EP0827912A2 - Resealable package - Google Patents

Resealable package Download PDFInfo

- Publication number

- EP0827912A2 EP0827912A2 EP19970305875 EP97305875A EP0827912A2 EP 0827912 A2 EP0827912 A2 EP 0827912A2 EP 19970305875 EP19970305875 EP 19970305875 EP 97305875 A EP97305875 A EP 97305875A EP 0827912 A2 EP0827912 A2 EP 0827912A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- package

- flap

- panel

- adhesive

- strip

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/16—End- or aperture-closing arrangements or devices

- B65D33/18—End- or aperture-closing arrangements or devices using adhesive applied to integral parts, e.g. to flaps

- B65D33/20—End- or aperture-closing arrangements or devices using adhesive applied to integral parts, e.g. to flaps using pressure-sensitive adhesive

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/16—End- or aperture-closing arrangements or devices

- B65D33/1691—End- or aperture-closing arrangements or devices using adhesive applied to attached closure elements

Definitions

- This invention relates to packages, and more particularly to flexible packages for holding products under vacuum therein, and which are arranged to be repeatedly re-opened and resealed, while keeping the contents fresh.

- gussetted package One common type of flexible package is the so-called "gussetted" package or bag.

- a package has walls formed from a web of flexible stock material, e.g. polyethylene, polyester, polypropylene, metal foil, and combinations thereof in single or multiple plies, into a body, having a face panel, a back panel and a pair of gussetted sides.

- Each gussetted side is formed by a pair of gusset sections and a central fold edge between a pair of outer fold edges.

- the lower end of the bag is permanently sealed, e.g. heat sealed, along a line extending across the width of the bag close to its bottom edge.

- the top of the bag is sealed across the entire width of the bag in a number of ways to maintain the contents under vacuum until the bag is opened.

- the top seal is made peelable by modifying the sealant layer with a peelable coating or incompatible additive.

- US-A-4,705,174 discloses a package which includes a peel strip secured to the inner surface of the package below the top edges. The strip is an airtight interfacial seal which can be readily peeled apart to provide access to the interior of the package.

- Fres-Co System USA, Inc. has provided a package for holding particulate chemicals, e.g. a crystalline catalyst, which included a band of an adhesive transfer on a portion of its exterior surface substantially below the mouth.

- the package was arranged so that the top edge portion forming the mouth could be folded over to form a flap and to bring the flap into engagement with the band of the adhesive transfer to hold the flap in place.

- a paper liner or cover strip was releasably secured over the band of the adhesive transfer. Once that package was opened and a portion of its contents removed the cover sheet or strip was peeled off the band of the adhesive transfer to expose it.

- the top portion of the package was then folded over itself to form a flap and the flap brought into engagement with the exposed band of the adhesive transfer to hold the flap in place.

- this package has proved generally suitable for its intended purposes, it has shortcomings.

- the package is to hold a substantial weight (e.g. 25 Kg. or more) of material, and a plurality of such packages are stacked on one another vertically, with the plane of the abutting surfaces forming the peelable mouth of each package being horizontal

- the pressure on a package by the weight contents by the weight of the package(s) stacked thereon may cause the peelable seal at the mouth of the package to rupture or peel apart, thereby enabling the contents to spill out.

- the stress of shipping and/or distribution can result in the peelable mouth accidentally opening.

- a package comprising a front wall, a rear wall and sides, the upper portions of which form a mouth sealed by peelable closure means, the upper portions of the package being folded to form a flap characterised in that a second seal is present beyond the peelable closure means and in that an adhesive surface covered by a release sheet extends substantially across the width of one wall.

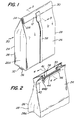

- a flexible package of the invention comprises a gussetted bag 20 adapted to hold under vacuum any material, e.g. coffee beans, ground coffee, chemicals and the like for dispensing, e.g. pouring, therefrom.

- the bag or package 20 is formed of a web of any suitable, flexible material in a manner to be described hereinafter.

- the package 20 comprises a front wall or panel 24, a rear wall or panel 26, a pair of gussetted sides 28, a top end portion 30 and a bottom end portion 32.

- the top end portion 30 of the package terminates in a top marginal edge 34 ( Figures 1 to 4).

- the bottom end portion 32 of the package terminates in a bottom marginal edge 36.

- the package has a vertical seamed fin 38.

- a one-way venting valve may be included in any suitable portion of the package to enable gases which may be produced by the material(s), e.g. coffee, contained within the sealed package to vent to the ambient air without air gaining ingress to the interior of the package.

- the front panel 24, rear panel 26, and the two gussetted sides 28 of the package are all integral portions of a single sheet or web of the flexible material, of single or multiple ply or layers, which has been folded and seamed to form a tubular body.

- One particularly useful laminated web is commercially available from Fres-Co System USA, Inc. of Telford PA, United States of America. That material comprises a 48 gauge polyester layer, ink, an adhesive layer, a 28 gauge aluminium foil layer, another adhesive layer, and a 600 gauge easy open sealant layer. When a web of such material is formed into the tubular body for the package the polyester layer serves as the outer surface of the package, with the easy-open sealant layer being the inner surface of the package.

- the mouth of the bag 20 is internally hermetically sealed along a transverse, peelable seal line 40 after the bag has been filled and vacuum sealed.

- the seal line 40 is formed in a conventional manner and extends across the width of the bag 20 slightly below the top edge 34 and the seal includes the gussetted sides.

- the peelable seal line 40 is formed by heat sealing of the abutting easy-open sealant layer portions forming the inner surface of the bag 20.

- the seal line 40 can be formed by any other conventional manner.

- the lower or bottom end 32 of the bag is sealed closed along a transverse, permanent seam line close to the bottom edge 36, as is the vertical seamed fin 38.

- the top portion 30 of the package is folded along a fold line 12A to form a flap 12, Figure 1.

- the flap 12 is held in place by an elongate bead of adhesive 42 (Figure 3), e.g. a hot-melt adhesive between the abutting surfaces.

- Figure 3 the hot-melt adhesive 42 is interposed between the outer surface of the rear panel 26 between its top edge 34 and the fold line 12A (i.e. the portion forming rear surface of the flap 12) and the outer surface of the rear panel immediately below the fold line 12A.

- the bead 42 was applied to the outer surface of the panel 26.

- the folded-over flap reinforces the peelable seal 40 to prevent it from accidentally peeling apart even when pressure is applied to the package (as may occur during the stacking of plural packages or during rough handling).

- a strip of double sided adhesive tape 44 is secured to the front panel between the top marginal edge 34 and the fold line 12A.

- the tape 44 extends for a substantial width of the front panel 24 and includes an inner surface 44A secured to the underlying surface portion of the front panel 24.

- a release sheet, i.e. a cover or liner strip 46 is releasably secured to the outer surface 44B of the tape strip 44.

- the adhesive tape is a two-sided adhesive film preferably that sold by Minnesota Mining & Manufacturing Company (3M) under the product designation "3M Double Coated Film Tape #476L".

- the liner or cover strip 46 is paper.

- a strip of adhesive tape 14 is used to hold the flap 12 to the panel 26, as shown in Figure 3, the tape 44 thus being shielded within a pocket.

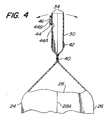

- the tape 14 is removed and the free edge of the flap 12 is grasped and pulled outward away from the plane of the portion of the package to which the flap is secured by adhesive 42.

- This action breaks the adhesive bead 42 at the interface with the underlying portion of the package, whereupon the flap can be unfolded to the condition shown in Figure 4.

- the top marginal edges 34 of the front and rear panels of the package can then be grasped and pulled apart in the direction of the arrows in Figure 4 to peel open the peelable seal line 40, and thereby open the mouth 41 of the package as shown in Figure 2.

- the contents of the package can then be poured through the open mouth 41.

- the package 20 is closed again by refolding the top portion along the fold line 12A to reform the flap 12.

- the inner strip 46 is removed from the tape strip 44, exposing the adhesive outer surface 44B of that strip.

- the upper portion of the package from the fold line 12A to the marginal edge of the package, i.e. the portion of the package forming the flap 12, is then folded over itself so that the exposed adhesive surface 44B of the strip engages the rear panel 26 of the package, to releasably secure the folded over portion in place as shown in Figure 5.

- the package is reopened by pulling on the double folded portion of the package to break the adhesion of the tape 44, whereupon the flap 12 can be unfolded and the mouth 41 reopened.

- the package may be reopened repeatedly so long as the adhesive outer surface 44B of the tape 44 remains relatively uncontaminated so that it still exhibits adhesive properties. To ensure such action the liner strip 46 (if retained) can be reapplied to the outer surface 44B of the tape strip 44.

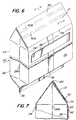

- the package 22 of Figure 6 is considerably larger than package 20 and is suitable for packaging of large quantities of particulate materials, e.g. agricultural chemical, dry pet foods, etc.

- the adhesive means for reclosing the package 22 is located on a portion of the package not forming the flap 12. (The same reference numerals will be used to describe this embodiment, where convenient.)

- the package 22 includes a pair of peelable seal lines 40A above a sealable line 40B.

- the adhesive strip for reclosing the mouth of the bag 22 is similar to the strip 40 of package 20, but it is larger, i.e. it is a wide strip 44 1 , having an inner surface secured to the rear panel 26 of the bag below the edge 34 of the folded flap 12.

- the strip 44 1 extends substantially the full width of the rear panel 26 and includes an outer surface which is initially covered by a liner or cover strip 46 1 .

- Initial opening of the package 22 is similar to that of package 20 except that there is no tape strip 14 to remove.

- the mouth of the bag 22 can be pulled open (peeled apart) by pulling on the upper edges of the front and rear panels of the bag in the direction of the arrows in Figure 9.

- the action breaks in succession the peelable seal lines 40A and 40B.

- the package 22 is reclosed by refolding the top portion of the package 22 along the fold line 12A to reform the flap 12.

- the liner strip 46 1 is removed from the tape strip 44 1 on the rear panel, exposing the adhesive outer surface of that strip.

- the upper portion of the package from the fold line 12A to the marginal edge 34 of the package, i.e. the portion of the package from the flap 12, is then folded over itself and engaged with the exposed adhesive surface of the strip 44 1 on the rear panel 26 of the package 22.

- the package 22 can readily be opened again by pulling on the double folded portion of the package to break the adhesion of the interposed tape 44 1 , whereupon the flap 12 can be unfolded and the mouth opened.

- a package or bag of the invention is resistant to premature or accidental opening.

- the bag may however be opened when required by pulling side panels apart, i.e. a knife or scissors are not needed.

- the invention is not limited to the embodiment shown.

- the package may be of any cross sectional shape, and of any size.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

Abstract

A bag (20, 22) has a mouth (41) internally sealed by a heat seal (40). The top portion (34)

of the walls of the bag form a flap (12) which is further sealed by a bead (42). An extra

adhesive layer (44B) is present to reapply the flap to the outside wall (26) of the bag when it

has been partially emptied.

Description

This invention relates to packages, and more particularly to flexible packages for holding

products under vacuum therein, and which are arranged to be repeatedly re-opened and

resealed, while keeping the contents fresh.

Various flexible packages for holding particulate materials, e.g. ground or whole bean

coffee, foodstuffs, pet foods and chemicals, etc., under vacuum therein are known, see e.g.

US-A- 4,576,285, US-A- 4,705,174 and US-A- 4,913,561.

One common type of flexible package is the so-called "gussetted" package or bag. Typically

such a package has walls formed from a web of flexible stock material, e.g. polyethylene,

polyester, polypropylene, metal foil, and combinations thereof in single or multiple plies, into

a body, having a face panel, a back panel and a pair of gussetted sides. Each gussetted side

is formed by a pair of gusset sections and a central fold edge between a pair of outer fold

edges. The lower end of the bag is permanently sealed, e.g. heat sealed, along a line

extending across the width of the bag close to its bottom edge. The top of the bag is

sealed across the entire width of the bag in a number of ways to maintain the contents under

vacuum until the bag is opened. In one known package the top seal is made peelable by

modifying the sealant layer with a peelable coating or incompatible additive. Thus, when the

seal is peeled apart the unsealed portions form an open mouth through which the contents of

the package may be removed. US-A-4,705,174 discloses a package which includes a peel

strip secured to the inner surface of the package below the top edges. The strip is an airtight

interfacial seal which can be readily peeled apart to provide access to the interior of the

package.

For many applications it is desirable to be able to reclose the package. One way of doing so

is to fold over the top portion of the package contiguous with the peeled-open mouth to

form a flap and to then apply a short length of adhesive tape or a small preprinted label onto

a portion of the flap and a portion of the contiguous package to hold the flap in place.

These tapes or labels only secure a small, e.g. approximately a 25 mm, portion of the folded

package mouth, and are prone to releasing and allowing the mouth to reopen. They can be

lost or misplaced .

Another approach is to make the adhesive an integral part of the flexible package. Fres-Co

System USA, Inc. has provided a package for holding particulate chemicals, e.g. a crystalline

catalyst, which included a band of an adhesive transfer on a portion of its exterior surface

substantially below the mouth. The package was arranged so that the top edge portion

forming the mouth could be folded over to form a flap and to bring the flap into engagement

with the band of the adhesive transfer to hold the flap in place. A paper liner or cover strip

was releasably secured over the band of the adhesive transfer. Once that package was

opened and a portion of its contents removed the cover sheet or strip was peeled off the

band of the adhesive transfer to expose it. The top portion of the package was then folded

over itself to form a flap and the flap brought into engagement with the exposed band of the

adhesive transfer to hold the flap in place. While this package has proved generally suitable

for its intended purposes, it has shortcomings. For example, when the package is to hold a

substantial weight (e.g. 25 Kg. or more) of material, and a plurality of such packages are

stacked on one another vertically, with the plane of the abutting surfaces forming the

peelable mouth of each package being horizontal, the pressure on a package by the weight

contents by the weight of the package(s) stacked thereon may cause the peelable seal at the

mouth of the package to rupture or peel apart, thereby enabling the contents to spill out. In

other cases the stress of shipping and/or distribution can result in the peelable mouth

accidentally opening.

It is a first object of this invention to provide a flexible package which is peelably sealed and

has a reclosable mouth, which overcomes the disadvantages of the prior art. It is a further

object ef this invention to provide a flexible package which includes adhesive means for

enabling the package to be resealed after initial opening and which adhesive means is

protected from contamination by dust, dirt, product residue, etc, until it is desired to be

used.

According to the invention in one aspect there is provided a package comprising a front wall, a

rear wall and sides, the upper portions of which form a mouth sealed by peelable closure means, the

upper portions of the package being folded to form a flap characterised in that a second seal is

present beyond the peelable closure means and in that an adhesive surface covered by a release sheet

extends substantially across the width of one wall..

Other features are set out in the dependant Claims.

In order that the invention may be well understood it will now be described by way of

illustration only with reference to the accompanying diagrammatic drawings in which:

A flexible package of the invention comprises a gussetted bag 20 adapted to hold under

vacuum any material, e.g. coffee beans, ground coffee, chemicals and the like for

dispensing, e.g. pouring, therefrom. The bag or package 20 is formed of a web of any

suitable, flexible material in a manner to be described hereinafter.

The package 20 comprises a front wall or panel 24, a rear wall or panel 26, a pair of

gussetted sides 28, a top end portion 30 and a bottom end portion 32. The top end portion

30 of the package terminates in a top marginal edge 34 (Figures 1 to 4). The bottom end

portion 32 of the package terminates in a bottom marginal edge 36. The package has a

vertical seamed fin 38. If desired, a one-way venting valve (not shown) may be included in

any suitable portion of the package to enable gases which may be produced by the

material(s), e.g. coffee, contained within the sealed package to vent to the ambient air

without air gaining ingress to the interior of the package.

The front panel 24, rear panel 26, and the two gussetted sides 28 of the package are all

integral portions of a single sheet or web of the flexible material, of single or multiple ply or

layers, which has been folded and seamed to form a tubular body. One particularly useful

laminated web is commercially available from Fres-Co System USA, Inc. of Telford PA,

United States of America. That material comprises a 48 gauge polyester layer, ink, an

adhesive layer, a 28 gauge aluminium foil layer, another adhesive layer, and a 600 gauge

easy open sealant layer. When a web of such material is formed into the tubular body for the

package the polyester layer serves as the outer surface of the package, with the easy-open

sealant layer being the inner surface of the package.

The mouth of the bag 20 is internally hermetically sealed along a transverse, peelable seal

line 40 after the bag has been filled and vacuum sealed. The seal line 40 is formed in a

conventional manner and extends across the width of the bag 20 slightly below the top edge

34 and the seal includes the gussetted sides. The peelable seal line 40 is formed by heat

sealing of the abutting easy-open sealant layer portions forming the inner surface of the bag

20. Alternatively, the seal line 40 can be formed by any other conventional manner.

The lower or bottom end 32 of the bag is sealed closed along a transverse, permanent seam

line close to the bottom edge 36, as is the vertical seamed fin 38.

When the bag 20 is filled, and vacuum sealed its contents, e.g. whole bean coffee or

chemicals, will be kept isolated from the ambient air by the seal line 40. The top portion 30

of the package is folded along a fold line 12A to form a flap 12, Figure 1. The flap 12 is

held in place by an elongate bead of adhesive 42 (Figure 3), e.g. a hot-melt adhesive

between the abutting surfaces. As shown in Figure 3 the hot-melt adhesive 42 is interposed

between the outer surface of the rear panel 26 between its top edge 34 and the fold line 12A

(i.e. the portion forming rear surface of the flap 12) and the outer surface of the rear panel

immediately below the fold line 12A. As shown in Figure 4 the bead 42 was applied to the

outer surface of the panel 26. The folded-over flap reinforces the peelable seal 40 to prevent

it from accidentally peeling apart even when pressure is applied to the package (as may

occur during the stacking of plural packages or during rough handling).

A strip of double sided adhesive tape 44 is secured to the front panel between the top

marginal edge 34 and the fold line 12A. The tape 44 extends for a substantial width of the

front panel 24 and includes an inner surface 44A secured to the underlying surface portion of

the front panel 24. A release sheet, i.e. a cover or liner strip 46 is releasably secured to the

outer surface 44B of the tape strip 44. The adhesive tape is a two-sided adhesive film

preferably that sold by Minnesota Mining & Manufacturing Company (3M) under the

product designation "3M Double Coated Film Tape #476L". The liner or cover strip 46 is

paper. A strip of adhesive tape 14 is used to hold the flap 12 to the panel 26, as shown in

Figure 3, the tape 44 thus being shielded within a pocket.

To gain access to the contents of the package the tape 14 is removed and the free edge of

the flap 12 is grasped and pulled outward away from the plane of the portion of the package

to which the flap is secured by adhesive 42. This action breaks the adhesive bead 42 at the

interface with the underlying portion of the package, whereupon the flap can be unfolded to

the condition shown in Figure 4. The top marginal edges 34 of the front and rear panels of

the package can then be grasped and pulled apart in the direction of the arrows in Figure 4

to peel open the peelable seal line 40, and thereby open the mouth 41 of the package as

shown in Figure 2. The contents of the package can then be poured through the open mouth

41.

The package 20 is closed again by refolding the top portion along the fold line 12A to

reform the flap 12. The inner strip 46 is removed from the tape strip 44, exposing the

adhesive outer surface 44B of that strip. The upper portion of the package from the fold

line 12A to the marginal edge of the package, i.e. the portion of the package forming the

flap 12, is then folded over itself so that the exposed adhesive surface 44B of the strip

engages the rear panel 26 of the package, to releasably secure the folded over portion in

place as shown in Figure 5. The package is reopened by pulling on the double folded

portion of the package to break the adhesion of the tape 44, whereupon the flap 12 can be

unfolded and the mouth 41 reopened. The package may be reopened repeatedly so long as

the adhesive outer surface 44B of the tape 44 remains relatively uncontaminated so that it

still exhibits adhesive properties. To ensure such action the liner strip 46 (if retained) can be

reapplied to the outer surface 44B of the tape strip 44.

The package 22 of Figure 6 is considerably larger than package 20 and is suitable for

packaging of large quantities of particulate materials, e.g. agricultural chemical, dry pet

foods, etc. The adhesive means for reclosing the package 22 is located on a portion of the

package not forming the flap 12. (The same reference numerals will be used to describe this

embodiment, where convenient.)

As can be seen in Figures 8 and 9, the package 22 includes a pair of peelable seal lines 40A

above a sealable line 40B. The adhesive strip for reclosing the mouth of the bag 22 is

similar to the strip 40 of package 20, but it is larger, i.e. it is a wide strip 441, having an inner

surface secured to the rear panel 26 of the bag below the edge 34 of the folded flap 12. The

strip 441 extends substantially the full width of the rear panel 26 and includes an outer

surface which is initially covered by a liner or cover strip 461.

Initial opening of the package 22 is similar to that of package 20 except that there is no tape

strip 14 to remove. Thus, once the flap 12 is lifted up from its position in Figures 6 and 7

to the position shown in Figures 8 and 9, the mouth of the bag 22 can be pulled open (peeled

apart) by pulling on the upper edges of the front and rear panels of the bag in the direction

of the arrows in Figure 9. The action breaks in succession the peelable seal lines 40A and

40B.

The package 22 is reclosed by refolding the top portion of the package 22 along the fold line

12A to reform the flap 12. The liner strip 461, is removed from the tape strip 441 on the rear

panel, exposing the adhesive outer surface of that strip. The upper portion of the package

from the fold line 12A to the marginal edge 34 of the package, i.e. the portion of the

package from the flap 12, is then folded over itself and engaged with the exposed adhesive

surface of the strip 441 on the rear panel 26 of the package 22. The package 22 can readily

be opened again by pulling on the double folded portion of the package to break the

adhesion of the interposed tape 441, whereupon the flap 12 can be unfolded and the mouth

opened.

A package or bag of the invention is resistant to premature or accidental opening. The bag

may however be opened when required by pulling side panels apart, i.e. a knife or scissors

are not needed. The invention is not limited to the embodiment shown. The package may

be of any cross sectional shape, and of any size.

Claims (7)

- A package (20,22) comprising a front wall (24), a rear wall (26) and sides (28), the upper portions (34) of which form a mouth (41) sealed by peelable closure means (40;40B), the upper portions of the package being folded to form a flap (12) characterised in that a second seal (42) is present beyond the peelable closure means (40,40B) and in that an adhesive surface (44B; 441B) covered by a release sheet (46;461) extends substantially across the width of one wall (24 or 26).

- A package (20, Figures 1 to 5) according to Claim 1, wherein the second seal (42) is present between the inside faces of the panels (24, 26) in the upper portion (34) thereof.

- A package (22, Figures 6 to 11) according to Claim 1, wherein the second seal (42) is present on the outside of a panel (26) between the outside faces of the panels (24 and 26).

- A package according to any preceding Claim, wherein the adhesive surface (44B; 441B) is the outer surface of a strip (44; 441) secured by adhesive on its inner face (44A; 441A) to the panel (24 or 26).

- A package (20) (Figures 1 to 5) according to Claim 4, wherein the strip (44) is located on the panel (24) adjacent the top (34) thereof.

- A package according to Claim 5, including a tape (14) to hold the flap (12) to the panel (24) with the adhesive surface (44B) between the flap (12) and the facing panel (26).

- A package (22) (Figures 6 to 11) according to any of Claims 1 to 4 adapted to hold substantial weight, wherein the adhesive surface (441B) is present on the panel (26) below the edge (34) of the flap (12) when the package is first filled and unopened.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US71133296A | 1996-09-06 | 1996-09-06 | |

| US711332 | 1996-09-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0827912A2 true EP0827912A2 (en) | 1998-03-11 |

Family

ID=24857667

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19970305875 Withdrawn EP0827912A2 (en) | 1996-09-06 | 1997-08-04 | Resealable package |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0827912A2 (en) |

| CA (1) | CA2214738A1 (en) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2829997A1 (en) * | 2001-09-26 | 2003-03-28 | Jpj Internat | Bag closure comprises film strip with adhesive on both sides to hold down folded edge of bag |

| EP1016598B1 (en) * | 1998-12-01 | 2003-08-06 | Sonoco Development, Inc. | Package with resealable closure |

| GB2388583A (en) * | 2002-04-24 | 2003-11-19 | Simpac Ltd | Re-sealable closure of bag |

| FR2847234A1 (en) * | 2002-11-18 | 2004-05-21 | Cetec Ind Conditionnement | Bag with quick opening and repositionable closure has folded over top with perforated line to form pouring spout reclosable by adhesive label |

| WO2005028325A1 (en) * | 2003-09-24 | 2005-03-31 | Monica Svensson | Packing for openable enclosing of material |

| NL1025987C2 (en) * | 2004-04-20 | 2005-10-24 | Robert Bosch Verpakkingsmachin | Device, assembly and method for manufacturing bags as well as such a bag. |

| WO2008058418A1 (en) * | 2006-11-16 | 2008-05-22 | Zip Pack Ip Ag | Reclosable bag having a security closing device |

| EP1982927A1 (en) * | 2003-10-03 | 2008-10-22 | NEW MADAPLAST S.r.l. | An airtight bag with single opening |

| US20090263048A1 (en) * | 2008-04-16 | 2009-10-22 | Iannelli Ii Michael Louis | Bag Structures And Methods Of Assembling The Same |

| WO2010081315A1 (en) * | 2009-01-14 | 2010-07-22 | Chen Ping | Manufacturing method of garbage containing bag with lacing rope and garbage containing bag with lacing rope |

| GB2523391A (en) * | 2014-02-24 | 2015-08-26 | Essentra Packaging & Security Ltd | Packaging method and apparatus |

| EP3023242A1 (en) * | 2014-11-21 | 2016-05-25 | PETROPLAST GmbH Chemikalien und Kunststoffe | Packaging film and device and method for manufacturing same |

| EP3326804A1 (en) * | 2016-11-23 | 2018-05-30 | PETROPLAST GmbH Chemikalien und Kunststoffe | Packaging film and device and method for manufacturing same |

| CN110589204A (en) * | 2019-10-15 | 2019-12-20 | 东莞职业技术学院 | Fresh food packaging bag made of natural plant fiber and having high freshness retaining degree |

-

1997

- 1997-08-04 EP EP19970305875 patent/EP0827912A2/en not_active Withdrawn

- 1997-09-05 CA CA 2214738 patent/CA2214738A1/en not_active Abandoned

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1016598B1 (en) * | 1998-12-01 | 2003-08-06 | Sonoco Development, Inc. | Package with resealable closure |

| FR2829997A1 (en) * | 2001-09-26 | 2003-03-28 | Jpj Internat | Bag closure comprises film strip with adhesive on both sides to hold down folded edge of bag |

| EP1298068A2 (en) * | 2001-09-26 | 2003-04-02 | Jpj International | Bag closure device |

| EP1298068A3 (en) * | 2001-09-26 | 2004-08-11 | Jpj International | Bag closure device |

| GB2388583A (en) * | 2002-04-24 | 2003-11-19 | Simpac Ltd | Re-sealable closure of bag |

| FR2847234A1 (en) * | 2002-11-18 | 2004-05-21 | Cetec Ind Conditionnement | Bag with quick opening and repositionable closure has folded over top with perforated line to form pouring spout reclosable by adhesive label |

| WO2005028325A1 (en) * | 2003-09-24 | 2005-03-31 | Monica Svensson | Packing for openable enclosing of material |

| EP1982927A1 (en) * | 2003-10-03 | 2008-10-22 | NEW MADAPLAST S.r.l. | An airtight bag with single opening |

| EP1588949A1 (en) * | 2004-04-20 | 2005-10-26 | Robert Bosch Verpakkingsmachines B.V. | Device, assembly and method for producing bags as well as such a bag |

| NL1025987C2 (en) * | 2004-04-20 | 2005-10-24 | Robert Bosch Verpakkingsmachin | Device, assembly and method for manufacturing bags as well as such a bag. |

| WO2008058418A1 (en) * | 2006-11-16 | 2008-05-22 | Zip Pack Ip Ag | Reclosable bag having a security closing device |

| US20090263048A1 (en) * | 2008-04-16 | 2009-10-22 | Iannelli Ii Michael Louis | Bag Structures And Methods Of Assembling The Same |

| WO2010081315A1 (en) * | 2009-01-14 | 2010-07-22 | Chen Ping | Manufacturing method of garbage containing bag with lacing rope and garbage containing bag with lacing rope |

| GB2523391A (en) * | 2014-02-24 | 2015-08-26 | Essentra Packaging & Security Ltd | Packaging method and apparatus |

| EP3023242A1 (en) * | 2014-11-21 | 2016-05-25 | PETROPLAST GmbH Chemikalien und Kunststoffe | Packaging film and device and method for manufacturing same |

| EP3326804A1 (en) * | 2016-11-23 | 2018-05-30 | PETROPLAST GmbH Chemikalien und Kunststoffe | Packaging film and device and method for manufacturing same |

| CN110589204A (en) * | 2019-10-15 | 2019-12-20 | 东莞职业技术学院 | Fresh food packaging bag made of natural plant fiber and having high freshness retaining degree |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2214738A1 (en) | 1998-03-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0823381A1 (en) | Reclosable package | |

| US6315448B1 (en) | Multiwall bag with peelable opening | |

| EP1020369B1 (en) | Resealable flexible package | |

| US6461708B1 (en) | Resealable container and closure seal | |

| US6213645B1 (en) | Flexible package with sealed edges and easy to open mouth | |

| US5044776A (en) | Resealable closure system | |

| US4441613A (en) | Container with resealable closure | |

| US5035518A (en) | Hinge pressure sensitive adhesive tab closure for package | |

| US6082897A (en) | Segmented snap closure for flexible packages and flexible packages including the same | |

| US6120184A (en) | Bag apparatus with reclosable pour spout | |

| US5186543A (en) | Tear-open bag having guide strips | |

| US7300207B2 (en) | Closure for containers and reclosable containers including the same | |

| US7670050B2 (en) | Packaging container consisting of a plastic film | |

| US20230174269A1 (en) | Tamper evident hybrid resealable container | |

| EP0905048A1 (en) | Composite cover sheet for the re-closure of containers | |

| EP0827912A2 (en) | Resealable package | |

| MXPA06012943A (en) | Flexible package with internal, resealable closure feature. | |

| US4715528A (en) | Reclosable opening arrangement on a packing container | |

| MX2007009500A (en) | Package integrity indicating closure. | |

| MXPA01006248A (en) | Package having re-sealable end closure and method for making same. | |

| MX2007012006A (en) | Resealable closure with package integrity feature. | |

| US20100247003A1 (en) | Package Having Resealable Closure And Method Of Making Same | |

| US5165568A (en) | Container with external resealing bag | |

| EP0764592A1 (en) | Reclosable packaging | |

| US20010000461A1 (en) | Multiwall bag with easy open and reclose |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19980323 |