EP1349767B1 - Method of joining closed section members between frame modules - Google Patents

Method of joining closed section members between frame modules Download PDFInfo

- Publication number

- EP1349767B1 EP1349767B1 EP02705711A EP02705711A EP1349767B1 EP 1349767 B1 EP1349767 B1 EP 1349767B1 EP 02705711 A EP02705711 A EP 02705711A EP 02705711 A EP02705711 A EP 02705711A EP 1349767 B1 EP1349767 B1 EP 1349767B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- side rail

- rail portions

- rearward

- portions

- module

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D27/00—Connections between superstructure or understructure sub-units

- B62D27/02—Connections between superstructure or understructure sub-units rigid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D21/00—Understructures, i.e. chassis frame on which a vehicle body may be mounted

- B62D21/02—Understructures, i.e. chassis frame on which a vehicle body may be mounted comprising longitudinally or transversely arranged frame members

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D21/00—Understructures, i.e. chassis frame on which a vehicle body may be mounted

- B62D21/12—Understructures, i.e. chassis frame on which a vehicle body may be mounted assembled from readily detachable parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D27/00—Connections between superstructure or understructure sub-units

- B62D27/02—Connections between superstructure or understructure sub-units rigid

- B62D27/023—Assembly of structural joints

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49616—Structural member making

- Y10T29/49622—Vehicular structural member making

Definitions

- This invention relates in general to vehicle frames and more particularly to a modular vehicle frame.

- a vehicle ladder frame typically includes a pair of transversely spaced longitudinal side rails interconnected by a series of transverse cross members.

- Various vehicle subassemblies are mounted on the frame, such as the engine, passenger compartment, suspension, etc.

- each module subassembly typically includes two side rail frame portions interconnected by at least one cross portion.

- the modules are formed individually and have respectively associated vehicle components mounted thereon. The modules are then joined and connected together forming the full vehicle frame.

- the modules are smaller and lighter than the whole of the vehicle frame, the modules are easier to manipulate in a manufacturing environment.

- frame side rails that have at least forward portions thereof disposed in angular relation with one another.

- at least the forward portions of the side rails are not parallel to one another, but rather are angled so as to have an increasing distance therebetween as they extend rearwardly.

- the angular configuration of the side rails increases structural performance of the frame for certain applications.

- Closed section or tubular side rail members are desirable, particularly towards the front end of a ladder frame, as such tubular frame members are more suitable for bearing the load of the vehicle engine.

- US-A-6 010 155 discloses a frame assembly for a motor vehicle and a method for manufacturing the same according to the preambles of claims 1, 8 and 12, respectively.

- a frame assembly for a motor vehicle that includes a forward module and a rearward module.

- the forward module has a pair of tubular forward side rail portions that are interconnected by a cross portion.

- the forward side rail portions are disposed at an angle with respect to one another such that they have an increasing distance between them as they extend rearwardly.

- the rearward module has a pair of tubular rearward side rail portions that are interconnected by a cross portion. Rearward ends of the forward side rail portions are connected to associated forward ends of the rearward side rail portions.

- At least one of the side rail portions has a notch formed therein to enable connection thereof to the side rail portion associatively connected therewith.

- the notch permits an end portion of the at least one side rail portion to be bent laterally to permit interface with the associated side rail portion connected thereto and then be bent back to be welded to the associated side rail portion connected thereto.

- This method is accomplished by providing a forward module that has a pair of forward side rail portions interconnected by a cross portion.

- the forward side rail portions are disposed at an angle with respect to one another such that they have an increasing distance therebetween as they extend rearwardly.

- a rearward module is also provided that has a pair of tubular rearward side rail portions that are interconnected by a cross portion.

- the forward module is then connected to the rearward module by, first forming a notch in an end of at least one of the side rail portions so as to form first and second split portions.

- the first split portion is then bent to widen the at least one of the side rail portions to thereby enable the end of the at least one of the side rail portions to receive an associated end of an adjoining one of the side rail portions.

- the first split portion is bent back to narrow the widened end of the at least one of the side rail portions.

- the forward ends of the rearward side rail portions are then welded to rearward ends of the forward side rail portions.

- the forward side rail portions are disposed at an angle with respect to one another such that the forward side rail portions have an increasing distance therebetween as they extend rearwardly.

- the forward side rail portions have associated rearward ends.

- the method includes constructing a rearward module comprising a pair of rearward side rail portions interconnected by a cross portion.

- the rearward side rail portions have associated forward ends.

- the method further includes connecting the forward module with the rearward module after the modules have been constructed. The connecting is accomplished by (a) bending at least one end of the ends so that the rearward ends of the forward side rail portions mate with the forward ends of the rearward side rail portions, and (b) welding the rearward ends to the forward ends.

- FIG. 1A shows a frame assembly 10, embodying the principles of the present invention, which includes a forward module 12 and a rearward module 14.

- the forward module 12 has a pair of forward side rail portions 16, 18 that are interconnected by one or more cross portions 20.

- the forward side rail portions 16, 18 are disposed at an angle with respect to one another such that they have an increasing distance between them as they extend rearwardly.

- the rearward module 14 has a pair of rearward side rail portions 22, 24 that are interconnected by at least one cross portion 26.

- Rearward ends 28, 30 of the forward side rail portions 16, 18, respectively, are connected to associated forward end portions 32, 34 of the rearward side rail portions 22, 24, respectively.

- the forward end portions 32, 34 of the rearward side rail portions 22, 24 are provided with a notch 36 to enable connection of the rearward side rail portions 22, 24 with the forward side rail portions 16, 18, as will be described.

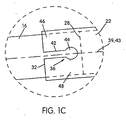

- the notch 36 shown in detail in Figure 1C, permits first split portions 46 of the forward end portions 32, 34 of the rearward side rail portions to be bent laterally outwardly (splayed open) to permit interface with the associated rearward ends of the forward side rail portion connected thereto and then be bent back to be welded as will be described in greater detail later.

- the entire extent of the rearward side rail portions 22, 24 are disposed at an angle with respect to one another such that they have an increasing distance between them as they extend rearwardly, as shown in Figure 1B.

- the angle between rearward side rail portions 22 and 24 is the same angle as the forward side portions 16, 18 are disposed at with respect to each other.

- the forward and rearward modules 12, 14 are then formed by joining respective side rail portions to each other with associated cross portions.

- the forward and rearward side rail portions may be formed by a roll forming process. It is also contemplated that the forward and rearward side rail portions may be formed by a hydroforming process.

- side rails 22 and 24 are referred to here as "rearward,” they need not be the rearwardmost side rails in the assembly 10. Rather, they are rearward in relation to the forward side rails 12, 14, and there may be yet additional side rail structures further rearwardly of side rails 22, 24.

- forward side rail portions 16, 18 are rigidly connected to one another by cross portion 20.

- Cross portion 20 may be either a closed or an open-section member and is connected to each forward side rail portion 16, 18 preferably by a welding process. It is also contemplated that cross portion 20 may be connected to the side rail portions via fasteners, such as bolts.

- an integrally formed cross portion may be provided, for example in the instance in which a frame module is formed by a U-shaped tubular structure, such as one manufactured in a hydroforming operation. In such a U-shaped frame member, the bight portion comprises the laterally interconnected cross portion and is disposed towards the front of the vehicle, leaving the free rearward ends of the side rail portions extending rearwardly for connection with the rearward frame module side rail portions.

- Forward side rail portions 16, 18 are configured with respect to one another so as to generally form an angle ⁇ 1 therebetween.

- An angle ⁇ 1 is formed between a longitudinal axis 37 of the vehicle frame assembly and a central axis 39 of the forward side rail portion 16; and an angle ⁇ 2 is formed between longitudinal axis 37 and a central axis 41 of forward side rail portion 18.

- Rearward side rail portions 22, 24 are rigidly connected to one another by cross portion 26, as shown in Figures 1A and 1B.

- Cross portion 26 may be either a closed or an open-section member and is connected to each rearward side rail portion 22, 24 preferably by a welding process. It is also contemplated that cross portion 26 may be connected to the side rail portions via fasteners, such as bolts or rivets.

- the forward end portions 32, 43 are configured with respect to one another so as to form an angle ⁇ 2 between themselves.

- An angle ⁇ 1 is formed between longitudinal axis 37 and a centroidal axis 43 of forward end portion 32 and an angle ⁇ 2 is formed between longitudinal axis 37 and a central axis 45 of forward end portion 34.

- the forward and rearward modules prefferably be configured and constructed such that angles ⁇ 1 and ⁇ 2 are substantially equal. It is contemplated, however, that ⁇ 1 and ⁇ 2 may differ by up to about 2°.

- the notches 36 are formed within the forward end portions 32, 34 of each of the rearward side rails 22, 24, respectively.

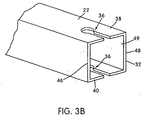

- the notches 36 extend vertically through upper and lower portions 38, 40 respectively, shown in Figure 3B, of the forward end portions 32, 34.

- the notches 36 include a longitudinally extending (relative to the central axis 43, 45 of the associated forward end portions 32, 34) slot portion 42.

- a circular cut out 44 having a diameter that exceeds the transverse width of the slot portion 42 is formed at an innermost end of the slot portion 42 forming the notch 36 into a keyhole-shaped vertically extending opening in each rearward side rail portion 22, 24.

- the notch 36 provides first and second split portions 46, 48 relative to outer and inner sides (respectively) of the rearward side rail portions 22, 24.

- longitudinal opening 49 defined by an inner periphery of rearward side rail portion 22, corresponds to an embodiment of the rearward side rail portions 22, 24 being constructed of tubular members having a generally rectangular cross section.

- the forward side rail portions 16, 18 may also have a generally rectangular sectional configuration.

- Other embodiments of the forward and rearward side rail portions include other closed-section configurations, such as five-sided and irregularly shaped cross sections.

- the tubular side rail portions may be formed in a hydroforming operation, such as that described in U.S. Patent No. 5,979,201, hereby incorporated by reference. It is also contemplated that forward and rearward side rail portions may be formed by a roll-forming process.

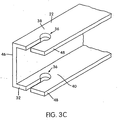

- open-section configurations may also be utilized for the rearward side rail portions, such as a C-shaped configuration, as shown in Figure 3C, and other open-section configurations being open on one side.

- Forward and rearward modules 12, 14 are then formed by connecting respective side rail portions to each other with the cross portions.

- the forward side rail portions 16, 18 it may be preferable for the forward side rail portions 16, 18 to be configured such that an outer peripheral surface thereof is shaped to conform to the inner peripheral surface of the rearward side rail portions 22, 24.

- FIG 3B is rearward side rail portion 22 with the rectangular tubular configuration.

- a preferred configuration of the forward side rail portion to be used in conjunction with this rectangular tubular rearward side rail portion has a similar rectangular tubular configuration of a size sufficiently small to engage within opening 49.

- the respective sectional geometries of the forward and rearward side rail portions need not be identical (e.g., both rectangular) to implement the method of the present invention described herein.

- the first split portions 46 are bent laterally outwardly, effectively widening a transverse distance 50, shown in Figure 3A, of opening 49 to a sufficient relatively greater distance 50', shown in Figure 4, to allow front side rail portions 16,18 to engage therein.

- the circular cut outs 44 serve as bending points for deflection of material of the rearward side rail portions 22, 24 and allow the first split portions 46 to bend without producing excessive stress concentrations in the material. Since the circular cut outs 44 have smooth peripheries, there are no sharp corners to concentrate stress in the first split portions and stress, produced by the deflection of material, is significantly evenly distributed along the peripheries of circular cut outs 44. Furthermore, the notches 36 allow the first split portions 46 to be bent without excessively thinning, stretching, or buckling the material proximate the notches 36.

- forward module 12 is then moved a distance (relative to the rearward module, or vice versa) along the longitudinal axis 37 in the direction indicated by arrow A in Figure 4, such that the rearward ends 28, 30 of the forward side rails 16, 18 are slidably received within the expanded openings 49 in the forward end portions 32, 34 of the rearward side rail portions 22, 24, as shown in Figure 5.

- the first split portions 46 are then both transversely bent back to their original positions, as shown for the first split portion 46 of rearward side rail portion 22 in Figure 5.

- the forward and rearward modules 12, 14 are then welded together, as shown in Figure 5 at 52 for forward side rail portion 16 and rearward side rail portion 22, effectively securing the modules to each other.

- Figure 5 is provided for illustrative purposes only, and that it is preferred for both of the first split portions 46 to be bent back to their original positions before they are welded at a separate station.

- the rearward side rails 22, 24 are also welded at the notches 36 to allow for additional weld connection area and to further secure the connection of the forward and rearward modules 12, 14.

- the notches 36 are configured to allow the first split portions 46 to be bent and to reduce stress concentration within and buckling of the material proximate the notches 36.

- notch 36 may allow the first split portions 46 to be bent without producing significant stress concentrations or buckling.

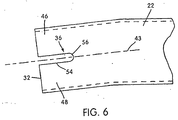

- Figure 6 shows an embodiment utilizing a substantially straight longitudinally extending slot portion 54.

- a circular cut out 56 with a diameter substantially equal to the transverse width of the slot portion 54 is formed at a rearward end of the slot portion 54.

- Figure 7 shows another possible embodiment of the notch 36.

- the notch of this embodiment includes a generally longitudinally extending portion 58.

- An arcuate portion 60 is configured such that the notch 36 curves toward the first split portion 46 (laterally outwardly, in other words) and has a curved edge 62 at a rearward end of the notch 36.

- the notch of this embodiment may be generally L-shaped.

- FIG. 8 Another embodiment of the notch 36, shown in Figure 8, includes a generally straight slot portion 64 and a circular cut out portion 66 at a rearward end of the notch 36.

- the notch 36 is angularly disposed with respect to centroidal axis 43 such that the notch is angled toward the first split portion 46.

- the notches 36 may be formed in the rearward ends 28, 30 of the forward side rail portions 16, 18, as shown in Figure 9.

- the first spilt portions 66 of this embodiment are deflected laterally inwardly, as shown in Figure 10, such that the rearward side rail portions 22, 24 may be slidably received within an inner periphery of the forward side rail portions 16, 18, as shown in Figure 11.

- the first split portions 66 are then deflected laterally outwardly toward their respective original positions, as shown for first split portion 66 of forward side rail portion 18 in Figure 11.

- a connection between the forward module 12 and the rearward module 14 is then securely formed by welding, bonding, or mechanical fasteners.

- the side rails (either one of the forward side rail portions or one of the rearward side rail portions) needs to be provided with a notch and bent laterally. In this case, it would be necessary to bend the single split portion significantly more (for example, about twice as much) as in the case where two frame portions are provided with notches to be bent.

- a benefit of the present invention is that both prefabricated forward and rearward modules can be formed and assembled, with the forward module including angled side rails.

- the modules can be attached to one another after assembly thereof, irrespective of the angled geometry of the forward side rails.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Body Structure For Vehicles (AREA)

- Automobile Manufacture Line, Endless Track Vehicle, Trailer (AREA)

Description

- This invention relates in general to vehicle frames and more particularly to a modular vehicle frame.

- A vehicle ladder frame typically includes a pair of transversely spaced longitudinal side rails interconnected by a series of transverse cross members. Various vehicle subassemblies are mounted on the frame, such as the engine, passenger compartment, suspension, etc.

- To enhance manufacturing efficiencies, some vehicle ladder frames are designed with a plurality of modular subassemblies. Each module subassembly typically includes two side rail frame portions interconnected by at least one cross portion. The modules are formed individually and have respectively associated vehicle components mounted thereon. The modules are then joined and connected together forming the full vehicle frame.

- Since the modules are smaller and lighter than the whole of the vehicle frame, the modules are easier to manipulate in a manufacturing environment.

- For some applications, it is desirable to provide frame side rails that have at least forward portions thereof disposed in angular relation with one another. In other words, at least the forward portions of the side rails are not parallel to one another, but rather are angled so as to have an increasing distance therebetween as they extend rearwardly. The angular configuration of the side rails increases structural performance of the frame for certain applications.

- Because of the geometries and manufacturability problems involved, modularized ladder frame assemblies with angular forward side rail members have not been pursued.

- Increased geometric and manufacturing difficulties for such an arrangement are also introduced when closed section side rail members are desired. Closed section or tubular side rail members are desirable, particularly towards the front end of a ladder frame, as such tubular frame members are more suitable for bearing the load of the vehicle engine.

- US-A-6 010 155 discloses a frame assembly for a motor vehicle and a method for manufacturing the same according to the preambles of

claims - It is an object of the present invention to provide a vehicle ladder frame that benefits from having both a modular construction and an angular side rail configuration, at least towards the front end thereof. In accordance with the principles of the present invention, this objective is achieved by providing a frame assembly for a motor vehicle that includes a forward module and a rearward module. The forward module has a pair of tubular forward side rail portions that are interconnected by a cross portion. The forward side rail portions are disposed at an angle with respect to one another such that they have an increasing distance between them as they extend rearwardly. The rearward module has a pair of tubular rearward side rail portions that are interconnected by a cross portion. Rearward ends of the forward side rail portions are connected to associated forward ends of the rearward side rail portions. At least one of the side rail portions has a notch formed therein to enable connection thereof to the side rail portion associatively connected therewith. The notch permits an end portion of the at least one side rail portion to be bent laterally to permit interface with the associated side rail portion connected thereto and then be bent back to be welded to the associated side rail portion connected thereto.

- It is a further object of the invention to provide a method of forming a modular frame assembly for a motor vehicle. This method is accomplished by providing a forward module that has a pair of forward side rail portions interconnected by a cross portion. The forward side rail portions are disposed at an angle with respect to one another such that they have an increasing distance therebetween as they extend rearwardly. A rearward module is also provided that has a pair of tubular rearward side rail portions that are interconnected by a cross portion. The forward module is then connected to the rearward module by, first forming a notch in an end of at least one of the side rail portions so as to form first and second split portions. The first split portion is then bent to widen the at least one of the side rail portions to thereby enable the end of the at least one of the side rail portions to receive an associated end of an adjoining one of the side rail portions. Next, the first split portion is bent back to narrow the widened end of the at least one of the side rail portions. The forward ends of the rearward side rail portions are then welded to rearward ends of the forward side rail portions.

- It is a further object of the invention to provide a method comprising constructing a forward module comprising a pair of forward side rail portions interconnected by a cross portion. The forward side rail portions are disposed at an angle with respect to one another such that the forward side rail portions have an increasing distance therebetween as they extend rearwardly. The forward side rail portions have associated rearward ends. The method includes constructing a rearward module comprising a pair of rearward side rail portions interconnected by a cross portion. The rearward side rail portions have associated forward ends. The method further includes connecting the forward module with the rearward module after the modules have been constructed. The connecting is accomplished by (a) bending at least one end of the ends so that the rearward ends of the forward side rail portions mate with the forward ends of the rearward side rail portions, and (b) welding the rearward ends to the forward ends.

-

- Figure 1A is a top plan view of one embodiment of an angular modular vehicle frame assembly of the present invention;

- Figure 1B is a top plan view of another embodiment of an angular modular vehicle frame assembly;

- Figure 1C is an enlarged view of the encircled portion indicated in Figures 1A and 1B;

- Figure 2 is a partial top plan view of the forward and rearward modules of the modular vehicle frame assembly of Figure 1A, shown prior to connection;

- Figure 3A is a partial top plan view of the rearward module shown in Figure 2, with the notches formed within forward ends of the rearward side rail portions;

- Figure 3B is a perspective view of one forward end portion of an associated rearward side rail portion shown in Figure 3A;

- Figure 3C is a perspective view of one forward end portion of an associated rearward side rail portion, wherein the side rail portion has a C-shaped sectional configuration;

- Figure 4 is a partial top plan view of the forward and rearward modules shown in Figure 3A, shown with first split portions bent laterally outwardly;

- Figure 5 is a partial top plan view of the forward and rearward modules shown connected with one of the first split portions deflected to its original position and welded;

- Figures 6-8 are top views of alternate embodiments of the notch formed in one of the side rail portions;

- Figure 9 is a top view of the forward and rearward modules with the notches formed in the forward side rail portions;

- Figure 10 is a top view of the forward and rearward modules shown in Figure 9 with the first split portions deflected laterally inwardly; and

- Figure 11 is a top view of the forward and rearward modules shown in Figure 10 connected with one of the first split portions deflected to its original position and welded.

- Figure 1A shows a

frame assembly 10, embodying the principles of the present invention, which includes aforward module 12 and arearward module 14. Theforward module 12 has a pair of forwardside rail portions more cross portions 20. The forwardside rail portions rearward module 14 has a pair of rearwardside rail portions cross portion 26. Rearward ends 28, 30 of the forwardside rail portions forward end portions side rail portions forward end portions side rail portions notch 36 to enable connection of the rearwardside rail portions side rail portions notch 36, shown in detail in Figure 1C, permitsfirst split portions 46 of theforward end portions - In one embodiment, the entire extent of the rearward

side rail portions side rail portions forward side portions side rail portions rearward modules - While side rails 22 and 24 are referred to here as "rearward," they need not be the rearwardmost side rails in the

assembly 10. Rather, they are rearward in relation to the forward side rails 12, 14, and there may be yet additional side rail structures further rearwardly of side rails 22, 24. - As shown in Figure 2, forward

side rail portions cross portion 20.Cross portion 20 may be either a closed or an open-section member and is connected to each forwardside rail portion cross portion 20 may be connected to the side rail portions via fasteners, such as bolts. Alternatively, an integrally formed cross portion may be provided, for example in the instance in which a frame module is formed by a U-shaped tubular structure, such as one manufactured in a hydroforming operation. In such a U-shaped frame member, the bight portion comprises the laterally interconnected cross portion and is disposed towards the front of the vehicle, leaving the free rearward ends of the side rail portions extending rearwardly for connection with the rearward frame module side rail portions. - Forward

side rail portions longitudinal axis 37 of the vehicle frame assembly and acentral axis 39 of the forwardside rail portion 16; and an angle α2 is formed betweenlongitudinal axis 37 and acentral axis 41 of forwardside rail portion 18. The configuration of theside rail portions - Rearward

side rail portions cross portion 26, as shown in Figures 1A and 1B.Cross portion 26 may be either a closed or an open-section member and is connected to each rearwardside rail portion cross portion 26 may be connected to the side rail portions via fasteners, such as bolts or rivets. Shown in Figure 2, theforward end portions longitudinal axis 37 and acentroidal axis 43 offorward end portion 32 and an angle β 2 is formed betweenlongitudinal axis 37 and acentral axis 45 offorward end portion 34. The configuration of theside rail portions - It is preferable for the forward and rearward modules to be configured and constructed such that angles θ 1 and θ 2 are substantially equal. It is contemplated, however, that θ 1 and θ 2 may differ by up to about 2°.

- The

notches 36, shown in Figure 3A, are formed within theforward end portions notches 36 extend vertically through upper andlower portions forward end portions notches 36 include a longitudinally extending (relative to thecentral axis forward end portions 32, 34)slot portion 42. A circular cut out 44 having a diameter that exceeds the transverse width of theslot portion 42 is formed at an innermost end of theslot portion 42 forming thenotch 36 into a keyhole-shaped vertically extending opening in each rearwardside rail portion notch 36 provides first andsecond split portions side rail portions - Shown in Figure 3B,

longitudinal opening 49, defined by an inner periphery of rearwardside rail portion 22, corresponds to an embodiment of the rearwardside rail portions side rail portions rearward modules side rail portions side rail portions side rail portions side rail portions side rail portion 22 with the rectangular tubular configuration. A preferred configuration of the forward side rail portion to be used in conjunction with this rectangular tubular rearward side rail portion has a similar rectangular tubular configuration of a size sufficiently small to engage withinopening 49. However, it is noted that the respective sectional geometries of the forward and rearward side rail portions need not be identical (e.g., both rectangular) to implement the method of the present invention described herein. For example, it may be preferable to nest forward side rail portions with an open sectional configuration (such as a C-shaped configuration) with rearward side rail portions with a closed sectional configuration (such as a rectangular configuration). - Shown in Figure 4, to allow telescopic nesting of the front

side rail portions side rail portions first split portions 46 are bent laterally outwardly, effectively widening atransverse distance 50, shown in Figure 3A, of opening 49 to a sufficient relatively greater distance 50', shown in Figure 4, to allow frontside rail portions - The

circular cut outs 44 serve as bending points for deflection of material of the rearwardside rail portions first split portions 46 to bend without producing excessive stress concentrations in the material. Since thecircular cut outs 44 have smooth peripheries, there are no sharp corners to concentrate stress in the first split portions and stress, produced by the deflection of material, is significantly evenly distributed along the peripheries ofcircular cut outs 44. Furthermore, thenotches 36 allow thefirst split portions 46 to be bent without excessively thinning, stretching, or buckling the material proximate thenotches 36. - After the bending operation,

forward module 12 is then moved a distance (relative to the rearward module, or vice versa) along thelongitudinal axis 37 in the direction indicated by arrow A in Figure 4, such that the rearward ends 28, 30 of the forward side rails 16, 18 are slidably received within the expandedopenings 49 in theforward end portions side rail portions first split portions 46 are then both transversely bent back to their original positions, as shown for thefirst split portion 46 of rearwardside rail portion 22 in Figure 5. The forward andrearward modules side rail portion 16 and rearwardside rail portion 22, effectively securing the modules to each other. It should be appreciated that Figure 5 is provided for illustrative purposes only, and that it is preferred for both of thefirst split portions 46 to be bent back to their original positions before they are welded at a separate station. The rearward side rails 22, 24 are also welded at thenotches 36 to allow for additional weld connection area and to further secure the connection of the forward andrearward modules - As described above, the

notches 36 are configured to allow thefirst split portions 46 to be bent and to reduce stress concentration within and buckling of the material proximate thenotches 36. There are various other embodiments ofnotch 36 that may allow thefirst split portions 46 to be bent without producing significant stress concentrations or buckling. Figure 6 shows an embodiment utilizing a substantially straight longitudinally extendingslot portion 54. A circular cut out 56 with a diameter substantially equal to the transverse width of theslot portion 54 is formed at a rearward end of theslot portion 54. - Figure 7 shows another possible embodiment of the

notch 36. The notch of this embodiment includes a generally longitudinally extendingportion 58. Anarcuate portion 60 is configured such that thenotch 36 curves toward the first split portion 46 (laterally outwardly, in other words) and has acurved edge 62 at a rearward end of thenotch 36. As shown in Figure 7, the notch of this embodiment may be generally L-shaped. - Another embodiment of the

notch 36, shown in Figure 8, includes a generallystraight slot portion 64 and a circular cut outportion 66 at a rearward end of thenotch 36. Thenotch 36 is angularly disposed with respect tocentroidal axis 43 such that the notch is angled toward thefirst split portion 46. - It is also contemplated that the

notches 36, as described herein above, may be formed in the rearward ends 28, 30 of the forwardside rail portions portions 66 of this embodiment are deflected laterally inwardly, as shown in Figure 10, such that the rearwardside rail portions side rail portions first split portions 66 are then deflected laterally outwardly toward their respective original positions, as shown forfirst split portion 66 of forwardside rail portion 18 in Figure 11. A connection between theforward module 12 and therearward module 14 is then securely formed by welding, bonding, or mechanical fasteners. - It can be appreciated from the above that in the embodiment where the split portions are provided on the forward ends of the rearward rail portions, the outer split portions are bent outwardly, and where the split portions are provided on the rearward ends of the forward rail portions, the inner split portions are bent inwardly.

- As a further embodiment, it is contemplated that only one of the side rails (either one of the forward side rail portions or one of the rearward side rail portions) needs to be provided with a notch and bent laterally. In this case, it would be necessary to bend the single split portion significantly more (for example, about twice as much) as in the case where two frame portions are provided with notches to be bent. As yet another embodiment, it is also possible to provide a notch in a rearward end of a single front side rail member and a notch in a forward end of a single rearward side rail member on opposite sides of the frame. While it is further possible to completely remove the first split portions rather than bend them back prior to welding, however this is not preferred since it would provide less surface area for the welded connection.

- A benefit of the present invention is that both prefabricated forward and rearward modules can be formed and assembled, with the forward module including angled side rails. The modules can be attached to one another after assembly thereof, irrespective of the angled geometry of the forward side rails.

- While the present invention has been described in relation to the above exemplary embodiments it will be understood that various modifications may be made within the scope of the invention as defined in the following claims.

Claims (18)

- A frame assembly (10) for a motor vehicle comprising:a forward module (12) comprising a pair of forward side rail portions (16, 18),a rearward module (14) comprising a pair of rearward side rail portions (22, 24) interconnected by a cross portion (26),rearward ends (28, 30) of said forward side rail portions (16, 18) being connected to associated forward ends (32, 34) of said rearward side rail portions (22, 24) being disposed at the same angle with respect to one another as said forward side rail portions (16, 18) are disposed with respect to each other,at least one of said side rail portions comprising a tubular structure having a notch (36) formed in an end portion thereof to enable connection thereof to the side rail portion associatively connected thereto, characterized in thatthe forward side rail portions of said forward module are interconnected by a cross portion (20) and disposed at an angle (θ1) with respect to one another such that said forward side rail portions (16, 18) have an increasing distance therebetween as they extend rearwardly, and in that

- A frame assembly (10) according to claim 1, wherein said rearward side rail portions (22, 24) are disposed at an angle with respect to one another such that said rearward side rail portions have an increasing distance therebetween as the extend rearwardly. said notch (36) permitting said end portion of the at least one side rail portion to be bent laterally to permit interface with the associated side rail portion connected thereto, and then bent back to be welded to the associated side rail portion connected thereto.

- A frame assembly (10) according to claim 1, wherein said rearward side rail portions (22, 24) are disposed generally parallel to each other and comprise associated forward end portions (32, 34), which are angled laterally inwardly with respect to associated rearward side rail portions.

- A frame assembly (10) according to claim 1, wherein said at least one side rail portion having said notch (36) comprises two sides rail portions (22, 24).

- A frame assembly (10) according to claim 4, wherein said two side rail portions having said notch comprises said rearward side rail portions (22, 24).

- A frame assembly (10) according to claim 5, wherein said angle (θ1) between said forward side rail portions (16, 18) is within about 2° of said angle (θ2) between said rearward side rail portions (22, 24).

- A frame assembly (10) according to claim 6, wherein said angle (θ1) between said forward side rail portions (16, 18) is about the same as said angle (θ2) between said rearward side rail portions (22, 24).

- A method of forming a frame assembly (10) for a motor vehicle, comprising:providing a forward module (12) comprising a pair of tubular forward side rail portions (16, 18),providing a rearward module (14) comprising a pair of tubular rearward side rail portions (22, 24) interconnected by a cross portion (26),connecting said forward module (12) to said rearward module byforming a notch (36) in an end (32, 34) of at least one of said side rail portions (22, 24) so as to form first and second split portions (46, 48), characterized byinterconnecting said forward side rail portions (16, 18) of said forward module (12) by a cross portion (20), said forward side rail portions (16, 18) disposed at an angle (θ1) with respect to one another such that said forward side rail portions (16, 18) have an increasing distance therebetween as the extend rearwardly, andfurther connecting said forward module (12) to said rearward module (14) bybending said first split portion (46) to widen said end (32, 34) of said at least one of said side rail portions (22, 24) to receive an associate end (28, 30) of an adjoining one of said side rail portions,bending said first split portion (46) back to narrow said widened end (28, 30) of said at least one of said side rail portions (22, 24), andwelding forward ends (32, 34) of said rearward side rail portions (22, 24) to rearward ends (28, 30) of said forward side rail portions (16, 18).

- A method according to claim 8, wherein said rearward side rail portions (22, 24) are disposed at an angle (θ2) with respect to one another such that said rearward side rail portions have an increasing distance therebetween as they extend rearwardly.

- A method according to claim 8, wherein said rearward side rail portions (22, 24) are disposed generally parallel to each other and comprise associated forward end portions (32, 34), which are angled laterally inwardly with respect to associated rearward side rail portions.

- A method according to claim 8, wherein said forming of a notch (36) in an end of at least one of said rail portions comprises forming notches in forward ends (32, 34) of said rearward side rail members (16, 18).

- A method of forming a frame assembly (10) for a motor vehicle comprising:constructing a forward module (12) comprising a pair of forward side rail portions (16, 18) having associated rearward ends (28, 30),constructing a rearward module (14) comprising a pair of rearward side rail portions (22, 24) interconnected by a cross portion (26), said rearward side rail portions having associated forward ends (32, 34),connecting said forward module (12) with said rearward module (14) after said modules have been contructed, characterized byinterconnecting said forward rail portions (16, 18) of said forward module (12) by a cross portion (20), said forward side rail portions (16, 18) disposed at an angle (θ1) with respect to one another such that said forward side rail portions (16, 18) have an increasing distance therebetween as they extend rearwardly, andconnecting said forward module (12) with said rearward module (14) by accomplishing (a) bending at least one end of said ends so that said rearward ends (28, 30) of said forward side rail portions (16, 18) mate with said forward ends (32, 34) of said rearward side rail portions (22, 24), and (b) welding said rearward ends (28, 30) to said forward ends (32, 34).

- A method according to claim 12, wherein said at least one end comprises a front end of a first of said rearward side rail potions (22, 24).

- A method according to claim 12, wherein said at least one end further comprises a front end of a second of said rearward side rail portions (22, 24).

- A method according to claim 12, wherein said at least one end further comprises a rearward end (28, 30) of a first of said forward side rail portions (16, 18), said first of said rearward side rail portions (22, 24) being on an opposite side of said frame assembly relative to said first of said forward side rail portions (16, 18).

- A method according to claim 12, wherein said at least one end comprises a rearward end of a first of said forward side rail portions (16, 18).

- A method according to claim 15, wherein said at least one end comprises a rearward end of a second of said forward side rail portions (16, 18).

- A method according to claim 12, wherein said construction of said forward module (12) comprises hydroforming said side rail portions (16, 18) from a blank prior to said side rail portions being interconnected by said cross portion (20).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US26068201P | 2001-01-11 | 2001-01-11 | |

| US260682P | 2001-01-11 | ||

| PCT/US2002/000493 WO2002055363A2 (en) | 2001-01-11 | 2002-01-10 | Method of joining closed section members between frame modules |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1349767A2 EP1349767A2 (en) | 2003-10-08 |

| EP1349767B1 true EP1349767B1 (en) | 2006-04-05 |

Family

ID=22990169

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02705711A Expired - Lifetime EP1349767B1 (en) | 2001-01-11 | 2002-01-10 | Method of joining closed section members between frame modules |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7121586B2 (en) |

| EP (1) | EP1349767B1 (en) |

| CA (1) | CA2433299C (en) |

| DE (1) | DE60210410T2 (en) |

| WO (1) | WO2002055363A2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007060867A1 (en) * | 2007-12-18 | 2009-06-25 | GM Global Technology Operations, Inc., Detroit | Rear frame structure e.g. for vehicle such as motor vehicle, has, in vehicle longitudinal direction, classified under section with strut |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2890367B1 (en) * | 2005-09-02 | 2007-11-30 | Plastic Omnium Cie | CASE IN WHITE OF MOTOR VEHICLE IN SEVERAL PARTS |

| DE102006014980A1 (en) | 2006-03-31 | 2007-10-18 | Dr.Ing.H.C. F. Porsche Ag | Connecting arrangement of support elements of a vehicle body |

| FR2911303B1 (en) * | 2007-01-12 | 2009-03-20 | Renault Sas | ARRANGEMENT OF A MOTOR COMPARTMENT |

| KR20090023758A (en) * | 2007-09-03 | 2009-03-06 | 현대자동차주식회사 | Chassis frame for fuel cell vehicle |

| ES2445187T3 (en) * | 2008-03-20 | 2014-02-28 | Iveco S.P.A. | Vehicle chassis |

| US8286352B1 (en) * | 2008-07-15 | 2012-10-16 | Ray D Leon | Modular ornamental structures |

| FR2939733B1 (en) * | 2008-12-16 | 2010-12-17 | Envision Vehicle Engineering Novasio Technology Event | MODULE FOR MODULAR CHASSIS OF PORT VEHICLE |

| US8152200B2 (en) * | 2009-06-23 | 2012-04-10 | Harley Murray, Inc. | Heavy equipment trailer with deck extension |

| ITBO20100024A1 (en) * | 2010-01-18 | 2011-07-19 | Ferrari Spa | COMPOSITE BAR FOR THE FRAME OF A VEHICLE |

| US8985631B2 (en) | 2011-11-11 | 2015-03-24 | Norco Industries, Inc. | Trailer frame |

| US8491010B2 (en) * | 2011-11-11 | 2013-07-23 | Norco Industries, Inc. | Trailer frame |

| DE102012013901B4 (en) | 2012-07-13 | 2024-03-14 | Man Truck & Bus Se | Frame support structure made from modular assemblies |

| DE102014209130A1 (en) * | 2014-05-14 | 2015-11-19 | Engineering Center Steyr Gmbh & Co. Kg | Chassis for commercial vehicles |

| DE102014011263A1 (en) * | 2014-07-28 | 2016-01-28 | GM Global Technology Operations LLC (n. d. Ges. d. Staates Delaware) | Multi-part structure |

| EP2985107B1 (en) * | 2014-08-15 | 2017-03-01 | Volvo Car Corporation | A structural component and a method of manufacturing such a component |

| US9776659B2 (en) * | 2014-11-05 | 2017-10-03 | Lippert Components, Inc. | Bolted trailer frame |

| US10215327B2 (en) | 2016-03-02 | 2019-02-26 | Cummins Power Generation Limited | Mounting chassis for genset with reduced clearance |

| IT201600101007A1 (en) * | 2016-10-07 | 2018-04-07 | P Gevs S R L | ELECTRIC TRACTION MOTOR VEHICLE, AND ITS APPLICATION METHOD |

| JP7413844B2 (en) * | 2020-03-03 | 2024-01-16 | トヨタ自動車株式会社 | Vehicle undercarriage structure |

| PL440773A1 (en) * | 2022-03-28 | 2023-10-02 | Nysa Zakład Pojazdów Spółka Akcyjna | Modular vehicle chassis frame |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1547263A (en) * | 1921-02-10 | 1925-07-28 | Pomeroy Laurence Henry | Motor-vehicle frame |

| US1711765A (en) * | 1927-02-18 | 1929-05-07 | James A Wright | Motor chassis |

| US1928942A (en) | 1931-03-02 | 1933-10-03 | Midland Steel Prod Co | Cross frame member |

| NL48957C (en) | 1935-05-04 | |||

| US2880013A (en) | 1954-06-21 | 1959-03-31 | Budd Co | Chassis frame with tubular side sills for automobiles |

| US2901266A (en) * | 1954-06-21 | 1959-08-25 | Budd Co | Automobile chassis or underframe structure |

| US2809050A (en) * | 1955-12-30 | 1957-10-08 | Budd Co | Frame with bracket for automobiles |

| US2927817A (en) * | 1958-01-13 | 1960-03-08 | Raup Clyde Nelson | Slidable and detachable interlocking connection of a vehicle body to a chassis |

| US3412825A (en) | 1967-08-11 | 1968-11-26 | Oldberg Mfg Company | Silencer or muffler and method of producing same |

| JPH02164675A (en) * | 1988-12-16 | 1990-06-25 | Suzuki Motor Co Ltd | Frame for vehicle |

| SE503425C2 (en) | 1993-10-12 | 1996-06-10 | Volvo Ab | End section of a frame beam |

| US5561902A (en) * | 1994-09-28 | 1996-10-08 | Cosma International Inc. | Method of manufacturing a ladder frame assembly for a motor vehicle |

| ATE226856T1 (en) | 1996-08-26 | 2002-11-15 | Cosma Int Inc | METHOD AND DEVICE FOR HYDROFORMING TUBES |

| US6003935A (en) | 1996-12-27 | 1999-12-21 | Dana Corporation | Modular vehicle frame assembly |

| US6010155A (en) | 1996-12-31 | 2000-01-04 | Dana Corporation | Vehicle frame assembly and method for manufacturing same |

-

2002

- 2002-01-10 CA CA002433299A patent/CA2433299C/en not_active Expired - Lifetime

- 2002-01-10 WO PCT/US2002/000493 patent/WO2002055363A2/en active IP Right Grant

- 2002-01-10 EP EP02705711A patent/EP1349767B1/en not_active Expired - Lifetime

- 2002-01-10 US US10/250,558 patent/US7121586B2/en not_active Expired - Lifetime

- 2002-01-10 DE DE60210410T patent/DE60210410T2/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007060867A1 (en) * | 2007-12-18 | 2009-06-25 | GM Global Technology Operations, Inc., Detroit | Rear frame structure e.g. for vehicle such as motor vehicle, has, in vehicle longitudinal direction, classified under section with strut |

Also Published As

| Publication number | Publication date |

|---|---|

| DE60210410T2 (en) | 2006-11-16 |

| EP1349767A2 (en) | 2003-10-08 |

| WO2002055363A3 (en) | 2003-05-08 |

| US20040056468A1 (en) | 2004-03-25 |

| US7121586B2 (en) | 2006-10-17 |

| WO2002055363A2 (en) | 2002-07-18 |

| DE60210410D1 (en) | 2006-05-18 |

| CA2433299C (en) | 2009-06-09 |

| CA2433299A1 (en) | 2002-07-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1349767B1 (en) | Method of joining closed section members between frame modules | |

| EP0568251B1 (en) | Space frame construction | |

| EP0570150B1 (en) | Space frame construction | |

| US7500802B2 (en) | Three-dimensional node structure | |

| US6679523B2 (en) | Sub-frame structure of motor-vehicle | |

| US5622382A (en) | Rollover bar for a motor vehicle | |

| US7857349B2 (en) | Suspension member | |

| US6412857B2 (en) | Hydroformed space frame and joints therefor | |

| US8376427B2 (en) | Energy absorber for a bumper assembly of a vehicle and method for the manufacture thereof | |

| US20130119680A1 (en) | Bumper reinforcement structure | |

| GB2305639A (en) | Vehicle body frame structure | |

| EP1074456A2 (en) | Joint between side rail and cross member in a vehicle frame assembly | |

| DE202005001773U1 (en) | Backrest frame for motor vehicle seat has two side frame which are connected to each other whereby side frame are formed identically in the section so that side frame can be used alternatively as left or right side frame | |

| US7389586B2 (en) | Method for producing a Y-shaped node structure for the supporting frame of a motor vehicle | |

| JP3219278B2 (en) | Module element and manufacturing method | |

| US8020926B2 (en) | Vehicular structural frame assembly | |

| US6532639B2 (en) | Hydroformed tubular structures and methods of making | |

| RU2727644C1 (en) | Frame assembly for vehicle | |

| US20040150208A1 (en) | Vehicle structure having cross members overlapped by apertured rails | |

| EP0921972B1 (en) | Vehicle frame and method of assembling it | |

| EP1083119B1 (en) | Body structure for vehicle | |

| JPH07149261A (en) | Car body front structure | |

| GB2598573A (en) | Vehicle structure | |

| WO2024059666A1 (en) | Rocker insert with plurality of enclosed sections | |

| CN111434571A (en) | Lower structure of vehicle body |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20030625 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17Q | First examination report despatched |

Effective date: 20031124 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE FR GB LI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE FR GB |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60210410 Country of ref document: DE Date of ref document: 20060518 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070108 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 60210410 Country of ref document: DE Representative=s name: GLAWE DELFS MOLL PARTNERSCHAFT MBB VON PATENT-, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20181213 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190111 Year of fee payment: 18 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200110 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20201229 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 60210410 Country of ref document: DE |