EP1152144B1 - Hydraulically-actuated fuel injector with direct control needle valve - Google Patents

Hydraulically-actuated fuel injector with direct control needle valve Download PDFInfo

- Publication number

- EP1152144B1 EP1152144B1 EP01117613A EP01117613A EP1152144B1 EP 1152144 B1 EP1152144 B1 EP 1152144B1 EP 01117613 A EP01117613 A EP 01117613A EP 01117613 A EP01117613 A EP 01117613A EP 1152144 B1 EP1152144 B1 EP 1152144B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- fuel

- actuation fluid

- valve member

- cavity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000446 fuel Substances 0.000 title claims description 121

- 239000012530 fluid Substances 0.000 claims description 152

- 238000002347 injection Methods 0.000 description 93

- 239000007924 injection Substances 0.000 description 93

- 230000006835 compression Effects 0.000 description 17

- 238000007906 compression Methods 0.000 description 17

- 239000003921 oil Substances 0.000 description 14

- 230000009471 action Effects 0.000 description 13

- 230000001276 controlling effect Effects 0.000 description 7

- 239000002828 fuel tank Substances 0.000 description 4

- 238000004891 communication Methods 0.000 description 3

- 239000010687 lubricating oil Substances 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000007493 shaping process Methods 0.000 description 2

- 125000006850 spacer group Chemical group 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000009877 rendering Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M45/00—Fuel-injection apparatus characterised by having a cyclic delivery of specific time/pressure or time/quantity relationship

- F02M45/02—Fuel-injection apparatus characterised by having a cyclic delivery of specific time/pressure or time/quantity relationship with each cyclic delivery being separated into two or more parts

- F02M45/04—Fuel-injection apparatus characterised by having a cyclic delivery of specific time/pressure or time/quantity relationship with each cyclic delivery being separated into two or more parts with a small initial part, e.g. initial part for partial load and initial and main part for full load

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M47/00—Fuel-injection apparatus operated cyclically with fuel-injection valves actuated by fluid pressure

- F02M47/02—Fuel-injection apparatus operated cyclically with fuel-injection valves actuated by fluid pressure of accumulator-injector type, i.e. having fuel pressure of accumulator tending to open, and fuel pressure in other chamber tending to close, injection valves and having means for periodically releasing that closing pressure

- F02M47/027—Electrically actuated valves draining the chamber to release the closing pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M57/00—Fuel-injectors combined or associated with other devices

- F02M57/02—Injectors structurally combined with fuel-injection pumps

- F02M57/022—Injectors structurally combined with fuel-injection pumps characterised by the pump drive

- F02M57/025—Injectors structurally combined with fuel-injection pumps characterised by the pump drive hydraulic, e.g. with pressure amplification

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M57/00—Fuel-injectors combined or associated with other devices

- F02M57/02—Injectors structurally combined with fuel-injection pumps

- F02M57/022—Injectors structurally combined with fuel-injection pumps characterised by the pump drive

- F02M57/025—Injectors structurally combined with fuel-injection pumps characterised by the pump drive hydraulic, e.g. with pressure amplification

- F02M57/026—Construction details of pressure amplifiers, e.g. fuel passages or check valves arranged in the intensifier piston or head, particular diameter relationships, stop members, arrangement of ports or conduits

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/02—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps of reciprocating-piston or reciprocating-cylinder type

- F02M59/10—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps of reciprocating-piston or reciprocating-cylinder type characterised by the piston-drive

- F02M59/105—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps of reciprocating-piston or reciprocating-cylinder type characterised by the piston-drive hydraulic drive

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/44—Details, components parts, or accessories not provided for in, or of interest apart from, the apparatus of groups F02M59/02 - F02M59/42; Pumps having transducers, e.g. to measure displacement of pump rack or piston

- F02M59/46—Valves

- F02M59/466—Electrically operated valves, e.g. using electromagnetic or piezoelectric operating means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0014—Valves characterised by the valve actuating means

- F02M63/0028—Valves characterised by the valve actuating means hydraulic

- F02M63/0029—Valves characterised by the valve actuating means hydraulic using a pilot valve controlling a hydraulic chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0031—Valves characterized by the type of valves, e.g. special valve member details, valve seat details, valve housing details

- F02M63/004—Sliding valves, e.g. spool valves, i.e. whereby the closing member has a sliding movement along a seat for opening and closing

- F02M63/0042—Sliding valves, e.g. spool valves, i.e. whereby the closing member has a sliding movement along a seat for opening and closing combined with valve seats of the lift valve type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0031—Valves characterized by the type of valves, e.g. special valve member details, valve seat details, valve housing details

- F02M63/0045—Three-way valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M63/00—Other fuel-injection apparatus having pertinent characteristics not provided for in groups F02M39/00 - F02M57/00 or F02M67/00; Details, component parts, or accessories of fuel-injection apparatus, not provided for in, or of interest apart from, the apparatus of groups F02M39/00 - F02M61/00 or F02M67/00; Combination of fuel pump with other devices, e.g. lubricating oil pump

- F02M63/0012—Valves

- F02M63/0031—Valves characterized by the type of valves, e.g. special valve member details, valve seat details, valve housing details

- F02M63/0049—Combined valve units, e.g. for controlling pumping chamber and injection valve

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/21—Fuel-injection apparatus with piezoelectric or magnetostrictive elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M2200/00—Details of fuel-injection apparatus, not otherwise provided for

- F02M2200/50—Arrangements of springs for valves used in fuel injectors or fuel injection pumps

- F02M2200/502—Springs biasing the valve member to the open position

Definitions

- the present invention relates generally to fuel injection, and more particularly to hydraulically-actuated fuel injectors with direct control needle valve members, and fuel injection systems.

- Known hydraulically-actuated fuel injection systems and/or components are shown, for example, in US-A-5,121,730, US-A-5,271,371, US-A-5,297,523 and US-A-5 522 545.

- a spring biassed needle check opens to commence fuel injection when pressure is raised by an intensifier piston/plunger assembly to a valve opening pressure.

- the intensifier piston is acted upon by a relatively high pressure actuation fluid, such as engine lubricating oil, when a solenoid driven actuation fluid control valve opens the injector's high pressure inlet. Injection is ended by deactivating the solenoid to release pressure above the intensifier piston.

- the present invention is directed to improving the ability of hydraulically actuated fuel injectors to reliably produce better injection rate shapes during each injection event.

- a hydraulically actuated fuel injector comprising:

- Fuel system 10 includes one or more hydraulically-actuated electronically-controlled fuel injectors 14, which are adapted to be positioned in a respective cylinder head bore of engine 12.

- Fuel system 10 includes an apparatus or means 16 for supply actuating fluid to each injector 14, an apparatus or means 18 for supplying fuel to each injector, a computer 20 for electronically controlling the fuel injection system and an apparatus or means 22 for re-circulating actuation fluid and for recovering hydraulic energy from the actuation fluid leaving each of the injectors.

- the actuating fluid supply means 16 preferably includes an actuating fluid sump 24, a relatively low pressure actuating fluid transfer pump 26, an actuating fluid cooler 28, one or more actuation fluid filters 30, a high pressure pump 32 for generating relatively high pressure in the actuation fluid and at least one relatively high pressure actuation fluid manifold 36.

- a common rail passage 38 is arranged in fluid communication with the outlet from the relatively high pressure actuation fluid pump 32.

- a rail branch passage 40 connects the actuation fluid inlet of each injector 14 to the high pressure common rail passage 38.

- Actuation fluid leaving the actuation fluid drain 52, 54 (see Fig. 2) of each injector 14 enters a re-circulation line 27 that carries the same to the hydraulic energy re-circulating or recovering means 22.

- a portion of the re-circulated actuation fluid is channeled to high pressure actuation fluid pump 32 and another portion is returned to actuation fluid sump 24 via re-circulation line 33.

- the actuation fluid is engine lubricating oil and the actuation fluid sump 24 is an engine lubrication oil sump. This allows the fuel injection system to be connected as an additional subsystem to the engine's lubricating oil circulation system.

- the actuation fluid could be fuel provided by a fuel tank 42 or another source, such as coolant fluid, etc.

- the fuel supply means 18 preferably includes a fuel tank 42, a fuel supply passage 44 arranged in fluid communication between fuel tank 42 and the fuel inlet 60 (Fig. 2) of each injector 14, a relatively low pressure fuel transfer pump 46, one or more fuel filters 48, a fuel supply regulating valve 49, and a fuel circulation and return passage 47 arranged in fluid communication between injectors 14 and fuel tank 42.

- the computer 20 preferably includes an electronic control module 11 which controls 1) the fuel injection timing; 2) the total fuel injection quantity during an injection cycle; 3) the fuel injection pressure; 4) the number of separate injections or injection segments during each injection cycle; 5) the time intervals between the injection segments; 6) the fuel quantity of each injection segment during an injection cycle; 7) the actuation fluid pressure; and 8) any combination of the above parameters.

- Computer 20 receives a plurality of sensor input signals S 1 - S 8 , which correspond to known sensor inputs, such as engine operating condition, load, etc., that are used to determine the precise combination of injection parameters for a subsequent injection cycle.

- control signal S 9 to control the actuation fluid pressure and a control signal S 10 to control the fluid control valve(s) within each injector 14.

- control signal S 10 is current to the solenoid commanded by the computer.

- Injector 14 includes an injector body 15 having an actuation fluid inlet 50 that is connected to a branch rail passage 40, actuation fluid drains 52 and 54 that are connected to actuation fluid recirculation line 27 and a fuel inlet 60 connected to a fuel supply passage 44. (See Fig. 1).

- Injector 14 includes a hydraulic means for pressurizing fuel within the injector during each injection event and a needle control valve that controls the opening and closing of nozzle outlet 63.

- the hydraulic means for pressurizing fuel includes an actuation fluid control valve that alternately opens actuation fluid cavity 51 to the high pressure of actuation fluid inlet 50 or the low pressure of actuation fluid drain 52.

- the actuation fluid control valve includes a three-way solenoid 75 attached to a pin spool valve member 76.

- An intensifier spool valve member 78 responds to movement of pin spool valve member 76 to alternately open actuation fluid cavity 51 to actuation fluid inlet 50 or low pressure drain 52.

- the hydraulic pressurizing means also includes actuation fluid cavity 51 that opens to a piston bore 56, within which an intensifier piston 83 reciprocates between a return position (as shown) and a forward position.

- Injector body 15 also includes a plunger bore 58, within which a plunger 85 reciprocates between a retracted position (as shown) and an advanced position.

- a portion of plunger bore 58 and plunger 85 define a fuel pressurization chamber 64, within which fuel is pressurized during each injection event.

- Plunger 85 and intensifier piston 83 are returned to their retracted positions between injection events under the action of compression spring 84.

- the hydraulic means for pressurizing fuel includes the fuel pressurization chamber 64, plunger 85, intensifier piston 83, actuation fluid inlet 50, actuation fluid cavity 51 and the various components of the actuation fluid control valve, which includes solenoid 75, pin spool valve member 76, ball 53 and intensifier spool valve member 78, etc.

- Needle valve member 86 includes opening hydraulic surfaces 87 exposed to fluid pressure within nozzle chamber 62 and a closing hydraulic surface 88 exposed to fluid pressure within a needle control chamber 72. Needle valve member 86 includes a needle portion 91 and intensifier portion 92 that are shown as separate pieces for ease of manufacturing, but both portions could be machined as a single integral component.

- pressurized fuel acts upon the opening hydraulic surfaces 87 whereas actuation fluid acts upon the closing hydraulic surface 88.

- the closing hydraulic surface and the opening hydraulic surface are sized and arranged such that the needle valve member 86 is hydraulically biassed toward its closed position when the needle control chamber is open to a source of high pressure fluid.

- needle valve member 86 When needle control chamber 72 is opened to a low pressure passage, needle valve member 86 performs as a simple check valve of a type known in the art, in that it opens when fuel pressure acting upon opening hydraulic surfaces 87 is greater than a valve opening pressure sufficient to overcome return spring 89.

- opening hydraulic surfaces 87 and closing hydraulic surface 88 are preferably sized and arranged such that the needle valve member is hydraulically biassed toward its open position when the needle control chamber is connected to a low pressure passage and the fuel pressure within the nozzle chamber is greater than the valve opening pressure.

- pin spool valve member 76 is not only considered part of the actuation fluid control valve, but also acts as the needle control valve to alternately open actuation fluid control passage 71 to the high pressure of actuation fluid inlet 50 or the low pressure in actuation fluid drain 54.

- actuation fluid drain 54 constitutes a low pressure passage and actuation fluid inlet 50 constitutes a source of high pressure fluid.

- Intensifier spool valve member 78 is biassed by a compression spring 82 from a closed position, as shown, toward an open position.

- intensifier spool valve member 78 When intensifier spool valve member 78 is in its closed position as shown, actuation fluid cavity 51 is closed to actuation fluid inlet 50, but open to low pressure actuation fluid drain 52.

- intensifier spool valve member 78 moves under the action of compression spring 82 to its open position, actuation fluid cavity 51 is opened to actuation fluid inlet 50 and closed to drain 52.

- the position of intensifier spool valve member 78 is controlled by three position solenoid 75, which is capable of moving actuation pin spool valve member 76 between a first position, a second position, and a third position against the action of compression spring 77.

- solenoid 75 When solenoid 75 is energized with a full or pull-in current, pin spool valve member 76 is pulled to the left against its stop to a second position. When this occurs, the high pressure actuation fluid pushes ball 53 off of seat 59 to close seat 61. This causes intensifier spool valve member 78 to become hydraulically balanced and it moves toward the right to its open position under the action of compression spring 82. At the same time, pin spool valve member 76 closes control passage 71 to second drain 54 and opens actuation fluid control passage 71 to a transfer passage 70, which is open to the high pressure in actuation fluid cavity 51.

- a two-way solenoid fuel injector 14' is presented as an alternative to the three-way solenoid fuel injector 14 just described.

- Fuel injector 14' utilizes a single two-way solenoid 130 to alternately open actuation fluid cavity 109 to actuation fluid inlet 106 or low pressure actuation fluid drain 104, and uses the same solenoid 130 to control the exposure of a needle control chamber 118 to a low pressure passage or a source of high pressure fluid.

- Fuel injector 14' could be substituted in for the injectors 14 shown in Fig. 1 since both injectors perform substantially similar while one uses a single three-way solenoid and the other uses a single two-way solenoid to accomplish the same tasks.

- the single two-way solenoid of injector 14' accomplishes what the three-way solenoid of injector 14 does by exploiting a hysteresis effect in the actuation fluid control valve versus the quick response of the needle valve member to the needle control valve.

- Injector 14' includes an injector body 105 having an actuation fluid inlet 106 that is connected to a branch rail passage 40, an actuation fluid drain 104 that is connected to actuation fluid re-circulation line 27 and a fuel inlet 120 connected to a fuel supply passage 44. (See Fig. 1).

- Injector 14' includes a hydraulic means for pressurizing fuel within the injector during each injection event and a needle control valve that controls the opening and closing of nozzle outlet 117.

- the hydraulic means for pressurizing fuel includes an actuation fluid control valve that includes two-way solenoid 130 which is attached to a pin 135.

- An intensifier spool valve member 140 responds to movement of pin 135 and ball valve member 136 to alternately open actuation fluid cavity 109 to actuation fluid inlet 106 or low pressure drain 104.

- Actuation fluid cavity 109 opens to a stepped piston bore 110 within which a stepped intensifier piston 150 reciprocates between a return position (as shown) and a forward position.

- Injector body 105 also includes a plunger bore 111, within which a plunger 153 reciprocates between a retracted position (as shown) and an advanced position.

- plunger bore 111 and plunger 153 define a fuel pressurization chamber 112, within which fuel is pressurized during each injection event. Plunger 153 and intensifier piston 150 are returned to their retracted positions between injection events under the action of compression spring 154.

- the hydraulic means for pressurizing fuel includes the fuel pressurization chamber 112, plunger 153, intensifier piston 150, actuation fluid inlet 106, actuation fluid cavity 109 and the various components of the actuation fluid control valve, which includes solenoid 130, ball 136, pin 135 and intensifier spool valve member 140, etc.

- Ball check 121 prevents the reverse flow of fuel from fuel pressurization chamber 112 into the fuel supply passage during the plunger's downward stroke.

- Pressurized fuel travels from fuel pressurization chamber 112 via a connection passage 113 to nozzle chamber 114.

- a needle valve member 160 moves within nozzle chamber 114 between an open position in which nozzle outlet 117 is open and a closed position in which nozzle outlet 117 is closed.

- needle valve member 160 includes a lower needle portion 161 and an upper intensifier portion 162 separated by spacers 164 and 166, which are all machined as separate components but could be machined as a single integral piece if spring 165 were relocated. Needle valve member 160 is mechanically biassed to its closed position by a compression spring 165. Unlike the previous embodiment, compression spring 165 is compressed between spacer 164 and intensifier portion 162. Thus, in this embodiment, when needle valve member 160 is closed and needle control chamber 118 is open to low pressure, intensifier portion 162 is pushed to its upper stop.

- Needle valve member 160 includes opening hydraulic surfaces 163 exposed to fluid pressure within nozzle chamber 114 and a closing hydraulic surface 167 exposed to fluid pressure within needle control chamber 118.

- the closing hydraulic surface and the opening hydraulic surfaces are sized and arranged such that the needle valve member 160 is hydraulically biassed toward its closed position when the needle control chamber 118 is open to a source of high pressure fluid.

- the opening hydraulic surfaces 163 and closing hydraulic surface 167 are also preferably sized and arranged such that needle valve member 160 is hydraulically biassed toward its open position when the needle control chamber 118 is connected to a low pressure passage and the fuel pressure within nozzle chamber 114 is greater than the valve opening pressure.

- the actuation fluid control valve of injector 14' can be thought of as including two-way solenoid 130 that is attached to a pin 135 which is normally in contact with ball 136 except when pin 135 is fully retracted. Pin 135 is biassed by a compression spring 138 and the hydraulic force on ball 136 toward a retracted position. In this position, ball 136 closes seat 172 and opens seat 173 so that high pressure actuation fluid flows into contact with the end hydraulic surface 141 of intensifier spool valve member 140.

- solenoid 130 is de-energized

- actuation fluid cavity 109 is opened to actuation fluid drain 104 past seat 170, and intensifier spool valve member 140 is hydraulically balanced and forced down, as shown, to close seat 171 and open seat 170.

- the opening and closing of the nozzle outlet 117 via needle valve member 160 is controlled by the needle control valve which includes solenoid 130.

- pin 135 retracts under the action of compression spring 138 so that high pressure actuation fluid flowing through hollow interior 147 pushes ball 136 to open seat 173 and close seat 172.

- the high pressure actuation fluid inlet 106 flows past seat 173 along a hidden passage into actuation fluid control passage 119.

- Actuation fluid control passage 119 opens to needle control chamber 118 and acts upon the closing hydraulic surface 167 of needle valve member 160, pushing the same downward to close nozzle outlet 117.

- the needle control valve includes solenoid 130, pin 135, ball 136, seat 172 and seat 173.

- the actuation fluid control valve includes all the components of the needle control valve plus intensifier spool valve member 140, compression spring 145, seat 170 and seat 171.

- stepped piston bore 110 includes an upper bore 115 and a larger diameter lower bore 116.

- the stepped top of piston 150 includes a first area 122 that is separated from a second area 132 by a regular cylindrical portion 133.

- First area 122 and upper bore 115 define an upper cavity 123 that is connected to actuation fluid cavity 109 through a relatively unrestricted flow area 127 when piston 150 is in its retracted position, as shown.

- Second area 132 and lower bore 116 define a lower cavity 126 that is connected to the actuation fluid cavity 109 via a restricted passage 128 that includes a restricted flow area 131, when the piston is in its retracted position.

- a restricted passage 128 that includes a restricted flow area 131, when the piston is in its retracted position.

- the restricted flow area 131 prevents second area 132 from experiencing the full fluid pressure in actuation fluid cavity 109 until the piston moves a sufficient distance downward that fluid can also flow around annular taper 134 onto second area 132.

- restricted passage 128 is defined by injector body 105.

- the height of annular taper 134 is preferably chosen to be sufficiently long that the movement rate of the piston is not influenced by the height of the annular taper. This eliminates one possible area of variability when injectors of this type are mass produced. Control over the design parameters A, B, C and D gives one substantial control over the initial movement rate of piston 150, and hence the initial injection rate profile from the injector.

- the hole diameter "A" that defines restricted flow area 131, the diameter "B" of upper bore 115 and the height "C” of the regular cylindrical portion 133 can be sized such that when the regular cylindrical portion 133 is still in upper bore 115, the fluid pressure in lower cavity 126 can be made to be essentially a low constant pressure.

- the height of regular cylindrical portion 133 controls the duration of the slowed piston movement in order to produce a boot injection profile.

- the regular cylindrical portion 133 moves out of upper bore 115 to open an annular gap between annular taper 134 and upper bore 115.

- Fig. 8e shows that the pressure on second area 132 remains low until cylindrical portion 133 clears upper bore 115.

- the height "C” of regular cylindrical portion 133 controls the duration of a flat portion of a boot shaped injection profile. If dimension “C” is short enough, the initial flat portion would disappear, resulting in a ramp up only portion as illustrated in Fig. 8f. Still, dimension “C” preferably has some minimal lead distance length because some movement of the piston is typically necessary to compress the fuel below plunger 153 to a satisfactory injection pressure. Thus, by varying dimensions "A”, “B”, “C”, and “D”, the present invention provides near total flexibility in controlling the front portion of the injection rate trace, which is very important in controlling engine emissions.

- stepped piston 180 includes a first area 181 that is separated from a second area 182 by a regular cylindrical portion 184.

- Stepped piston 180 sits atop a plunger 153 and a return spring 154, which are identical to the embodiment previously described.

- the first area 181 and upper bore 178 define an upper cavity 190 that is connected to an actuation fluid cavity 175 through a relatively unrestricted flow area.

- the second area 182 and the lower bore 177 define a lower cavity 191 connected to actuation fluid cavity 175 through a relatively restricted flow passage 174 defined by the area between regular cylindrical portion 184 and upper bore 178.

- This version performs substantially similar to the earlier version but instead of the injector body defining a separate restricted passageway, the piston and barrel define restricted passage 174. Also, this embodiment is different in that instead of an annular taper on the upper stepped portion of the piston, a slot 187 is machined therein.

- the width of slot 187 is the counterpart to the slope "D" shown in Fig. 2. In other words, the wider the slot, the steeper the ramp up portion of the injection profile. In this embodiment, the difference in the height of the upper step portion from the depth of the slot corresponds to the dimension "C" shown in Fig. 6. In other words, the deeper the slot the less a flat portion (boot) will appear in the injection rate profile.

- a stepped piston 280 is slidably received in a piston bore 270, which includes a lower bore 271 and an upper bore 272.

- a first area 281 is separated from a second area 282 by a regular cylindrical portion 284.

- the first area 281 and upper bore 272 define an upper cavity 290 that is open to the actuation fluid cavity 222 via a relatively unrestricted flow area.

- the second area 282 and the lower bore 271 define a lower cavity 291 that is connected to actuation fluid cavity 222 via a restricted passage 224.

- regular cylindrical portion 284 substantially isolates the lower cavity from the upper cavity.

- a stepped plunger 380 is slidably received and a piston bore 370 that includes a lower bore 371 and an upper bore 372.

- a first area 381 and the upper bore 372 define an upper cavity, as in the previous embodiments.

- a second area 382 and lower bore 371 define a lower cavity that is connected to actuation fluid cavity 322 via a restricted passage 324, which in this embodiment is created by slots cut into annular taper 385.

- the piston and barrel define the restricted passage 324.

- this embodiment is like the embodiment shown in Fig. 6 in that it includes a regular cylindrical portion 384 and an annular taper portion 385.

- a stepped piston 480 is slidably received in a piston bore 470 that includes an upper bore 471 and a lower bore 472. Also like the embodiment shown in Fig. 6, the stepped piston includes a regular cylindrical portion 484 and an annular taper 485.

- Fig. 14 shows another embodiment of the present invention in which still another geometrical variation of the present invention is shown.

- a stepped piston 580 is slidably received in a piston bore 570.

- the first area 581 is separated from a second area 582 by a regular cylindrical portion 584.

- a first cavity 591 is connected to an actuation fluid cavity (not shown) through a restricted passage 524 that includes a restricted flow area 525.

- a second cavity 590 which acts upon first area 581, is connected to an actuation fluid cavity via an unrestricted flow area 523.

- each injection sequence is started by applying pull-in current to solenoid 75 in order to move pin spool valve member 76 to the left.

- Oil pressure that entered the injector and was trapped at seat 59 is now able to push ball valve 53 to close seat 61.

- High pressure oil can flow past seat 59 through cross grooves in the back side of intensifier spool valve member 78 to act on end hydraulic surface 79.

- the intensifier spool valve member 78 is now pressure balanced and spring 82 moves it to the right. This opens seat 55 and closes seat 57.

- the main oil supply can flow through radial openings 81, past seat 55, into actuation fluid cavity 51 to the top of intensifier piston 83, starting it moving downward.

- Oil is also flowing through a connection passage 70 to the pin spool valve member 76.

- seat 67 opens and seat 65 closes causing the high pressure in transfer passage 70 to be connected to actuation fluid control passage 71.

- the high pressure acting on closing hydraulic surface 88 holds needle valve member 86 in its closed position.

- intensifier piston 83 and plunger 85 moving downward, fuel pressure starts to build within fuel pressurization chamber 64, closing ball check 65.

- the solenoid pull-in current is reduced to its hold-in current after fuel pressure reaches valve opening pressure.

- a different injection characteristic takes place. Dropping back to a hold-in current from the initial pull-in current causes the pin spool valve member 76 to close seat 67 and open seat 65. Hold-in current will provide enough force to prevent the solenoid spring 77 from pushing ball valve 53 off of seat 61. The high pressure oil can no longer flow past seat 67 into actuation fluid control passage 71 to pressurize needle control chamber 72. If the solenoid hold-in current is maintained, fuel pressure within nozzle chamber 62 will build via its connection passage 69 to fuel pressurization chamber 64 until a valve opening pressure (VOP) is reached and the needle valve member opens against the action of needle return spring 89.

- VOP valve opening pressure

- needle valve member 86 With the full pull-in current being applied, fuel pressure continues to build from the intensifier piston 83 and plunger 85 moving downward (or stopped at a point where the fuel is fully compressed rendering the plunger hydraulically locked), but the needle valve member 86 will not open because high pressure oil is allowed to flow into needle control chamber 72 to act on closing hydraulic surface 88 of needle valve member 86. This pressure on needle valve member 86 provides a force required to keep it closed.

- solenoid 75 changes from pull-in current to its lower hold-in current.

- the needle control chamber is opened to the low pressure of drain 54 past seat 65. This removes the force keeping the needle valve member closed, and now it opens allowing fuel to exit nozzle chamber 62 through nozzle outlet 63.

- Fuel injection can be paused or temporarily halted by returning the solenoid current to its pull-in level. This re-pressurizes the closing hydraulic surface 88 of needle valve member 86 causing it to close. This direct control of needle valve member 86 allows the nozzle outlet to be opened and closed any number of times during each injection cycle without affecting the hydraulic pressurizing means.

- solenoid 75 is de-energized. This causes actuation pin spool valve member 76 to close seat 67 and open seat 65. This releases the pressurized oil acting on closing hydraulic surface 88.

- the solenoid spring 77 causes the actuation valve member 76 to push ball valve 53 from seat 61 back to close seat 59.

- the high pressure oil supply is closed off at seat 59 and oil pressure on the hydraulic end surface 79 of intensifier spool valve member 78 is released past seat 61 to low pressure drain 54.

- Intensifier spool valve member 78 is again hydraulically unbalanced causing it to move left against the action of spring 82 to close seat 55 and open seat 57.

- This injection system provides the ability to vary injection pressures by controlling the pressure of the actuation fluid and provides the ability to control injection characteristics through the direct control of the needle valve member.

- the direct control of the needle valve member allows the computer to control when the needle valve member is opened at any pressure between valve opening pressure and a maximum injection pressure. This provides a significant amount of control over initial injection mass flow rate in order to produce some rate shaping, if desired.

- the direct control aspects of the present invention allow for a desirable abrupt end to injection by providing the means by which the needle valve member can be quickly closed at any desired time.

- each injection sequence is started by energizing the solenoid 130 in order to move ball 136 to open seat 172 and close seat 173.

- the pressurized fluid previously acting on the end hydraulic surface 141 of spool valve member 140 can drain past seat 172.

- Intensifier spool valve member 140 is now hydraulically imbalanced and begins to move upward against the action of compression spring 145. This opens seat 171 and closes seat 170.

- the main oil supply can now flow through radial openings 146, past seat 171, into actuation fluid cavity 109 to the top of intensifier piston 150, starting it moving downward.

- intensifier piston 150 accelerates downward at a rate lower than it otherwise would if the full fluid pressure were acting over the complete top surface of the intensifier piston.

- the volume above annular top surface 156 of intensifier piston 150 is filled by fluid flowing through restricted passage 128. As the intensifier piston continues to move downward, it eventually reaches a point where the volume above space 156 is growing faster than fluid can be supplied via passage 128. This causes a momentary hesitation in the piston's downward movement resulting in a slower build-up of fuel pressure underneath plunger 153 in fuel pressurization chamber 112.

- solenoid 130 is de-energized. This causes ball 136 to open seat 173 and closes seat 172. This resumes the pressurized oil acting on closing hydraulic surface 167 and, with the help of return spring 165, causes needle valve member 160 to close and provide an abrupt end to the injection.

- the opening of seat 173 causes intensifier spool valve member 140 to again become hydraulically balanced so that compression spring 145 moves the same downward to close seat 171 and open seat 170. This allows actuation fluid in actuation fluid cavity 109 to drain into actuation fluid drain 104 so that intensifier piston 150 and plunger 153 can retract under the action of return spring 154.

- the present invention is capable of far more complex injection rate profiles than that illustrated in Fig. 8f.

- the graphs in Figs. 9a - 9e show that, as an example, the injector 14' can be made to produce a pilot injection segment C followed by a "square" main injection segment E.

- solenoid 130 is initially energized with a maximum current so that ball 136 moves to open seat 172 and close seat 173.

- the intensifier spool valve member begins to move from its closed position to its open position so that high pressure actuation fluid begins to flow into actuation fluid cavity 109 beginning the piston and plunger moving in their downward stroke.

- the needle valve member briefly opens to allow pilot injection segment C to occur.

- the solenoid is briefly de-energized a sufficient amount of time that the ball 136 moves back to its original position to open seat 173 and close seat 172. This again pressurizes the closing hydraulic surface of needle valve member 160 causing it to close.

- intensifier spool valve member becomes hydraulically balanced and begins to move to close seat 171.

- spring 145 is relatively weak, the intensifier spool valve member moves rather slowly.

- the solenoid is again energized causing ball 136 to again close seat 173 and re-open seat 172.

- a simple "square" injection rate profile can be created by de-energizing the solenoid before fuel pressure in the nozzle chamber reaches the valve opening pressure, and then re-energizing the solenoid before intensifier spool valve member 140 is moved to close seat 170, but after fuel pressure has reached a desired injection pressure above the valve opening pressure.

- the stepped piston aspect of the present invention finds potential application to any piston and barrel assembly that is hydraulically driven and in which it is desirable to slow the initial movement rate of the piston. This slowing of the initial movement rate of the piston is accomplished by machining various geometrical relationships between the piston and the piston bore rather than through control of the pressure of the fluid acting on the piston as a whole.

- the present invention finds special application in the case of hydraulically-actuated fuel injectors in which it is desirable to slow the initial movement rate of the piston in order to provide a more desirable front end injection rate trace to reduce undesirable engine emissions.

- Fig. 6 While any of the embodiments illustrated could be utilized in a fuel injector, the embodiment shown in Fig. 6 is most desired because of the ease with which circular features can be machined in a bore or on a cylindrical piston to relatively tight tolerances. In other words, the slots illustrated in some of the embodiments could prove more difficult to reliably manufacture is mass quantities while maintaining the tight dimension tolerances necessary to produce consistent results.

- the subject invention is capable of varying peak fuel injection pressure independent of engine speed and load.

- the subject invention is capable of variably controlling the fuel quantity of each separate fuel injection segment during an injection cycle.

- the invention is also capable of variably controlling each time interval between each separate fuel injection segment during an injection cycle.

- the injector solenoid can be energized and de-energized once or a selected plurality of times during an injection cycle to produce one or a variably-selected plurality of injection segments.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Electromagnetism (AREA)

- Fuel-Injection Apparatus (AREA)

Description

- The present invention relates generally to fuel injection, and more particularly to hydraulically-actuated fuel injectors with direct control needle valve members, and fuel injection systems.

- Known hydraulically-actuated fuel injection systems and/or components are shown, for example, in US-A-5,121,730, US-A-5,271,371, US-A-5,297,523 and US-A-5 522 545. In these hydraulically actuated fuel injectors, a spring biassed needle check opens to commence fuel injection when pressure is raised by an intensifier piston/plunger assembly to a valve opening pressure. The intensifier piston is acted upon by a relatively high pressure actuation fluid, such as engine lubricating oil, when a solenoid driven actuation fluid control valve opens the injector's high pressure inlet. Injection is ended by deactivating the solenoid to release pressure above the intensifier piston. This in turn causes a drop in fuel pressure causing the needle check to close under the action of its return spring to end injection. While these hydraulically actuated fuel injectors have performed magnificently over many years, there remains room for improvement, especially in the area of shaping an injection rate trace from beginning to end to precisely suit a set of engine operating conditions.

- Over the years, engineers have discovered that engine emissions can be significantly reduced at certain operating conditions by providing a particular injection rate trace. In many cases emissions are improved when the initial injection rate is controllable, and when there is a nearly vertical abrupt end to injection. While these prior hydraulically actuated fuel injection systems have some ability to control the injection rate shape, there remains room to improve the ability to control injection rate shape with hydraulically actuated fuel injection systems.

- The present invention is directed to improving the ability of hydraulically actuated fuel injectors to reliably produce better injection rate shapes during each injection event.

- According to the present invention there is provided a hydraulically actuated fuel injector comprising:

- an injector body that defines an actuation fluid cavity, a piston bore, and a nozzle outlet;

- said piston bore includes a first bore, and a second bore;

- a piston with a top being slidably received in said piston bore and movable between a retracted position and an advanced position;

- said top of said piston including a first area that is separate from a second area;

- said first area and said first bore defining a first cavity connected to said actuation fluid cavity through a relatively unrestricted flow area when said piston is in said retracted position;

- said second area and said second bore defining a second cavity connected to said actuation fluid cavity through a relatively restricted flow area when said piston is in said retracted position; and

- said first area being exposed to fluid pressure in said first cavity and said second area being exposed to fluid pressure in said second cavity over a portion of said piston's movement from said retracted position toward said advanced position;

- at least one of said piston said injector body further defining a restricted passage connecting said actuation fluid cavity to said second cavity, and said restricted passage includes said restricted flow area; and

- a needle valve member positioned in said injector body and movable between an open position in which said nozzle outlet is open and a closed position in which said nozzle outlet is blocked.

-

- In the accompanying drawings:

- Fig. 1 is a schematic view of a fuel injection system according to the present invention.

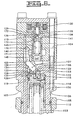

- Fig. 2 is a sectioned side elevational view of a fuel injector.

- Fig. 3 is a partial sectioned side elevational view of an upper portion of the fuel injector shown in Fig. 2.

- Fig. 4 is a partial sectioned side elevational view of the lower portion of the injector shown in Fig. 2.

- Fig. 5 is a sectioned side elevational view of a fuel injector according to the present invention.

- Fig. 6 is a partial sectioned side elevational view of an upper portion of the fuel injector shown in Fig. 5.

- Fig. 7 is a partial sectioned side elevational view of the lower portion of the injector shown in Fig. 5.

- Figs. 8a-f are a group of curves showing component positions and injection parameters versus time over a single "ramp-square" injection event.

- Figs. 9a-e are a group of curves showing component positions and injection parameters versus time over a "pilot plus square" injection event.

- Fig. 10 is a partial sectioned side view of a stepped piston/barrel assembly according to another embodiment of the present invention.

- Fig. 11 is a partial sectioned side view of a stepped piston/barrel assembly according to still another embodiment of the present invention.

- Fig. 12a is the partial sectioned side view of a stepped piston/barrel assembly according to another embodiment of the present invention.

- Fig. 12b is a top view of the central portion of the stepped piston shown in Fig. 12a.

- Fig. 13 is a partial sectioned side view of the stepped piston/barrel assembly according to still another embodiment of the present invention.

- Fig. 14 is a partial sectioned side view of a stepped piston/barrel assembly according to still another embodiment of the present invention.

-

- Referring now to Fig. 1, there is shown an embodiment of a hydraulically-actuated electronically-controlled

fuel injection system 10 in an example configuration as adapted for a direct-injection diesel-cycleinternal combustion engine 12.Fuel system 10 includes one or more hydraulically-actuated electronically-controlledfuel injectors 14, which are adapted to be positioned in a respective cylinder head bore ofengine 12.Fuel system 10 includes an apparatus or means 16 for supply actuating fluid to eachinjector 14, an apparatus or means 18 for supplying fuel to each injector, acomputer 20 for electronically controlling the fuel injection system and an apparatus or means 22 for re-circulating actuation fluid and for recovering hydraulic energy from the actuation fluid leaving each of the injectors. - The actuating fluid supply means 16 preferably includes an actuating

fluid sump 24, a relatively low pressure actuatingfluid transfer pump 26, an actuatingfluid cooler 28, one or moreactuation fluid filters 30, ahigh pressure pump 32 for generating relatively high pressure in the actuation fluid and at least one relatively high pressureactuation fluid manifold 36. Acommon rail passage 38 is arranged in fluid communication with the outlet from the relatively high pressureactuation fluid pump 32. Arail branch passage 40 connects the actuation fluid inlet of eachinjector 14 to the high pressurecommon rail passage 38. - Actuation fluid leaving the

actuation fluid drain 52, 54 (see Fig. 2) of eachinjector 14 enters are-circulation line 27 that carries the same to the hydraulic energy re-circulating or recoveringmeans 22. A portion of the re-circulated actuation fluid is channeled to high pressureactuation fluid pump 32 and another portion is returned toactuation fluid sump 24 viare-circulation line 33. - Any available engine fluid is preferably used as the actuation fluid in the present invention. However, in the preferred embodiments, the actuation fluid is engine lubricating oil and the

actuation fluid sump 24 is an engine lubrication oil sump. This allows the fuel injection system to be connected as an additional subsystem to the engine's lubricating oil circulation system. Alternatively, the actuation fluid could be fuel provided by afuel tank 42 or another source, such as coolant fluid, etc. - The fuel supply means 18 preferably includes a

fuel tank 42, afuel supply passage 44 arranged in fluid communication betweenfuel tank 42 and the fuel inlet 60 (Fig. 2) of eachinjector 14, a relatively low pressurefuel transfer pump 46, one ormore fuel filters 48, a fuelsupply regulating valve 49, and a fuel circulation andreturn passage 47 arranged in fluid communication betweeninjectors 14 andfuel tank 42. - The

computer 20 preferably includes anelectronic control module 11 which controls 1) the fuel injection timing; 2) the total fuel injection quantity during an injection cycle; 3) the fuel injection pressure; 4) the number of separate injections or injection segments during each injection cycle; 5) the time intervals between the injection segments; 6) the fuel quantity of each injection segment during an injection cycle; 7) the actuation fluid pressure; and 8) any combination of the above parameters.Computer 20 receives a plurality of sensor input signals S1 - S8, which correspond to known sensor inputs, such as engine operating condition, load, etc., that are used to determine the precise combination of injection parameters for a subsequent injection cycle. In this example,computer 20 issues control signal S9 to control the actuation fluid pressure and a control signal S10 to control the fluid control valve(s) within eachinjector 14. Each of the injection parameters are variably controllable independent of engine speed and load. In the case ofinjector 14, control signal S10 is current to the solenoid commanded by the computer. - Referring now to Figs. 2-4, a

fuel injector 14 with a single three-way solenoid 75 is shown.Injector 14 includes aninjector body 15 having anactuation fluid inlet 50 that is connected to abranch rail passage 40,actuation fluid drains fluid recirculation line 27 and afuel inlet 60 connected to afuel supply passage 44. (See Fig. 1).Injector 14 includes a hydraulic means for pressurizing fuel within the injector during each injection event and a needle control valve that controls the opening and closing ofnozzle outlet 63. - The hydraulic means for pressurizing fuel includes an actuation fluid control valve that alternately opens

actuation fluid cavity 51 to the high pressure ofactuation fluid inlet 50 or the low pressure ofactuation fluid drain 52. The actuation fluid control valve includes a three-way solenoid 75 attached to a pinspool valve member 76. An intensifierspool valve member 78 responds to movement of pinspool valve member 76 to alternately openactuation fluid cavity 51 to actuationfluid inlet 50 orlow pressure drain 52. The hydraulic pressurizing means also includesactuation fluid cavity 51 that opens to a piston bore 56, within which anintensifier piston 83 reciprocates between a return position (as shown) and a forward position.Injector body 15 also includes a plunger bore 58, within which aplunger 85 reciprocates between a retracted position (as shown) and an advanced position. A portion of plunger bore 58 andplunger 85 define afuel pressurization chamber 64, within which fuel is pressurized during each injection event.Plunger 85 andintensifier piston 83 are returned to their retracted positions between injection events under the action ofcompression spring 84. Thus, the hydraulic means for pressurizing fuel includes thefuel pressurization chamber 64,plunger 85,intensifier piston 83,actuation fluid inlet 50,actuation fluid cavity 51 and the various components of the actuation fluid control valve, which includessolenoid 75, pinspool valve member 76, ball 53 and intensifierspool valve member 78, etc. - Fuel enters

injector 14 atfuel inlet 60 and travels alongfuel supply passage 66, pastball check valve 68 and intofuel pressurization chamber 64, whenplunger 85 is retracting.Ball check 68 prevents the reverse flow of fuel fromfuel pressurization chamber 64 intofuel supply passage 66 during the plunger's downward stroke. Unused fuel is re-circulated from each injector via a return opening 74. Pressurized fuel travels fromfuel pressurization chamber 64 via aconnection passage 69 tonozzle chamber 62. Aneedle valve member 86 moves withinnozzle chamber 62 between an open position in whichnozzle outlet 63 is opened and a closed position in whichnozzle outlet 63 is closed.Needle valve member 86 is mechanically biassed to its closed position by acompression spring 89. -

Needle valve member 86 includes openinghydraulic surfaces 87 exposed to fluid pressure withinnozzle chamber 62 and a closinghydraulic surface 88 exposed to fluid pressure within aneedle control chamber 72.Needle valve member 86 includes aneedle portion 91 andintensifier portion 92 that are shown as separate pieces for ease of manufacturing, but both portions could be machined as a single integral component. - It should be appreciated that pressurized fuel acts upon the opening

hydraulic surfaces 87 whereas actuation fluid acts upon the closinghydraulic surface 88. Preferably, the closing hydraulic surface and the opening hydraulic surface are sized and arranged such that theneedle valve member 86 is hydraulically biassed toward its closed position when the needle control chamber is open to a source of high pressure fluid. Thus, in order to maintain direct control ofneedle valve member 86 despite high fuel pressure withinnozzle chamber 62, there should be adequate pressure on the closinghydraulic surface 88 to maintainnozzle outlet 63 closed. Whenneedle control chamber 72 is opened to a low pressure passage,needle valve member 86 performs as a simple check valve of a type known in the art, in that it opens when fuel pressure acting upon openinghydraulic surfaces 87 is greater than a valve opening pressure sufficient to overcomereturn spring 89. Thus, openinghydraulic surfaces 87 and closinghydraulic surface 88 are preferably sized and arranged such that the needle valve member is hydraulically biassed toward its open position when the needle control chamber is connected to a low pressure passage and the fuel pressure within the nozzle chamber is greater than the valve opening pressure. - In this injector, pin

spool valve member 76 is not only considered part of the actuation fluid control valve, but also acts as the needle control valve to alternately open actuationfluid control passage 71 to the high pressure ofactuation fluid inlet 50 or the low pressure inactuation fluid drain 54. One can control the opening and closing ofnozzle outlet 63 when fuel is above a valve opening pressure by controlling the exposure of closinghydraulic surface 88 to either a source of high pressure fluid or a low pressure passage. Thus, in this injector,actuation fluid drain 54 constitutes a low pressure passage andactuation fluid inlet 50 constitutes a source of high pressure fluid. - Intensifier

spool valve member 78 is biassed by acompression spring 82 from a closed position, as shown, toward an open position. When intensifierspool valve member 78 is in its closed position as shown,actuation fluid cavity 51 is closed to actuationfluid inlet 50, but open to low pressureactuation fluid drain 52. When intensifierspool valve member 78 moves under the action ofcompression spring 82 to its open position,actuation fluid cavity 51 is opened to actuationfluid inlet 50 and closed to drain 52. The position of intensifierspool valve member 78 is controlled by threeposition solenoid 75, which is capable of moving actuation pinspool valve member 76 between a first position, a second position, and a third position against the action ofcompression spring 77. - When

solenoid 75 is de-energized, as shown,compression spring 77 pushes pinspool valve member 76 to the right to its first position in which actuationfluid control passage 71 is opened to second low pressureactuation fluid drain 54 past seat 65. At the same time, pinspool valve member 76 pushes ball 53 to closeseat 59 and open seat 61 so that the endhydraulic surface 79 of intensifierspool valve member 78 is exposed to the low pressure ofsecond drain 54. This causes the high pressure actuation fluid acting on the other end of intensifierspool valve member 78 to hold it in its closed position as shown against the action ofcompression spring 82. Thus, whensolenoid 75 is de-energized, actuation fluid cavity is open toactuation fluid drain 52 and closed to actuationfluid inlet 50. - When

solenoid 75 is energized with a full or pull-in current, pinspool valve member 76 is pulled to the left against its stop to a second position. When this occurs, the high pressure actuation fluid pushes ball 53 off ofseat 59 to close seat 61. This causes intensifierspool valve member 78 to become hydraulically balanced and it moves toward the right to its open position under the action ofcompression spring 82. At the same time, pinspool valve member 76 closescontrol passage 71 tosecond drain 54 and opens actuationfluid control passage 71 to atransfer passage 70, which is open to the high pressure inactuation fluid cavity 51. - When

solenoid 75 is energized with a medium or hold-in current, pinspool valve member 76 moves slightly to the right to a third position that is a sufficient distance to close actuationfluid control passage 71 to the high pressure intransfer passage 70 and re-open the same tolow pressure drain 54. However, the hold-in current is not sufficient to cause any change in the position of intensifierspool valve member 78, which remains in its open position withactuation fluid cavity 51 open to high pressureactuation fluid inlet 50. When intensifierspool valve member 78 is in its open position, actuation fluid flows throughinlet 50 into thehollow interior 80 of intensifierspool valve member 78, throughradial openings 81, and then simultaneously intoconnection passage 70 andactuation fluid cavity 51. - Referring now to Figs. 5-7, a two-way solenoid fuel injector 14' is presented as an alternative to the three-way

solenoid fuel injector 14 just described. Fuel injector 14' utilizes a single two-way solenoid 130 to alternately openactuation fluid cavity 109 to actuationfluid inlet 106 or low pressureactuation fluid drain 104, and uses thesame solenoid 130 to control the exposure of aneedle control chamber 118 to a low pressure passage or a source of high pressure fluid. Fuel injector 14' could be substituted in for theinjectors 14 shown in Fig. 1 since both injectors perform substantially similar while one uses a single three-way solenoid and the other uses a single two-way solenoid to accomplish the same tasks. The single two-way solenoid of injector 14' accomplishes what the three-way solenoid ofinjector 14 does by exploiting a hysteresis effect in the actuation fluid control valve versus the quick response of the needle valve member to the needle control valve. - Injector 14' includes an

injector body 105 having anactuation fluid inlet 106 that is connected to abranch rail passage 40, anactuation fluid drain 104 that is connected to actuationfluid re-circulation line 27 and afuel inlet 120 connected to afuel supply passage 44. (See Fig. 1). Injector 14' includes a hydraulic means for pressurizing fuel within the injector during each injection event and a needle control valve that controls the opening and closing ofnozzle outlet 117. - The hydraulic means for pressurizing fuel includes an actuation fluid control valve that includes two-

way solenoid 130 which is attached to apin 135. An intensifierspool valve member 140 responds to movement ofpin 135 andball valve member 136 to alternately openactuation fluid cavity 109 to actuationfluid inlet 106 orlow pressure drain 104.Actuation fluid cavity 109 opens to a stepped piston bore 110 within which a steppedintensifier piston 150 reciprocates between a return position (as shown) and a forward position.Injector body 105 also includes aplunger bore 111, within which aplunger 153 reciprocates between a retracted position (as shown) and an advanced position. A portion of plunger bore 111 andplunger 153 define afuel pressurization chamber 112, within which fuel is pressurized during each injection event.Plunger 153 andintensifier piston 150 are returned to their retracted positions between injection events under the action ofcompression spring 154. Thus, the hydraulic means for pressurizing fuel includes thefuel pressurization chamber 112,plunger 153,intensifier piston 150,actuation fluid inlet 106,actuation fluid cavity 109 and the various components of the actuation fluid control valve, which includessolenoid 130,ball 136,pin 135 and intensifierspool valve member 140, etc. - Fuel enters injector 14' at

fuel inlet 120 and travels past ball check 121, along a hiddenfuel supply passage 124, and intofuel pressurization chamber 112, whenplunger 153 is retracting.Ball check 121 prevents the reverse flow of fuel fromfuel pressurization chamber 112 into the fuel supply passage during the plunger's downward stroke. Pressurized fuel travels fromfuel pressurization chamber 112 via aconnection passage 113 tonozzle chamber 114. Aneedle valve member 160 moves withinnozzle chamber 114 between an open position in whichnozzle outlet 117 is open and a closed position in whichnozzle outlet 117 is closed. In this embodiment,needle valve member 160 includes alower needle portion 161 and anupper intensifier portion 162 separated byspacers spring 165 were relocated.Needle valve member 160 is mechanically biassed to its closed position by acompression spring 165. Unlike the previous embodiment,compression spring 165 is compressed betweenspacer 164 andintensifier portion 162. Thus, in this embodiment, whenneedle valve member 160 is closed andneedle control chamber 118 is open to low pressure,intensifier portion 162 is pushed to its upper stop. -

Needle valve member 160 includes openinghydraulic surfaces 163 exposed to fluid pressure withinnozzle chamber 114 and a closinghydraulic surface 167 exposed to fluid pressure withinneedle control chamber 118. As in the previous embodiment the closing hydraulic surface and the opening hydraulic surfaces are sized and arranged such that theneedle valve member 160 is hydraulically biassed toward its closed position when theneedle control chamber 118 is open to a source of high pressure fluid. Thus, there should be adequate pressure on the closinghydraulic surface 167 to maintainnozzle outlet 117 closed despite the presence of high pressure fuel innozzle chamber 114 that is otherwise above a valve opening pressure. The openinghydraulic surfaces 163 and closinghydraulic surface 167 are also preferably sized and arranged such thatneedle valve member 160 is hydraulically biassed toward its open position when theneedle control chamber 118 is connected to a low pressure passage and the fuel pressure withinnozzle chamber 114 is greater than the valve opening pressure. - The actuation fluid control valve of injector 14' can be thought of as including two-

way solenoid 130 that is attached to apin 135 which is normally in contact withball 136 except whenpin 135 is fully retracted.Pin 135 is biassed by acompression spring 138 and the hydraulic force onball 136 toward a retracted position. In this position,ball 136 closes seat 172 and opensseat 173 so that high pressure actuation fluid flows into contact with the endhydraulic surface 141 of intensifierspool valve member 140. When solenoid 130 is de-energized,actuation fluid cavity 109 is opened to actuationfluid drain 104past seat 170, and intensifierspool valve member 140 is hydraulically balanced and forced down, as shown, to closeseat 171 andopen seat 170. When solenoid 130 is energized, pin 135 moves downward causingball 136 to open seat 172 andclose seat 173. This causes endhydraulic surface 141 to be exposed to the low pressure indrain passage 129, which is connected to asecond drain 108. This creates a hydraulic imbalance in intensifierspool valve member 140 causing it to move upward against the action ofcompression spring 145 to closeseat 170 andopen seat 171. This allows actuation fluid to flow frominlet 106, into thehollow interior 147 of intensifierspool valve member 140, throughradial openings 146,past seat 171 and intoactuation fluid cavity 109 to act upon the stepped top of theintensifier piston 150. - The opening and closing of the

nozzle outlet 117 vianeedle valve member 160 is controlled by the needle control valve which includessolenoid 130. As stated earlier, when de-energized,pin 135 retracts under the action ofcompression spring 138 so that high pressure actuation fluid flowing throughhollow interior 147 pushesball 136 toopen seat 173 and close seat 172. When in this configuration, the high pressureactuation fluid inlet 106 flows pastseat 173 along a hidden passage into actuationfluid control passage 119. Actuationfluid control passage 119 opens toneedle control chamber 118 and acts upon the closinghydraulic surface 167 ofneedle valve member 160, pushing the same downward to closenozzle outlet 117. When solenoid 130 is energized,pin 135 is moved downward pushingball 136 to closeseat 173 and open seat 172. This opens actuationfluid control passage 119 to the low pressure withindrain passage 129, which is connected to second lowpressure fluid drain 108.Drains injector body 105. Thus, with thesolenoid 130 energized, the closinghydraulic surface 167 ofneedle valve member 160 is now exposed to a low pressure passage and the needle valve member begins to behave like a simple check valve in that it will now open if fuel pressure within thenozzle chamber 114 is greater than a valve opening pressure sufficient to overcomereturn spring 165. In this embodiment, the needle control valve includessolenoid 130,pin 135,ball 136, seat 172 andseat 173. The actuation fluid control valve includes all the components of the needle control valve plus intensifierspool valve member 140,compression spring 145,seat 170 andseat 171. - Referring again to Fig. 6, stepped piston bore 110 includes an

upper bore 115 and a larger diameterlower bore 116. The stepped top ofpiston 150 includes afirst area 122 that is separated from asecond area 132 by a regularcylindrical portion 133.First area 122 andupper bore 115 define anupper cavity 123 that is connected to actuationfluid cavity 109 through a relativelyunrestricted flow area 127 whenpiston 150 is in its retracted position, as shown. -

Second area 132 andlower bore 116 define alower cavity 126 that is connected to theactuation fluid cavity 109 via arestricted passage 128 that includes a restrictedflow area 131, when the piston is in its retracted position. When the piston begins its movement from its retracted position toward its advanced position, thefirst area 122 is exposed to the full fluid pressure inupper cavity 123, whereassecond area 132 is exposed to the fluid pressure inlower cavity 126. Because of the rate at which the volume oflower cavity 126 grows as thepiston 150 moves in its downward stroke, the restrictedflow area 131 preventssecond area 132 from experiencing the full fluid pressure inactuation fluid cavity 109 until the piston moves a sufficient distance downward that fluid can also flow aroundannular taper 134 ontosecond area 132. In this embodiment, restrictedpassage 128 is defined byinjector body 105. - Also shown in Fig. 6 are the design parameters "A", "B", "C", and "D". The height of

annular taper 134 is preferably chosen to be sufficiently long that the movement rate of the piston is not influenced by the height of the annular taper. This eliminates one possible area of variability when injectors of this type are mass produced. Control over the design parameters A, B, C and D gives one substantial control over the initial movement rate ofpiston 150, and hence the initial injection rate profile from the injector. The hole diameter "A" that defines restrictedflow area 131, the diameter "B" ofupper bore 115 and the height "C" of the regularcylindrical portion 133 can be sized such that when the regularcylindrical portion 133 is still inupper bore 115, the fluid pressure inlower cavity 126 can be made to be essentially a low constant pressure. Thus, the height of regularcylindrical portion 133 controls the duration of the slowed piston movement in order to produce a boot injection profile. As thepiston 150 continues its downward movement, the regularcylindrical portion 133 moves out ofupper bore 115 to open an annular gap betweenannular taper 134 andupper bore 115. Fig. 8e shows that the pressure onsecond area 132 remains low untilcylindrical portion 133 clearsupper bore 115. This reduced pressure slows the initial movement rate ofpiston 150 and reduces the initial injection rate. After sufficient movement ofpiston 150, actuation fluid flows freer intolower cavity 126 both through restrictedpassage 128 and pastannular taper 134 so that pressure inlower cavity 126 begins to rise. As a result, fuel pressure increases, producing the ramp up portion of an injection profile. The slope "D" ofannular taper 134 controls the slope of the ramp up portion. - The height "C" of regular

cylindrical portion 133 controls the duration of a flat portion of a boot shaped injection profile. If dimension "C" is short enough, the initial flat portion would disappear, resulting in a ramp up only portion as illustrated in Fig. 8f. Still, dimension "C" preferably has some minimal lead distance length because some movement of the piston is typically necessary to compress the fuel belowplunger 153 to a satisfactory injection pressure. Thus, by varying dimensions "A", "B", "C", and "D", the present invention provides near total flexibility in controlling the front portion of the injection rate trace, which is very important in controlling engine emissions. - Referring now to Fig. 10, an alternative embodiment of the present invention is shown which includes a

piston 180 with a stepped top slidably received in apiston bore 176, which includes alower bore 177 and anupper bore 178. Like the earlier embodiment, steppedpiston 180 includes afirst area 181 that is separated from asecond area 182 by a regularcylindrical portion 184. Steppedpiston 180 sits atop aplunger 153 and areturn spring 154, which are identical to the embodiment previously described. - Like the previous embodiment, the

first area 181 andupper bore 178 define anupper cavity 190 that is connected to anactuation fluid cavity 175 through a relatively unrestricted flow area. Thesecond area 182 and thelower bore 177 define a lower cavity 191 connected to actuationfluid cavity 175 through a relatively restricted flow passage 174 defined by the area between regularcylindrical portion 184 andupper bore 178. This version performs substantially similar to the earlier version but instead of the injector body defining a separate restricted passageway, the piston and barrel define restricted passage 174. Also, this embodiment is different in that instead of an annular taper on the upper stepped portion of the piston, aslot 187 is machined therein. In this case, the width ofslot 187 is the counterpart to the slope "D" shown in Fig. 2. In other words, the wider the slot, the steeper the ramp up portion of the injection profile. In this embodiment, the difference in the height of the upper step portion from the depth of the slot corresponds to the dimension "C" shown in Fig. 6. In other words, the deeper the slot the less a flat portion (boot) will appear in the injection rate profile. - Referring now to Fig. 11, still another embodiment of the present invention is shown in which the piston itself defines the restricted passage to 224. Like the previous embodiments a stepped

piston 280 is slidably received in apiston bore 270, which includes alower bore 271 and anupper bore 272. Afirst area 281 is separated from asecond area 282 by a regularcylindrical portion 284. Thefirst area 281 andupper bore 272 define anupper cavity 290 that is open to theactuation fluid cavity 222 via a relatively unrestricted flow area. Like the previous embodiments, thesecond area 282 and thelower bore 271 define alower cavity 291 that is connected to actuationfluid cavity 222 via arestricted passage 224. Like the embodiment shown in Fig. 2, regularcylindrical portion 284 substantially isolates the lower cavity from the upper cavity. This embodiment of the invention operates substantially identical to the earlier embodiments described, but just contains different geometry to accomplish the same purposes. - Referring now to Figs. 12a, and 12b, still another embodiment is shown in which a stepped