorteilhafte Ausgestaltungen sind in den Unteransprüchen beansprucht.This object is achieved by the subject matter of the independent claims. Advantageous embodiments are claimed in the subclaims.

Die Erfindung sieht vor, den Bohrkopf aus mindestens drei Bohrkopfabschnitten auszuführen.The invention provides to carry out the drill head from at least three drill head sections.

Der erste Bohrkopfabschnitt, der dem vorderen Ende der Vorrichtung am nächsten gelegen ist, weist Abführkanäle auf und kann zur Lockerung des Erdreichs bzw. zum Zertrümmern von Hindernissen dienen. Das gelockerte bzw. zertrümmerte Erdreich kann durch die Abführkanäle in dem ersten Bohrkopfabschnitt nach hinten in Richtung des zweiten Kopfabschnittes und je nach Ausführung auch nach außen geführt werden.The first drill head section closest to the front end of the device has discharge channels and can be used to loosen the soil or smash obstacles. The loosened or crushed soil can be guided through the discharge channels in the first drill head portion to the rear in the direction of the second head portion and depending on the version also to the outside.

Unter "Bohrkopf' im Sinne der Erfindung ist dabei insbesondere das Werkzeug am Kopfende eines Erdbohrgeräts zu verstehen, welches zum Herstellen und Aufweiten von Bohrungen und bereits verlegten Leitungen dienen kann.The term "drill head" in the sense of the invention is to be understood in particular as meaning the tool at the head end of an earth boring device, which can serve for producing and widening bores and already laid lines.

Unter "Abführkanälen" werden Vertiefungen beziehungsweise Vertiefungsabschnitte oder Bohrungen verstanden, die nicht quer zu der Längsrichtung des Erdbohrgeräts verlaufen. Dabei sind die Begriffe "Vertiefung" und "Bohrung" nicht herstellungstechnisch beschränkend, sondern geometrisch zu verstehen, so daß erfindungsgemäße Vertiefungen bzw. Bohrungen auch durch Anbau hergestellt werden können.By "discharge channels" are depressions or recessed portions or holes understood that do not extend transversely to the longitudinal direction of the Erdbohrgeräts. The terms "recess" and "hole" are not manufacturing technology limiting, but to understand geometric, so that wells or holes according to the invention can also be produced by cultivation.

Besonders vorteilhaft ist, wenn die Abführkanäle, je nach Ausführung des Erdbohrgeräts, mit einem Winkel zwischen 0° und 45° zu der Längsrichtung des Erdbohrgeräts angeordnet sind.It is particularly advantageous if the discharge channels, depending on the design of the Erdbohrgeräts, are arranged at an angle between 0 ° and 45 ° to the longitudinal direction of the Erdbohrgeräts.

Der zweite Bohrkopfabschnitt mit einem oder mehreren weitgehend konischen Abschnitten auf der Mantelfläche kann für die radiale Verdichtung des gelockerten Erdreichs sorgen. Die erfindungsgemäße Wirkung läßt sich aber auch mit beliebigen anderen Geometrien erreichen.The second drill head section with one or more substantially conical sections on the lateral surface can provide for the radial compaction of the loosened soil. The effect of the invention can also be achieved with any other geometries.

Unter weitgehend konischer Form wird dabei insbesondere eine Mantelfläche verstanden, die - zumindest teilweise -, ausgehend von einer kleinen radialen Erstreckung, kontinuierlich bis zu einer größeren radialen Erstreckung ansteigt und somit keine Abschnitte innerhalb des konischen Bereichs aufweist, in denen sich der Radius wieder verringert.In this case, a largely conical shape is understood in particular to mean a lateral surface which-at least partially-rises continuously from a small radial extent to a larger radial extent and thus has no sections within the conical region in which the radius is reduced again.

Der dritte Bohrkopfabschnitt ist für eine Befestigung des gesamten Bohrkopfs mit dem Gehäuse eines Erdbohrgeräts ausgelegt. Diese Befestigung mit dem Gehäuse kann direkt oder indirekt, d.h. über Zwischenelemente ausgeführt sein.The third drill head section is designed for attachment of the entire drill head to the housing of an earth boring device. This attachment to the housing may be direct or indirect, i. be executed via intermediate elements.

Die Unterteilung des Bohrkopfs in die verschiedenen Abschnitte ist insbesondere funktionell zu sehen, so daß es nicht erforderlich ist, daß eine bauliche Trennung aller Abschnitte in jeder erfindungsgemäßen Ausführungsform gegeben sein muß.The subdivision of the drill head into the various sections is in particular to be seen functionally, so that it is not necessary that a structural separation of all sections must be given in each embodiment of the invention.

Ein besonderer Vorteil des erfindungsgemäßen Bohrkopfs liegt darin, daß die Lockerungsarbeit bzw. die Zertrümmerungsarbeit zunächst von einem vorauseilenden Bohrkopfabschnitt ausgeführt wird, dessen Formgebung für diese Aufgabe optimiert wurde. Die bevorzugte Kombination der Meißelspitze mit sternförmig angeordneten Schneiden sorgt für eine hohe Zertrümmerungsleistung des ersten Kopfabschnitts bei gleichzeitig niedrigem Bewegungswiderstand. Durch das Fehlen großer, schräg (nicht senkrecht) zur Bewegungsrichtung liegender Flächen fällt die Reaktion des ersten Bohrkopfabschnitts auf isolierte Seitenkräfte infolge einseitiger Hindernisse gering aus.A particular advantage of the drill head according to the invention is that the loosening work or the work of fragmentation is first carried out by a leading drill head section whose shape has been optimized for this task. The preferred combination of the chisel tip with star-shaped blades ensures a high fragmentation performance of the first head section with low resistance to movement. Due to the absence of large, oblique (not vertical) to Moving direction of lying surfaces of the response of the first drill head section on isolated lateral forces due to one-sided obstacles low.

Der zweite Bohrkopfabschnitt verdichtet das gelockerte und zertrümmerte Erdreich, welches durch die Vertiefungen hinter den ersten Kopfabschnitt geführt wurde. Durch die weitgehend konische Formgebung (von Abschnitten) des zweiten Kopfabschnitts ist dieser besonders gut für die radiale Verdrängung des Erdreichs bei gleichzeitig geringem Bewegungswiderstand ausgelegt.The second drill head section compacts the loosened and shattered soil which has been passed through the depressions behind the first head section. Due to the largely conical shape (of sections) of the second head section this is particularly well designed for the radial displacement of the soil with low resistance to movement.

Ein solcher Bohrkopf wird nun erfindungsgemäß für Verdrängungsbohrungen in entsprechend verdrängbaren Böden eingesetzt. Insbesondere kann dies vorteilhaft beim Erstellen von Horizontalbohrungen erfolgen.Such a drill head is now used according to the invention for displacement bores in corresponding displaceable soils. In particular, this can be advantageous when creating horizontal bores.

Unter ".Verdrängungsbohrung" wird erfindungsgemäß eine Bohrung verstanden, die im wesentlichen darauf beruht, ein Bohrloch durch radiale Verdrängung der Umgebung herzustellen, wobei sich der entsprechend "verdrängbare Boden" im wesentlichen plastisch verformt und das Bodengefüge durch Adhäsion oder andere physikalische Effekte im wesentlichen in der verformten Struktur verbleibt."Displacement bore" according to the invention is understood to mean a bore which is essentially based on producing a borehole by radially displacing the environment, whereby the corresponding "displaceable bottom" deforms substantially plastically and the soil structure is substantially deformed by adhesion or other physical effects the deformed structure remains.

Der formimmanente Nachteil dieser Kopfform, die hohe Empfindlichkeit gegen einseitige Krafteinleitung, die beim Gesteinsbohren nicht zum tragen kommt, wird dadurch weitgehend kompensiert, daß der erste Kopfabschnitt auftretende Hindernisse bereits zerstört haben kann und weiterhin dadurch, daß der zweite Bohrkopfabschnitt ausschließlich der durch den ersten Abschnitt vorgegebenen Richtung folgt.The formimmanente disadvantage of this head shape, the high sensitivity to unilateral force application, which does not apply in rock drilling, is largely compensated by the fact that the first head portion may have already destroyed obstacles and further characterized in that the second drill head section exclusively by the first section given direction follows.

Um eine gezielte Übertragung der Schlagenergie des Erdbohrgeräts auf das Erdreich zu erreichen, kann erfindungsgemäß vorgesehen sein, daß mindestens zwei der Bohrkopfabschnitte längsaxial (im Bezug zur Längsachse des Erdbohrgeräts) zueinander beweglich sind.In order to achieve a targeted transmission of the impact energy of Erdbohrgeräts on the soil, it can be provided according to the invention that at least two of the drill head sections are longitudinally axially movable (relative to the longitudinal axis of the Erdbohrgeräts) to each other.

Eine vorteilhafte Ausführungsform sieht vor, den ersten und zweiten Bohrkopfabschnitt zueinander beweglich auszuführen. Hierbei ist bevorzugt vorgesehen, den zweiten Bohrkopfabschnitt fest - zumindest längsaxial - zu dem dritten Bohrkopfabschnitt auszuführen. Dadurch kann erreicht werden, daß zunächst der erste Kopfabschnitt in das Erdreich vorgetrieben wird. Dabei wird das Erdreich gelockert bzw. zertrümmert und nach hinten geleitet. Der daraufhin vorgetriebene zweite Kopfabschnitt verdichtet das gelockerte Erdreich und erstellt somit den gewünschten Durchmesser des Bohrlochs. Gleichzeitig wird durch die feste Verbindung mit dem dritten Bohrkopfabschnitt bzw. mit dem Gehäuse der Erdbohrvorrichtung dieses mitgeführt.An advantageous embodiment provides to perform the first and second drill head portion to each other movable. Here, it is preferably provided to execute the second drill head section fixedly - at least longitudinally - to the third drill head section. This can be achieved that first the first head section is driven into the soil. The soil is loosened or smashed and directed backwards. The then driven second head section compresses the loosened soil and thus creates the desired diameter of the borehole. At the same time this is entrained by the fixed connection with the third drill head section or with the housing of Erdbohrvorrichtung.

Ein besonderer Vorteil dieser Ausführung ist, daß bei dem Vorwärtstreiben des ersten Bohrkopfabschnitts das Gehäuse und der zweite und dritte Kopfabschnitt zunächst nicht beschleunigt werden, so daß ein großer Teil der kinetischen Energie des Schlagkolbens zur Zertrümmerung und Lockerung des Erdreichs in dieses übertragen wird.A particular advantage of this embodiment is that, as the first drill head section is propelled, the housing and the second and third head sections are not initially accelerated, so much of the kinetic energy of the percussion piston is transmitted to crush and loosen the soil.

Eine alternative Ausführungsform kann vorsehen, den ersten und zweiten Bohrkopfabschnitt (zumindest längsaxial) fest verbunden auszuführen und diese Einheit beweglich zu dem dritten Bohrkopfabschnitt vorzusehen. In diesem Fall werden die Funktionen des ersten Kopfabschnitts - insbesondere das Lockern, Zertrümmern und Ableiten des Erdreichs - und diejenigen des zweiten Kopfabschnitts - insbesondere das radiale Verdichten des gelockerten Erdreichs - in einem gemeinsamen Arbeitsschritt ausgeführt. Hierzu kann die gesamte, von dem Schlagkolben des Erdbohrgeräts übertragene Energie genutzt werden. Das Nachführen des Erdbohrgeräts an sich erfolgt dann erst in einem zweiten Schritt, wenn der dritte mit dem Gehäuse verbundene Bohrkopfabschnitt vorgetrieben wird.An alternative embodiment may provide for rigidly connecting the first and second bit sections (at least longitudinally) and for providing that unit movable with the third bit section. In this case, the functions of the first head section - in particular the loosening, shattering and diverting of the soil - and those of the second head section - in particular the radial compression of the loosened soil - are carried out in a joint operation. For this purpose, the entire, transmitted by the percussion piston of the Erdbohrgeräts energy can be used. The tracking of the auger per se is then only in a second step, when the third connected to the housing Bohrkopfabschnitt is propelled.

Weiterhin kann es vorteilhaft sein, alle drei Bohrkopfabschnitte längsaxial beweglich zueinander auszuführen. Dadurch, daß die drei Kopfabschnitte nacheinander vorgetrieben werden, kann eine noch gezieltere Einleitung der Schlagkräfte des Erdbohrgeräts in das Erdreich erreicht werden.Furthermore, it may be advantageous to perform all three drill head sections longitudinally axially movable relative to each other. The fact that the three head sections are driven one after the other, an even more targeted initiation of the impact forces of Erdbohrgeräts can be achieved in the soil.

Durch die gezielte Einleitung der Antriebsenergie in das Erdreich bei erfindungsgemäßen Bohrköpfen mit zueinander beweglichen Bohrkopfabschnitten eignen sich auch für den Einsatz in beliebigen Böden.The targeted introduction of the drive energy into the soil in drill heads according to the invention with mutually movable drill head sections are also suitable for use in any soil.

Vorteilhaft ist, wenn die Abführkanäle des ersten Bohrkopfabschnitts so dimensioniert sind, daß eine Vielzahl von in gleichmäßiger Teilung angeordneten Schneiden mit geringer Wandstärke entstehen. Die dünnen Schneiden sorgen für eine hohe Schnittwirkung, während eine großzügige Dimensionierung der Abführkanäle für einen widerstandsarmen Abtransport des Erdreichs sorgt.It is advantageous if the discharge channels of the first drill head section are dimensioned so that a large number of equally spaced cutting edges are formed with a small wall thickness. The thin cutting edges ensure a high cutting action, while a generous dimensioning of the discharge channels ensures a low-resistance removal of the soil.

Vorzugsweise sind die (in Vortriebsrichtung des Erdbohrgeräts) vorderen Kanten der Schneiden im wesentlichen senkrecht zur Längsachse des Bohrkopfs ausgerichtet. Dadurch können Seitenkräfte infolge des Auftreffens auf ein Hindernis, die ein Abweichen des Bohrgeräts von der Sollrichtung verursachen würden, vermieden werden.Preferably, the leading edges of the blades (in the advancing direction of the auger) are oriented substantially perpendicular to the longitudinal axis of the drill bit. As a result, side forces as a result of hitting an obstacle, which would cause the drilling device to deviate from the desired direction, can be avoided.

Im Sinne der Erfindung ist es nicht notwendig, daß die Abführkanäle konstant von der Vorderseite des ersten Bohrkopfabschnitts bis zu dessen Rückseite verlaufen. Vielmehr können die Abführkanäle innerhalb des ersten Bohrkopfabschnitts auslaufen oder der erste Bohrkopfabschnitt kann aus zwei Hälften bestehen, die beide mit Abführkanälen bzw. Schneiden versehen sind, jedoch rotatorisch zueinander versetzt sind. Somit kann hinter jedem Abführkanal der vorderen Hälfte des ersten Bohrkopfabschnitts eine Schneide der hinteren Hälfte angeordnet sein.For the purposes of the invention, it is not necessary for the discharge channels to run constantly from the front of the first drill head section to the rear side thereof. Rather, the discharge channels within the first drill head portion may leak or the first drill head portion may consist of two halves, both of which are provided with Abführkanälen or cutting, but are rotationally offset from one another. Thus, a cutting edge of the rear half can be arranged behind each discharge channel of the front half of the first drill head section.

Auf diese Weise treffen Festkörper, die von der vorderen Hälfte nicht zertrümmert wurden, auf die Schneiden der hinteren Hälfte.In this way, solids that have not been smashed by the front half meet the edges of the back half.

Ferner kann vorteilhaft sein, wenn der Durchmesser des ersten Bohrkopfabschnitts im wesentlichen dem Durchmesser eines nachfolgenden Gehäuses des Bohrgeräts entspricht. Damit kann erreicht werden, daß das Erdreich von den Schneiden des ersten Bohrkopfabschnitts in einem Querschnitt aufgelockert wird, der im wesentlichen dem des Gehäuses des Bohrgeräts entspricht. In der Regel entspricht der Gehäusedurchmesser und somit der aufgelockerte Durchmesser dem Nenndurchmesser der zu erstellenden Bohrung.Furthermore, it may be advantageous if the diameter of the first drill head section substantially corresponds to the diameter of a subsequent housing of the drill. It can thus be achieved that the soil is loosened up by the cutting edges of the first drill head section in a cross-section which substantially corresponds to that of the housing of the drill. In general, the housing diameter and thus the loosened diameter corresponds to the nominal diameter of the bore to be created.

Insbesondere können die Bohrkopfabschnitte so dimensioniert sein, daß der größte Durchmesser des ersten Bohrkopfabschnitts größer als der kleinste Durchmesser des zweiten Bohrkopfabschnitts ist. Durch diesen Durchmessersprung, ebenso wie durch die optionale Relativbewegung der zwei Kopfabschnitte zueinander, entsteht zwischen diesen ein Entspannungsraum, in dem sich das gelockerte Erdreich zunächst in Grenzen wieder entspannen kann.In particular, the drill head sections may be dimensioned such that the largest diameter of the first drill head section is greater than the smallest diameter of the second drill head section. By this diameter jump, as well as by the optional relative movement of the two head sections to each other, between them creates a relaxation space in which the loosened soil can initially relax within limits again.

Weiterhin kann es vorteilhaft sein, den größten Durchmesser des ersten Bohrkopfabschnitts größer zu machen als denjenigen des Gehäuses. Dadurch wird sichergestellt, daß ein ausreichendes Volumen innerhalb des Erdreichs gelockert wird und folglich der Bewegungswiderstand, der auf das Gehäuse wirkt, verringert wird.Furthermore, it may be advantageous to make the largest diameter of the first drill head portion larger than that of the housing. This ensures that a sufficient volume within the soil is relaxed and thus the resistance to movement acting on the housing is reduced.

Der erste Kopfabschnitt kann einen Schlagbolzen aufweisen oder mit einem solchen verbunden sein. Der Schlagbolzen wiederum kann eine in das Erdreich ragende Meißelspitze aufweisen, durch die eine gezielte Einleitung der Stoßenergie in das vor dem Bohrkopf befindliche Erdreich erfolgen kann. Insbesondere können durch die so erfolgende punktförmige Krafteinleitung Hindernisse, beispielsweise Steine im Erdreich, auf einfache Weise zertrümmert werden.The first head portion may include or be connected to a striker. The firing pin in turn may have a projecting into the ground chisel tip through which a targeted introduction of the impact energy can be done in the soil located in front of the drill head. In particular, by the point-like application of force that takes place in this way Obstacles, such as stones in the ground, are easily smashed.

In einer vorteilhaften Ausführungsform durchdringt der Schlagbolzen den zweiten und/oder dritten Kopfabschnitt und kann somit als Führung für eine Relativbewegung dieser Kopfabschnitte dienen, sofern diese zu dem ersten Kopfabschnitt längsaxial beweglich ausgeführt sind.In an advantageous embodiment, the firing pin penetrates the second and / or third head portion and can thus serve as a guide for a relative movement of these head portions, provided that they are designed to the first head portion längsaxial movable.

Bilden der erste und zweite Kopfabschnitt eine (längsaxial) feste Einheit, so kann der Schlagbolzen selbstverständlich auch mit dem zweiten Kopfabschnitt verbunden sein.Of course, if the first and second head sections form a (longitudinally axial) fixed unit, the firing pin can also be connected to the second head section.

Besonders vorteilhaft ist in diesem Fall, wenn ein Schlagkolben des Erdbohrgeräts, welcher durch ein Druckfluid zu reziproken Bewegungen angetrieben wird, zunächst auf eine Kontaktfläche des Schlagbolzens auftrifft und somit die Schlagenergie auf die Meißelspitze und den ersten bzw. den ersten und zweiten Bohrkopfabschnitt überträgt.It is particularly advantageous in this case, when a percussion piston of Erdbohrgeräts, which is driven by a pressurized fluid to reciprocal movements, first impinges on a contact surface of the firing pin and thus transmits the impact energy to the chisel tip and the first and the first and second Bohrkopfabschnitt.

Erst in einem zweiten Schritt wird die Schlagenergie auf den dritten Kopfabschnitt bzw. das damit verbundene Gehäuse der Vorrichtung übertragen. Dazu kann der Schlagkolben nach einer bestimmten Vorwärtsbewegung des Schlagbolzens auf eine Kontaktfläche des Gehäuses oder des zweiten Kopfabschnitts auftreffen.Only in a second step, the impact energy is transmitted to the third head portion or the associated housing of the device. For this purpose, the percussion piston can impinge on a contact surface of the housing or of the second head section after a certain forward movement of the firing pin.

Alternativ kann der Schlagbolzen eine Kontaktfläche aufweisen, die nach einer bestimmten Vorwärtsbewegung des Schlagbolzens auf eine korrespondierende Kontaktfläche des Gehäuses / des dritten Kopfabschnitts auftrifft.Alternatively, the firing pin may have a contact surface which, after a certain forward movement of the firing pin, strikes a corresponding contact surface of the housing / of the third head section.

Bei einem dreistufigen Vortrieb des Bohrgeräts werden die drei Kopfabschnitte dementsprechend nacheinander von dem Schlagkolben des Bohrgeräts - direkt oder indirekt - beaufschlagt.In a three-stage propulsion of the drill, the three head portions are accordingly sequentially applied by the percussion piston of the drill - directly or indirectly -.

In einer vorteilhaften Ausführungsform ist die Verbindung zwischen dem dritten Kopfabschnitt und dem Gehäuse formschlüssig ausgeführt. Dies ist insbesondere hinsichtlich der Wartungsfreundlichkeit von Vorteil. Der Bohrkopf kann schnell und einfach ausgewechselt werden. Hierzu eignen sich vorteilhaft Gewindeverbindungen und/oder Bajonette-Verschlüsse. Beliebige andere formschlüssige, aber auch kraftschlüssige Verbindungsarten sind möglich.In an advantageous embodiment, the connection between the third head portion and the housing is designed positively. This is particularly advantageous in terms of ease of maintenance. The drill head can be changed quickly and easily. Thread connections and / or bayonet closures are advantageously suitable for this purpose. Any other form-fitting, but also non-positive connection types are possible.

Alternativ kann die Verbindung auch durch Schweißen hergestellt werden, wofür sich insbesondere das Reibschweißverfahren eignet. Die Verbindung durch Schweißen eignet sich insbesondere dann, wenn eine möglichst kurze Baulänge der Vorrichtung gefordert wird.Alternatively, the connection can also be produced by welding, for which the friction welding method is particularly suitable. The connection by welding is particularly suitable when the shortest possible length of the device is required.

Jedoch sind neben den hier genannten jegliche Arten von Bauteilverbindungen einsetzbar und auch hinsichtlich der Schweißverfahren ist die Verbindung nicht eingeschränkt..However, in addition to the above-mentioned any types of component connections can be used and also in terms of welding processes, the connection is not limited.

In einer besonders vorteilhaften Ausgestaltung wird das gelockerte Erdreich hinter dem ersten Bohrkopfabschnitt mit Öl, Bentonit oder einem anderen Fluid vermischt. Ein Eintrag des Fluids kann jedoch auch vor dem ersten Kopfabschnitt erfolgen.In a particularly advantageous embodiment, the loosened soil behind the first drill head section with oil, bentonite or other fluid is mixed. However, an entry of the fluid can also take place before the first head section.

Zu diesem Zweck können Bohrungen in dem Gehäuse oder in einem der Kopfabschnitte vorgesehen sein, die das verwendete Fluid vorzugsweise radial in das gelockerte Erdreich einleiten.For this purpose, bores can be provided in the housing or in one of the head sections, which preferably introduce the fluid used radially into the loosened soil.

Die Vermischung des Erdreichs mit einem Fluid kann dazu dienen, die Mantelreibung des nachgezogenen Gehäuses zu reduzieren. Zudem kann es die auftretende Kohäsion des verdrängten Erdreichs erhöhen, so daß die Standfestigkeit des Bohrlochs verbessert wird und Einbrüche des Bohrlochs in verringerter Zahl auftreten.The mixing of the soil with a fluid can serve to reduce the skin friction of the redrawn housing. In addition, it can increase the occurring cohesion of the displaced soil, so that the stability of the well is improved and burglaries of the well occur in reduced numbers.

Die vorliegende Erfindung wird nachfolgend anhand von in den Zeichnungen dargestellten Ausführungsbeispielen näher erläutert, wobei ähnliche Bauteile der verschiedenen Ausführungsformen mit identischen Bezugsziffern versehen sind.The present invention will be explained in more detail with reference to embodiments shown in the drawings, wherein similar components of the various embodiments are provided with identical reference numerals.

In den Zeichnungen zeigt:

- Fig. 1

- in einer geschnittenen Seitenansicht einen Ausschnitt eines Erdbohrgeräts mit einem erfindungsgemäßen Bohrkopf in einer ersten Ausführungsform;

- Fig. 2

- ein Bauteil des ersten Bohrkopfabschnitts der Ausführungsform aus

Fig. 1 in einer Frontansicht; - Fig. 3

- eine zweite Ausführungsform eines erfindungsgemäßen Bohrkopfs in einer perspektivischen Seitenansicht;

- Fig. 4

- den Bohrkopf gemäß

Fig. 3 , wobei der bewegliche Teil des Bohrkopfs in vorauseilender Position dargestellt ist; - Fig. 5

- eine dritte Ausführungsform eines erfindungsgemäßen Bohrkopfs in einer perspektivischen Ansicht;

- Fig. 6

- eine vierte Ausführungsform eines erfindungsgemäßen Bohrkopfs in einer perspektivischen Ansicht;

- Fig. 7

- eine fünfte Ausführungsform eines erfindungsgemäßen Bohrkopfs in einer perspektivischen Ansicht.

- Fig. 1

- in a sectional side view of a section of a Erdbohrgeräts with a drill head according to the invention in a first embodiment;

- Fig. 2

- a component of the first drill head portion of the embodiment

Fig. 1 in a front view; - Fig. 3

- a second embodiment of a drill head according to the invention in a perspective side view;

- Fig. 4

- according to the drill head

Fig. 3 wherein the movable part of the drill head is shown in an anticipatory position; - Fig. 5

- a third embodiment of a drill head according to the invention in a perspective view;

- Fig. 6

- a fourth embodiment of a drill head according to the invention in a perspective view;

- Fig. 7

- a fifth embodiment of a drill head according to the invention in a perspective view.

Der Bohrkopf besteht im wesentlichen aus den Bauteilen, Schlagbolzen 2, Schneidring 3 und Verdränger 4. Schlagbolzen 2 und Schneidring 3 bilden zusammen in dieser Ausführungsform einen ersten Bohrkopfabschnitt, der zu dem zweiten Kopfabschnitt, hier in Form des Verdrängers 4 und dem dritten Kopfabschnitt 11 axial beweglich ist. Dazu wird der Verdränger 4 und der dritte Kopfabschnitt 11 auf dem Schlagbolzen 2 geführt.The drill head consists essentially of the components,

Das hintere Ende des Schlagbolzens 2 ragt in einen Arbeitsraum 5 des Gehäuses 1, in welchem sich ein Schlagkolben (nicht dargestellt), angetrieben durch ein Druckfluid, hin und her bewegt. Für den Fall der Vorwärtsbewegung des Rammbohrgeräts trifft der Schlagkolben zunächst auf das in den Arbeitsraum 5 ragende Ende des Schlagbolzens 2 und beschleunigt diesen in Richtung nach vorne. Infolge dessen wird der Schlagbolzen mitsamt der Meißelspitze 6 und dem Schneidring 3 in das Erdreich getrieben, um dieses zu lockern bzw. um auftretende Hindernisse zu zertrümmern.The rear end of the

Sowohl der Verdränger 4 als auch das Gehäuse 1 werden zunächst nicht mit bewegt.Both the

Je nach Auslegung der Vorrichtung trifft der Schlagkolben nach einer gewissen Relativbewegung des Schlagbolzens 2 zu dem Gehäuse 1 bzw. zu dem Verdränger 4 auf die Kontaktfläche 7 des Gehäuses 1, oder der Schlagbolzen 2 mit einem Absatz 12 trifft auf die Kontaktfläche 8 des Verdrängerbauteils 4. Dadurch wird das Gehäuse 1 mitsamt Verdränger 4 beschleunigt und folgt der Bewegung des Schneidrings 3. Dabei verdichtet der Verdränger 4 das gelockerte Erdreich und erzeugt ein Bohrloch mit dem Durchmesser des Gehäuses 1.Depending on the design of the device, the percussion piston hits the

In

Nach Beendigung eines Bewegungshubs unterstützt eine Feder 14, hier in Form einer Spiralfeder, das vollständige Zurückführen der zwei relativ zueinander beweglichen Teile des Bohrkopfs in die Ausgangslage.After completion of a movement stroke supports a spring 14, here in the form of a spiral spring, the complete return of the two relatively movable parts of the drill head to the starting position.

Der erfindungsgemäße Bohrkopf ist so gestaltet, daß er als Einheit von vorne in das Gehäuse 1 eingesetzt und dort fixiert werden kann. Dies ist besonders vorteilhaft für anfallende Wartungstätigkeiten, da der Bohrkopf die am stärksten beanspruchten Bauteile aufweist und folglich dem höchsten Verschleiß während des Betriebs unterliegt. Ein einfaches Auswechseln des Bohrkopfes ist somit möglich.The drill head according to the invention is designed so that it can be used as a unit from the front into the

Zudem können Bohrköpfe mit verschiedenen Formen, wie sie beispielsweise in den

Die

Der Verdränger 4 unterscheidet sich insbesondere dahingehend von dem der ersten Ausführungsform, daß dieser nur einzelne konische Abschnitte aufweist. Diese werden von weiteren Schneiden unterbrochen, die fluchtend zu jeweils einem Abführkanal 10 des Schneidrings 3 angeordnet sind.The

Die

Die weiteren Ausführungsformen gemäß

Die in der

In der in

In der Ausführungsform gemäß

Claims (26)

- Use of a boring head, comprising at least three boring head sections (3, 4, 11), wherein a first boring head section (3) is located at the front in a boring direction and has discharge passages (10), a subsequent second boring head section (4) has an outer surface formed with largely conical sections rising in opposition to the boring direction, and a third boring head section (11) has a base for fixing the boring head to a housing (1) of the ground-boring device, and wherein the discharge passages (10) of the first boring head section (3) are dimensioned such that a plurality of radially-arranged blades (9) are formed, for displacement boring, through displacing earth with a percussive action.

- Use according to Claim 1, characterised in that the front edges of the blades (9) are oriented substantially perpendicular to the longitudinal axis of the boring head.

- Use according to any one of the preceding claims, characterised in that the third boring head section (11) is positively connected to the housing (1).

- Use according to any one of claims 1 or 2, characterised in that the third boring head section (11) is welded to the housing (1).

- Use according to any one of the preceding claims, characterised in that the boring head has one or more fluid outlets in front of and/or in the region of the second boring head section (4).

- Use according to any one of the preceding claims, characterised in that the discharge passages (10) are arranged at an angle of between 0° and 45° to the longitudinal axis of the ground-boring device.

- Use according to any one of the preceding claims, characterised in that the boring head has V-shaped discharge passages (10).

- Use according to any one of the preceding claims, characterised in that the boring head has trapezoidal blades (9).

- Use according to any one of the preceding claims, characterised in that the first boring head section (3) has two cutting rings, which each have discharge passages (10), such that in each case a plurality of radially-arranged blades (9) are formed, the two cutting rings being rotationally offset from one another, such that the discharge passages (10) of the first cutting ring are aligned with the blades (9) of the second cutting ring.

- Boring head for a ground-boring device displacing earth with a percussive action comprising at least three boring head sections (3, 4, 11), wherein a first boring head section (3) is located at the front in a boring direction and has discharge passages (10), a subsequent second boring head section (4) has an outer surface formed with largely conical sections rising in opposition to the boring direction, and a third boring head section (11) has a base for fixing the boring head to a housing (1) of the ground-boring device, characterised in that at least two of the boring head sections (3, 4, 11-) are axially movable relative to one another with respect to the longitudinal axis of the boring head, and wherein the discharge passages (10) of the first boring head section (3) are dimensioned such that a plurality of radially-arranged blades (9) are formed.

- Boring head according to Claim 10, characterised in that the first (3) and second (4) boring head section are fixedly connected to one another along their longitudinal axis, and the third boring head section (11) is movable relative to these.

- Boring head according to Claim 10, characterised in that the second (4) and third (11) boring head section are fixedly connected to one another along their longitudinal axis, and the first boring head section (3) is movable relative to these.

- Boring head according to Claim 10, characterised in that the front edges of the blades (9) are oriented substantially perpendicular to the longitudinal axis of the boring head.

- Boring head according to any one of claims 10 to 13, characterised in that the diameter of the first boring head section (3) corresponds substantially to the diameter of the subsequent housing (1).

- Boring head according to any one of claims 10 to 14, characterised in that the largest diameter of the first boring head section (3) is greater than the smallest diameter of the second boring head section (4).

- Boring head according to any one of claims 10 to 15, characterised in that the first boring head section (3) has a percussion bolt (2) guided in the second (4) and/or third (11) boring head section.

- Boring head according to Claim 16, characterised in that the percussion bolt (2) has a chisel point (6) projecting into the earth.

- Boring head according to any one of claims 16 or 17, characterised in that a percussion piston firstly strikes a contact surface of the percussion bolt (2) and, after a further forward movement, strikes a contact surface (8; 7) of the second (4) or third boring head section (11) or of the housing (1).

- Boring head according to any one of claims 16 to 18, characterised in that, after a certain forward movement, a contact surface of the percussion bolt strikes a contact surface of the second (4) or third (11) boring head section or of the housing (1).

- Boring head according to any one of claims 10 to 19, characterised in that the third boring head section (11) is positively connected to the housing (1).

- Boring head according to any one of claims 10 to 19, characterised in that the third boring head section (11) is welded to the housing (1).

- Boring head according to any one of claims 10 to 21, characterised by one or more fluid outlets in front of and/or in the region of the second boring head section (4).

- Boring head according to any one of claims 10 to 22, characterised in that the discharge passages (10) are arranged at an angle of between 0° and 45° to the longitudinal axis of the ground-boring device.

- Boring head according to any one of claims 10 to 13, characterised by V-shaped discharge passages (10).

- Boring head according to any one of claims 10 to 24, characterised by trapezoidal blades (9).

- Boring head according to any one of claims 10 to 25, characterised in that the first boring head section (3) has two cutting rings, which each have discharge passages (10), such that in each case a plurality of radially-arranged blades (9) are formed, the two cutting rings being rotationally offset from one another, such that the discharge passages (10) of the first cutting ring are aligned with the blades (9) of the second cutting ring.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004032551.0A DE102004032551B4 (en) | 2004-07-06 | 2004-07-06 | wellhead |

| DE102005031707 | 2005-07-05 | ||

| PCT/EP2005/007286 WO2006002997A1 (en) | 2004-07-06 | 2005-07-06 | Drill head for a ground-boring device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1769131A1 EP1769131A1 (en) | 2007-04-04 |

| EP1769131B1 true EP1769131B1 (en) | 2011-11-16 |

Family

ID=35058071

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05772195A Active EP1769131B1 (en) | 2004-07-06 | 2005-07-06 | Drill head for a ground-boring device |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7938205B2 (en) |

| EP (1) | EP1769131B1 (en) |

| AU (1) | AU2005259407B2 (en) |

| WO (1) | WO2006002997A1 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009038383B4 (en) | 2009-08-24 | 2014-10-16 | Tracto-Technik Gmbh & Co. Kg | ram drilling apparatus |

| DE102009052335A1 (en) | 2009-08-28 | 2011-03-03 | Tracto-Technik Gmbh & Co. Kg | Plug-in coupling for a drill pipe and drill pipe |

| EP2325541B1 (en) * | 2009-11-18 | 2013-05-22 | Ondal Medical Systems GmbH | Adjustable stop mechanism for rotatable connection |

| US20120039739A1 (en) * | 2010-08-10 | 2012-02-16 | David Krauter | Cutter rings and method of manufacture |

| US8746369B2 (en) | 2011-09-30 | 2014-06-10 | Elwha Llc | Umbilical technique for robotic mineral mole |

| US8875807B2 (en) | 2011-09-30 | 2014-11-04 | Elwha Llc | Optical power for self-propelled mineral mole |

| CN102900371B (en) * | 2012-10-18 | 2014-09-24 | 中国石油天然气股份有限公司 | Impact rotary-cut composite rock breaking tool |

| CN103074617A (en) * | 2012-12-26 | 2013-05-01 | 光达光电设备科技(嘉兴)有限公司 | Control system and control method thereof |

| EP2937617B1 (en) | 2014-04-24 | 2017-03-01 | Ondal Medical Systems GmbH | Rotatable connection with limitation of the rotational angle |

| EP2937619B1 (en) | 2014-04-24 | 2017-03-15 | Ondal Medical Systems GmbH | Rotatable connection with limitation of the rotational angle |

| EP2937618B1 (en) | 2014-04-24 | 2017-09-06 | Ondal Medical Systems GmbH | Rotatable connection with limitation of the rotational angle |

| US11105165B2 (en) * | 2019-11-01 | 2021-08-31 | Baker Hughes Oilfield Operations Llc | Downhole device including a fluid propulsion system |

| DE102020005128A1 (en) | 2020-08-21 | 2022-02-24 | Tracto-Technik Gmbh & Co. Kg | Drill head for a percussive displacement earth auger and use of a drill head for a percussive displacement earth auger |

| US20220349129A1 (en) * | 2021-04-28 | 2022-11-03 | Nordco Inc. | Spiker anvil with tip insert |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1929608A (en) * | 1931-11-19 | 1933-10-10 | Economy Rock Bit Corp | Drill bit and method of making the same |

| US2054255A (en) * | 1934-11-13 | 1936-09-15 | John H Howard | Well drilling tool |

| US3708023A (en) * | 1970-12-30 | 1973-01-02 | Inst Gornogo Dela Sibirskogo O | Self-propelled air-punching mechanism |

| DE2630891C3 (en) * | 1976-07-09 | 1979-01-04 | Paul 5940 Lennestadt Schmidt | Device for connecting an earth displacement hammer provided with an expansion cone to a pulling pipe |

| US4144941A (en) * | 1977-09-30 | 1979-03-20 | Ritter Lester L | Directional impact tool for tunneling |

| DE2917292C2 (en) | 1979-04-27 | 1983-10-13 | Institut gornogo dela Sibirskogo otdelenija Akademii Nauk SSSR, Novosibirsk | Tool for making rock holes |

| DE3533995A1 (en) * | 1985-09-24 | 1987-04-16 | Tracto Technik | RAMM DRILLING DEVICE WITH IMPACT PISTON |

| US4681161A (en) * | 1986-03-17 | 1987-07-21 | Howard Smith Screen Company | Well screen centralizer and method for constructing centralizer and for joining of well screens |

| US4809789A (en) * | 1986-08-06 | 1989-03-07 | Oklahoma Airrow, Inc. | Finned impact operating boring tool |

| US4749050A (en) * | 1987-02-13 | 1988-06-07 | Ritter Lester L | Impact tool for tunneling |

| DE4014775C1 (en) * | 1990-05-09 | 1991-08-01 | Tracto-Technik Paul Schmidt Maschinenfabrik Kg, 5940 Lennestadt, De | |

| GB2255361B (en) * | 1991-05-02 | 1995-02-22 | Bp Exploration Operating | Drilling assembly |

| US5377770A (en) * | 1993-03-23 | 1995-01-03 | Ritter; Lester L. | Apparatus for improving impact tool lubrication |

| US5311950A (en) * | 1993-04-19 | 1994-05-17 | Spektor Michael B | Differential pneumopercussive reversible self-propelled soil penetrating machine |

| US5467831A (en) * | 1994-08-22 | 1995-11-21 | Spektor; Michael B. | Monotube differential pneumopercussive reversible self-propelled soil penetrating machine with stabilizers |

| DE19725052C2 (en) * | 1997-06-13 | 1999-10-28 | Tracto Technik | Drill |

| EP0957232A1 (en) * | 1998-05-13 | 1999-11-17 | BOART LONGYEAR GMBH & CO. KG HARTMETALLWERKZEUGFABRIK | Roller bit with segemented cutting rings for tunneling machines |

| DE19823629C2 (en) * | 1998-05-27 | 2001-08-02 | Tracto Technik | Housing for transmitter reception |

| DE10112985B4 (en) | 2001-03-17 | 2006-03-02 | Tracto-Technik Gmbh | Percussion drill head and a method for horizontal drilling with a percussion device |

| GB2376484B (en) * | 2001-06-12 | 2005-08-03 | Pilot Drilling Control Ltd | Improvements to steerable downhole tools |

| SE0201984L (en) * | 2002-06-26 | 2003-05-13 | Sandvik Ab | Rock drill bit and process for its manufacture |

| AU2005225802A1 (en) * | 2004-03-26 | 2005-10-06 | Downhole Products Limited | Apparatus and Method |

-

2005

- 2005-07-06 US US11/571,751 patent/US7938205B2/en active Active

- 2005-07-06 EP EP05772195A patent/EP1769131B1/en active Active

- 2005-07-06 AU AU2005259407A patent/AU2005259407B2/en active Active

- 2005-07-06 WO PCT/EP2005/007286 patent/WO2006002997A1/en active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| US20090211812A1 (en) | 2009-08-27 |

| EP1769131A1 (en) | 2007-04-04 |

| AU2005259407B2 (en) | 2010-09-09 |

| US7938205B2 (en) | 2011-05-10 |

| AU2005259407A1 (en) | 2006-01-12 |

| WO2006002997A1 (en) | 2006-01-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1769131B1 (en) | Drill head for a ground-boring device | |

| DE69704024T2 (en) | DEVICE FOR ROTATING AND IMPACT DRILLING AND METHOD THEREFOR | |

| CH640304A5 (en) | DRILLING TOOL FOR DRILLING HOLES, ESPECIALLY FOR A SELF-DRIVING IMPACT MACHINE. | |

| DE2343079C2 (en) | Device for the substantially horizontal piercing of a dam or the like. | |

| EP0494408B1 (en) | Method and device for enlarging a well | |

| EP1948900B1 (en) | Earth drilling device | |

| DE4220430C2 (en) | Method and device for making an earth borehole | |

| DE4142343A1 (en) | DEVICE FOR PRODUCING EARTH HOLES | |

| DE3124524C2 (en) | Ramming device for self-propelled pneumatic ram drilling rigs | |

| EP3215704B1 (en) | Drilling ram device | |

| DE3743817A1 (en) | STONE, DRILL AND CHISEL TOOL | |

| EP3656494A1 (en) | Step drill | |

| DE102004032551B4 (en) | wellhead | |

| EP1157787B1 (en) | Method for soil and stoneworking and hydraulic impact tool | |

| DE3029963C2 (en) | Drilling nozzle | |

| EP0358786A1 (en) | Superimposing drilling device | |

| DE19732479C1 (en) | Hammer drill | |

| EP3770375A1 (en) | Self-driven frilling head | |

| EP0195265B1 (en) | Tool for undercutting bore holes | |

| DE2917292C2 (en) | Tool for making rock holes | |

| DE4105738C2 (en) | Rotary impact drilling tool and method for rock drilling | |

| DE102008036722B4 (en) | Method, apparatus and drill head for introducing a hole in the soil | |

| EP3957818A1 (en) | Drilling head for percussive displacement soil boring device and use of a drilling head for a percussive displacement soil boring device | |

| DE102005050217A1 (en) | Earth test boring/drilling device, e.g. for drainage, has test boring equipment with a casing and a drive mechanism for driving test boring equipment forwards and backwards | |

| DE1652483C (en) | Hydraulically operated device for the mechanical dismantling of rock |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20070205 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): FR GB |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): FR GB |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20080401 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): FR GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120817 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240723 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240724 Year of fee payment: 20 |