EP1241636B1 - Appareil de traitement de pièces de monnaie - Google Patents

Appareil de traitement de pièces de monnaie Download PDFInfo

- Publication number

- EP1241636B1 EP1241636B1 EP02076007A EP02076007A EP1241636B1 EP 1241636 B1 EP1241636 B1 EP 1241636B1 EP 02076007 A EP02076007 A EP 02076007A EP 02076007 A EP02076007 A EP 02076007A EP 1241636 B1 EP1241636 B1 EP 1241636B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- coin

- discriminating

- detection sensor

- path

- signal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000005540 biological transmission Effects 0.000 claims abstract description 11

- 239000000919 ceramic Substances 0.000 claims description 19

- 238000005299 abrasion Methods 0.000 claims description 14

- 238000001514 detection method Methods 0.000 abstract description 30

- 239000000463 material Substances 0.000 abstract description 17

- 239000002184 metal Substances 0.000 abstract description 13

- 229910052751 metal Inorganic materials 0.000 abstract description 13

- 239000004020 conductor Substances 0.000 abstract description 5

- 230000005284 excitation Effects 0.000 abstract description 2

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 14

- 230000005611 electricity Effects 0.000 description 13

- 230000003068 static effect Effects 0.000 description 13

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 9

- 238000000034 method Methods 0.000 description 8

- 239000010410 layer Substances 0.000 description 7

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 102220418944 c.46C>A Human genes 0.000 description 4

- 238000007599 discharging Methods 0.000 description 3

- 229910052742 iron Inorganic materials 0.000 description 3

- 230000005389 magnetism Effects 0.000 description 2

- 239000012811 non-conductive material Substances 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 239000002344 surface layer Substances 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 230000002542 deteriorative effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000005121 nitriding Methods 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07D—HANDLING OF COINS OR VALUABLE PAPERS, e.g. TESTING, SORTING BY DENOMINATIONS, COUNTING, DISPENSING, CHANGING OR DEPOSITING

- G07D5/00—Testing specially adapted to determine the identity or genuineness of coins, e.g. for segregating coins which are unacceptable or alien to a currency

- G07D5/08—Testing the magnetic or electric properties

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07F—COIN-FREED OR LIKE APPARATUS

- G07F1/00—Coin inlet arrangements; Coins specially adapted to operate coin-freed mechanisms

- G07F1/06—Coins specially adapted to operate coin-freed mechanisms

Definitions

- the present invention relates to an abrasion resistant member and a coin discriminating sensor for preventing occurrence of noise caused by static electricity, suitable for a coin processing apparatus employing a coin discriminating method of discriminating coins while sliding and conveying coins on a path by a transporting belt, and particularly coin processors.

- Japanese Patent Application No. 2,539,521 B2 discloses an example of a coin conveyance device of a coin processor, in which a mirror-finished iron metal member is described as a coin path member. The outline of the device will be described hereinbelow with reference to FIG. 1 .

- Coins M are conveyed from a hopper 201 along a path face 204a of a coin path 204 by a belt 207 and a rubber roller 208 looped over pulleys 205 and 206 on the coin path 204 and reach the side of a coin path 211.

- the coin path 211 has a coin rail 223 projected from the path face 211a, and a plurality of windows(coin assorting holes) 222(222a to 222f). Dimensions 221(221a to 221f) of each from the outer face of the rail 223 to the outer side of the windows 222 correspond to the outer diameters of coins.

- a conveyance belt 215 that runs between a driving pulley 213 and a driven pulley 214 is provided in a tensioned state over the windows 222.

- presser rollers 251 each having a truncated cone shape are disposed.

- the coins M are conveyed while being slid in a state where the coins M are pressed against the conveyance belt 215 on the path face 211a of the coin path 211, so that the coins M drop from the corresponding windows 222 and housed in a housing portion(not shown) disposed below the windows 222.

- the coins M slide along the coin path faces 224a and 211a in a pressed state by the conveyance belts 207 and 215.

- a rolled steel plate bright member as a mirror-finished iron metal member is used as a path member of each of the coin paths 204 and 211.

- the surface of the member is subjected to a salting-in nitriding process to form a surface hardened layer and, after that, the surface hardened layer is polished, thereby obtaining a smoothed surface hardened layer.

- the path faces 204a and 211a are made of an iron metal member having a smooth surface hardened layer.

- an abrasion resistant plate made of an iron material can be used for the path portion other than a discriminating section in the conventional device, in the case of using a magnetic type coin sensor, if an iron material is used, the magnetic flux is shielded. Consequently, the iron material cannot be used for the path member in the path section in which a coin sensor is positioned.

- a plate of ceramics(insulator) is provided in a tensioned manner on the path face.

- a magnetic sensor for discriminating coins is disposed in the coin conveying path section, ceramics having high abrasion resistance is attached to an object passing portion so as to be easily detached, and the portion is used as a part of the conveyance path. Consequently, coins slide on the coin path.

- coins made of metal slide on the ceramics at high speed, so that static electricity is charged in the coins and often discharged in some places. Due to the discharging of the static electricity, noise(circled portion) occurs in sensor sensed data as shown in FIG. 2 , and a problem such as identification precision is not improved occurs.

- United States patent publication no. 4,086,527 discloses an apparatus for the authentication of monetary articles, using a magnetic detector, wherein the detected signals are altered due to the coins passing nearby.

- an object of the present invention is to provide an abrasion resistant member in a coin conveying path and a coin discriminating sensor capable of preventing occurrence of static electricity.

- the present invention relates to an abrasion resistant member in a coin conveyance path for discriminating coins and the object of the present invention is achieved by a conductive material in a thin plate shape adhered so as to cover a path face faced by a magnetic sensor provided so as to face the under face of the coin conveyance path or to cover both path guides for path regulation provided on both right and left sides in the travel direction of coins, in the coin conveyance path having a coin discriminating sensor for discriminating the kind of each of coins conveyed one by one with a spacing therebetween along a sliding face.

- Another invention relates to a coin discriminating sensor and the object of the present invention is realized by a coin discriminating sensor including a coin path portion, a reflection type sensor disposed so as to face the under face of the coin path portion, a first transmission type sensor disposed so as to sandwich one lateral end of the path, and a second transmission type sensor disposed so as to sandwich the other lateral end of the path, and the coin path portion of the coin discriminating sensor is made of a conductive material.

- the two inventions are more effectively achieved by using conductive ceramics as the conductive material and by using conductive alumina or conductive zirconia as the conductive ceramics.

- conductive ceramics (conductive alumina or conductive zirconia) is adhered to the coin sliding face of a magnetic sensor.

- the conductive ceramics is conductive and does not cause an eddy current so much. Since the resistivity of conductive ceramics is about 1000 times as high as a general metal, occurrence of an eddy current is about 1/10 3 (0.01%). Consequently, the conductive ceramics does not exert an influence on the quality of a magnetic signal, nor cause a problem of abrasion at the time of conveyance of coins, but has durability.

- FIG. 3 is a partial sectional perspective view of a structure of a coin detection sensor 10 of the present invention

- FIG. 4 is its sectional view.

- the coin detection sensor 10 is shaped in a pi-form having a clearance for detaching and attaching a conveying belt (not shown) in its upper part, and a central rectangular bottom space forms a passage 11 of coin, and a shield plate 12 for shielding external magnetism laminated on the outer circumference.

- the coin detection sensor 10 has a U-letter shape having, in its upper portion, a gap for attaching the conveyance belt (not shown).

- the bottom portion of a rectangular space in the center portion serves as a path 11.

- a shield plate 12 for shielding external magnetism is formed on the outer surface.

- side sensors 20 and 30 of transmission detection type are disposed each so as to sandwich an end portion of the path 11, and a cylindrical-shaped center sensor 40 of a reflection detection type is disposed below the path 11.

- the side sensors 20 and 30 are symmetric with respect to the center of the detection sensor 10.

- a primary coil 21 and a secondary coil 23 are wound around upper and lower portions, respectively, of a side core 22 having a U-letter shape which opens on the right side

- a primary coil 31 and a secondary coil 33 are wound around upper and lower portions, respectively, of a side core 32 having a U-letter shape which opens on the left side.

- the center sensor 40 has a cylindrical pot core 41.

- a primary coil 42 is wound around the pot core 41, and a secondary coil 43 is wound on the inner groove of the pot core 41 and buried.

- a coin(not shown) for a temperature sensor is provided.

- abrasion resistant plate made of zirconia which is a non-conductive material is conventionally used as the material of the path 11, in the present invention, conductive ceramics(conductive alumina or conductive zirconia) is used.

- an exciting and signal-detecting process is performed with a circuit configuration shown in FIG. 5 on the coin detection sensor 10.

- an ocillation signal from an oscillator 1 is frequency-divided by a frequency divider 2 into a low frequency(4 kHz), an intermediate frequency(16 kHz) and a high frequency(250 kHz) which are modulated(added) by an adder 4 via band pass filters(BPFs) 3L, 3M and 3H for the low, intermediate and high frequencies, respectively.

- BPFs band pass filters

- the resultant is applied to the primary coils 21, 32 and 42 of a coin detection sensor 10 via a current amplifier 5. That is, a composite excited signal of the low, intermediate and high frequencies is supplied to the primary coils 21 and 31 of the side sensors 20 and 30 and to the primary coil 42 of the center sensor 40 via the current amplifier 5.

- Outputs of the secondary coils 23, 33 and 43 are detected as output through amplifiers 44, 44L and 44R, respectively, and are passed to band pass filters, full wave rectifiers and low pass filters, thereby obtaining a reflected 4KHz signal R4S, a reflected 16KHz signal R16S, a reflected 250KHz signal R250S, a transmitted L4KHz signal TL4S, a transmitted L16KHz signal TL16S, a transmitted L250KHz signal TL250S, a transmitted R4KHz signal TR4S, a transmitted R16KHz signal TR16S, and a transmitted R250KHz signal TR250S.

- an output of the secondary coil 43 of the center sensor 40 is frequency-divided by band-pass filters(BPFs) 451 to 453 via an amplifier 44 into low, intermediate and high frequencies which pass through full wave rectifiers 461 to 463 and low pass filters(LPFs) 471 to 473.

- a reflected 4KHz signal R4S, a reflected 16KHz signal R16S, and a reflected 250KHz signal R250S are thereby obtained.

- the center sensor 40 takes the form of an eddy current loss type magnetic sensor by the primary coil 42 and the secondary coil 43.

- An output of the secondary coil 23 of the side sensor 20 passes through an amplifier 44L and is frequency-divided by band pass filters(BPFs) 45L1 to 45L3 into low, intermediate and high frequencies, respectively, which are further passed to the full wave rectifiers 46L1 to 46L3 and low pass filters 47L1 to 47L3.

- the transmitted L4KHz signal TL4S, transmitted L16KHz signal TL16S, and transmitted L250KHz signal TL250S are thereby obtained.

- An output of the secondary coil 33 of the side sensor 30 passes through an amplifier 44R and is frequency-divided by band pass filters(BPFs) 45R1 to 45R3 into low, intermediate and high frequencies, respectively, which are further passed to the full wave rectifiers 46R1 to 46R3 and low pass filers(LPFs) 47R1 to 47R3.

- the transmitted R4KHz signal TR4S, transmitted R16KHz signal TR16S, and transmitted R250KHz signal TR250S are thereby obtained.

- an output of the secondary coil of the temperature sensor passes through an amplifier 481, a BPF 482, a full wave rectifier 483, and an LPF 484 and is outputted as a temperature monitor signal THS.

- the reflected 4KHz signal R4S, reflected 16KHz signal R16S, reflected 250KHz signal R250S, transmitted L4KHz signal TL4S, transmitted L16KHz signal TL16S, transmitted L250KHz signal TL250S, transmitted R4KHz signal TR4S, transmitted R16KHz signal TR16S, transmitted R250KHz signal TR250S, and temperature monitor signal THS are respectively inputted to discriminating means(not shown) for discriminating a coin, and a discriminating process and judgement are executed.

- the discriminating means compares each feature quantity with a coin acceptance window predetermined in each coin, and discriminates a counterfeit.

- a signal difference depending on material is small, but the attenuation factor is determined by the material of the surface layer, and at low frequency, there is an effect also on the material of the intermediate layer, and therefore by comparing the attenuation factor at each frequency with the predetermined criterion, the coin can be discriminated.

- the coin is conveyed shifted to the flank of a side sensor 20.

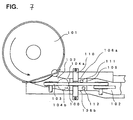

- FIG. 7 shows the structure of coin feeding, conveying, and discriminating portions of a coin processing apparatus including: a coin feeder 101 which takes the form of a turntable, a conveyance path 102 for conveying coins 100 one by one, a conveyance belt 103 for conveying coins while pressing the coins against the slide face, regulating guides 104a and 104b for guiding conveyance of coins, a diameter sensor 110 for detecting data of the diameter of a coin by a sensor for discriminating coins, material and thickness sensors 111 and 112 for detecting the material and thickness of each coin, and a path 105 of the discriminating portion.

- a coin feeder 101 which takes the form of a turntable

- a conveyance path 102 for conveying coins 100 one by one

- a conveyance belt 103 for conveying coins while pressing the coins against the slide face

- regulating guides 104a and 104b for guiding conveyance of coins

- a diameter sensor 110 for detecting data of the diameter of a coin by a sensor for discriminating coins

- a thin plate of conductive ceramics is adhered to the portion of the discriminating area 105 in the coin path portion, and a coin sliding face is provided so as to be smoothly connected to the front and rear paths 102.

- An abrasion resistant plate conventionally made of zirconia which is a non-conductive material is conventionally used as the material of the path member material for the discriminating sensor area 105 of the coin path portion. In the present invention, however, conductive ceramics(conductive alumina or conductive zirconia) is used.

- the conductive ceramics is also adhered to an identification portion path regulation guide 106a with which the rim of a coin comes into contact.

- the thickness of the conductive ceramics portion is 0.5 mm. The reason why the conductive ceramics is applied also to a path regulating guide 106 is to prevent a signal from becoming different from a normal signal due to leakage of an eddy current generated in the coin to the outside via path side walls.

- a second embodiment shown in FIG. 8 is characterized by a coin detection sensor 10 having a configuration similar to that of FIG. 7 except that all of magnetic sensors are integrated and built in a casing shown in FIG. 3 .

- an exciting and signal-detecting process is performed with a circuit configuration shown in FIG. 5 on the coin discriminating sensor 120.

- the discriminating means identifies, for example, as an object to be identified, a coin made of a plurality of metals, which is called a clad coin made of three kinds of metal layers.

- the discriminating means compares a characteristic amount with a determination frame preliminarily provided for each coin to discriminate whether the coin is true or false.

- a determination frame preliminarily provided for each coin to discriminate whether the coin is true or false.

- an attenuation factor is determined by the material of a surface layer.

- an influence is exerted also on the material of an intermediate layer. Consequently, by comparing the attenuation factor at each frequency with a predetermined determination reference, a coin can be identified.

- a coin is conveyed along the side sensor 20 side.

- the shape of the path guide 104a is formed so that the coin is conveyed upward by the conveyance belt 103 along one side.

- the discriminating means performs a signal process and detection as described in Japanese Patent Application Laid-open No. 9-245214 A .

- the path 11 of the coin sensor 10 is made of conductive ceramics(conductive alumina or conductive zirconia), so that static electricity is not charged in a coin conveyed for discrimination. Consequently, a noise-free characteristic is achieved as shown by detection signals of the reflected 4KHz signal R4S(upper signal waveform), reflected 16KHz signal R16S(intermediate signal waveform), and reflected 250KHz signal R250S(lower signal waveform) as outputs of the center sensor 40 shown in FIG. 6 .

- coins are not charged, and noise due to static electricity does not occur, so that coins can be accurately discriminated without taking countermeasures by software.

- abrasion-resistant conductive ceramics is provided, so that occurrence of static electricity can be prevented, and software for eliminating noise caused by static electricity which is conventionally necessary becomes unnecessary.

- the electrical resistivity of the conductive ceramics and that ofa metal are different from each other by three digits, an amount of an eddy current is small, and an influence on a magnetic signal is hardly exerted.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Testing Of Coins (AREA)

- Investigating Or Analyzing Materials By The Use Of Magnetic Means (AREA)

- Noodles (AREA)

- Photoreceptors In Electrophotography (AREA)

- Detergent Compositions (AREA)

Claims (3)

- Appareil de traitement de pièces de monnaie pour différencier des pièces de monnaie glissant sur un trajet de transport de pièces de monnaies, ayant un capteur de différenciation de pièces de monnaie permettant de différencier le type de chaque pièce de monnaie acheminée une par une avec un espacement entre elles le long d'une face coulissante, caractérisé en ce que un élément résistant à l'abrasion fabriqué dans un matériau céramique conducteur en forme de plaque mince adhère à la surface du trajet de transport de pièces de monnaie, afin de couvrir une zone de différenciation d'un capteur magnétique prévu sous le trajet de transport de pièces de monnaie.

- Appareil de traitement de pièces de monnaie selon la revendication 1, dans lequel des guides de trajet pour la régulation du trajet sont prévus sur les côtés droit et gauche dans le sens de déplacement des pièces de monnaie, dans lequel l'élément résistant à l'abrasion adhère et couvre les guides de trajet.

- Capteur de différenciation de pièces de monnaie défini dans un appareil de traitement de pièces de monnaie selon la revendication 1 ou la revendication 2, comprenant un capteur de type à réflexion placé de façon à faire face à la face inférieure du trajet de transport de pièces de monnaie, un premier capteur de type à transmission étant placé de manière à prendre en sandwich une extrémité latérale du trajet de transport de pièces de monnaie, et un second capteur de type à transmission placé de manière à prendre en sandwich l'autre extrémité latérale du trajet de transport de pièces de monnaie.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001073802A JP3995423B2 (ja) | 2001-03-15 | 2001-03-15 | 硬貨識別センサ |

| JP2001073802 | 2001-03-15 | ||

| JP2001075846 | 2001-03-16 | ||

| JP2001075846A JP3908473B2 (ja) | 2001-03-16 | 2001-03-16 | 複数材料で成る金属片の識別装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1241636A2 EP1241636A2 (fr) | 2002-09-18 |

| EP1241636A3 EP1241636A3 (fr) | 2004-06-30 |

| EP1241636B1 true EP1241636B1 (fr) | 2009-08-12 |

Family

ID=26611310

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02076007A Expired - Lifetime EP1241636B1 (fr) | 2001-03-15 | 2002-03-13 | Appareil de traitement de pièces de monnaie |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1241636B1 (fr) |

| AT (1) | ATE439657T1 (fr) |

| DE (1) | DE60233285D1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106530476A (zh) * | 2016-11-28 | 2017-03-22 | 东南大学 | 一种电磁式硬币分离机及方法 |

| WO2018183925A1 (fr) * | 2017-03-30 | 2018-10-04 | Tidel Engineering L.P. | Systèmes et procédés de recyclage de pièces de monnaie |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2393840A (en) * | 2002-10-01 | 2004-04-07 | Innovative Technology Ltd | Coin validation by measuring reflected magnetic field non-homogeneity |

| DE102007046390B3 (de) * | 2007-09-20 | 2008-11-27 | National Rejectors, Inc. Gmbh | Verfahren zum Prüfen von Münzen |

| JP5882772B2 (ja) * | 2012-02-10 | 2016-03-09 | グローリー株式会社 | 硬貨識別用磁気センサ |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2305809A1 (fr) * | 1975-03-25 | 1976-10-22 | Crouzet Sa | Dispositif d'authentification de titres monetaires |

| US4317149A (en) * | 1980-06-02 | 1982-02-23 | International Business Machines Corporation | Magnetic head having static discharge means |

| US4737809A (en) * | 1986-11-24 | 1988-04-12 | Canon Kabushiki Kaisha | Static electricity eliminating mechanism for camera |

| US4862316A (en) * | 1988-02-29 | 1989-08-29 | White's Electronics, Inc. | Static charge dissipating housing for metal detector search loop assembly |

| US4928194A (en) * | 1988-09-30 | 1990-05-22 | Eastman Kodak Company | Anti-static support for a cartridge in a disk drive |

| JP2539521B2 (ja) | 1989-11-30 | 1996-10-02 | 富士電機株式会社 | 硬貨処理機の硬貨通路 |

| WO1993002431A1 (fr) * | 1991-07-16 | 1993-02-04 | C.T. Coin A/S | Procede et dispositif de controle et de tri eventuel de pieces de monnaie |

| JP3384803B2 (ja) * | 1991-09-28 | 2003-03-10 | アンリツ株式会社 | 硬貨判別装置 |

| JP3363305B2 (ja) | 1996-03-08 | 2003-01-08 | グローリー工業株式会社 | 硬貨処理機における温度補正機能付き硬貨識別装置 |

| SE512200C2 (sv) * | 1998-01-30 | 2000-02-14 | Scan Coin Ind Ab | Anordning och metod för äkthetskontroll av bimetalliska mynt |

| JP3660496B2 (ja) * | 1998-02-26 | 2005-06-15 | 株式会社日本コンラックス | コインの真贋性を検査する方法及び装置 |

| ATE326044T1 (de) * | 1999-12-02 | 2006-06-15 | Glory Kogyo Kk | Verfahren und vorrichtung zur münzidentifizierung |

-

2002

- 2002-03-13 AT AT02076007T patent/ATE439657T1/de not_active IP Right Cessation

- 2002-03-13 EP EP02076007A patent/EP1241636B1/fr not_active Expired - Lifetime

- 2002-03-13 DE DE60233285T patent/DE60233285D1/de not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106530476A (zh) * | 2016-11-28 | 2017-03-22 | 东南大学 | 一种电磁式硬币分离机及方法 |

| CN106530476B (zh) * | 2016-11-28 | 2019-03-05 | 东南大学 | 一种电磁式硬币分离机及方法 |

| WO2018183925A1 (fr) * | 2017-03-30 | 2018-10-04 | Tidel Engineering L.P. | Systèmes et procédés de recyclage de pièces de monnaie |

Also Published As

| Publication number | Publication date |

|---|---|

| DE60233285D1 (de) | 2009-09-24 |

| EP1241636A3 (fr) | 2004-06-30 |

| ATE439657T1 (de) | 2009-08-15 |

| EP1241636A2 (fr) | 2002-09-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1895480B1 (fr) | Appareil de détection d'objets étrangers | |

| US5992601A (en) | Method and apparatus for document identification and authentication | |

| US4850468A (en) | Money discriminating apparatus | |

| EP1241636B1 (fr) | Appareil de traitement de pièces de monnaie | |

| KR101032111B1 (ko) | 주화 식별 장치 | |

| US6216843B1 (en) | Apparatus for taking out information using magnetic sensor and carrying out test of article by using that information | |

| JP5336900B2 (ja) | 硬貨識別装置及び硬貨識別方法 | |

| JP4157335B2 (ja) | 硬貨識別装置、及びそれに用いられる硬貨識別用センサ | |

| JP2000163620A (ja) | 自動取引装置 | |

| JP3995423B2 (ja) | 硬貨識別センサ | |

| KR100290690B1 (ko) | 기밀 문서의 체크 방법 및 장치 | |

| JP3908473B2 (ja) | 複数材料で成る金属片の識別装置 | |

| EP0939385B1 (fr) | Validateur de document avec un capteur inductif | |

| JPS6345691A (ja) | 硬貨処理機における硬貨識別装置 | |

| JPH0585074B2 (fr) | ||

| JP3844183B2 (ja) | 硬貨識別センサ及び装置 | |

| JPS6128185A (ja) | 紙幣鑑別装置 | |

| JPH10261128A (ja) | 磁気センサ装置 | |

| JP2000076512A (ja) | 硬貨処理装置 | |

| JP3192785B2 (ja) | コイン識別装置 | |

| JP3842510B2 (ja) | 硬貨識別方法及びそれに用いられる硬貨識別センサ | |

| JP3464812B2 (ja) | 硬貨処理装置 | |

| JP5021779B2 (ja) | 硬貨入出金装置 | |

| JP2011180958A (ja) | 硬貨識別装置の検出部 | |

| JP2008027277A (ja) | 物体識別装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7G 07D 5/08 A |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20041208 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17Q | First examination report despatched |

Effective date: 20050414 |

|

| RTI1 | Title (correction) |

Free format text: COIN PROCESSING APPARATUS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60233285 Country of ref document: DE Date of ref document: 20090924 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091123 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| 26N | No opposition filed |

Effective date: 20100517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091113 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20140319 Year of fee payment: 13 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20150313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150313 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170322 Year of fee payment: 16 Ref country code: FR Payment date: 20170322 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60233285 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 |