EP1074369B1 - Method for manufacturing highly stressed composite pieces - Google Patents

Method for manufacturing highly stressed composite pieces Download PDFInfo

- Publication number

- EP1074369B1 EP1074369B1 EP00115999A EP00115999A EP1074369B1 EP 1074369 B1 EP1074369 B1 EP 1074369B1 EP 00115999 A EP00115999 A EP 00115999A EP 00115999 A EP00115999 A EP 00115999A EP 1074369 B1 EP1074369 B1 EP 1074369B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fibres

- precomposite

- composition

- process according

- resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002131 composite material Substances 0.000 title claims abstract description 46

- 238000000034 method Methods 0.000 title claims description 58

- 238000004519 manufacturing process Methods 0.000 title claims description 11

- 229920005989 resin Polymers 0.000 claims abstract description 65

- 239000011347 resin Substances 0.000 claims abstract description 65

- 230000005855 radiation Effects 0.000 claims abstract description 26

- 238000000465 moulding Methods 0.000 claims abstract description 22

- 230000009477 glass transition Effects 0.000 claims abstract description 13

- 239000011159 matrix material Substances 0.000 claims abstract description 11

- 230000001681 protective effect Effects 0.000 claims abstract description 4

- 239000000203 mixture Substances 0.000 claims description 59

- 229920001971 elastomer Polymers 0.000 claims description 22

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Natural products C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 11

- 230000002787 reinforcement Effects 0.000 claims description 11

- 238000005470 impregnation Methods 0.000 claims description 10

- 239000003365 glass fiber Substances 0.000 claims description 9

- 239000000806 elastomer Substances 0.000 claims description 8

- 239000000178 monomer Substances 0.000 claims description 8

- -1 polyethylene Polymers 0.000 claims description 8

- 239000003292 glue Substances 0.000 claims description 6

- 238000010438 heat treatment Methods 0.000 claims description 6

- 229910052799 carbon Inorganic materials 0.000 claims description 5

- 239000003822 epoxy resin Substances 0.000 claims description 5

- 229920000647 polyepoxide Polymers 0.000 claims description 5

- 239000004698 Polyethylene Substances 0.000 claims description 4

- 229920000297 Rayon Polymers 0.000 claims description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 4

- 229920000728 polyester Polymers 0.000 claims description 4

- 229920000573 polyethylene Polymers 0.000 claims description 4

- 229920001567 vinyl ester resin Polymers 0.000 claims description 4

- GUCYFKSBFREPBC-UHFFFAOYSA-N [phenyl-(2,4,6-trimethylbenzoyl)phosphoryl]-(2,4,6-trimethylphenyl)methanone Chemical compound CC1=CC(C)=CC(C)=C1C(=O)P(=O)(C=1C=CC=CC=1)C(=O)C1=C(C)C=C(C)C=C1C GUCYFKSBFREPBC-UHFFFAOYSA-N 0.000 claims description 3

- 238000005452 bending Methods 0.000 claims description 3

- KVBYPTUGEKVEIJ-UHFFFAOYSA-N benzene-1,3-diol;formaldehyde Chemical compound O=C.OC1=CC=CC(O)=C1 KVBYPTUGEKVEIJ-UHFFFAOYSA-N 0.000 claims description 3

- 239000004816 latex Substances 0.000 claims description 3

- 229920000126 latex Polymers 0.000 claims description 3

- 229920003043 Cellulose fiber Polymers 0.000 claims description 2

- 239000004962 Polyamide-imide Substances 0.000 claims description 2

- 239000004642 Polyimide Substances 0.000 claims description 2

- 239000004743 Polypropylene Substances 0.000 claims description 2

- 239000004372 Polyvinyl alcohol Substances 0.000 claims description 2

- 239000004760 aramid Substances 0.000 claims description 2

- 229920003235 aromatic polyamide Polymers 0.000 claims description 2

- 125000003118 aryl group Chemical group 0.000 claims description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 2

- 239000000919 ceramic Substances 0.000 claims description 2

- 125000005609 naphthenate group Chemical group 0.000 claims description 2

- 229910052760 oxygen Inorganic materials 0.000 claims description 2

- 239000001301 oxygen Substances 0.000 claims description 2

- 229920002239 polyacrylonitrile Polymers 0.000 claims description 2

- 229920002312 polyamide-imide Polymers 0.000 claims description 2

- 229920002577 polybenzoxazole Polymers 0.000 claims description 2

- 229920001721 polyimide Polymers 0.000 claims description 2

- 229920001155 polypropylene Polymers 0.000 claims description 2

- 229920002451 polyvinyl alcohol Polymers 0.000 claims description 2

- 239000002964 rayon Substances 0.000 claims description 2

- 239000000377 silicon dioxide Substances 0.000 claims description 2

- 239000007790 solid phase Substances 0.000 claims description 2

- 238000002211 ultraviolet spectrum Methods 0.000 claims 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims 2

- 229920001225 polyester resin Polymers 0.000 claims 2

- 239000004645 polyester resin Substances 0.000 claims 2

- 125000003011 styrenyl group Chemical group [H]\C(*)=C(/[H])C1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 claims 2

- 238000004026 adhesive bonding Methods 0.000 claims 1

- 239000011248 coating agent Substances 0.000 claims 1

- 238000000576 coating method Methods 0.000 claims 1

- 239000000835 fiber Substances 0.000 abstract description 56

- 238000006116 polymerization reaction Methods 0.000 abstract description 20

- 230000005865 ionizing radiation Effects 0.000 abstract description 14

- 239000012783 reinforcing fiber Substances 0.000 abstract description 12

- 239000000463 material Substances 0.000 abstract description 9

- 239000010410 layer Substances 0.000 abstract 1

- 239000011185 multilayer composite material Substances 0.000 abstract 1

- 230000000379 polymerizing effect Effects 0.000 abstract 1

- 239000002356 single layer Substances 0.000 abstract 1

- 239000012071 phase Substances 0.000 description 14

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 8

- 230000003014 reinforcing effect Effects 0.000 description 6

- 230000015556 catabolic process Effects 0.000 description 5

- 238000006731 degradation reaction Methods 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 238000000748 compression moulding Methods 0.000 description 3

- 239000004744 fabric Substances 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 235000011837 pasties Nutrition 0.000 description 3

- 238000013517 stratification Methods 0.000 description 3

- 238000012360 testing method Methods 0.000 description 3

- UDHXJZHVNHGCEC-UHFFFAOYSA-N Chlorophacinone Chemical compound C1=CC(Cl)=CC=C1C(C=1C=CC=CC=1)C(=O)C1C(=O)C2=CC=CC=C2C1=O UDHXJZHVNHGCEC-UHFFFAOYSA-N 0.000 description 2

- 239000004593 Epoxy Substances 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000011152 fibreglass Substances 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 239000013067 intermediate product Substances 0.000 description 2

- 238000005304 joining Methods 0.000 description 2

- 229920006284 nylon film Polymers 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 208000032544 Cicatrix Diseases 0.000 description 1

- 206010073306 Exposure to radiation Diseases 0.000 description 1

- RRHGJUQNOFWUDK-UHFFFAOYSA-N Isoprene Chemical compound CC(=C)C=C RRHGJUQNOFWUDK-UHFFFAOYSA-N 0.000 description 1

- 241000287502 Phoenicopteriformes Species 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 229910000323 aluminium silicate Inorganic materials 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000002301 combined effect Effects 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 229920006241 epoxy vinyl ester resin Polymers 0.000 description 1

- 238000009730 filament winding Methods 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000001879 gelation Methods 0.000 description 1

- 230000000977 initiatory effect Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000012784 inorganic fiber Substances 0.000 description 1

- 150000002762 monocarboxylic acid derivatives Chemical class 0.000 description 1

- 210000005036 nerve Anatomy 0.000 description 1

- 229920003986 novolac Polymers 0.000 description 1

- 229920001195 polyisoprene Polymers 0.000 description 1

- 239000003505 polymerization initiator Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 231100000241 scar Toxicity 0.000 description 1

- 230000037387 scars Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 238000009987 spinning Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 238000013519 translation Methods 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

- 238000002371 ultraviolet--visible spectrum Methods 0.000 description 1

- 229920006337 unsaturated polyester resin Polymers 0.000 description 1

- 238000004073 vulcanization Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/06—Fibrous reinforcements only

- B29C70/10—Fibrous reinforcements only characterised by the structure of fibrous reinforcements, e.g. hollow fibres

- B29C70/16—Fibrous reinforcements only characterised by the structure of fibrous reinforcements, e.g. hollow fibres using fibres of substantial or continuous length

- B29C70/20—Fibrous reinforcements only characterised by the structure of fibrous reinforcements, e.g. hollow fibres using fibres of substantial or continuous length oriented in a single direction, e.g. roofing or other parallel fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/10—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation for articles of indefinite length

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/03—Use of materials for the substrate

- H05K1/0313—Organic insulating material

- H05K1/0353—Organic insulating material consisting of two or more materials, e.g. two or more polymers, polymer + filler, + reinforcement

- H05K1/0366—Organic insulating material consisting of two or more materials, e.g. two or more polymers, polymer + filler, + reinforcement reinforced, e.g. by fibres, fabrics

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/0011—Working of insulating substrates or insulating layers

- H05K3/0014—Shaping of the substrate, e.g. by moulding

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1002—Methods of surface bonding and/or assembly therefor with permanent bending or reshaping or surface deformation of self sustaining lamina

- Y10T156/1043—Subsequent to assembly

Definitions

- the present invention relates to processes for manufacturing composite parts, in particular in the case of pieces of complex shapes. It relates more particularly to coins composites very strongly mechanically stressed.

- a process for manufacturing composite parts consists in molding a dough by compression under high pressures and complete polymerization before demolding.

- the dough has been prepared previously, and comprises a mixture of resin and short fibers. This process is very widely used because of its ability to manufacture complex shaped parts and its high productivity.

- the compression molding process is incompatible with the use of long reinforcing fibers. For this reason, we can not consider achieve by this process the most mechanically stressed parts

- the object of the invention is to provide a method for manufacturing parts composites without degradation of the maximum possible reinforcing effect depending on the fibers selected, and which is applicable to a wide variety of shapes, including radii of curvature very small.

- another objective is to be able to introduce the constituents of the composite part into an open mold, as a mold for tires, which in practice excludes injection techniques.

- the invention aims to propose a manufacturing technique that meets the objectives mentioned above and which lends itself to the mechanization and rapid rates sought for industrial manufactures.

- the process is more particularly directed to the use of fibers of infinite length.

- spun comprising in general a large number (of the order of one hundred) of filaments elementals with a diameter of a few microns, these filaments being all side by side, so substantially parallel to each other, with some overlaps.

- the preferred reinforcement direction is, for example, the direction of tensile stresses in the part to be manufactured.

- warp yarns that is oriented in said preferred direction, and further containing other fibers, constituting for example weft son, regardless of the density.

- the step of impregnating the fibers is not in itself specific to the present invention, the man the profession can easily select any suitable method, the impregnation being precede or follow the phase of arrangement of the fibers parallel to a plane.

- Arrange the fibers parallel to a plane is intended that, at the latest, while one starts the polymerization of the resin, the reinforcing fibers are appropriately ordered to they are, in the final composite room, judiciously arranged to provide fully the reinforcing effect.

- precomposite is meant a material whose resin is prepolymerized to form a solid medium (so-called gelation step or beyond), so that the precomposite has a sufficient cohesion to be able to be installed in an open mold, with the solicitations this assumes, without risking a "spinning" of the fibers during which the rate of resin of the preform would decrease in a non-controlled way.

- the purpose of prepolymerization is therefore to achieve a minimum level of polymerization to avoid any flow of resin during further processing thereof (in fact, a treatment of the composite or article in which it will be incorporated) under the action of the temperature, even under the action of the pressure.

- the purpose of prepolymerization is also to achieve a minimum level of polymerization to give the precomposite resistance to buckling of its fibers during a bending as imposed by the application step on a non-planar support.

- the polymerization triggered by ionizing radiation not only achieves this stage, but also allows to stop the polymerization process by ceasing to issue said radiation. Indeed, the goal of prepolymerization is still not to exceed a level maximum of polymerization, allowing the bonding of the precomposite either on itself or on rubber as will be explained in detail later.

- Prepolymerization as proposed associated with an implementation of the material by stratification in sufficiently thin layers, allows to reconstitute a block of form and any thickness, with respect to a monolithic material prepared with the same resin and the same fibers in identical density, prepared for example by pultrusion.

- ionizing radiation it is proposed to use radiation in the spectrum ranging from 300 nm to 450 nm, or an accelerated electron beam.

- a precomposite is prepared in a ribbon approximately 0.1 mm thick (width whatever, chosen rather according to the part to be manufactured), and the piece made from stretches of this ribbon has the same properties as a monolith, ie a piece of simple form which is not constituted by stratification and superposition of thin layers.

- stresses are exerted on said sections of precomposite in order to force them to to intimately marry the said form of support.

- the deformation stresses are maintained on said sections of precomposite at least until the beginning of the heat treatment step.

- the beginning of the polymerization is advantageously carried out in thick layer “e” such that "e” is smaller than "r” divided by 20.

- the beginning of the polymerization is carried out in layer of thickness "e” such that "e” is smaller than "r” divided by 150.

- FIG. 1 shows a bobbin 10 containing a yarn 11 which, in the illustrated example, consists of by fiberglass.

- An impregnation device 20 having a tank 21 containing a composition based on a curable resin and a photoinitiator suitable for the radiation by which said composition will be treated.

- the device of impregnation 20 comprises an impregnating chamber 22.

- a prepreg 12 which is introduced into a prepolymerization device 30, in which the prepreg 12 is prepolymerized by ionizing radiation, the treatment being carried out protected from oxygen.

- the radiation 31 to which the composition is exposed its wavelength is typically less than 450 nanometers, preferably between 300 nm and 450 nm.

- rollers 40 result in the obtained precomposite 13 in the direction of the arrow F.

- a shear 50 can take sections 14 in the precomposite manufactured continuously, to implement them as explained below.

- the level of prepolymerization must be high enough to allow stacking of sections 14 on the desired support without causing buckling of the fibers 11 located inside of the curvature of the section 14 deformed, and to prevent the resin-based composition from becoming spread outside of the precomposite during the deformation, and also during a treatment subsequent thermal under pressure.

- This level of prepolymerization must however be low enough that the continuation of the polymerization of a stack of several sections of this precomposite under the combined effect of temperature and pressure creates through the interface between two adjacent sections of precomposite, in order to obtain a composite material having excellent mechanical properties, in particular flexural and in shear.

- the step of exposure to radiation ionizing is stopped after the index D constituted by the Shore D hardness of the divided precomposite by the Shore D hardness of the final composite has reached a value of the order of 0.5 and before said index D has reached a value of the order of 0.7.

- the exposure to ionizing radiation is stopped after the glass transition temperature T g of the composition of the precomposite has reached a value of the order of 40 ° C and before the glass transition temperature T g of the composition of the precomposite has reached a value of the order of 130 ° C.

- the prepolymerization level of the precomposite is such that that one is beyond the point of gelling of the resin.

- the level of prepolymerization is achieved by adapting, for example, the treatment time to ionizing radiation (speed of travel imposed by the rollers 40, length of the prepolymerization device 30).

- the nerve of the sections 14 is rather weak, it is necessary to make sure that that the stack of sections of precomposite keeps a shape in C, at least enough for allow the implementation of the following steps.

- the each other the different sections 14 of the stack by interposing at least partially a layer 15 of said composition, for example at the ends of the C and at the surface of one least sections to maintain on top of each other, as shown in Figure 2.

- ionizing radiation for example radiation ultraviolet - visible

- sections 14 as shown schematically in Figure 2

- we did not make sure that the sections are spontaneously maintained at the imposed deformation they must be maintained by externally applying the appropriate forces.

- Figure 3 shows the final step.

- a counter-mold 62 is brought over the support 61 coated with a stack 16 of sections 14 of precomposite.

- Final molding under pressure for example of the order of 10 bars.

- the temperature during the molding under pressure is preferably greater than the glass transition temperature T g of the composition of the precomposite.

- a suitable treatment temperature is of the order of at least 150 ° C.

- the final properties of the material are not solely and not even primarily due to said prepolymerization. They also result largely from the heat treatment during this final molding step, which ensures excellent bonding of previously stacked sections on each other.

- the control of the degree of prepolymerization is not carried out by thermal, it is possible to adjust the viscosity of the composition during the impregnation step fibers by a moderate rise in the temperature of said composition. For example, we can heat up to about 80 ° C, without any significant effect on the stability of the resin. This allows a much better impregnation of the fibers. We can thus have a adjustment parameter of the impregnation phase independent of the parameters of the steps subsequent processes.

- the resin can be chosen in the group consisting of vinylester resins and unsaturated polyester resins, or can be an epoxy resin.

- the reinforcing fibers let's mention that they can be chosen from organic fibers such as high polyacrylic fibers tenacity or oxidized polyacrylonitrile fibers, high tenacity polyvinyl alcohol fibers, aromatic polyamide fibers or polyamide-imide fibers or polyimide fibers, chlorofibers, high tenacity polyester fibers or aromatic polyester fibers, fibers high tenacity polyethylene, high tenacity polypropylene fibers, cellulose fibers or rayon or high tenacity viscose, polyphenylene benzobisoxazole fibers, fibers polyethylene naphthenate, or they can be chosen from inorganic fibers such as glass fibers, carbon fibers, silica fibers, ceramic fibers (alumina, aluminosilicate, boro

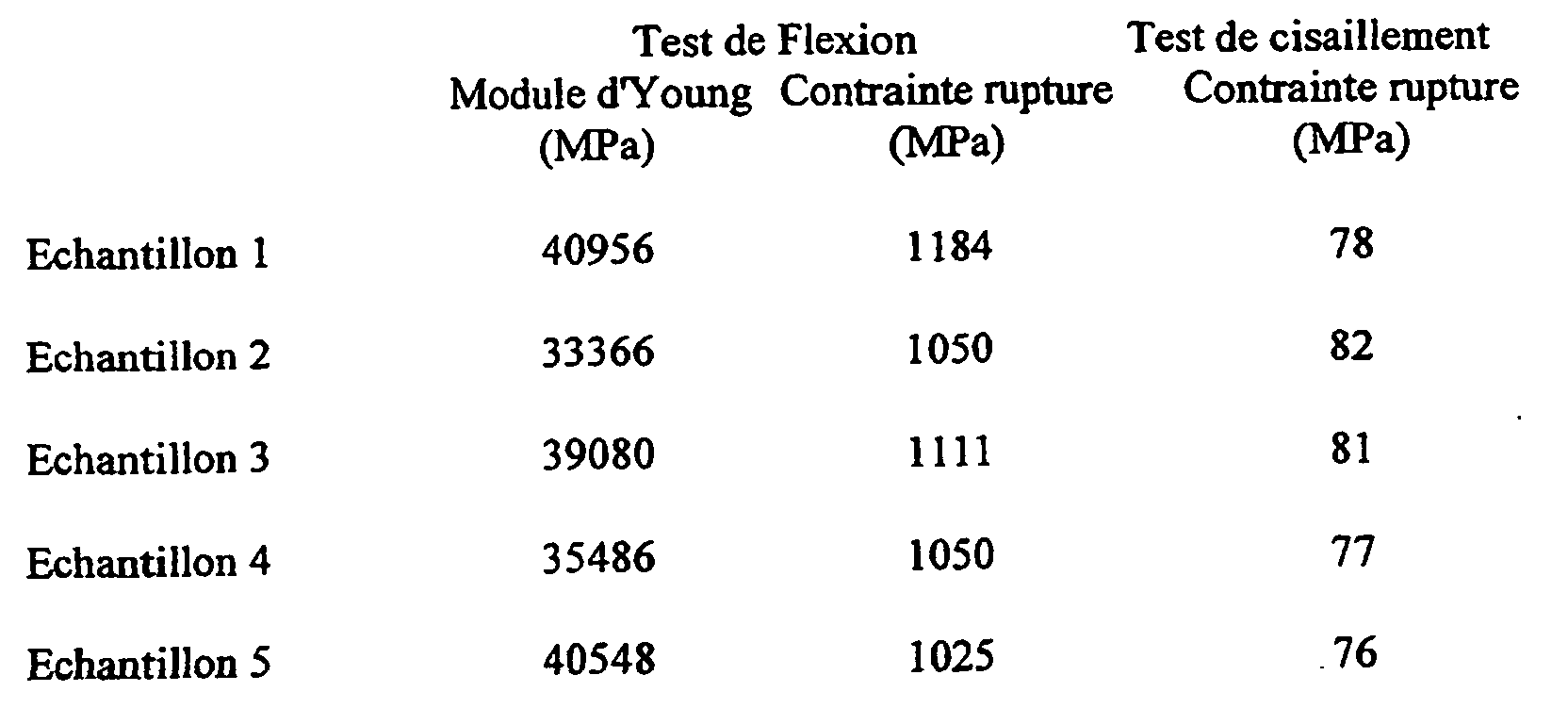

- the following table gives comparative results on different samples 1 to 5, prepared in medium of different resins.

- the prepared samples are parallelepipedic blocks 2 mm thick.

- the reinforcing fibers are fibers of glass, of the type indicated.

- Preparation "direct molding” means that one has prepared an equivalent monolith without any stratification; parallel fibers between them are regularly distributed in the resin matrix. All samples were final molded with heat treatment under pressure.

- Control 1 was prepared with a prepreg of unidirectional fibers, available commercially under the name Prepreg Vicotex (reference BE M10 / 29.5% / 25x2400 - P122 EPOXY 60 mm glass strip), consisting of unidirectional glass fibers embedded in an epoxy resin, manufactured by Hexcel Composites S.A ..

- the control 2 comprises yarns commercially available under the name PPG 2001 300Tex, embedded in a resin available commercially under the name Atlac 590.

- the control 3 is obtained by stacking 10 sections of precomposite, the precomposite having has been prepolymerized thermally. It has the same glass fibers embedded in the same resin as witness 2.

- the composition comprises a photograph polymerization initiator and the radiation is included in the ultraviolet - visible spectrum.

- a glass fiber is used.

- All the samples of the invention are obtained by stacking 10 precomposite sections 0.2 mm thick, protected by two 50 micron nylon films.

- the precomposite was prepolymerized by exposure for the number of seconds indicated under ultraviolet-visible radiation (Philips UV Tube TLK 40W / 03) placed at a distance of 180 mm from the section.

- the precomposite proves to be sufficiently transparent to the radiations so that the prepolymerization is well homogeneous and for the temporary maintenance as set out above, in which the radiation treatment is carried out through an already prepolymerized section, to be effective.

- the resins of Controls 2 and 3 and all samples are all vinyl ester resins. (Epoxy Vinyl Ester Resins).

- the supplier of ATLAC 590 resin is DSM - BASF Structural Resins. Note in passing that, as a variant of what was said in the preceding paragraph, it is possible to adjust the viscosity of said composition by adding a monomer copolymerizable with the resin and by varying the proportion. For example, the monomer whose proportion is styrene.

- the photoinitiator is bis (2,4,6-trimethylbenzoyl) -phenylphosphine oxide (Irgacure photoinitiator 819).

- the supplier of the resin "Heltron 970" is Ashland Chemical.

- the supplier of the "RD903" and “RD904" resins is UCB Chemicals.

- the Resin supplier "Derakane 470-36S” is Dow.

- witnesses 1 and 2 illustrate the best performance that can be expected from a monolith properly prepared.

- the mechanical performances of the samples are illustrated by the value of the Young's modulus, by the maximum stress at break of the sample in flexion test (Afnor Standard T57-302), and the maximum shear stress at break (Standard Afnor T57-303), this last property making it possible in particular to highlight the quality of the bonding between the layers of the control 3 and the sample according to the invention.

- the invention makes it possible to find substantially the properties of the witness 2, which is a monolith directly comparable.

- the mechanical properties of the material are the same, as the sections of precomposite have been deformed or not.

- the following table illustrates the partial polymerization treatment. It gives a qualitative description of the precomposite obtained for different values of the ultraviolet radiation treatment time.

- the samples concerned contain 70% by weight PPG 300 Tex glass fibers embedded in an Atlac 590 resin with 2% of Irgacure 819 photoinitiator.

- the precomposite is prepared in a 0.25 mm thick and 30 mm wide layer. glass fibers being unidirectional. The layer is surface protected by a 50 micron thick nylon film for irradiation. The irradiation is ensured by 2 Philips TLK 40W / 03 UV tubes placed at a distance of 180 mm from the layer to be treated. A stack of 15 sections of 30 mm of precomposite is then formed.

- the buckling strength is evaluated by manually winding a fiber-oriented sample onto a cylinder 30 mm in radius. The resistance is evaluated at a pressure of 30 bar at a temperature of 110 ° C.

- the Shore D hardness is measured according to the standard already indicated. UV exposure time (sec) Surface appearance Shore D hardness Resistance to buckling Resistance to pressure 10 poissant 20 many flamingos crushed composite, exuded resin 20 non-sticky 35 buckling crushed composite 25 non-sticky 45 little buckling composite not crushed 27 non-sticky 50 no buckling composite not crushed 30 non-sticky 65 no buckling composite not crushed 40 non-sticky 75 no buckling composite not crushed 60 non-sticky 80 no buckling composite not crushed

- the irradiation step is preferably limited in time as soon as the hardness Appropriate Shore D has been reached, the reader being referred to explanations already provided.

- the invention makes it possible to obtain an intermediate product constituted essentially by a precomposite prepared in great length and in a thickness of less than 0.3 millimeters, comprising reinforcing fibers parallel to at least one preferred reinforcing direction, said fibers being embedded in a matrix with base of a composition comprising an ionizing radiation curable resin, wherein the glass transition temperature T g of the matrix is between 40 ° C and 130 ° C, and wherein the Shore D hardness of said precomposite is between 50 and 65, coated with a protective film opaque to ultraviolet - visible radiation. Thanks to the protective film, this intermediate product can be stored without the prepolymerization rate noticeably changing. It can be used on another site and implemented according to the indications of the method of the invention.

- the invention relates to a method of joining a composite material to rubber.

- the described method makes it possible to produce a laminate in which said composite parts are intimately secured to rubber.

- a layer of resorcinol formaldehyde latex (RFL) glue on the surface of each section intended to receive a layer of rubber, one deposits a layer of resorcinol formaldehyde latex (RFL) glue, said layer of RFL glue being dried without reaching a temperature above 100 ° C, ie without treatment heat at high temperature, before receiving said rubber layer.

- RFL resorcinol formaldehyde latex

- the invention therefore also extends to a material in which, between some of said strata at less, is interposed a layer 17 of sulfur-vulcanizable elastomer composition.

- a layer 17 of sulfur-vulcanizable elastomer composition is interposed between at least some of said strata and said composition based on elastomer vulcanizable with sulfur.

- RTL glue resorcinol formaldehyde latex

- FIG. 4 shows the support 61 first covered by two sections 14 of precomposite stacked, deformed and temporarily maintained by a layer 15 of the composition prepolymerized with ultraviolet radiation.

- the two strata thus deposited and pre-stabilized spontaneously preserve their C-shape.

- a layer 17 of a composition based on raw rubber is then deposited over the second section 14.

- the Rubber-based composition can marry without much difficulty the shape imposed on first layers of precomposite.

- the final molding step illustrated in FIG. 5, allows both the good bonding of the sections 14 between them, the vulcanization of the rubber, the complete polymerization of the resin and the bonding the rubber and the resin.

- a counter-mold 63 is brought over the support 61 coated with a stack 18 of sections 14 of precomposite with the interposition of a layer 17 of rubber. Final molding is carried out with heat treatment under pressure.

Landscapes

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Thermal Sciences (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Composite Materials (AREA)

- Chemical & Material Sciences (AREA)

- Textile Engineering (AREA)

- Reinforced Plastic Materials (AREA)

- Moulding By Coating Moulds (AREA)

- Laminated Bodies (AREA)

- Polymerisation Methods In General (AREA)

- Graft Or Block Polymers (AREA)

- Macromonomer-Based Addition Polymer (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Glass Compositions (AREA)

Abstract

Description

La présente invention concerne les procédés de fabrication de pièces composites, notamment dans le cas de pièces de formes complexes. Elle se rapporte plus particulièrement aux pièces composites très fortement sollicitées mécaniquement.The present invention relates to processes for manufacturing composite parts, in particular in the case of pieces of complex shapes. It relates more particularly to coins composites very strongly mechanically stressed.

Un procédé de fabrication de pièces composites consiste à mouler une pâte par compression sous de hautes pressions puis à effectuer la polymérisation complète avant de démouler. La pâte a été préparée auparavant, et comporte un mélange de résine et de fibres courtes. Ce procédé est très largement utilisé en raison de son aptitude à la fabrication de pièces de formes complexes et de sa grande productivité. Cependant, le procédé de moulage par compression est incompatible avec l'utilisation de fibres de renforcement longues. Pour cette raison, on ne peut pas envisager de réaliser par ce procédé les pièces les plus sollicitées mécaniquementA process for manufacturing composite parts consists in molding a dough by compression under high pressures and complete polymerization before demolding. The dough has been prepared previously, and comprises a mixture of resin and short fibers. This process is very widely used because of its ability to manufacture complex shaped parts and its high productivity. However, the compression molding process is incompatible with the use of long reinforcing fibers. For this reason, we can not consider achieve by this process the most mechanically stressed parts

On connaít d'autres techniques permettant de mettre en oeuvre des fibres de renforcement longues. L'une de ces techniques est appelée "pultrusion". Il s'agit de dérouler les fibres de longueur illimitée, et de les plonger dans un bain de résine pour en assurer l'imprégnation. Ensuite, on les tire au travers d'une filière chauffée, puis au travers d'une enceinte chauffée où s'effectue la polymérisation. On peut de cette façon tirer en continu des produits de section quelconque, dictée par la forme de la filière. Mais il s'agit toujours de produits droits. Une autre technique connue est l'enroulement filamentaire. Sur un mandrin mobile en rotation et en translation, on enroule des ensembles de fibres de renforcement préimprégnées. L'objet fabriqué est polymérisé en étuve. On obtient des tubes, ou des pièces de grandes dimensions comme des réservoirs. Mais outre le fait que la variété de formes est très restreinte, il est difficile de positionner rigoureusement les fibres dans l'épaisseur de la paroi fabriquée. Celles-ci ont tendance à se rapprocher de la surface du mandrin. Il est également difficile de maintenir une proportion de fibres constante dans toute l'épaisseur de la paroi.Other techniques are known that make it possible to use reinforcing fibers long. One of these techniques is called "pultrusion". It involves unwinding the fibers of unlimited length, and immerse them in a bath of resin to ensure impregnation. Then they are pulled through a heated die, then through a heated chamber where the polymerization is carried out. This way you can continuously pull section products whatever, dictated by the shape of the die. But it's always about straight products. Another known technique is the filament winding. On a mandrel that is mobile in rotation and translation, winding sets of prepreg reinforced fibers. The manufactured object is polymerized in an oven. We get tubes, or large parts like tanks. But besides the fact that the variety of forms is very restricted, it is difficult to rigorously position the fibers in the thickness of the fabricated wall. These have tendency to get closer to the surface of the mandrel. It is also difficult to maintain a proportion of fibers constant throughout the thickness of the wall.

On connaít aussi des techniques de moulage de pièces réalisées en composite, faisant notamment appel à une préforme, elle même moulée, pour faciliter la mise en place des fibres de renforcement. Il a été proposé dans le brevet EP 0 655 319 et dans GB-A-1 522 441 de stabiliser une préforme en résine comportant des fibres de renforcement en chauffant la préforme pour obtenir une consistance pâteuse, dont la viscosité permet encore un moulage par compression. Puis on démoule la préforme pâteuse et on la met en place dans un second moule porté à une température plus élevée, afin d'effectuer un moulage par compression de la préforme pâteuse tout en effectuant la polymérisation.It is also known molding techniques of parts made of composite, including use of a preform, itself molded, to facilitate the placement of the fibers of enhancement. It has been proposed in patent EP 0 655 319 and in GB-A-1,522,441 to stabilize a resin preform having reinforcing fibers by heating the preform to obtain a consistency pasty, whose viscosity still allows a compression molding. Then we unmold pasty preform and is put in place in a second mold heated to a higher temperature high, in order to perform a compression molding of the pasty preform while performing the polymerization.

Cependant, le problème d'un tel traitement est qu'il est difficile de maítriser le stade auquel on amène ce que l'on conviendra d'appeler une « prépolymérisation » (polymérisation initiale partielle). Or il faut atteindre une consistance suffisante pour que les manipulations ultérieures ne provoquent pas trop de désorganisations dans le positionnement des fibres. Bien sûr plus la prépolymérisation est avancée et mieux on maintient les fibres, mais plus il devient difficile de changer la forme lors du moulage ultérieur de la préforme. Par ailleurs, il est en outre très difficile, même quasi impossible, d'interrompre ce processus de polymérisation, qui peut parfois être très rapide en raison de l'exothermie de la réaction. Dans ce cas, la rigidité de la résine renforcée devient rapidement trop importante, ce qui est incompatible avec un moulage ultérieur.However, the problem of such treatment is that it is difficult to control the stage at which bring what we will call a "prepolymerization" (initial polymerization partial). However, it is necessary to reach a sufficient consistency for the subsequent manipulations do not cause too much disorganization in the positioning of the fibers. Of course no longer prepolymerization is advanced and the fibers are better maintained, but the more difficult it becomes to change the shape during the subsequent molding of the preform. Moreover, it is also very difficult, even almost impossible, to interrupt this process of polymerization, which can sometimes be very fast because of the exothermic reaction. In this case, the stiffness of the resin reinforced becomes quickly too important, which is incompatible with a subsequent molding.

Ainsi, sauf pour des pièces en composite de forme plane ou en barreau ou en tube rectiligne, ou pour d'autres formes simples, on n'a pas réussi jusqu'à ce jour à positionner individuellement des fibres longues exactement selon l'orientation voulue et en densité correctement maítrisée dans toute l'épaisseur de la pièce. On peut noter que, dans le brevet précité, on coupe les fibres pour faciliter leur mise en oeuvre. Il en résulte une inévitable dégradation de l'effet de renforcement. On entend par "fibres en grande longueur" ou "fibres longues" ou "fibres de longueur infinie" des fibres dont la longueur n'est limitée que par les dimensions de la pièce, ou du moins par les dimensions des parties de la pièce qui doivent être renforcées, sans que cette longueur soit limitée par des contraintes venant du procédé de mise en oeuvre. On entend par "positionner individuellement" le fait de partir de filés ou de tissus plans simples, et non pas de tissus à trois dimensions qui sont chaque fois spécifiques d'une seule pièce fabriquée et qui posent eux aussi d'importants problèmes de manipulation.Thus, except for composite parts of flat shape or bar or rectilinear tube, or for other simple forms, we have not managed to position long fibers exactly in the correct orientation and in a properly controlled density throughout the thickness of the room. It may be noted that, in the aforementioned patent, the fibers are cut to facilitate their implementation. This results in an inevitable degradation of the effect of enhancement. "Long fiber" or "long fiber" or "fiber of infinite length "of fibers whose length is limited only by the dimensions of the part, or at least by the dimensions of the parts of the room that need to be reinforced, without this length is limited by constraints from the method of implementation. We hear by "position individually" the fact of starting yarns or simple flat fabrics, and not of three-dimensional fabrics that are each time specific to a single fabricated piece and that also pose significant handling problems.

L'objectif de l'invention est de proposer un procédé permettant de fabriquer des pièces composites sans dégradation de l'effet de renforcement maximal possible en fonction des fibres sélectionnées, et qui soit applicable à des formes très variées, notamment des rayons de courbure très petits. Pour pouvoir atteindre les formes les plus complexes et aussi dans certains cas pour pouvoir marier la structure composite avec d'autres matériaux comme du caoutchouc, un autre objectif est de pouvoir introduire les constituants de la pièce composite dans un moule ouvert, comme un moule pour pneumatiques, ce qui exclut en pratique les techniques d'injection. L'invention vise à proposer une technique de fabrication qui réponde aux objectifs mentionnés ci-dessus et qui se prête à la mécanisation et aux cadences rapides recherchées pour les fabrications industrielles.The object of the invention is to provide a method for manufacturing parts composites without degradation of the maximum possible reinforcing effect depending on the fibers selected, and which is applicable to a wide variety of shapes, including radii of curvature very small. In order to reach the most complex forms and also in some cases to can marry the composite structure with other materials like rubber, another objective is to be able to introduce the constituents of the composite part into an open mold, as a mold for tires, which in practice excludes injection techniques. The invention aims to propose a manufacturing technique that meets the objectives mentioned above and which lends itself to the mechanization and rapid rates sought for industrial manufactures.

L'invention a pour objet un procédé de fabrication de pièces composites d'épaisseur donnée, comprenant des fibres de renforcement parallèles à au moins une direction de renforcement privilégiée, lesdites fibres étant noyées dans une matrice à base d'une composition comprenant une résine durcissable par un rayonnement ionisant, le procédé comportant les étapes suivantes:

- disposer lesdites fibres de renforcement sensiblement parallèlement à un plan et les imprégner de ladite composition;

- exposer la composition contenant lesdites fibres, en couche d'épaisseur inférieure à ladite épaisseur donnée, à un rayonnement ionisant, pour polymériser partiellement la résine, l'exposition à un rayonnement ionisant étant arrêtée après que l'indice D constitué par la dureté Shore D du précomposite divisée par la dureté Shore D du composite final ait atteint une valeur de l'ordre de 0.5 et avant que ledit indice D ait atteint une valeur de l'ordre de 0.7 et obtenir un précomposite dans lequel ladite composition est en phase solide ;

- prélever des tronçons dans le précomposite et les appliquer sur un support, dont la surface est de forme non plane, en les empilant les uns sur les autres en nombre dicté par ladite épaisseur donnée, et en leur faisant épouser intimement ladite forme du support et ainsi créer un empilage de tronçons contraints ;

- soumettre l'empilage à un moulage final sous une pression et à une température appropriées afin de poursuivre la polymérisation de la résine et de solidariser les différents tronçons de précomposite.

- arranging said reinforcing fibers substantially parallel to a plane and impregnating them with said composition;

- exposing the composition containing said fibers, in a layer of thickness less than said given thickness, to ionizing radiation, to partially polymerize the resin, the exposure to ionizing radiation being stopped after the index D consisting of the Shore D hardness precomposite divided by the Shore D hardness of the final composite has reached a value of the order of 0.5 and before said index D has reached a value of about 0.7 and obtain a precomposite wherein said composition is in the solid phase;

- collecting sections in the precomposite and applying them on a support, the surface of which is of non-planar shape, stacking them on top of one another in a number dictated by said given thickness, and intimately marrying said shape of the support and thus create a stack of constrained sections;

- subjecting the stack to a final molding under a pressure and at an appropriate temperature in order to continue the polymerization of the resin and to secure the different sections of precomposite.

Le procédé s'adresse plus spécialement à l'utilisation de fibres de longueur infinie. On part d'un filé comportant en général un grand nombre (de l'ordre d'une centaine) de filaments élémentaires d'un diamètre de quelques microns, ces filaments étant tous côte à côte, donc sensiblement parallèles entre eux, à quelques chevauchements près. S'il est en effet impossible de garantir un rangement des filaments absolument parfaitement en parallèle, on veut indiquer par l'expression " sensiblement parallèlement à un plan " qu'il ne s'agit pas d'un cablé ou d'une tresse et que les filaments sont disposés parallèlement, à la précision géométrique de l'arrangement près. La direction de renforcement privilégiée est par exemple la direction des contraintes de traction dans la pièce à fabriquer. Mais on peut aussi partir d'un ruban ou d'un tissu ayant non seulement des fibres orientées parallèlement entre elles, appelées fils de chaíne, que l'on orientera selon ladite direction privilégiée, et contenant en outre d'autres fibres, constituant par exemple des fils de trame, quelle qu'en soit la densité. The process is more particularly directed to the use of fibers of infinite length. We start from spun comprising in general a large number (of the order of one hundred) of filaments elementals with a diameter of a few microns, these filaments being all side by side, so substantially parallel to each other, with some overlaps. If it is indeed impossible to guarantee filament storage absolutely perfectly in parallel, we want to indicate the expression "substantially parallel to a plan" that it is not a cable or a braid and that the filaments are arranged parallel to the geometric precision of the arrangement close. The preferred reinforcement direction is, for example, the direction of tensile stresses in the part to be manufactured. But we can also start from a ribbon or a fabric having not only fibers oriented parallel to each other, called warp yarns, that is oriented in said preferred direction, and further containing other fibers, constituting for example weft son, regardless of the density.

L'étape d'imprégnation des fibres n'est pas en soi spécifique de la présente invention, l'homme du métier pouvant aisément sélectionner toute méthode convenable, l'imprégnation pouvant précéder ou suivre la phase d'arrangement des fibres parallèlement à un plan. Le fait d'arranger les fibres parallèlement à un plan a pour but que, au plus tard pendant que l'on commence la polymérisation de la résine, les fibres de renforcement soient ordonnées convenablement pour qu'elles soient, dans la pièce composite finale, judicieusement disposées pour procurer pleinement l'effet de renforcement.The step of impregnating the fibers is not in itself specific to the present invention, the man the profession can easily select any suitable method, the impregnation being precede or follow the phase of arrangement of the fibers parallel to a plane. Arrange the fibers parallel to a plane is intended that, at the latest, while one starts the polymerization of the resin, the reinforcing fibers are appropriately ordered to they are, in the final composite room, judiciously arranged to provide fully the reinforcing effect.

On entend par " précomposite " un matériau dont la résine est prépolymérisée jusqu'à former un milieu solide (stade dit de gélification ou au delà), afin que le précomposite possède une cohésion suffisante pour pouvoir être installé dans un moule ouvert, avec les sollicitations mécaniques que cela suppose, sans risquer un " essorage " des fibres au cours duquel le taux de résine de la préforme diminuerait de façon non maítrisée. L'objectif de la prépolymérisation est donc d'atteindre un niveau minimal de polymérisation permettant d'éviter tout écoulement de résine lors d'un traitement ultérieur de celle-ci (en fait, un traitement du composite ou de l'article dans lequel il sera incorporé) sous l'action de la température, voire sous l'action de la pression. L'objectif de la prépolymérisation est aussi d'atteindre un niveau minimal de polymérisation permettant de conférer au précomposite une résistance au flambage de ses fibres lors d'une flexion telle qu'imposée par l'étape d'application sur un support de forme non plane.By "precomposite" is meant a material whose resin is prepolymerized to form a solid medium (so-called gelation step or beyond), so that the precomposite has a sufficient cohesion to be able to be installed in an open mold, with the solicitations this assumes, without risking a "spinning" of the fibers during which the rate of resin of the preform would decrease in a non-controlled way. The purpose of prepolymerization is therefore to achieve a minimum level of polymerization to avoid any flow of resin during further processing thereof (in fact, a treatment of the composite or article in which it will be incorporated) under the action of the temperature, even under the action of the pressure. The purpose of prepolymerization is also to achieve a minimum level of polymerization to give the precomposite resistance to buckling of its fibers during a bending as imposed by the application step on a non-planar support.

La polymérisation enclenchée par rayonnement ionisant non seulement permet d'atteindre ce stade, mais permet aussi d'arrêter le processus de polymérisation en cessant d'émettre ledit rayonnement. En effet, l'objectif de la prépolymérisation est encore de ne pas dépasser un niveau maximal de polymérisation, permettant le collage du précomposite soit sur lui-même soit sur du caoutchouc comme cela sera expliqué en détails dans la suite.The polymerization triggered by ionizing radiation not only achieves this stage, but also allows to stop the polymerization process by ceasing to issue said radiation. Indeed, the goal of prepolymerization is still not to exceed a level maximum of polymerization, allowing the bonding of the precomposite either on itself or on rubber as will be explained in detail later.

La prépolymérisation telle que proposée, associée à une mise en oeuvre du matériau par stratification en couches suffisamment minces, permet de reconstituer un bloc de forme et d'épaisseur quelconques, par rapport à un matériau monolithique préparé avec la même résine et les mêmes fibres en densité identique, préparé par exemple par pultrusion.Prepolymerization as proposed, associated with an implementation of the material by stratification in sufficiently thin layers, allows to reconstitute a block of form and any thickness, with respect to a monolithic material prepared with the same resin and the same fibers in identical density, prepared for example by pultrusion.

Comme rayonnement ionisant convenable, il est proposé d'utiliser un rayonnement dans le spectre allant de 300 nm à 450 nm, ou un faisceau d'électrons accélérés. As suitable ionizing radiation, it is proposed to use radiation in the spectrum ranging from 300 nm to 450 nm, or an accelerated electron beam.

Par exemple, on prépare un précomposite en ruban d'épaisseur de 0.1 mm environ (largeur quelconque, choisie plutôt en fonction de la pièce à fabriquer), et la pièce constituée à partir de tronçons de ce ruban jouit des mêmes propriétés qu'un monolithe, c'est à dire une pièce de forme simple qui n'est pas constituée par stratification et superposition de couches minces. En d'autres termes, on n'observe pas de dégradation des propriétés qui sont celles dues à la résine choisie et surtout dues à la fibre de renforcement choisie. Soulignons que, lors de l'empilage, rien n'interdit de croiser les fibres d'un tronçon à l'autre, en fonction de l'effet de renforcement visé pour la pièce en composite à fabriquer. Il s'agit là d'un paramètre de conception de la pièce en composite sur lequel on ne reviendra pas dans la suite, mais qui entre dans le champ de l'invention.For example, a precomposite is prepared in a ribbon approximately 0.1 mm thick (width whatever, chosen rather according to the part to be manufactured), and the piece made from stretches of this ribbon has the same properties as a monolith, ie a piece of simple form which is not constituted by stratification and superposition of thin layers. In in other words, we do not observe degradation of the properties which are those due to the resin chosen and especially due to the chosen reinforcement fiber. Note that when stacking, nothing precludes crossing the fibers from one section to another, depending on the reinforcing effect referred to for the composite part to be manufactured. This is a design parameter of the part Composite on which we will not return in the sequel, but which enters the field of the invention.

Selon une mise en oeuvre avantageuse de l'invention, lors de l'application des tronçons sur ledit support, on exerce des contraintes sur lesdits tronçons de précomposite afin de les forcer à épouser intimement ladite forme du support. De préférence, la surface du support contre laquelle on empile les tronçons est développable; il est plus facile de leur faire épouser intimement ladite surface. De préférence, on maintient les contraintes de déformation sur lesdits tronçons de précomposite au moins jusqu'au début de l'étape de traitement thermique.According to an advantageous embodiment of the invention, during the application of the sections on said support, stresses are exerted on said sections of precomposite in order to force them to to intimately marry the said form of support. Preferably, the surface of the support against which the stacks are stackable; it is easier to intimately marry them area. Preferably, the deformation stresses are maintained on said sections of precomposite at least until the beginning of the heat treatment step.

C'est d'une part l'état de prépolymérisation atteint, parfaitement maítrisé grâce à une prépolymérisation par un rayonnement ionisant, et d'autre part la subdivision en plusieurs couches de faible épaisseur, qui permettent à la fois d'imposer des rayons de courbure assez petits sans qu'il n'en résulte de contraintes résiduelles importantes au sein de chaque tronçon, sans qu'il n'apparaisse de flambage des fibres lors de l'empilage, et sans qu'il n'en résulte de dispersions des fibres dans la section transversale de l'empilage, notamment des dispersions dans l'épaisseur. Le rappel élastique des empilages ainsi réalisés vers une configuration dans laquelle les contraintes internes seraient nulles est relativement faible, ce qui permet assez aisément de maintenir mécaniquement ou de figer la déformation imposée sans gêner les étapes ultérieures de réalisation de la pièce composite finale.It is on the one hand the state of prepolymerization reached, perfectly controlled thanks to a prepolymerization by ionizing radiation, and on the other hand the subdivision into several layers of thin, which allow at the same time to impose enough bending radii small without significant residual stresses within each section, without any buckling of the fibers during stacking, and without the result of dispersions of fibers in the cross section of the stack, including dispersions in thickness. The elastic return of the stacks thus made to a configuration in which the internal stresses would be zero is relatively small, which allows quite easily mechanically maintain or freeze the deformation imposed without hindering the subsequent stages of completion of the final composite part.

Le fait d'effectuer le commencement de la polymérisation de la résine en couche d'épaisseur très inférieure à l'épaisseur de la pièce composite finale facilite les déformations dont on a parlé ci-dessus. En considérant le rayon de courbure minimal " r " de ladite pièce composite, le commencement de la polymérisation est avantageusement effectué en couche d'épaisseur " e " telle que « e » est plus petit que « r » divisé par 20. De préférence, et notamment pour faciliter le maintien provisoire de l'état déformé avant que la suite du procédé ne fige définitivement la structure du produit final, le commencement de la polymérisation est effectué en couche d'épaisseur " e " telle que « e » est plus petit que « r » divisé par 150.Initiating the polymerization of the resin in a very thick layer less than the thickness of the final composite part facilitates the deformations mentioned above. Considering the minimum radius of curvature "r" of said composite part, the beginning of the polymerization is advantageously carried out in thick layer "e" such that "e" is smaller than "r" divided by 20. Preferably, and in particular to facilitate the temporary maintenance of the deformed state before the rest of the process freezes definitively the structure of the final product, the beginning of the polymerization is carried out in layer of thickness "e" such that "e" is smaller than "r" divided by 150.

Deux exemples de mise en oeuvre du procédé selon l'invention vont maintenant être décrits à l'aide des figures annexées suivantes :

- la figure 1 est un schéma partiel d'une installation mettant oeuvre une première phase du procédé selon l'invention ;

- la figure 2 est un schéma illustrant une phase ultérieure du procédé selon l'invention appliqué à la réalisation d'une pièce composite ;

- la figure 3 est un schéma illustrant la phase suivant celle illustrée à la figure 2;

- la figure 4 est un schéma illustrant une phase ultérieure du procédé selon l'invention appliqué à la réalisation d'une pièce lamifiée comportant à la fois une pièce composite et du caoutchouc ;

- la figure 5 est un schéma illustrant la phase suivant celle illustrée à la figure 4.

- Figure 1 is a partial diagram of an installation implementing a first phase of the method according to the invention;

- Figure 2 is a diagram illustrating a subsequent phase of the method according to the invention applied to the production of a composite part;

- Figure 3 is a diagram illustrating the phase following that illustrated in Figure 2;

- Figure 4 is a diagram illustrating a subsequent phase of the method according to the invention applied to the production of a laminated part comprising both a composite part and rubber;

- FIG. 5 is a diagram illustrating the phase following that illustrated in FIG. 4.

On voit à la figure 1 une bobine 10 contenant un filé 11 qui, dans l'exemple illustré, est constitué

par des fibres de verre. On a schématisé ensuite un dispositif d'imprégnation 20 comportant un

réservoir 21 contenant une composition à base d'une résine durcissable et un photoinitiateur

approprié pour le rayonnement par lequel ladite composition va être traitée. Le dispositif

d'imprégnation 20 comporte une chambre d'imprégnation 22. Il en ressort un préimprégné 12 qui

est introduit dans un dispositif de prépolymérisation 30, dans lequel le préimprégné 12 est

prépolymérisé par un rayonnement ionisant, le traitement étant effectué à l'abri de l'oxygène.

Quant au rayonnement 31 auquel on expose la composition, sa longueur d'onde est typiquement

inférieure à 450 nanomètres, de préférence comprise entre 300 nm et 450 nm. On peut par

exemple utiliser une lampe à ultraviolets. Des galets 40 entraínent le précomposite 13 obtenu

dans le sens de la flèche F. Enfin, une cisaille 50 permet de prélever des tronçons 14 dans le

précomposite fabriqué en continu, pour les mettre en oeuvre comme expliqué dans la suite.FIG. 1 shows a

Ensuite vient la phase de mise en oeuvre des tronçons 14 de précomposite. A la figure 2, on voit

un support 61 dont la forme permet de fabriquer un objet en " C " (par exemple un ressort en C).

Les tronçons 14 de précomposite sont déformés (voir flèches D à la figure 2) pour leur faire

épouser la forme du support 61. Les tronçons sont disposés sur le support 61 de façon à ce que

les fibres soient parallèles au plan de la figure 2, en cheminant d'un bout à l'autre de l'objet

en C.Then comes the implementation phase of the

Le niveau de prépolymérisation doit être suffisamment élevé pour permettre l'empilage des

tronçons 14 sur le support voulu sans provoquer de flambage des fibres 11 situées à l'intérieur de

la courbure du tronçon 14 déformé, et pour éviter que la composition à base de résine ne se

répande en dehors du précomposite lors de la déformation, et aussi lors d'un traitement

thermique ultérieur sous pression. Ce niveau de prépolymérisation doit cependant être

suffisamment faible pour que la poursuite de la polymérisation d'un empilage de plusieurs

tronçons de ce précomposite sous l'effet conjugué de la température et de la pression crée des

liaisons au travers de l'interface entre deux tronçons de précomposite adjacents, afin d'obtenir un

objet en matériau composite doté d'excellentes propriétés mécaniques, notamment en flexion et

en cisaillement.The level of prepolymerization must be high enough to allow stacking of

Il est proposé de contrôler expérimentalement le niveau de prépolymérisation au moyen d'une analyse de la dureté Shore D du précomposite. Les valeurs de dureté Shore données ci-dessous sont mesurées avec un duromètre Shore D tel que décrit dans la norme NF T 46-052. L'exposition à un rayonnement ionisant est de préférence arrêté par exemple après que la dureté Shore D du précomposite soit devenue supérieure à 45 et avant que la dureté Shore D du précomposite soit supérieure à 65 si l'on vise des dureté Shore D de l'ordre de 90 à 95 pour le composite final. Plus généralement, on propose que l'étape d'exposition à un rayonnement ionisant soit arrêté après que l'indice D constitué par la dureté Shore D du précomposite divisée par la dureté Shore D du composite final ait atteint une valeur de l'ordre de 0.5 et avant que ledit indice D ait atteint une valeur de l'ordre de 0.7.It is proposed to experimentally control the level of prepolymerization by means of a analysis of the Shore D hardness of the precomposite. Shore hardness values given below are measured with a Shore D durometer as described in standard NF T 46-052. Exposure to ionizing radiation is preferably stopped for example after the hardness Shore D of the precomposite became greater than 45 and before the Shore D hardness of the precomposite is greater than 65 if the Shore D hardness of the order of 90 to 95 is final composite. More generally, it is proposed that the step of exposure to radiation ionizing is stopped after the index D constituted by the Shore D hardness of the divided precomposite by the Shore D hardness of the final composite has reached a value of the order of 0.5 and before said index D has reached a value of the order of 0.7.

On peut aussi contrôler expérimentalement le niveau de prépolymérisation au moyen d'une analyse de la température de transition vitreuse Tg de la composition du précomposite. On propose une règle de bonne pratique selon laquelle, en considérant l'indice T = Tgf - Tgpr, Tgpr étant la température de transition vitreuse de la composition du précomposite et Tgf étant la température de transition vitreuse de la composition du composite final, l'exposition à un rayonnement ionisant est arrêtée après que l'indice T soit devenu inférieur à 120°C et avant que ledit indice T soit devenu inférieur à 30°C. Par exemple, dans le cas où la température de transition vitreuse Tg de la composition du composite final serait de l'ordre de 160°C, l'exposition à un rayonnement ionisant est arrêtée après que la température de transition vitreuse Tg de la composition du précomposite ait atteint une valeur de l'ordre de 40°C et avant que la température de transition vitreuse Tg de la composition du précomposite ait atteint une valeur de l'ordre de 130°C.The level of prepolymerization can also be experimentally controlled by means of an analysis of the glass transition temperature T g of the composition of the precomposite. It is proposed a rule of good practice that, considering the index T = T gf -T gpr , T gpr being the glass transition temperature of the composition of the precomposite and T gf being the glass transition temperature of the composition of the composite Finally, the exposure to ionizing radiation is stopped after the index T has become less than 120 ° C and before said index T has become less than 30 ° C. For example, in the case where the glass transition temperature T g of the composition of the final composite is of the order of 160 ° C, the exposure to ionizing radiation is stopped after the glass transition temperature T g of the composition of the precomposite has reached a value of the order of 40 ° C and before the glass transition temperature T g of the composition of the precomposite has reached a value of the order of 130 ° C.

Au passage, on peut faire remarquer que le niveau de prépolymérisation du précomposite est tel

que l'on se trouve au-delà du point de gélification de la résine. Le niveau de prépolymérisation

voulu est atteint en adaptant par exemple le temps de traitement aux rayonnements ionisants

(vitesse de défilement imposée par les galets 40, longueur du dispositif de prépolymérisation 30).In passing, it can be noted that the prepolymerization level of the precomposite is such that

that one is beyond the point of gelling of the resin. The level of prepolymerization

is achieved by adapting, for example, the treatment time to ionizing radiation

(speed of travel imposed by the

Pour faire épouser au précomposite la forme de la surface du support 61, on peut envisager les

possibilités suivantes. Soit lesdits tronçons 14 de précomposite sont empilés et déformés

individuellement (voir flèches D à la figure 2) pour leur faire épouser chacun successivement la

forme du support 61. Soit lesdits tronçons 14 de précomposite sont empilés et déformés par

groupes de plusieurs, ou tous ensemble, pour leur faire épouser collectivement la forme du

support 61.To marry the shape of the surface of the

Dans tous les cas, bien que le nerf des tronçons 14 soit assez faible, il convient de faire en sorte

que l'empilage de tronçons de précomposite garde une forme en C, au moins suffisamment pour

permettre la mise en oeuvre des étapes suivantes. On peut rendre provisoirement solidaires les

uns des autres les différents tronçons 14 de l'empilage en interposant au moins partiellement une

couche 15 de ladite composition, par exemple aux extrémités du C et à la surface de l'un au

moins des tronçons à maintenir l'un sur l'autre, comme montré à la figure 2. Il suffit d'exposer

au moins partiellement ladite couche 15 à un rayonnement ionisant, par exemple un rayonnement

ultraviolet - visible, même au travers des tronçons 14 comme schématisé à la figure 2, pour

polymériser partiellement la résine de ladite couche 15. Bien entendu, tant que la liaison entre

tronçons adjacents décrite ci-dessus n'est pas réalisée, ou plus généralement tant que, quelle que

soit la manière, on n'a pas fait en sorte que les tronçons se maintiennent spontanément à la

déformation imposée, il faut les maintenir en appliquant extérieurement les forces appropriées.In all cases, although the nerve of the

En variante de la solidarisation provisoire des différents tronçons 14 par photoinitiation, on peut

envisager de soumettre l'empilage à un moulage sous une pression et à une température

appropriées (par exemple de l'ordre de 130°C) afin de poursuivre au moins partiellement la

polymérisation de la résine, avant d'autres étapes intermédiaires éventuelles et avant le moulage

final. Dans une autre variante, on peut envisager de rendre provisoirement solidaires les uns des

autres les différents tronçons 14 de l'empilage en interposant une couche de maintien provisoire

comportant essentiellement une composition de haute viscosité. Signalons encore que ces

différentes méthodes peuvent aussi être utilisées concomitamment.As a variant of the provisional joining of the

La figure 3 schématise l'étape finale. Un contre-moule 62 est amené par dessus le support 61

revêtu d'un empilage 16 de tronçons 14 de précomposite. On effectue un moulage final sous

pression, par exemple de l'ordre de 10 bars. La température lors du moulage sous pression est de

préférence supérieure à la température de transition vitreuse Tg de la composition du

précomposite. A titre indicatif, une température de traitement convenable est de l'ordre de 150°C

au moins. Les propriétés finales du matériau ne sont pas uniquement et même pas principalement

dues à ladite prépolymérisation. Elles résultent aussi en grande partie du traitement thermique

pendant cette étape de moulage final, qui assure un excellent collage des tronçons préalablement

empilés les uns sur les autres.Figure 3 shows the final step. A counter-mold 62 is brought over the

Grâce au fait que le contrôle du degré de prépolymérisation n'est pas effectué par voie thermique, il est possible d'ajuster la viscosité de la composition pendant l'étape d'imprégnation des fibres par une élévation modérée de la température de ladite composition. Par exemple, on peut chauffer jusqu'à 80°C environ, sans qu'il n'en résulte d'effet sensible sur la stabilité de la résine. Cela permet une bien meilleure imprégnation des fibres. On peut ainsi disposer d'un paramètre de réglage de la phase d'imprégnation indépendant des paramètres des étapes ultérieures du procédé.Thanks to the fact that the control of the degree of prepolymerization is not carried out by thermal, it is possible to adjust the viscosity of the composition during the impregnation step fibers by a moderate rise in the temperature of said composition. For example, we can heat up to about 80 ° C, without any significant effect on the stability of the resin. This allows a much better impregnation of the fibers. We can thus have a adjustment parameter of the impregnation phase independent of the parameters of the steps subsequent processes.

Quant aux résines convenables, à titre d'illustration, mentionnons que la résine peut être choisie dans le groupe constitué par les résines vinylesters et les résines polyesters insaturées, ou encore peut être une résine époxyde. Et en ce qui concerne les fibres de renforcement, mentionnons qu'elles peuvent être choisies parmi les fibres organiques comme les fibres polyacrylique haute ténacité ou les fibres polyacrylonitrile oxydé, les fibres d'alcool polyvinylique haute ténacité, les fibres polyamide aromatique ou les fibres polyamide-imide ou les fibres polyimide, les chlorofibres, les fibres polyester haute ténacité ou les fibres polyester aromatique, les fibres polyéthylène haute ténacité, les fibres polypropylène haute ténacité, les fibres de cellulose ou de rayonne ou de viscose haute ténacité, les fibres polyphénylène benzobisoxazole, les fibres polyéthylène naphténate, ou elles peuvent être choisies parmi les fibres inorganiques comme les fibres de verre, les fibres de carbone, les fibres de silice, les fibres céramiques (alumine, aluminosilicate, borosilicoaluminate). De préférence, le procédé utilise des fibres unidirectionnelles parallèles à ladite au moins une direction de renforcement privilégiée, disposées sensiblement parallèlement pendant l'imprégnation par ladite composition.As for the suitable resins, by way of illustration, let us mention that the resin can be chosen in the group consisting of vinylester resins and unsaturated polyester resins, or can be an epoxy resin. And as for the reinforcing fibers, let's mention that they can be chosen from organic fibers such as high polyacrylic fibers tenacity or oxidized polyacrylonitrile fibers, high tenacity polyvinyl alcohol fibers, aromatic polyamide fibers or polyamide-imide fibers or polyimide fibers, chlorofibers, high tenacity polyester fibers or aromatic polyester fibers, fibers high tenacity polyethylene, high tenacity polypropylene fibers, cellulose fibers or rayon or high tenacity viscose, polyphenylene benzobisoxazole fibers, fibers polyethylene naphthenate, or they can be chosen from inorganic fibers such as glass fibers, carbon fibers, silica fibers, ceramic fibers (alumina, aluminosilicate, borosilicoaluminate). Preferably, the process uses fibers unidirectional parallel to said at least one preferred reinforcing direction, arranged substantially parallel during the impregnation with said composition.

Le tableau suivant donne des résultats comparatifs sur différents échantillons 1 à 5, préparés au moyen de différentes résines. Les échantillons préparés sont des blocs parallélépipèdiques d'épaisseur de 2 mm.The following table gives comparative results on different samples 1 to 5, prepared in medium of different resins. The prepared samples are parallelepipedic blocks 2 mm thick.