EP0560524A1 - Laminated fork - Google Patents

Laminated fork Download PDFInfo

- Publication number

- EP0560524A1 EP0560524A1 EP93301557A EP93301557A EP0560524A1 EP 0560524 A1 EP0560524 A1 EP 0560524A1 EP 93301557 A EP93301557 A EP 93301557A EP 93301557 A EP93301557 A EP 93301557A EP 0560524 A1 EP0560524 A1 EP 0560524A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fork

- layers

- heel

- lamination

- blade

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66F—HOISTING, LIFTING, HAULING OR PUSHING, NOT OTHERWISE PROVIDED FOR, e.g. DEVICES WHICH APPLY A LIFTING OR PUSHING FORCE DIRECTLY TO THE SURFACE OF A LOAD

- B66F9/00—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes

- B66F9/06—Devices for lifting or lowering bulky or heavy goods for loading or unloading purposes movable, with their loads, on wheels or the like, e.g. fork-lift trucks

- B66F9/075—Constructional features or details

- B66F9/12—Platforms; Forks; Other load supporting or gripping members

Definitions

- This invention relates to improvements in forks for material handling vehicles popularly known as lift trucks.

- Forks for use with lift trucks are typically manufactured of steel or other metallic members.

- the fork comprises a blade, a heel and a shank.

- Various means may be used to attach the fork to the lift truck.

- Forks may be of any size or configuration required to carry the load intended. Most often forks are used with the blade extending substantially horizontally and the shank extending substantially vertically upwardly. Occasionally, however, forks are used where the blade is substantially horizontal and the shank portion extends substantially vertically downwardly. These latter types of forks are referred to in this disclosure as inverted forks.

- Forks are typically manufactured from steel.

- the steel may be configured in the desired shape for the cross-sectional configuration for the shank and blade.

- the thickness of the material normally requires that the material be heated, at least in the region of the heel so that the material can be bent into the typical substantially right angle configuration. In many cases an upset procedure is used to ensure thickening of the fork material in the heel region. This is often advantageous because the stresses are highest in the heel region and thicker metal can be used to carry those stresses.

- the tip of the blade may be considerably thinner in cross-section than the portions of the fork immediately adjacent to the heel as the stresses at the tip of the blade are considerably lower than adjacent the heel.

- a fork formed from a solid steel bar may be surface coated with brass or bronze or be made from solid brass or bronze or the like to reduce or eliminate sparking.

- a fork may be coated with various forms of surface coating or made entirely from a suitable material such as stainless steel all to meet whatever need is required.

- the fork has a plurality of lamination layers. While the fork will have a blade, a heel and a shank, any one or more of those portions of the fork may be formed from a plurality of lamination layers. Each lamination layer is fixed to the next adjacent layer so that stresses are communicated from one layer into the next adjacent layer. Fixation of the layers may be accomplished with adhesives or by welding.

- a method for making such a fork involves bending a first lamination layer in a die.

- a second lamination layer may be bent using the first layer which remains in the die to form the next lamination. This can be repeated for as many layers as desired.

- the layers may be fixed to each other as they are bent or after all bending has been completed.

- the tensile layer is of a strength to provide the basic surface capabilities while providing sufficient thickness to allow the use of any desired joining media.

- Each successive lamination layer is to be of any desired thickness and strength. The exact parameters of each layer is dependent upon the total thickness and width of the fork and the load to be applied.

- the fork designer has complete freedom as to the number of lamination layers, the thickness of the lamination layers and the location of the lamination layers. In certain cases only the shank will be laminated. In other cases only the blade will be laminated and in still other cases it will be only the heel area that contains lamination layers. These may be combined as the designer chooses.

- the individual lamination layers are affixed to one another. This may be done by applying adhesives that form chemical bonds or by any form of welding. Suitable adhesives for bonding layers of steel include epoxy resins and urethanes.

- top surface is used to describe the surface that is loaded in tension under load. In most cases this will be the upper surface of the blade and in the case of a typical fork would be the inner surface of the shank, while in the case of an inverted fork would be the outer surface of the shank.

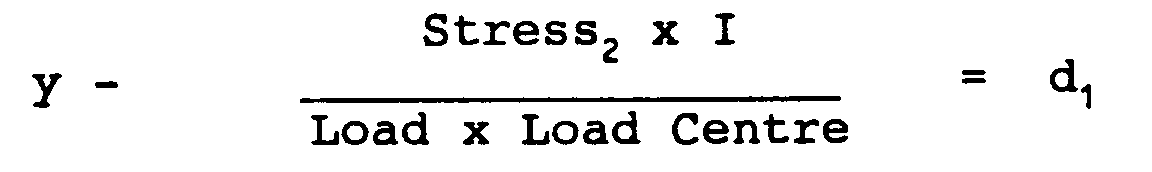

- the top surface of a fork requires a yield point which provides a three to one safety factor in accordance with the following calculation: where where

- the thickness of the top layer is variable and is determined by an adaptation of the previous formulae:

- lower strength materials such as C1010, C1015, C1018 or equivalent material in the bottom layers is sufficient as the compressive strength of such materials far exceeds the tensile strength and compression action is not normally a feature of fatigue failure mechanism within the confines of fork stresses.

- the material of the bottom layer may be modified at will to suit specific requirements. While it may be appropriate to vary the material from lamination to lamination, it is within the scope of this invention to create a fork having a plurality of lamination layers where all of the layers are of the same material. It is possible to make a fork of sufficient thicknesses required to resist flexing at the designed load of entirely low strength materials by using sufficient thicknesses and numbers of lamination layers.

- a fork required to resist corrosion could be made entirely from stainless steel.

- a very light fork could be made from aluminium.

- a spark resistant fork could be made entirely from brass or a series of brass or bronze alloys, again reflecting the surface strength requirements.

- Figure 1 illustrates a fork 10 having a blade 12, a heel 14 and a shank 16.

- This fork as illustrated is intended to be used in the conventional fashion, that is with the blade extending substantially horizontally and the shank extending substantially vertically upwardly from the blade.

- the fork has an inner surface 20 which comprises the upper surface of the blade 12, the inner radius of the heel 14 and the inner surface of the shank 16.

- the fork has an outer surface 22 which comprises the lower surface of the blade 12, the outer radius of the heel 14 and the outer surface of shank 16. In this fork the surface 20 will be loaded in tension while the surface 22 will be loaded in compression.

- Figure 2 illustrates the lamination layers of the fork of Figure 1.

- the shank 16 includes four lamination layers 30, 32, 34 and 36.

- the blade 12 also includes the same four lamination layers 32, 34 and 36.

- the blade is tapered in the region 40 as the stresses are considerably lower towards the tip of the fork than adjacent the heel region.

- the layer 36 which is at the outer surface of the shank and the fork does not extend all the way to the tip of the fork. Machining of the fork may be required in the area 40 to give a smooth surface to the bottom of the fork.

- the heel region 14 includes two additional lamination layers 44 and 46. These layers will be loaded in compression during use of the fork of Figure 1.

- the lamination layers 44 and 46 as shown in Figure 2 comprise portions of a longer length of material that has been affixed to the lamination layer 36. After affixation the heel area will be machined to the configuration shown. This is done to provide a smooth generally vertical surface 22 so that the surface of lamination layers 44 and 46 is a continuation of the flat, vertical surface 22 at the outside surface of the shank 16.

- the lamination layers 44 and 46 may be machined to comprise a flat surface aligned with surface 22, the lower surface of the blade 12.

- All of the lamination layers 30, 32, 34, 36, 44 and 46 comprise two surfaces, an inner surface and an outer surface.

- the outer surface of lamination layer 30 matches precisely the inner surface of lamination layer 32.

- these surfaces are referred to as complimentary surfaces. By this it is meant that when the two lamination layers are placed against each other there is full surface contact throughout the entire extent of that surface.

- lamination layers 32 and 34 have complimentary surfaces.

- Lamination layers 34 and 36 have complimentary surfaces

- layers 36 and 44 have complimentary surfaces

- layers 44 and 46 have complimentary surfaces.

- the complimentary surfaces may be joined by adhesives forming suitable chemical bonds. Such a bond is shown by way of illustration in Figure 4 as a heavy line 50 between layers 34 and 36.

- layer 30 is fixed to layer 32 and layer 32 is fixed to layer 34 by welding.

- the weld beads 52 extend along the side edges of the fork for the entire extent of the contact between the complimentary surfaces. Any type of welding which is satisfactory for joining the materials in question may be used.

- the weld need not be continuous but must of course be sufficient to affix the two surfaces one to the other to pass the stresses from the respective layers of the lamination.

- the type of welding and the amount of welding may vary depending upon how close the weld is to the neutral axis of the material where there will be a minimum requirement. It may also be possible to use less weld material if desired away from the heel region of the fork where the maximum stresses will be occurring.

- Figure 3 illustrates a portion of a fork in which the shank 16 and the blade 12 comprise a single layer material 60.

- the heel 14 comprises additional reinforcing lamination layers 62 and 64.

- the lamination layers 62 and 64 are essentially similar to those discussed above as layers 44 and 46. In a fork of this configuration the lamination layer 60 will be loaded in tension at its surface 20 and loaded in compression at its surface 22.

- the reinforcing lamination layers 62 and 64 of the heel 14 will be loaded in compression or tension depending upon the location of the neutral axis for the particular configuration of the heel chosen.

- the fork of Figure 5 is similar in most respects to the forks discussed above, but is intended to be used as an inverted fork.

- This fork 70 comprises a blade 12, a heel 14 and a shank 16.

- the inner surface 20 comprises the lower surface of the blade 12, the inner radius of the heel 14 and the inside surface of the shank 16.

- the outer surface 22 of the fork 70 comprises the upper surface of the blade 12, the outer radius of the heel 14 and the outer surface of the shank 16. In this fork the outer surface 22 is loaded in tension and the inner surface 20 is loaded in compression when the fork is in use.

- the fork 70 comprises three lamination layers 72, 74 and 76 which have respective complimentary surfaces. These three lamination layers extend from the shank 16 through the heel 14 and into the blade 12.

- the heel 14 comprises two additional lamination layers 78 and 80 which extend only over the heel area 14.

- the affixing and machining of the lamination layers 72, 74, 76, 78 and 80 is similar to the production of the fork 10 referred to above.

- a further lamination layer 82 is then added to the fork.

- the lamination layer 82 has a surface which is complimentary to the lamination layer 76 in the region of the shank 16 and in the region of the blade 12.

- the lamination layer 16 has a surface which is complimentary to the machined surfaces of the lamination layers 78 and 80.

- the complimentary surface of the lamination layer 16 provides full surface to surface contact which the remainder of the fork.

- the lamination layer 82 which is of the hi-tensile material while the remainder of the layers 72, 74, 76, 78 and 80 may be chosen from other materials as appropriate.

- the thicknesses of the various lamination layers are not necessarily the same and may be selected by the designer to meet the strength requirements as selected by the designer.

- a plate of the required thickness would be cut to form a bar of the correct length and width. In some cases the widths or thicknesses may be varied along the length.

- the bar would then be placed in the correct position in a die and bent to the radius of that die. This bar would then constitute the inside surface 20, that is the surface having the smallest radius for the heel section.

- the second bar could then be formed by leaving the first layer in position in the die. The second bar can then be bent in accordance with the radius formed by the combination of the die and the first layer. This will then produce a complimentary surface between the first and second lamination layers. The process is then continued by adding successive layers including those designed for the heel area until the desired thickness of the fork is achieved.

- each layer apart from the first may be determined by the maximum thickness which may be bent over the particular radius without undue deformation and for the strength of the press available and/or whether or not heat is used in the bend area.

- inverted fork machining would be required in the heel section before inserting the formed fork into the die for production of any additional layer such as lamination layer 82.

- any desired machining may be carried out in a normal fashion. This could be used to produce smooth edges where tapers are required or desirable or include shaping of the heel sections as may be most appropriate. Any of the ordinary configuration of heel section may be machined into the laminated fork made in accordance with this invention.

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Structural Engineering (AREA)

- Civil Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mechanical Engineering (AREA)

- Laminated Bodies (AREA)

Abstract

A fork (10) for use with a fork lift truck is manufactured from a plurality of lamination layers (30,32,34,36). The layers may be of the same material or different materials to reflect the stresses imposed on the different layers. Layers subjected to high tensile stresses may be manufactured from high tensile materials while layers subject to lesser stresses may be made from less expensive materials. The layers may occur in any one or more of the blade (12), shank (16) or heel (14) areas of the fork to meet the stresses involved. Various areas may have different numbers of layers, a particular advantage occurring in use of reinforcing layers in the heel (14) area. The lamination layers are secured to one another by adhesives or by welding or the like.

Description

- This invention relates to improvements in forks for material handling vehicles popularly known as lift trucks.

- Forks for use with lift trucks are typically manufactured of steel or other metallic members. The fork comprises a blade, a heel and a shank. Various means may be used to attach the fork to the lift truck. Forks may be of any size or configuration required to carry the load intended. Most often forks are used with the blade extending substantially horizontally and the shank extending substantially vertically upwardly. Occasionally, however, forks are used where the blade is substantially horizontal and the shank portion extends substantially vertically downwardly. These latter types of forks are referred to in this disclosure as inverted forks.

- Forks are typically manufactured from steel. The steel may be configured in the desired shape for the cross-sectional configuration for the shank and blade. Where the fork is intended to carry relatively larger loads, then the thickness of the material normally requires that the material be heated, at least in the region of the heel so that the material can be bent into the typical substantially right angle configuration. In many cases an upset procedure is used to ensure thickening of the fork material in the heel region. This is often advantageous because the stresses are highest in the heel region and thicker metal can be used to carry those stresses. Similarly the tip of the blade may be considerably thinner in cross-section than the portions of the fork immediately adjacent to the heel as the stresses at the tip of the blade are considerably lower than adjacent the heel.

- While forks which have been made to date are entirely satisfactory in terms of load carrying capabilities there are some significant limits in the manufacturing processes. As the load to be carried by the fork increases, the cross-sectional area of the shank and blade adjacent the heel must also increase in order to carry those stresses. As the bar of material from which the fork is made increases in cross-sectional area so too does the power required to bend the fork to the appropriate configuration. With a larger fork a very much larger press may be required.

- In the past specialized forks have been created where special needs dictate. Thus, where a fork is to be used in an atmosphere where sparking is not permitted, a fork formed from a solid steel bar may be surface coated with brass or bronze or be made from solid brass or bronze or the like to reduce or eliminate sparking. Similarly, if there are corrosive conditions to be encountered a fork may be coated with various forms of surface coating or made entirely from a suitable material such as stainless steel all to meet whatever need is required.

- In accordance with the present invention the fork has a plurality of lamination layers. While the fork will have a blade, a heel and a shank, any one or more of those portions of the fork may be formed from a plurality of lamination layers. Each lamination layer is fixed to the next adjacent layer so that stresses are communicated from one layer into the next adjacent layer. Fixation of the layers may be accomplished with adhesives or by welding.

- A method for making such a fork involves bending a first lamination layer in a die. A second lamination layer may be bent using the first layer which remains in the die to form the next lamination. This can be repeated for as many layers as desired. The layers may be fixed to each other as they are bent or after all bending has been completed.

- A more complete understanding of the invention can be gained from review of the attached drawings which illustrate preferred embodiments of the invention and in which:

- Figure 1 is a view of a fork formed in accordance with the invention;

- Figure 2 is a vertical section through the fork of Figure 1 showing the lamination layers;

- Figure 3 is a vertical section view similar to Figure 2 illustrating use of lamination layers in the heel of a fork only;

- Figure 4 is a cross-section through the blade of the fork of Figure 1 along line 4-4, and

- Figure 5 is a view similar to Figure 2 showing a vertical section through an inverted fork and illustrating the lamination layers.

- An analysis of stresses in typical forks clearly shows that the stresses are tensile in form in the top surface of the blade, the inner heel radius and on the inside surface of the shank. The stresses are of a compressive form on the opposite side of each of the portions of the fork. Both stresses approach zero in a substantially linear fashion from the surface to the neutral axis of the cross-section of the fork. When a fork is used as an inverted fork the tensile stresses are in the upper surface of the blade, the outside radii of the heel and the outside surface of the shank. The compressive forces are thus located on the lower surface of the blade, the inside radius and the inner surface of the shank. (In each case this is assuming the load is applied to the upper surface of the blade.) This unalterable characteristic of fork stresses allows for forks to be manufactured with the tensile surface being made of a material of sufficient strength to withstand the applied tensile forces while the subsurface materials can be of lesser tensile strength but which are sufficient to withstand the loads at the given location.

- This invention takes advantage of this phenomenon and permits production of forks in laminated layers instead of using a solid bar. The tensile layer is of a strength to provide the basic surface capabilities while providing sufficient thickness to allow the use of any desired joining media. Each successive lamination layer is to be of any desired thickness and strength. The exact parameters of each layer is dependent upon the total thickness and width of the fork and the load to be applied.

- In accordance with this invention the fork designer has complete freedom as to the number of lamination layers, the thickness of the lamination layers and the location of the lamination layers. In certain cases only the shank will be laminated. In other cases only the blade will be laminated and in still other cases it will be only the heel area that contains lamination layers. These may be combined as the designer chooses.

- The individual lamination layers are affixed to one another. This may be done by applying adhesives that form chemical bonds or by any form of welding. Suitable adhesives for bonding layers of steel include epoxy resins and urethanes.

- In this disclosure the term top surface is used to describe the surface that is loaded in tension under load. In most cases this will be the upper surface of the blade and in the case of a typical fork would be the inner surface of the shank, while in the case of an inverted fork would be the outer surface of the shank. The top surface of a fork requires a yield point which provides a three to one safety factor in accordance with the following calculation:

where

where - b =

- fork width

- d =

- fork thickness

- y =

- distance of the top surface from the neutral axis

-

- d₁ =

- thickness of the top layer

- Stress₂ =

- the yield point of the second layer

- The use of lower strength materials such as C1010, C1015, C1018 or equivalent material in the bottom layers is sufficient as the compressive strength of such materials far exceeds the tensile strength and compression action is not normally a feature of fatigue failure mechanism within the confines of fork stresses. However, within the bounds of this invention the material of the bottom layer may be modified at will to suit specific requirements. While it may be appropriate to vary the material from lamination to lamination, it is within the scope of this invention to create a fork having a plurality of lamination layers where all of the layers are of the same material. It is possible to make a fork of sufficient thicknesses required to resist flexing at the designed load of entirely low strength materials by using sufficient thicknesses and numbers of lamination layers. A fork required to resist corrosion could be made entirely from stainless steel. A very light fork could be made from aluminium. A spark resistant fork could be made entirely from brass or a series of brass or bronze alloys, again reflecting the surface strength requirements.

- Figure 1 illustrates a fork 10 having a

blade 12, aheel 14 and ashank 16. This fork as illustrated is intended to be used in the conventional fashion, that is with the blade extending substantially horizontally and the shank extending substantially vertically upwardly from the blade. The fork has aninner surface 20 which comprises the upper surface of theblade 12, the inner radius of theheel 14 and the inner surface of theshank 16. The fork has anouter surface 22 which comprises the lower surface of theblade 12, the outer radius of theheel 14 and the outer surface ofshank 16. In this fork thesurface 20 will be loaded in tension while thesurface 22 will be loaded in compression. - Figure 2 illustrates the lamination layers of the fork of Figure 1. In this example the

shank 16 includes fourlamination layers blade 12 also includes the same fourlamination layers region 40 as the stresses are considerably lower towards the tip of the fork than adjacent the heel region. In order to accomplish this thelayer 36 which is at the outer surface of the shank and the fork does not extend all the way to the tip of the fork. Machining of the fork may be required in thearea 40 to give a smooth surface to the bottom of the fork. - The

heel region 14 includes two additional lamination layers 44 and 46. These layers will be loaded in compression during use of the fork of Figure 1. The lamination layers 44 and 46 as shown in Figure 2 comprise portions of a longer length of material that has been affixed to thelamination layer 36. After affixation the heel area will be machined to the configuration shown. This is done to provide a smooth generallyvertical surface 22 so that the surface of lamination layers 44 and 46 is a continuation of the flat,vertical surface 22 at the outside surface of theshank 16. Similarly the lamination layers 44 and 46 may be machined to comprise a flat surface aligned withsurface 22, the lower surface of theblade 12. - All of the lamination layers 30, 32, 34, 36, 44 and 46 comprise two surfaces, an inner surface and an outer surface. As shown, the outer surface of

lamination layer 30 matches precisely the inner surface oflamination layer 32. In this respect and in this disclosure, these surfaces are referred to as complimentary surfaces. By this it is meant that when the two lamination layers are placed against each other there is full surface contact throughout the entire extent of that surface. Similarly, lamination layers 32 and 34 have complimentary surfaces. Lamination layers 34 and 36 have complimentary surfaces, layers 36 and 44 have complimentary surfaces and layers 44 and 46 have complimentary surfaces. - The complimentary surfaces may be joined by adhesives forming suitable chemical bonds. Such a bond is shown by way of illustration in Figure 4 as a

heavy line 50 betweenlayers illustration layer 30 is fixed to layer 32 andlayer 32 is fixed to layer 34 by welding. Theweld beads 52 extend along the side edges of the fork for the entire extent of the contact between the complimentary surfaces. Any type of welding which is satisfactory for joining the materials in question may be used. The weld need not be continuous but must of course be sufficient to affix the two surfaces one to the other to pass the stresses from the respective layers of the lamination. The type of welding and the amount of welding may vary depending upon how close the weld is to the neutral axis of the material where there will be a minimum requirement. It may also be possible to use less weld material if desired away from the heel region of the fork where the maximum stresses will be occurring. - Figure 3 illustrates a portion of a fork in which the

shank 16 and theblade 12 comprise asingle layer material 60. Theheel 14 comprises additional reinforcinglamination layers layers lamination layer 60 will be loaded in tension at itssurface 20 and loaded in compression at itssurface 22. The reinforcinglamination layers heel 14 will be loaded in compression or tension depending upon the location of the neutral axis for the particular configuration of the heel chosen. - Although not illustrated, similarly the designer has the freedom in the concept of this invention to manufacture a fork wherein only the blade comprises the laminated structure, or wherein only the shank comprises the laminated structure.

- The fork of Figure 5 is similar in most respects to the forks discussed above, but is intended to be used as an inverted fork. This

fork 70 comprises ablade 12, aheel 14 and ashank 16. Theinner surface 20 comprises the lower surface of theblade 12, the inner radius of theheel 14 and the inside surface of theshank 16. Theouter surface 22 of thefork 70 comprises the upper surface of theblade 12, the outer radius of theheel 14 and the outer surface of theshank 16. In this fork theouter surface 22 is loaded in tension and theinner surface 20 is loaded in compression when the fork is in use. - As shown, the

fork 70 comprises threelamination layers shank 16 through theheel 14 and into theblade 12. In addition, theheel 14 comprises two additional lamination layers 78 and 80 which extend only over theheel area 14. In the manufacture of thefork 70 the affixing and machining of the lamination layers 72, 74, 76, 78 and 80 is similar to the production of the fork 10 referred to above. However, after machining the lamination layers 78 and 80 to the configuration as shown in Figure 5, afurther lamination layer 82 is then added to the fork. Thelamination layer 82 has a surface which is complimentary to thelamination layer 76 in the region of theshank 16 and in the region of theblade 12. Thelamination layer 16 has a surface which is complimentary to the machined surfaces of the lamination layers 78 and 80. Thus, the complimentary surface of thelamination layer 16 provides full surface to surface contact which the remainder of the fork. In this case it is thelamination layer 82 which is of the hi-tensile material while the remainder of thelayers - The production of forks in layers permits each layer to be bent to a required radius without the use of heat, although heat is not precluded by this invention. The relatively thin sections permit the bending to proceed without significant loss in section size, thus eliminating the use of the usual upset procedure.

- In order to proceed a plate of the required thickness would be cut to form a bar of the correct length and width. In some cases the widths or thicknesses may be varied along the length. The bar would then be placed in the correct position in a die and bent to the radius of that die. This bar would then constitute the

inside surface 20, that is the surface having the smallest radius for the heel section. The second bar could then be formed by leaving the first layer in position in the die. The second bar can then be bent in accordance with the radius formed by the combination of the die and the first layer. This will then produce a complimentary surface between the first and second lamination layers. The process is then continued by adding successive layers including those designed for the heel area until the desired thickness of the fork is achieved. The thickness of each layer apart from the first may be determined by the maximum thickness which may be bent over the particular radius without undue deformation and for the strength of the press available and/or whether or not heat is used in the bend area. In the case of the inverted fork machining would be required in the heel section before inserting the formed fork into the die for production of any additional layer such aslamination layer 82. - While the above procedure is a particularly economical procedure requiring only one die form, it is of course possible to achieve the same end result by bending each section separately in a separate die and then assembling the individual lamination layers. If a chemical bonding type adhesive is to be used to affix the lamination layers together, the lamination affixation may take place during the bending operation or separately. Welding of the complimentary surfaces together can occur at any time convenient in the manufacturing steps.

- Once the lamination layers have been affixed to one another, any desired machining may be carried out in a normal fashion. This could be used to produce smooth edges where tapers are required or desirable or include shaping of the heel sections as may be most appropriate. Any of the ordinary configuration of heel section may be machined into the laminated fork made in accordance with this invention.

- It will be appreciated that many changes and alterations can be made to the invention as described above. In particular, the designer is free to mix and match any materials in the lamination layers as desired. The precise configuration and shape including thickness of lamination layers may also be changed to meet any particular requirements. Also, any form of fixation of the layers can be used which is sufficient to communicate the stresses from one layer to another.

Claims (12)

- A fork (10) for use with a fork lift truck, said fork having a shank (16), a blade (12) and a heel (14), characterised in that at least a portion of the fork includes a plurality of lamination layers (30, 32, 34, 36) and each layer is fixed to an adjacent layer of the lamination.

- A fork according to claim 1 wherein said heel comprises lamination layers.

- A fork according to claim 1 or claim 2 wherein, said blade, shank and heel comprise lamination layers.

- A fork according to any one of above claims wherein said heel comprises reinforcing lamination layers.

- A fork according to any one of the above claims wherein the material of at least one of said lamination layers is hi-tensile strength material and the material of at least one of said lamination layers is a low tensile strength material.

- A fork according to any one of the above claims wherein said shank, blade and heel have inner and outer surfaces and the lamination layer along the inner surface of said shank, blade and heel is a hi-tensile strength material.

- A fork according to claim 3 or claim 6 wherein, said shank, blade and heel have inner and outer surfaces and the lamination layer along the outer surface of said blade, shank and heel is a hi-tensile strength material.

- A method for making forks (10) for use with a fork lift truck including the step of:1) bending a first bar of material to form a shank (16), heel (14) and a blade (12), with an inner surface and an outer surface, characterised in that it further includes the step of:2) bending at least one second bar of material to form a shank, a heel and a blade with an inner surface and an outer surface, the inner surface of one of said second bars having a complementary surface to the outer surface of said first bar, and affixing said bars together with said complementary surfaces contacting one another to form a laminated fork.

- A method according to claim 8 wherein there are a plurality of second bars and said second bars form a set of bent bars with complementary surfaces and affixing said bars together with said complementary surfaces contacting one another to form a fork with a plurality of lamination layers.

- A method according to claim 8 or claim 9 in which said bars are bent while cold.

- A method according to any one of claims 8 to 10 wherein said bars are affixed to one another by welding.

- A method according to any one of claims 8 to 10 wherein said bars are affixed to one another by adhesives.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US84878092A | 1992-03-10 | 1992-03-10 | |

| US848780 | 1992-03-10 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0560524A1 true EP0560524A1 (en) | 1993-09-15 |

Family

ID=25304247

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93301557A Withdrawn EP0560524A1 (en) | 1992-03-10 | 1993-03-01 | Laminated fork |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0560524A1 (en) |

| CA (1) | CA2089960A1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19515834C1 (en) * | 1995-04-29 | 1996-05-23 | Vetter Umformtechnik Gmbh | Fork tine for forklift truck |

| EP1690822A2 (en) * | 2005-02-15 | 2006-08-16 | Vetter Umformtechnik GmbH | Coated forks in particular for a forklift truck |

| WO2012171051A1 (en) | 2011-06-15 | 2012-12-20 | Szlezak Philipp | Method for producing a fork arm, and fork arm |

| US9802802B2 (en) | 2015-03-23 | 2017-10-31 | Caterpillar Inc. | Work tool |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE379976C (en) * | 1922-11-25 | 1923-08-31 | Ag Deutsche Maschf | Load hook for hoists |

| GB666102A (en) * | 1949-09-27 | 1952-02-06 | Wards Welders Ltd | Improvements relating to mechanical handling trucks |

| US2817792A (en) * | 1956-01-11 | 1957-12-24 | Production Plastics Corp | Material handling apparatus |

| FR2237831A1 (en) * | 1973-07-17 | 1975-02-14 | Lancer Boss Ltd | |

| US3897097A (en) * | 1974-01-07 | 1975-07-29 | Jr Howard G Davis | Flying fork-type lifting member |

| DD265050A3 (en) * | 1987-04-20 | 1989-02-22 | Fortschritt Veb K | FORK PLATE FOR LOAD CARRIER EQUIPMENT |

| US4810016A (en) * | 1984-10-16 | 1989-03-07 | Stelco Inc. | Lifting hook |

-

1993

- 1993-02-19 CA CA 2089960 patent/CA2089960A1/en not_active Abandoned

- 1993-03-01 EP EP93301557A patent/EP0560524A1/en not_active Withdrawn

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE379976C (en) * | 1922-11-25 | 1923-08-31 | Ag Deutsche Maschf | Load hook for hoists |

| GB666102A (en) * | 1949-09-27 | 1952-02-06 | Wards Welders Ltd | Improvements relating to mechanical handling trucks |

| US2817792A (en) * | 1956-01-11 | 1957-12-24 | Production Plastics Corp | Material handling apparatus |

| FR2237831A1 (en) * | 1973-07-17 | 1975-02-14 | Lancer Boss Ltd | |

| US3897097A (en) * | 1974-01-07 | 1975-07-29 | Jr Howard G Davis | Flying fork-type lifting member |

| US4810016A (en) * | 1984-10-16 | 1989-03-07 | Stelco Inc. | Lifting hook |

| DD265050A3 (en) * | 1987-04-20 | 1989-02-22 | Fortschritt Veb K | FORK PLATE FOR LOAD CARRIER EQUIPMENT |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19515834C1 (en) * | 1995-04-29 | 1996-05-23 | Vetter Umformtechnik Gmbh | Fork tine for forklift truck |

| EP0739854A1 (en) * | 1995-04-29 | 1996-10-30 | Vetter Umformtechnik GmbH | Fork arm |

| EP1690822A2 (en) * | 2005-02-15 | 2006-08-16 | Vetter Umformtechnik GmbH | Coated forks in particular for a forklift truck |

| EP1690822A3 (en) * | 2005-02-15 | 2007-08-15 | Vetter Umformtechnik GmbH | Coated forks in particular for a forklift truck |

| WO2012171051A1 (en) | 2011-06-15 | 2012-12-20 | Szlezak Philipp | Method for producing a fork arm, and fork arm |

| AT511652A1 (en) * | 2011-06-15 | 2013-01-15 | Szlezak Philipp | FORK TINE |

| AT511652B1 (en) * | 2011-06-15 | 2013-07-15 | Szlezak Philipp | FORK TINE |

| CN103648962A (en) * | 2011-06-15 | 2014-03-19 | 菲利普·斯勒扎克 | Method for producing a fork arm, and fork arm |

| JP2014522353A (en) * | 2011-06-15 | 2014-09-04 | スレザック,フィリップ | Fork arm manufacturing method and fork arm |

| RU2556807C1 (en) * | 2011-06-15 | 2015-07-20 | Филипп ШЛЕЗАК | Method of manufacturing of tine, and tine |

| US9624080B2 (en) | 2011-06-15 | 2017-04-18 | Philipp Szlezak | Method for producing a fork arm, and fork arm |

| US9802802B2 (en) | 2015-03-23 | 2017-10-31 | Caterpillar Inc. | Work tool |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2089960A1 (en) | 1993-09-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109382631B (en) | Design features of dissimilar materials-reinforcing stock and forming extrusion | |

| US4824314A (en) | Composite fastener system and manufacturing method thereof | |

| AU612268B2 (en) | Compound steel work pieces and method for their production | |

| US3610290A (en) | Metal laminates and tubing embodying such laminates | |

| EP2127797A1 (en) | Method for joining dissimilar metals of steel product and light metal product with each other | |

| AU711682B2 (en) | Composite panel | |

| US5016807A (en) | Method for producing workpieces of metal | |

| EP0305113B1 (en) | Rotating or moving metal components and methods of manufacturing such components | |

| US6314834B1 (en) | Hollow crank arm | |

| CA2718862A1 (en) | Solid rivet for joining composite component parts | |

| JPS61289973A (en) | Method for fixing blade to outer periphery of rotor main body of steam turbine | |

| EP0813455B1 (en) | Stainless steel tubes, assemblies and methods of making same | |

| US5289965A (en) | Method of superplastically forming and braze bonding a structure | |

| US5429879A (en) | Laminated metal composite formed from low flow stress layers and high flow stress layers using flow constraining elements and making same | |

| EP0560524A1 (en) | Laminated fork | |

| US5664453A (en) | Hollow extruder die for extruding a hollow member of a zinc-containing aluminum alloy | |

| US4722125A (en) | Method for producing a tungsten carbide tip punch | |

| US4133471A (en) | Method for making clad metal sheets having at least one curved major surface | |

| US4551896A (en) | Method of manufacturing a rotor for a rotary fluid pump | |

| EP0995511A2 (en) | Layered material and method for manufacturing same | |

| US4893744A (en) | Lining method using clad pieces and a clad piece for the method | |

| US4469349A (en) | Stabilizer | |

| EP0592495B1 (en) | Superplastic deformation of diffusion bonded aluminium structures | |

| WO2021200695A1 (en) | Method for manufacturing rivet joint, rivet joint, and automotive part | |

| DE2745163C2 (en) | Method for manufacturing a wheel for air or gas-filled tires of motor vehicles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19940316 |