EP0972905A2 - Kugelgelenkausbildung bei einer Halterung für eine spannungsfreie Lagerung einer Glasscheibe - Google Patents

Kugelgelenkausbildung bei einer Halterung für eine spannungsfreie Lagerung einer Glasscheibe Download PDFInfo

- Publication number

- EP0972905A2 EP0972905A2 EP99113916A EP99113916A EP0972905A2 EP 0972905 A2 EP0972905 A2 EP 0972905A2 EP 99113916 A EP99113916 A EP 99113916A EP 99113916 A EP99113916 A EP 99113916A EP 0972905 A2 EP0972905 A2 EP 0972905A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- sleeve

- shaped part

- ball

- glass pane

- ball joint

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/54—Fixing of glass panes or like plates

- E06B3/5436—Fixing of glass panes or like plates involving holes or indentations in the pane

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D3/00—Roof covering by making use of flat or curved slabs or stiff sheets

- E04D3/02—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant

- E04D3/06—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F13/00—Coverings or linings, e.g. for walls or ceilings

- E04F13/07—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor

- E04F13/08—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements

- E04F13/14—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements stone or stone-like materials, e.g. ceramics concrete; of glass or with an outer layer of stone or stone-like materials or glass

- E04F13/145—Coverings or linings, e.g. for walls or ceilings composed of covering or lining elements; Sub-structures therefor; Fastening means therefor composed of a plurality of similar covering or lining elements stone or stone-like materials, e.g. ceramics concrete; of glass or with an outer layer of stone or stone-like materials or glass with an outer layer of glass

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D3/00—Roof covering by making use of flat or curved slabs or stiff sheets

- E04D3/02—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant

- E04D3/06—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor

- E04D2003/065—Corner- or point-supported glazing

Definitions

- the invention relates to a ball joint formation in a Bracket for tension-free storage at a distance to a substructure to be assembled, a recess for the holder glass pane.

- the invention also relates to such a ball joint training specially adapted bracket.

- Panes of glass can be in any orientation on the Outside of a building. So is one side cladding with glass panes or an overhead arrangement same possible.

- Brackets are regularly on every single pane of glass available. Each bracket sits in one in the glass pane existing recess, so that the bracket to a certain extent like a mushroom head from the glass pane towards the substructure, to which it is attached.

- the on the Glass plate existing multiple brackets need the location the glass pane in its intended orientation Ensure substructure and that on the glass pane acting loads that may be caused by Dead weight, wind suction and wind pressure forces as well as Temperature changes, safely in the substructure can initiate.

- the Ball head is between two spherical spheres Sleeves with wall area held. This in the mounting hole of the glass pane protruding, in Art A sleeve-shaped ball head bearing is in the area of Mounting hole with one from the outside of the Glass pane protruding into the mounting hole screwed. This sleeve protrudes from the outside an outer lid-like plate, the outside of the Glass plate rests.

- DE 43 40 511 A1 is also a building construction known that a glass pane facade or a Owns glass pane roof.

- this previously known generic construction is in the mounting hole the relevant glass sheet insertable sleeve-shaped Part known, the spherical cap-like inside areas owns.

- One that can be screwed onto this sleeve from the outside Plate holder also has a spherical cap-like Arching so that the ball head through the two spherical spherical wall areas on the one hand the inner sleeve-shaped part and on the other hand of the plate-like Holder fixed in position and yet slightly articulated is held.

- the spherical cap Formation of two different turned parts complex in production is also used.

- the invention is based on this prior art based on the task of being economically advantageous Possibility of attaching a glass plate to the one at the beginning specified type, if possible without doing so in technical Considering disadvantages.

- the invention is characterized once from that a ball joint formation according to the invention Has bridge link as a support device.

- the ball joint training is at least partially within the The glass pane can be placed and has a recess sleeve-shaped part, in the interior of which one on one Mounting bolt cantilevered ball head in one Support device is articulated.

- the pontic is in the interior between the sleeve-shaped part and the Ball head in such a way that the ball head in axial Direction of the mounting bolt on this support device pressing and so in this direction by the Bridge link is held immovably.

- the pontic, on the one hand pressing against the ball head is present, on the other hand, in the surrounding the ball head Protrude construction parts.

- Such a bridge part can also in the Drawing shown embodiment particularly simple can be realized by a locking ring. After insertion of the ball head attached to a rod-shaped molded part the locking ring can then be inserted into the sleeve-shaped part just pushed over the rod-shaped part and against the ball head are created.

- the locking ring the anchors itself on the outside of the ball head Lock ring in one at this point in the sleeve-shaped part provided recess, which can be designed as an annular groove can. This way you need to anchor the ball head only the locking ring in the ring groove, for example to be inserted.

- Such a lock-ring-ring groove training can be for both Ball halves of the ball head are provided so that then the ball head in the axial direction only through this two locking rings is held.

- the lock ring other parts can be used that are as Bridge members can act.

- the ball head can also be retrofitted instead of one used pontic also on one with the sleeve-shaped part firmly connected projection or on a held with the sleeve-shaped part transverse wall become.

- This transverse wall then represents the direction of insertion of the ball head front boundary wall for the ball head After it is put on, it is then from the back moving back by means of the locking ring, for example of the ball head effectively and technically simple prevented.

- the substructure, to which the glass pane is statically attached should be, a ball joint training according to the invention be provided.

- This is a constraint-free storage also possible in cases where the substructure not at a constant distance, i.e. parallel to the plane the glass pane is present. Since this bracket is not Bending stresses in the area of the substructure due to their articulated training must include such Bending forces are absorbed by other measures. This can happen that not all brackets one Glass pane with one ankle, that is, with one joint in the area of the substructure.

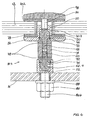

- Bracket 10 shown in Fig. 1 is a Glass pane 12 attached to a substructure 14.

- the Bracket 10 has a ball joint formation 15 in Area of the glass pane 12 and a similar 15.1 in the area the substructure 14, so that the bracket 10 as Pendulum rod is statically effective.

- the bracket 10 has a mounting bolt 16.

- a Grub screw 18 or 20 projecting in the longitudinal direction 22 screwed in.

- the diameter of the set screws 18, 20 is compared to the diameter of the mounting bolt 16 smaller.

- the set screw 18 facing the glass pane 12 is screwed at the end into a spherical shell 26.

- the Ball shell 26 is located with outer wall areas that the Set screw 18 opposite, on a spherical cap Inner region 28 of a sleeve 30.

- On the for Mounting bolt 16 pointing end of the sleeve 30 is one Washer 34 attached in one piece. This washer 34 forms the inner - in Fig. 1 lower - support plate for the glass pane 12.

- the glass pane 12 can - this applies to all embodiments - from one or more Glass panes should be assembled.

- the outer transition region between the sleeve 30 and the Washer 34 is formed obliquely to the longitudinal direction 22. Accordingly, the washer 34 has a corresponding conical bevel 36.

- This elastomer washer 38 is pushed onto threaded pin 18.

- the outer diameter of this elastomer disc 38 corresponds in the present example, the outer diameter of the Montagbolzens 16.

- This elastomer washer 38 has a outer bevel 40 with which they are on the bevel 36 of the Ring disc 34 lies flat.

- the sleeve 30 has a central threaded bore 42 in which a glass holding disc 50 with one molded onto its underside screwed screw-like central projection 51 is.

- the glass holding disc 50 has a circular cylindrical, - in Fig. 1 - flared upwards Body. The glass holding disc 50 closes flush with the Glass pane 12 above.

- the glass pane 12 has a recess 56, which after on the outside a conically widening inner surface 58 owns.

- a conically widening inner surface 58 owns.

- this inner surface 58 is an elastomer sleeve 60 used.

- the sleeve 30 and the glass holding disc 50 are the sleeve 30 and the glass holding disc 50.

- the mounting bolt 16 can be mounted on the glass pane 12 done as follows:

- the mounting bolt 16 is used Elastomer disc 38 pushed on. Then the on the set screw 18 screwed on the spherical shell 26 in the Mounting bolt 16 screwed in. This head so prepared of the mounting bolt 16 is then in the sleeve 30 from the inside, from the direction of area 74. From the direction the glass holding disc 50 becomes the outside of the pane 12 screwed to the sleeve 30.

- the latter screw connection is the only measure on site to fix the Bracket 10 to be made on the glass sheet 12 needs.

- the elastomer washers 78 and the elastomer sleeve 60 can for example when assembling on site glued to the washer 34 or on the glass holding disc 50 be present.

- the elastomer disc 38 forms a seal for the Ball 26 surrounding lubricant. It also prevents the penetration of dirt and moisture into it Interior of the sleeve 30. When installed, the Elastomeric washer 38 under pressure prestressing such that when the disc 12 is skewed, no gap between the annular disc 34 and the elastomer disc 38 occur can. In addition, the elastomer disc 38 is one Assembly aid for the attachment of the glass pane 12, by making sure that the washer is properly aligned 34 cares.

- a ball head training is also at the bottom of the Mounting bolt 16 available.

- the ball head there is in the same way as the above described Ball head formed and attached to the mounting bolt 16.

- the ball head sits in a sleeve 62, one of which Ball-shaped inner surface 64 owns.

- the end plate 44 of this sleeve 62 lies flat the substructure 14. Protrudes from this end plate 44 a threaded shaft 66 through the substructure 14 through it.

- a nut 68 is on the threaded shaft 66 screwed a washer 69 to the substructure 14 presses.

- a locking ring 72 is attached to the end region of the sleeve 30.

- the locking ring 72 is seated in an annular groove 76 in the sleeve 30.

- the locking ring 72 prevents the ball head from being backwards, when tensile forces are exerted, from the sleeve 30 can move out.

- the mounting bolt 16 with a grub screw 20 surrounding elastomer disc 38 provided.

- the set screw 20 can otherwise be identical to the threaded pin 18 his.

- the bracket 10.2 shown in Fig. 2 differs in their constructive training in the field of glass 12 not from the holder 10.

- upper end of a mounting bolt 16.2 the same constructive components available, as in the Bracket 10 are provided in the region of the glass pane 12.

- Wind pressure forces acting on the glass pane 12 from the outside are from the washer 34 on the the mounting bolt 16.2 supporting elastomer washer 38 the mounting bolt 16.2 and further into the substructure 14 headed.

- the mounting bolt 16.2 projects through the substructure 14 with one end protruding from it - downward in FIG. 2 attached threaded shaft 80.

- a threaded shaft 80 On this threaded shaft 80 is a nut 86 screwed on Washer 88 pressing on the substructure 14

- the threaded shaft 80 can have a Cap nut 82 can be screwed on.

- On the of the glass pane 12 facing side is between the substructure 14 and the mounting bolt 16.2 another washer 88.2 arranged. By tightening the nut 86 accordingly can the disc 12 by means of the bracket 10.2 Place the substructure 14 at a distance.

- the length of the mounting bolt 16.2 or 16 (Fig. 1) depends of the distance between the glass sheet 12 and the Substructure 14 from.

- holder 10.3 shown in Fig. 3 is a flexible formation of the same in the area of the substructure 14 in place while attaching the bracket 10.3 on the glass pane 12.3, which in the present case is a Double glazing is a rigid construction is trained. So the disc 12.3 by an inner and outer washer 96, 98 held over interposed elastomer washers 100, 102 pressing on the Fit washer 12.3.

- a cap nut 82 can the threaded rod 66 are screwed on. This applies to everyone corresponding embodiments.

- the bracket 10.4 shown in Fig. 4 corresponds functional of the bracket 10 shown in Fig. 1 Difference to the bracket 10 are in the bracket 10.4 no spherical spherical investment areas for the respective Ball head available. So is the bracket 10.4 Upper ball head shown face on a transverse wall 110 on, which forms a cover for a sleeve 30.4. The in Fig. 4 lower ball head is also on a transverse wall 112, which in the area of the substructure 14 existing ball joint training the bottom 112 of a sleeve 62.4 forms. On the to the transverse walls 110 and 112 opposite investment sides of the respective ball head there is a locking ring 72 in each case corresponding annular groove 76 of the relevant sleeve 30.4 or 62.4 after inserting the ball head are.

- the bottom of the Transverse wall 112 forming sleeve 62.4 has a threaded shaft 80.4 attached cantilevered down.

- a Threaded shaft 80.4 screwed nut 86 can thus an intermediate washer 88 the bracket 10.4 be screwed firmly to the substructure 14.

- the ball heads shown in Fig. 4 correspond constructively the ball heads shown in Fig. 1.

- the spherical shell of the ball head in question can have a Grub screw 120 or a corresponding pin on unintentional turning of the setscrew 18 or 20 be prevented.

- one Bracket 10.5 is the ball head in contrast to the bracket 10.4 in the longitudinal direction 22 front and rear, i.e. in Fig. 5 above and below by a locking ring 72 each held that the ball head in the longitudinal direction 22 is not Nevertheless, the articulated pivoting option remains available for the ball head.

- Also at this embodiment for a bracket is one Glass holding disc 98.5 available, the one opposite the embodiment 10.4 thicker threaded shaft 114.5 in the Sleeve 30.4 is screwed in. Otherwise corresponds to Bracket 10.5 of the aforementioned bracket 10.4.

- the substructure 14 ball joint training may or may not be present.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Load-Bearing And Curtain Walls (AREA)

- Securing Of Glass Panes Or The Like (AREA)

- Window Of Vehicle (AREA)

Abstract

Die Stützvorrichtungfür den Kugelkopf (26) ist als Brückenglied (72) im Innenraum des hülsenförmigen Teils (30) zwischen der Innenseite dieses hülsenförmigen Teils (30) und dem Kugelkopf (26) so vorhanden ist, dass der Kugelkopf (26) in axialer Richtung des Montagebolzens (16) drückend anliegend an der Stützvorrichtung (72) von derselben unverrückbar gehalten ist.

Description

- Fig. 1

- einen Längsschnitt durch eine im Bereich der Scheibe und im Bereich ihrer Unterkonstruktion jeweils mit einer Kugelgelenkausbildung versehene Halterung nach der Erfindung,

- Fig. 2

- einen Längsschnitt durch eine nur im Bereich der Glasscheibe mit einer Kugelgelenkausbildung versehene Halterung nach der Erfindung,

- Fig. 3

- einen Längsschnitt durch eine nur im Bereich der Unterkonstruktion mit einer Kugelgelenkausbildung versehene Halterung nach der Erfindung,

- Fig. 4

- einen Längsschnitt durch eine gegenüber der in Fig. 1 dargestellten Halterung abgewandelte Ausführungsform einer Halterung nach der Erfindung.

Claims (16)

- Kugelgelenkausbildung (15) bei einer Halterung (10) für eine spannungsarme Lagerung einer im Abstand zu einer Unterkonstruktion (14) zu montierenden, eine Aussparung (56) für die Halterung (10) aufweisenden Glasscheibe (12), die zumindest teilweise innerhalb der Aussparung (56) der Glasscheibe (12) plazierbar ist und die enthält:dadurch gekennzeichnet, dassein hülsenförmiges Teil (30, 62), in derem Innenraum ein an einem Montagebolzen (16) auskragend befestigter Kugelkopf (26) in einer Stützvorrichtung gelenkig haltbar ist,die Stützvorrichtung (72) für den Kugelkopf (26) als Brückenglied im Innenraum des hülsenförmigen Teils (30, 62) zwischen der Innenseite dieses hülsenförmigen Teils (30, 62) und dem Kugelkopf (26) so vorhanden ist, dass der Kugelkopf (26) in axialer Richtung des Montagebolzens (16) drückend anliegend an der Stützvorrichtung (72) von derselben unverrückbar gehalten ist.

- Kugelgelenkausbildung nach Anspruch 1,

dadurch gekennzeichnet, dassdie Stützvorrichtung (72) in die Innenseite des hülsenförmigen Teils (30, 62) hineinragend ausgebildet ist. - Kugelgelenkausbildung nach Anspruch 2,

dadurch gekennzeichnet, dassein Sperr-Ring (72) vorhanden ist, der in eine in der Innenseite des hülsenförmigen Teils eingeformte Ringnut (76) eingreifbar ausgebildet ist. - Kugelgelenkausbildung nach einem der vorstehenden Ansprüche,

dadurch gekennzeichnet, dassan in axialer Richtung des Montagebolzens (16) beiden Kugelhälften des Kugelkopfes jeweils eine als Brückenglied ausgebildete Stützvorrichtung (72) anlegbar ist. - Kugelgelenkausbildung nach einem der vorstehenden Ansprüche 1 bis 4,

dadurch gekennzeichnet, dassan in axialer Richtung des Montagebolzens (16) einer der beiden Kugelhälften des Kugelkopfes (26) eine als Brückenglied ausgebildete Stützvorrichtung (72) anlegbar ist,die in axialer Richtung des Montagebolzens (16) andere Kugelhälfte gegen einen Bereich (28, 44, 110, 112) des hülsenförmigen Teils (30, 62) anlegbar ist. - Kugelgelenkausbildung nach Anspruch 5,

dadurch gekennzeichnet, dassder Bereich des hülsenförmigen Teils (30) eine kugelkalottenförmige Innenseite (28) besitzt. - Kugelgelenkausbildung nach Anspruch 5,

dadurch gekennzeichnet, dassder Bereich als Querwand (44, 110, 112) des hülsenförmigen Teils ausgebildet ist. - Halterung (10) für eine spannungsarme Lagerung einer im Abstand zu einer Unterkonstruktion (14) zu montierenden, eine Aussparung (56) für die Halterung (10) aufweisenden Glasscheibe (12),dadurch gekennzeichnet, dassmit einem Montagebolzen (16), der einerseits an der Glasscheibe (12) und andererseits an der Unterkonstruktion (14) zu befestigen ist, undmit einer Kugelgelenkausbildung (15), nach einem der vorstehenden Ansprüche,eine den inneren Auflageteller für die Glasscheibe (12) bildende Ringscheibe (34) an dem hülsenförmigen Teil (30) vorhanden ist,ein die Glasscheibe (12) gegen die Ringscheibe (34) pressendes äußeres Halteteil (50, 98) mit dem hülsenförmigen Teil (30) verschraubbar ist.

- Halterung nach Anspruch 8,

dadurch gekennzeichnet, dassdas äußere Halteteil (98) eine äußere Ringscheibe besitzt, die von außen gegen die Glasscheibe (12) drückend anlegbar ist. - Halterung nach Anspruch 8 oder 9,

dadurch gekennzeichnet, dassein elastisch nachgiebiges Material (60, 78, 100, 102) zwischen der Ringscheibe (34, 50, 98) und der Glasscheibe (12) vorhanden ist. - Halterung nach einem der Ansprüche 8 bis 10,

dadurch gekennzeichnet, dassein elastisch nachgiebiges Material (34) auf der Außenseite des hülsenförmigen Teils (30) vorhanden ist. - Halterung nach Anspruch 8,

dadurch gekennzeichnet, dassein Gewindestab (51, 114) auskragend an dem äußeren Halteteil (50,98) befestigt ist, der mit dem hülsenförmigen Teil (30) verschraubbar ist. - Halterung nach Anspruch 12,

dadurch gekennzeichnet, dassder Gewindestab (114) in der Querwand (110) des hülsenförmigen Teils (30) einschraubbar ist. - Halterung nach Anspruch 8,

dadurch gekennzeichnet, dassdas äußere Halteteil (50) in der Aussparung (56) der Glasscheibe (12) versenkt anbringbar ist. - Halterung nach einem der Ansprüche 8 bis 14,

dadurch gekennzeichnet, dasseine Kugelgelenkausbildung (15) an dem an der Unterkonstruktion (14) zu befestigenden Ende des Montagebolzens (16) vorhanden ist. - Halterung nach Anspruch 15,

dadurch gekennzeichnet, dassdas hülsenförmige Teil (62) zusammen mit seiner Querwand (44,112) als kugelkalottentopfartiges Teil ausgebildet ist,ein Gewindeschaft (80) auskragend an diesem Teil (62) befestigt ist,dieser Gewindeschaft (80) an der Unterkonstruktion (14) festschraubbar ist.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19832117A DE19832117A1 (de) | 1998-07-17 | 1998-07-17 | Halterung für eine spannungsfreie Lagerung einer Glasscheibe |

| DE19832117 | 1998-07-17 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0972905A2 true EP0972905A2 (de) | 2000-01-19 |

| EP0972905A3 EP0972905A3 (de) | 2000-10-04 |

| EP0972905B1 EP0972905B1 (de) | 2004-04-07 |

Family

ID=7874364

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99113916A Expired - Lifetime EP0972905B1 (de) | 1998-07-17 | 1999-07-16 | Glasscheibe mit einer Halterung für eine spannungsfreie Lagerung der Glasscheibe |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0972905B1 (de) |

| AT (1) | ATE263899T1 (de) |

| DE (2) | DE19832117A1 (de) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2001092657A1 (es) * | 2000-05-30 | 2001-12-06 | Hortsmann Largacha, Carlos | Tornillo de cabeza elastica par fijacion de paneles de vidrio en los edificios |

| US6796091B2 (en) * | 2000-04-26 | 2004-09-28 | Dorma Gmbh + Co. Kg | Building glass facade, a method for mounting glass panes in a building glass facade, and a clamping arrangement for mounting glass panes in a building glass facade |

| DE102010032749B4 (de) * | 2010-07-29 | 2013-06-06 | SÜD-Metall Beschläge GmbH | Punkthalter |

| US20140047849A1 (en) * | 2012-08-15 | 2014-02-20 | United Technologies Corporation | Spherical button washer for exhaust duct liner hanger |

| WO2014052626A1 (en) * | 2012-09-28 | 2014-04-03 | United Technologies Corporation | Panel support hanger for a turbine engine |

| WO2014052629A1 (en) * | 2012-09-28 | 2014-04-03 | United Technologies Corporation | Support hanger for flexibly connecting a plurality of panels |

| CN105756498A (zh) * | 2016-04-25 | 2016-07-13 | 江苏齐光玻璃科技有限公司 | 一种用于对玻璃的安装结构 |

| EP3052717A2 (de) * | 2013-09-18 | 2016-08-10 | Atlas Sp. z o. o. | Selbsteinstellender regulierter stabilisator und verfahren zur befestigung des regulierten selbsteinstellenden stabilisators auf oberflächen |

| GB2574407A (en) * | 2018-06-04 | 2019-12-11 | Celtic Heights Ltd | Roof or wall hole closing device |

| CN111364695A (zh) * | 2020-05-08 | 2020-07-03 | 中建八局第一建设有限公司 | 一种可有限转动的球铰式屋面玻璃系统及其安装方法 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10203133C1 (de) * | 2002-01-25 | 2003-10-30 | Dorma Gmbh & Co Kg | Befestigungsvorrichtung eines Montagebolzens an einem Punkthalter für eine Gebäudeplatte |

| DE10317081A1 (de) * | 2003-04-13 | 2004-10-28 | Espich, Gerhard, Dr.-Ing. | Verbindungselement zwischen Lagerungselement und Platte |

| DE202011105693U1 (de) | 2011-09-15 | 2011-12-16 | Glassline Gmbh | Geklebter Punkthalter |

| DE102014220137A1 (de) * | 2014-10-06 | 2016-04-07 | Bayerische Motoren Werke Aktiengesellschaft | Komponentenanordnung |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4340511A1 (de) | 1993-11-27 | 1995-06-08 | Glasbau Seele Gmbh | Gebäudekonstruktion als Fassade oder Dach |

| DE29622780U1 (de) | 1996-01-23 | 1997-07-10 | Zlatomir, Krstin, 88131 Lindau | Punktbefestigungssystem für Flachglasmontage |

| EP0733148B1 (de) | 1993-12-10 | 1997-08-06 | DANZ, Robert | Halterung für die biegemomentfreie lagerung von glasplatten |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2300406A1 (de) * | 1973-01-05 | 1974-07-11 | Elsbett Gmbh Geb | Kolben fuer brennkraftmaschinen |

| DE3004028C2 (de) * | 1980-02-05 | 1983-07-28 | Josef 5000 Köln Lottner | Gleitschutzkörper für den Stock einer Gehhilfe |

| DE3211732A1 (de) * | 1982-03-30 | 1983-10-06 | Xaver Frank | Nachgiebiger stuetzfuss fuer gehhilfsmittel, insbesondere fuer kruecken |

| DE3607150A1 (de) * | 1986-03-05 | 1987-09-10 | Bosch Gmbh Robert | Kugelgelenk |

| DE3607149A1 (de) * | 1986-03-05 | 1987-09-10 | Bosch Gmbh Robert | Kugelgelenk |

| GB2242248B (en) * | 1990-03-21 | 1993-04-14 | Thomas Albert Summers | A structural bolt |

| DE4128641C2 (de) * | 1991-08-29 | 1995-07-06 | Daimler Benz Ag | Gelenkverbindung |

| CH689389A5 (de) * | 1995-03-31 | 1999-03-31 | Ferag Ag | Saugorgan. |

| DE19519527C2 (de) * | 1995-05-27 | 1999-11-18 | Seele Gmbh | Halterung für Platten |

| DE29521574U1 (de) * | 1995-07-27 | 1997-10-23 | GTD Glas-Technik-Design GmbH, 68723 Schwetzingen | Schwenkbare Halterung für an Gebäuden oder Gerüsten anzubringende Platten |

| DE19652773C2 (de) * | 1996-12-19 | 1998-11-26 | Dorma Gmbh & Co Kg | Klemmbeschlag für die Befestigung von Glasscheiben |

-

1998

- 1998-07-17 DE DE19832117A patent/DE19832117A1/de not_active Ceased

-

1999

- 1999-07-16 AT AT99113916T patent/ATE263899T1/de active

- 1999-07-16 EP EP99113916A patent/EP0972905B1/de not_active Expired - Lifetime

- 1999-07-16 DE DE59909086T patent/DE59909086D1/de not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4340511A1 (de) | 1993-11-27 | 1995-06-08 | Glasbau Seele Gmbh | Gebäudekonstruktion als Fassade oder Dach |

| EP0733148B1 (de) | 1993-12-10 | 1997-08-06 | DANZ, Robert | Halterung für die biegemomentfreie lagerung von glasplatten |

| DE29622780U1 (de) | 1996-01-23 | 1997-07-10 | Zlatomir, Krstin, 88131 Lindau | Punktbefestigungssystem für Flachglasmontage |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6796091B2 (en) * | 2000-04-26 | 2004-09-28 | Dorma Gmbh + Co. Kg | Building glass facade, a method for mounting glass panes in a building glass facade, and a clamping arrangement for mounting glass panes in a building glass facade |

| WO2001092657A1 (es) * | 2000-05-30 | 2001-12-06 | Hortsmann Largacha, Carlos | Tornillo de cabeza elastica par fijacion de paneles de vidrio en los edificios |

| ES2182636A1 (es) * | 2000-05-30 | 2003-03-01 | Aguirregabiria Benito Lauret | Tornillo de cabeza elastica para fijacion de paneles de vidrio en los edificios. |

| DE102010032749B4 (de) * | 2010-07-29 | 2013-06-06 | SÜD-Metall Beschläge GmbH | Punkthalter |

| US20140047849A1 (en) * | 2012-08-15 | 2014-02-20 | United Technologies Corporation | Spherical button washer for exhaust duct liner hanger |

| US9382875B2 (en) * | 2012-08-15 | 2016-07-05 | United Technologies Corporation | Spherical button washer for exhaust duct liner hanger |

| US9243515B2 (en) | 2012-09-28 | 2016-01-26 | United Technologies Corporation | Support hanger for flexibly connecting a plurality of panels |

| EP2900972A4 (de) * | 2012-09-28 | 2015-11-11 | United Technologies Corp | Paneeltrageaufhänger für einen turbinenmotor |

| WO2014052629A1 (en) * | 2012-09-28 | 2014-04-03 | United Technologies Corporation | Support hanger for flexibly connecting a plurality of panels |

| US9249732B2 (en) | 2012-09-28 | 2016-02-02 | United Technologies Corporation | Panel support hanger for a turbine engine |

| WO2014052626A1 (en) * | 2012-09-28 | 2014-04-03 | United Technologies Corporation | Panel support hanger for a turbine engine |

| EP3052717A2 (de) * | 2013-09-18 | 2016-08-10 | Atlas Sp. z o. o. | Selbsteinstellender regulierter stabilisator und verfahren zur befestigung des regulierten selbsteinstellenden stabilisators auf oberflächen |

| CN105756498A (zh) * | 2016-04-25 | 2016-07-13 | 江苏齐光玻璃科技有限公司 | 一种用于对玻璃的安装结构 |

| GB2574407A (en) * | 2018-06-04 | 2019-12-11 | Celtic Heights Ltd | Roof or wall hole closing device |

| GB2574407B (en) * | 2018-06-04 | 2020-11-11 | Celtic Heights Ltd | Roof or wall hole closing anchor |

| CN111364695A (zh) * | 2020-05-08 | 2020-07-03 | 中建八局第一建设有限公司 | 一种可有限转动的球铰式屋面玻璃系统及其安装方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19832117A1 (de) | 2000-01-27 |

| EP0972905A3 (de) | 2000-10-04 |

| ATE263899T1 (de) | 2004-04-15 |

| EP0972905B1 (de) | 2004-04-07 |

| DE59909086D1 (de) | 2004-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0938872B1 (de) | Schwenkbares Befestigungssystem an einer Knochenschraube | |

| DE69308288T2 (de) | Vorrichtung zur Befestigung von Verglasungen an einer Tragstruktur | |

| EP2532568B1 (de) | Vorrichtung zur Befestigung eines Anbauteils, zum Beispiel einer Reling, an einer Fahrzeugkarosserie | |

| DE4445724C2 (de) | Befestigungsanordnung von Platten | |

| EP0972905B1 (de) | Glasscheibe mit einer Halterung für eine spannungsfreie Lagerung der Glasscheibe | |

| WO2000060207A1 (de) | Befestigungsvorrichtung für eine glasplatte an einer gebäudeseitigen halterung | |

| EP1180193A1 (de) | Klemmbeschlag für die befestigung von glasscheiben | |

| DE4436483C2 (de) | Befestigungsvorrichtung zur Befestigung von Gebäudeplatten | |

| DE4436484C2 (de) | Schwenkbare Befestigungsvorrichtung zur Befestigung von Gebäudeplatten | |

| AT401080B (de) | Halter für die biegemomentfreie lagerung von glasplatten | |

| DE20115867U1 (de) | Befestigungselement für Platten | |

| EP2277742A2 (de) | Vorrichtung zur Befestigung eines Anbauteils, z. B. einer Reling, an einer Fahrzeugkarosserie | |

| DE3142432A1 (de) | "duebel mit setzkraftanzeige" | |

| EP0451529A1 (de) | Scharnier für eine Tür eines Kraftfahrzeuges, insbesondere eines Personenkraftwagens | |

| DE3307529A1 (de) | Scharnier zur befestigung eines tuerfluegels an einem tuerrahmen | |

| EP1120514B1 (de) | Befestigungselement zur Abstandsbefestigung von Latten, Profilen, Platten oder dergleichen an einem festen Untergrund | |

| AT501658A2 (de) | Vorrichtung zum befestigen eines fensterrahmens mittels einer justierschraube | |

| DE10153844B4 (de) | Vorrichtung zur lösbaren Befestigung von wenigstens einem Flächenelement, ein System mit mehreren solcher Vorrichtungen und deren Verwendung | |

| DE2730618A1 (de) | Formschluessig setzbarer duebel | |

| DE29820923U1 (de) | Befestigungselement | |

| EP0925420B1 (de) | Klemmbeschlag für die befestigung von glasscheiben | |

| AT504276B1 (de) | Stütze für hohlraumböden | |

| EP1172510B1 (de) | Bauanordnung für flache Elemente | |

| DE19926254B4 (de) | Bauanordnung für flache Elemente | |

| DE29911296U1 (de) | Klemmhaltersystem |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BANGRATZ, RENE, DIPL.-ING. |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BANGRATZ, RENE, DIPL.-ING. |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20001129 |

|

| 17Q | First examination report despatched |

Effective date: 20010223 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: GLAZING PANEL WITH A FASTENING DEVICE FOR A STRAIN-FREE MOUNTING OF THE GLAZING PANEL |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20040407 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040407 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040407 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040407 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59909086 Country of ref document: DE Date of ref document: 20040513 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040707 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040707 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040707 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040718 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040731 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050110 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040907 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20170720 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20170724 Year of fee payment: 19 Ref country code: FR Payment date: 20170720 Year of fee payment: 19 Ref country code: DE Payment date: 20170726 Year of fee payment: 19 Ref country code: CH Payment date: 20170724 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20170720 Year of fee payment: 19 Ref country code: AT Payment date: 20170719 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59909086 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20180801 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 263899 Country of ref document: AT Kind code of ref document: T Effective date: 20180716 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180716 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190201 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180716 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180801 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180731 |