Background of the Invention

-

Liquid automatic dishwasher detergent compositions both aqueous and nonaqueous, have recently received much attention, and the aqueous products have achieved commercial popularity.

-

The acceptance and popularity of the liquid formulations as compared to the more conventional powder products stems from the convenience and performance of the liquid products. However, even the best of the currently available liquid formulations still suffer from two major problems, product phase instability and bottle residue, and to some extent cup leakage from the dispenser cup of the automatic dishwashing machine.

-

Representative patent art in this area includes Rek, U.S. Patent 4,556,504; Bush, et al., U.S. Patent 4,226,736; Ulrich, U.S. Patent 4,431,559; Sabatelli, U.S. Patent 4,147,650; Paucot, U.S. Patent 4,079,015; Leikhem, U.S. Patent 4,116,849; Milora, U.S. Patent 4,521,332; Jones, U.S. Patent 4,597,889; Heile, U.s. Patent 4,512,908; Laitem, U.S. Patent 4,753,748; Sabatelli, U.S. Patent 3,579,455; Hynam, U.S. Patent 3,684,722. Other patents relating to thickened aqueous detergent compositions include U.S. Patent 3,985,668; U.K. Patent Applications GB 2,116, 199A and GB 240,450A; U.S. Patent 4,511,487; U.S. Patent 4,752,409 (Drapier, et al.); U.S. Patent 4,801,395 (Drapier, et al.); U.S. Patent 4,836,946 (Dixit); U.S. Patent 4,889,653 (Ahmed, et al.). Commonly assigned co-pending patents include, for example, S 427,912 filed October 24, 1989; Serial No. 924,385, filed October 29, 1986; Serial No. 323,138, filed March 13, 1989; Serial No. 328,716, filed March 27, 1989; Serial No. 323,137, filed March 13, 1989; Serial No. 323,134, filed March 13, 1989. The solubilizing effect of potassium salts on sodium tripolyphosphate in aqueous detergent compositions is described in U.S. Patent 3,720,621 (Smeets).

-

U.S. Patent 4,836,948 discloses a viscoelastic gel detergent composition characterized by its viscosity under low and high shear conditions, pH, and steady state viscoelastic deformation compliance. The recently issued U.S. Patent 4,859,358 discloses the incorporation of metal salts of long chain hydroxy fatty acids, as anti-tarnishing agents, in thickened aqueous automatic dishwashing detergent compositions.

Brief Description of the Drawings

-

Figures 1-3 are rheograms, plotting elastic modulus G' and viscous modulus G'' as a function of applied strain, for the compositions of Example 1, Formulations A, B, and C, respectively.

Summary of the Invention

-

According to the present invention there is provided an improved aqueous liquid automatic dishwasher detergent composition. The composition is characterized by its substantially indefinite stability against phase separation or settling of dissolved or suspended particles under high and low temperature conditions, low levels of bottle residue, relatively high bulk density, and substantial absence of loosely bound water, but also by its overall product consistency from batch to batch and run to run and over a wide range of storage and aging conditions, including superior aesthetics, freedom from fish-eyes, absence of crystal formation and growth, and resistance to cup leakage.

-

The lineair viscoelastic aqueous liquid automatic dishwasher detergent comprises water, 0.01 to 2% by weight of a long chain fatty acid or salt thereof from 0 to 20% by weight of an alkali metal metal silicate, from 5 to 40% by weight of at least one alkali metal detergent builder salt, a sufficient amount of a chlorine bleach compound to provide 0.2 to 4% by weight of available chlorine, and 0.1 to 2% by weight of at least one cross-linked polyacrylic-type thickening agent having a molecular weight of at least 500,000 wherein at least 95 weight % of the water is bound to the polyacrylic acid type thickening agent and there is an excess of sodium to potassium ions in the composition.

-

A preferred detergent according to the invention comprises, by weight

- (a) 5 to 40% of at least one alkali metal detergent builder salt;

- (b) 0 to 20% alkali metal silicate;

- (c) 0 to 6% alkali metal hydroxide;

- (d) 0 to 5% chlorine bleach stable, water-dispersible organic detergent active material;

- (e) 0 to 1.5% chlorine bleach stable foam depressant;

- (f) chlorine bleach compound in an amount to provide 0.2 to 4% of available chlorine;

- (g) 0.1 to 2.0% of at least one hydrophilic cross-linked water insoluble polyacrylic acid thickening agent having a molecular weight of from 500,000 to 4,000,000 to provide said linear viscoelastic property;

- (h) 0.01 to 2.0% of long chain fatty acid or a metal salt of a long chain fatty acid as a physical stabilizer to increase the physical stability of the composition;

- (i) 0 to 10% of a non-cross-linked polyacrylic acid having a molecular weight in the range of from 800 to 200,000; and

- (j) water;

and wherein at least 98 weight % of the water is bound to the polyacrylic acid thickening agent, there further being an excess of sodium to potassium ions in the composition.

-

In another aspect of the invention, a method for preparing the aqueous composition is provided. According to this aspect, the method comprises the steps of

- I.

- (a) fully hydrating the cross-linked polycarboxylate thickener by slowly adding the thickener to heated water while moderate agitating the mixture.

- (b) slowly adding a neutralizing amount of caustic soda to the mixture from (a) while continuing agitation to obtain a dispersion of the neutralized thickener;

- II.

- (c) forming an aqueous mixture of surface active agents;

- (d) heating the mixture in (c) to a temperature higher than that of the heated water in (a) and mixing until a homogeneous smooth premix is obtained;

- III.

- (e) uniformly mixing alkali metal builder salts with the dispersion (b),

- (f) uniformly mixing the heated premix (d) with the mixture (e),

- (g) cooling the mixture (f) to a temperature above the temperature of the heated water in step (a), and

- (h) adding bleach to the mixture (g).

-

In a preferred embodiment of the invention process, the pH of the aqueous slurry of the cross-linked polycarboxylate thickener after the neutralization in step (b) and in each succeeding step is maintained at a value of at least 11.

Detailed Description and Preferred Embodiments

-

The compositions of this invention are thickened aqueous liquids containing various cleansing active ingredients, detergent builder salts and other detergent adjuvants, structuring and thickening agents and stabilizing components, although some ingredients may serve more than one of these functions.

-

The advantageous characteristics of the compositions of this invention include physical stability, as manifested by little or no phase separation, solid settling or viscosity changes over time or resulting from exposure to low or high temperatures, low bottle residue, low cup leakage, high cleaning performance, e.g. low spotting and filming, dirt residue removal, and consistency in product characteristics and performance, and superior aesthetics. These characteristics are believed to be attributed to several interrelated factors such as low solids, i.e. undissolved particulate content, product density and linear viscoelastic rheology. These factors are, in turn, dependent on several critical compositional components and processing conditions of the formulations, namely, (a) the inclusion of a thickening effective amount of a temperature, bleach and salt stable cross-linked polymeric thickening agent having high water absorption capacity, exemplified by cross-linked polyacrylic acid, (2) inclusion of a physical stabilizing amount of a long chain fatty acid or salt thereof, and (3) a product bulk density of at least 1.28 g/cc, especially at least 1.32 g/cc, (4) hydrating the cross-linked polymeric thickener with heated water, and (5) maintaining the pH of the neutralized polymeric thickener at a pH of at least 11, preferably at least 11.5.

-

In particular, the aqueous liquid automatic dishwasher detergent compositions of this invention will, at least in the preferred embodiments, satisfy each of the following stability criteria over the aging temperature-time schedule shown by the following Table A:

TABLE A | Aging Temperature (°F) | Duration (Weeks) |

| | Minimum | Preferred |

| 140 | > 1 | > 2 |

| 120 | > 6 | > 8 |

| 100 | > 13 | > 16 |

| Ambient | > 24 | > 24 |

More specifically, the compositions are considered stable if each of the following stability criteria is satisfied for at least the minimum number of weeks for each aging temperature shown in Table A:

- o no visible phase separation (i.e. no solid/liquid separation)

- o no significant change (e.g. less than 10%) in viscosities, yield stress or other dynamic-mechanical properties

- o no crystal growth under repeated heating-cooling cycles over a temperature range of at least 7°F to 140°F

- o no decolorization or significant color change. in addition to the above stability criteria, the compositions of this invention are further characterized by their low bottle residue. Specifically, for the preferred cross-linked polyacrylic acid thickened compositions of this invention, bottle residue, under the usual use conditions, will be no more than 6 to 8%, preferably no more than 4 to 5%, of the original bottle contents, on a weight basis.

-

The polymeric thickening agents contribute to the gel-type rheology of the invention compositions. As used herein, "linear viscoelastic" or "linear viscoelasticity" means that the elastic (storage) moduli (G') and the viscous (loss) moduli (G'') are both substantially independent of strain, at least in an applied strain range of from 0-50%, and preferably over an applied strain range of from 0 to 80%. More specifically, a composition is considered to be linear viscoelastic for purposes of this invention, if over the strain range of 0-50% the elastic moduli G' has a minimum value of 100 dynes/sq.cm., preferably at least 250 dynes/sq.cm., and varies less than 500 dynes/sq.cm., preferably less than 300 dynes/sq.cm., especially preferably less than 100 dynes/sq.cm. Preferably, the minimum value of G' and maximum variation of G' applies over the strain range of 0 to 80%. Typically, the variation in loss moduli G'' will be less than that of G'. As a further characteristic of the preferred linear viscoelastic compositions the ratio of G''/G' (tan δ) is less than 1, preferably less than 0.8, but more than 0.05, preferably more than 0.2, at least over the strain range of 0 to 50%, and preferably over the strain range of 0 to 80%. It should be noted in this regard that % strain is shear strain x100.

-

By way of further explanation, the elastic (storage) modulus G' is a measure of the energy stored and retrieved when a strain is applied to the composition while viscous (loss) modulus G'' is a measure of the amount of energy dissipated as heat when strain is applied. Therefore, a value of tan δ,

preferably

means that the compositions will retain sufficient energy when a stress or strain is applied, at least over the extent expected to be encountered for products of this type, for example, when poured from or shaken in the bottle, or stored in the dishwasher detergent dispenser cup of an automatic dishwashing machine, to return to its previous condition when the stress or strain is removed. The compositions with tan δ values in these ranges, therefore, will also have a high cohesive property, namely, when a shear or strain is applied to a portion of the composition to cause it to flow, the surrounding portions will follow. As a result of this cohesiveness of the linear viscoelastic characteristic, the compositions will readily flow uniformly and homogeneously from a bottle when the bottle is tilted, thereby contributing to the physical (phase) stability of the formulation and the low bottle residue (low product loss in the bottle) which characterizes the invention compositions. The linear viscoelastic property also contributes to improved physical stability against phase separation of any undissolved suspended particles by providing a resistance to movement of the particles due to the strain exerted by a particle on the surrounding fluid medium. Linear viscoelasticity also contributes to the elimination of dripping of the contents when the product is poured from a bottle and hence reduction of formation of drops around the container mouth at the conclusion of pouring the product from a container.

-

A still further attribute of the invention compositions contributing to the overall product stability and low bottle residue is the high water absorption capacity of the cross-linked polyacrylic acid-type thickening agent. As a result of this high water absorption capacity virtually all of the aqueous vehicle component appears to be held tightly bound to the polymer matrix. Therefore, there appears to be no or substantially no free water present in the invention compositions. This apparent absence of free water (as well as the cohesiveness of the composition) is manifested by the observation that when the composition is poured from a bottle onto a piece of water absorbent filter paper virtually no water is absorbed onto the filter paper over a period of at least several hours or longer and, furthermore, the mass of the linear viscoelastic material poured onto the filter paper will retain its shape and structure. As a result of the absence of loosely bound water, there is virtually no phase separation between the aqueous phase and the polymeric matrix or dissolved solid particles. This characteristic is manifested by the fact that when the subject compositions are subjected to centrifugation, e.g. at 1000 rpm for 30 minutes, there is no phase separation and the composition remains homogeneous. The preferred compositions have remained stable for period in excess of 6 months and more.

-

In order to maximize physical (phase) stability, the density of the composition should be controlled such that the bulk density of the liquid phase is approximately the same as the bulk density of the entire composition, including the polymeric thickening agent. This control and equalization of the densities was achieved, according to our earlier invention, by providing the composition with a bulk density of at least 1.32 g/cc. A density of 1.42 g/cc is essentially equivalent to zero air content.

-

It is important to note that the bulk density of the product can be adjusted by controlling the degree of aeration, as well as total solid content. Further, the dispersed air bubbles also contribute to the viscoelastic property of the product.

-

However, it has now been found that air bubble incorporation is not required to achieve stabilization and, in fact, we have been able to prepare stable thickened products with densities as low as 1.28 g/cc. At densities below the 1.28 cc/g, however, the flowability of the product tends to be degraded and the large air bubble content tends to cause the composition to be too highly translucent or cloudy to opaque. Therefore, the product density is preferably selected in the range of 1.28 to 1.42 g/cc, especially 1.32 to 1.40 g/cc, and most preferably from 1.35 to 1.40 g/cc. Within these ranges air bubble incorporation is determined to achieve the desired product aesthetic appearance and flow characteristics.

-

It has previously been found in connection with other types of thickened aqueous liquid, automatic dishwasher detergent compositions that agglomeration or escape of incorporated air bubbles could be avoided by incorporating certain surface active ingredients, especially higher fatty acids and the salts thereof, such as stearic acid, behenic acid, palmitic acid, sodium stearate, aluminum stearate, and the like.

-

Therefore, in the present invention, in order to avoid stabilization of air bubbles which may become incorporated into the compositions during normal processing, such as during various mixing steps, is avoided by post-adding the surface active ingredients to the remainder of the composition, under low shear conditions using mixing devices designed to minimize cavitation and vortex formation.

-

As will be described in greater detail below the surface active ingredients present in the composition will include anti-foaming agent (e.g. phosphate ester) and higher fatty acid or salt thereof as a physical stabilizer and optionally a detergent surface active cleaning agent.

-

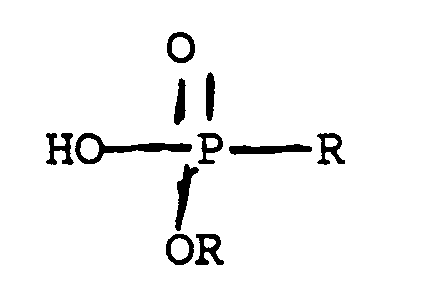

Exemplary of the polycarboxylate type thickening agents are cross-linked polyacrylic acid-type thickening agents sold by B. F. Goodrich under their Carbopol trademark, including both the 900 series resins, especially Carbopol 941, which is the most ion-insensitive of this class of polymers, and Carbopol 940 and Carbopol 934, and the 600 series resins, especially Carbopol 614. The Carbopol 900 series resins are hydrophilic high molecular weight, cross-linked linear acrylic acid polymers having an average equivalent weight of 76, and the general structure illustrated by the following formula:

Carbopol 941 has a molecular weight of 1,250,000; Carbopol 940 a molecular weight of approximately 4,000,000 and Carbopol 934 a molecular weight of approximately 3,000,000. The Carbopol 900 series resins are cross-linked with polyalkenyl polyether, e.g. 1% of a polyallyl ether of sucrose having an average of 5.8 allyl groups for each molecule of sucrose. The preparation of this class of cross-linked carboxylic polymers is described in U.S. Patent 2,798,053. Further detailed information on the Carbopol 900 series resins is available from B. F. Goodrich, see, for example, the B. F. Goodrich catalog GC-67, Carbopol

(R) Water Soluble Resins.

-

In general, these thickening resins are preferably copolymers of a water dispersible copolymer of an alpha-beta monoethylenically unsaturated lower aliphatic carboxylic acid cross-linked with a polyether of a polyol selected from oligo saccharides, reduced derivatives thereof in which the carbonyl group is converted to an alcohol group and pentaerythritol, the hydroxyl groups of the polyol which are modified being etherified with allyl groups, there being preferably at least two such allyl groups per molecule.

-

These water-dispersible cross-linked thickening resins as described in the aforementioned U.S. Patent 2,798,053 and which have been commercialized by B. F. Goodrich as the Carbopol 900 series resins are prepared from essentially linear copolymers. More recently, B. F. Goodrich has introduced the Carbopol 600 series resin. These are high molecular weight, non-linear polyacrylic acid cross-linked with polyalkenyl ether. In addition to the non-linear or branched nature of these resins, they are also believed to be more highly cross-linked than the 900 series resins and have molecular weights between 1,000,000 and 4,000,000. Mixtures of two or more Carbopol resins can be used in the composition.

-

Most especially useful of the Carbopol 600 series resins is Carbopol 614 which is the most chlorine bleach stable of this class of thickening resins. Carbopol 614 is also highly stable in the high alkalinity environment of the preferred liquid automatic dishwasher detergent compositions and is also high stable to any anticipated storage temperature conditions from below freezing to elevated temperatures as high as 120°F, preferably 140°F, and especially 160°F, for periods of as long as several days to several weeks or months or longer.

-

While the most favorable results have now been achieved with Carbopol 614 polyacrylic resin, other linear or branched cross-linked polycarboxylate-type thickening agents can also be used in the compositions of this invention. As used herein "polycarboxylate-type" refers to water-soluble carboxyvinyl polymers of alpha,beta monoethylenically unsaturated lower aliphatic carboxylic acids, which may be linear or non-linear, and are exemplified by homopolymers of acrylic acid or methacrylic acid or water-dispersible or water-soluble salts, esters or amides thereof, or water-soluble copolymers of these acids or their salts, esters or amides with each other or with one or more other ethylenically unsaturated monomers, such as, for example, styrene, maleic acid, maleic anhydride, 2-hydroxyethylacrylate, acrylonitrile, vinyl acetate, ethylene, propylene, and the like, and which have molecular weights of from 500,000 to 10,000,000 and are cross-linked or interpolymerized with a multi-vinyl or multi-allelic functionalized cross-linking agent, especially with a polyalkenyl ether of a polyhydric compound.

-

These homopolymers or copolymers are characterized by their high molecular weight, in the range of from 500,000 to 10,000,000, preferably 750,000 to 5,000,000, especially from 1,000,000 to 4,000,000, and by their water solubility, generally at least to an extent of up to about 5% by weight, or more, in water at 25°C.

-

These thickening agents are used in their cross-linked form wherein the cross-linking may be accomplished by means known in the polymer arts, as by irradiation, or, preferably, by the incorporation into the monomer mixture to be polymerized of known chemical cross-linking monomeric agents, typically polyunsaturated (e.g. diethylenically unsaturated) monomers, such as, for example, divinylbenzene, divinylether of diethylene glycol, N,N'-methylene-bisacrylamide, polyalkenylpolyethers (such as described above), and the like. Typically, amounts of cross-linking agent to be incorporated in the final polymer may range from 0.01 to 5 percent, preferably from 0.05 to 2 percent, and especially, preferably from 0.1 to 1.5 percent, by weight of cross-linking agent to weight of total polymer. Generally, those skilled in the art will recognize that the degree of cross-linking should be sufficient to impart some coiling of the otherwise generally linear or non-linear polymeric compound while maintaining the cross-linked polymer at least water dispersible and highly water-swellable in an ionic aqueous medium.

-

The amount of at least one high molecular weight, cross-linked polyacrylic acid or other high molecular weight, hydrophilic cross-linked polycarboxylate thickening agent used to impart the desired rheological property of linear viscoelasticity will be in the range of from 0.1 to 2%, preferably from 0.2 to 1.4%, by weight, based on the weight of the composition, and within this range the amount selected will depend on the particular cross-linking agent ionic strength of the composition, hydroxyl donors and the like.

-

Specific examples of detergent builder salts used in the instant composition include the polyphosphates, such as alkali metal pyrophosphate, alkali metal tripolyphosphate, alkali metal metaphosphate, and the like, for example, sodium or potassium tripolyphosphate (hydrated or anhydrous), tetrasodium or tetrapotassium pyrophosphate, sodium or potassium hexa-metaphosphate, trisodium or tripotassium orthophosphate and the like, sodium or potassium carbonate, sodium or potassium citrate, sodium or potassium nitrilotriacetate, and the like.

-

An opaque composition can be prepared by the use of sodium tripolyphosphate or a mixture of sodium tripolyphosphate and potassium tripolyphosphate or potassium pyrophosphate wherein the ratio of sodium tripolyphosphate to either potassium tripolyphosphate and/or potassium pyrophosphate is 100/1 to 1.01/1, more preferably 100/1 to 1.05/1. In other words, there is an excess of sodium ions to potassium ions in the composition.

-

The compositions of this invention contain a small, but stabilizing effective amount of a long chain fatty acid or monovalent or polyvalent salt thereof. Although the manner by which the fatty acid or salt contributes to the rheology and stability of the composition has not been fully elucidated it is hypothesized that it may function as a hydrogen bonding agent or cross-linking agent for the polymeric thickener.

-

The preferred long chain fatty acids are the higher aliphatic fatty acids having from 10 to 50 carbon atoms, more preferably from 12 to 40 carbon atoms, and especially preferably from 14 to 40 carbon atoms, and most preferably about 20 to 40, inclusive of the carbon atom of the carboxyl group of the fatty acid. The aliphatic radical may be saturated or unsaturated and may be straight or branched. Straight chain saturated fatty acids are preferred. Mixtures of fatty acids may be used, such as those derived from natural sources, such as tallow fatty acid, coco fatty acid, soya fatty acid, etc., or from synthetic sources available from industrial manufacturing processes.

-

Thus, examples of the fatty acids include, for example, decanoic acid, dodecanoic acid, palmitic acid, myristic acid, stearic acid, behenic acid, oleic acid, eicosanoic acid, tallow fatty acid, coco fatty acid, soya fatty acid, mixtures of these acids, etc. Stearic acid and mixed fatty acids, e.g. stearic acid/palmitic acid, are preferred.

-

It has, however, also recently been discovered by some of us and others that further improvements in phase stability, particularly under elevated temperature storage conditions, and maintenance of product viscosity levels can be obtained by using longer chain length fatty acids in the range of from C₁₈ to C₄₀. Either individual or mixtures of these longer chain length fatty acids can be used, however, the average chain length should be in the range of from about 20 to 32 carbon atoms, especially 24 to 30 carbon atoms and mixture of fatty acids encompassing this range are preferred. Suitable mixed fatty acids are commercially available, for instance those sold under the trade name Syncrowax by Croda.

-

When the free acid form of the fatty acid is used directly it will generally associate with the potassium and sodium ions in the aqueous phase to form the corresponding alkali metal fatty acid soap. However, the fatty acid salts may be directly added to the composition as sodium salt or potassium salt, or as a polyvalent metal salt, although the alkali metal salts of the fatty acids are preferred fatty acid salts.

-

The preferred polyvalent metals are di- and trivalent metals of Groups IIA, IIB and IIIB, such as magnesium, calcium, aluminium and zinc, although other polyvalent metals, including those of Groups IIIA, IVA, VA, IB, IVB, VB, VIIB and VIII of the Periodic Table of the Elements can also be used. Specific examples of such other polyvalent metals include Ti, Zr, V, Nb, Mn, Fe, Co, Ni, Cd, Sn, Sb, Bi, etc. Generally, the metals may be present in the divalent to pentavalent state. Naturally, for use in automatic dishwashers, as well as any other applications where the invention composition will or may come into contact with articles used for the handling, storage or serving of food products or which otherwise may come into contact with or be consumed by people or animals, the metal salt should be selected by taking into consideration the toxicity of the metal. For this purpose, the alkali metal and calcium and magnesium salts are especially higher preferred as generally safe food additives.

-

The amount of the fatty acid or fatty acid salt stabilizer (within the range of 0.01-2%) to achieve the desired enhancement of physical stability will depend on such factors as the nature the fatty acid or its salt, the nature and amount of the thickening agent, detergent active compound, inorganic salts, other ingredients, as well as the anticipated storage and shipping conditions.

-

Generally, however, amounts of the fatty acid or fatty acid salt stabilizing agents in the range of from 0.02 to 2% preferably 0.04 to 1%, more preferably from 0.06 to 0.8%, especially preferably from 0.08 to 0.4%, provide a long term stability and absence of phase separation upon standing or during transport at both low and elevated temperatures as are required for a commercially acceptable product.

-

Depending on the amounts, proportions and types of fatty acid physical stabilizers and polyacrylic acid-type thickening agents, the addition of the fatty acid or salt not only increases physical stability but also provides a simultaneous increase in apparent viscosity. Amounts of fatty acid or salt to polymeric thickening agent in the range of from 0.01 - 2.0 weight percent fatty acid and salt from 0.1 - 2.0 weight percent polymeric thickening agent are usually sufficient to provide these simultaneous benefits and, therefore, the use of these ingredients in these amounts is more preferred.

-

In order to achieve the desired benefit from the fatty acid or fatty acid salt stabilizer, without stabilization of excess incorporated air bubbles and consequent excessive lowering of the product bulk density, the fatty acid or salt should be post-added to the formulation, preferably together with the other surface active ingredients, including detergent active compound and anti-foaming agent, when present. These surface active ingredients are preferably added as an emulsion in water wherein the emulsified oily or fatty materials are finely and homogeneously dispersed throughout the aqueous phase. To achieve the desired fine emulsification of the fatty acid or fatty acid salt and other surface active ingredients, it is usually necessary to heat the emulsion (or preheat the water) to an elevated temperature near the melting temperature of the fatty acid or its salt. For example, for stearic acid having a melting point of 68° - 69°C, a temperature in the range of between 50°C and 70°C will be used. For lauric acid (m.p.=47°C) an elevated temperature of 35° to 50°C can be used.

-

Foam inhibition is important to increase dishwasher machine efficiency and minimize destabilizing effects which might occur due to the presence of excess foam within the washer during use. Foam may be reduced by suitable selection of the type and/or amount of detergent active material, the main foam-producing component. The degree of foam is also somewhat dependent on the hardness of the wash water in the machine whereby suitable adjustment of the proportions of the builder salts, such as NaTPP which has a water softening effect, may aid in providing a degree of foam inhibition. However, it is generally preferred to include a chlorine bleach stable foam depressant or inhibitor. Particularly effective are the alkyl phosphoric acid esters of the formula

and especially the alkyl acid phosphate esters of the formula

In the above formulas, one or both R groups in each type of ester may represent independently a C₁₂-C₂₀ alkyl or ethoxylated alkyl group. The ethoxylated derivatives of each type of ester, for example, the condensation products of one mole of ester with from 1 to 10 moles, preferably 2 to 6 moles, more preferably 3 or 4 moles, ethylene oxide can also be used. Some examples of the foregoing are commercially available, such as the products SAP from Hooker and LPKN-158 from Knapsack. Mixtures of the two types, or any other chlorine bleach stable types, or mixtures of mono- and diesters of the same type, may be employed. Especially preferred is a mixture of mono- and di-C₁₆-C₁₈ alkyl acid phosphate esters such as monostearyl/distearyl acid phosphates 1.2/1, and the 3 to 4 mole ethylene oxide condensates thereof. When employed, proportions of 0.05 to 1.5 weight percent, preferably 0.1 to 0.5 weight percent, of foam depressant in the composition is typical, the weight ratio of detergent active component (d) to foam depressant (e) generally ranging from 10:1 to 1:1 and preferably 5:1 to 1:1. Other defoamers which may be used include, for example, the known silicones, such as available from Dow Chemicals. In addition, it is an advantageous feature of this invention that many of the stabilizing salts, such as the stearate salts, for example, aluminum stearate, when included, are also effective as foam killers.

-

Although any chlorine bleach compound may be employed in the compositions of this invention, such as dichloroisocyanurate, dichloro-dimethyl hydantoin, or chlorinated TSP, alkali metal or alkaline earth metal, e.g. potassium, lithium, magnesium and especially sodium, hypochlorite is preferred. The composition should contains sufficient amount of chlorine bleach compound to provide 0.2 to 4.0% by weight of available chlorine, as determined, for example, by acidification of 100 parts of the composition with excess hydrochloric acid. A solution containing 0.2 to 4.0% by weight of sodium hypochlorite contains or provides roughly the same percentage of available chlorine. 0.8 to 1.6% by weight of available chlorine is especially preferred. For example, sodium hypochlorite (NaOCl) solution of from 11 to 13% available chlorine in amounts of 3 to 20%, preferably 7 to 12%, can be advantageously used.

-

Another surprising and unexpected benefit and advantage of the preferred Carbopol thickened compositions of this invention is the essentially total masking of any chlorine bleach odor which is characteristic of, for example, the prior known clay thickened products. By virtue of the masking of chlorine bleach odor, it has been found that the subject compositions can be blended with substantially lower amounts of fragrance, e.g. lemon oil fragrance, to achieve the same or superior olfactory sensation for the consumer. For instance, as little as 0.05% of lemon fragrance will have the same effect as 0.12% in clay thickened products.

-

Furthermore, the addition of fragrance does not adversely affect the stability criteria, as previously defined, such as viscosity or phase stability, of the compositions.

-

Detergent active material which are optionally useful herein should be low-foaming and stable in the presence of chlorine bleach, when present, especially hypochlorite bleach, and for this purpose those of the organic anionic, nonionic, amine oxide, phosphine oxide, sulphoxide or betaine water dispersible surfactant types are preferred, the first mentioned anionics being most preferred. Particularly preferred surfactants herein are the linear or branched alkali metal mono- and/or di-(C₈-C₁₄) alkyl diphenyl oxide mono₋ and/or di-sulphates, commercially available for example as DOWFAX (registered trademark) 3B-2 and DOWFAX 2A-1. In addition, the surfactant should be compatible with the other ingredients of the composition. Other suitable organic anionic, non-soap surfactants include the primary alkylsulphates, alkylsulphonates, alkylarylsulphonates and sec.-alkylsulphates, Examples include sodium C₁₀₋C₁₈ alkylsulphates such as sodium dodecylsulphate and sodium tallow alcoholsulphate; sodium C₁₀-C₁₀ alkanesulphonates such as sodium hexadecyl-1-sulphonate and sodium C₁₂-C₁₈ alkylbenzenesulphonates such as sodium dodecylbenzenesulphonates. The corresponding potassium salts may also be employed.

-

As other suitable surfactants or detergents, the amine oxide surfactants are typically of the structure R₂R¹NO, in which each R represents a lower alkyl group, for instance, methyl, and R1 represents a long chain alkyl group having from 8 to 22 carbon atoms, for instance a lauryl, myristyl, palmityl or cetyl group. Instead of an amine oxide, a corresponding surfactant phosphine oxide R₂R₁PO or sulphoxide RR₁SO can be employed. Betaine surfactants are typically of the structure R₂R₁N⁺R''COO-, in which each R represents a lower alkylene group having from 1 to 5 carbon atoms. Specific examples of these surfactants include lauryl-dimethylamine oxide, myristyl-dimethylamine oxide, the corresponding phosphine oxides and sulphoxides, and the corresponding betaines, including dodecyldimethylammonium acetate, tetradecyldiethylammonium pentanoate, hexadecyldimethylammonium hexanoate and the like. For biodegradability, the alkyl groups in these surfactants should be linear, and such compounds are preferred.

-

Surfactants of the foregoing type, all well known in the art, are described, for example, in U.S. Patents 3,985,668 and 4,271,030. If chlorine bleach is not used then any of the well known low-foaming nonionic surfactants such as alkoxylated fatty alcohols, e.g. mixed ethylene oxide-propylene oxide condensates of C₈-C₂₂ fatty alcohols can also be used.

-

The chlorine bleach stable, water dispersible organic detergent-active material (surfactant) will normally be present in the composition in minor amounts, generally 1% by weight of the composition, although smaller or larger amounts, such as up to 5%, such as from 0.1 to 5%, preferably from 0.3 or 0.4 to 3% by weight of the composition, may be used.

-

Alkali metal (e.g. potassium or sodium) silicate, which provides alkalinity and protection of hard surfaces, such as fine china glaze and pattern, is generally employed in an amount ranging from 5 to 20 weight percent, preferably 5 to 15 weight percent, more preferably 8 to 12% in the composition. The sodium or potassium silicate is generally added in the form of an aqueous solution, preferably having Na₂O:SiO₂ or K₂O:SiO₂ ratio of 1:1.3 to 1:2.8, especially preferably 1:2.0 to 1:2.6. At this point, it should be mentioned that many of the other components of this composition, especially alkali metal hydroxide and bleach, are also often added in the form of a preliminary prepared aqueous dispersion or solution. However, unless otherwise noted, when amounts of a particular ingredient are given, the reference is to an active ingredient basis, i.e. does not include the aqueous carrier.

-

In addition to the detergent active surfactant, foam inhibitor, alkali metal silicate corrosion inhibitor, and detergent builder salts, which all contribute to the cleaning performance, it is also known that the effectiveness of the liquid automatic dishwasher detergent compositions is related to the alkalinity, and particularly to moderate to high alkalinity levels. Accordingly, the composition of this invention will have pH values of at least 9.5, preferably at least 11 to as high as 14, generally up to 13 or more, and, when added to the aqueous wash bath at a typical concentration level of 10 grams per liter, will provide a pH in the wash bath of at least 9, preferably at least 10, such as 10.5, 11, 11.5 or 12 or more.

-

The alkalinity will be achieved, in part, by the alkali metal ions contributed by the alkali metal detergent builder salts, e.g. sodium tripolyphosphate, potassium tripolyphosphate, and alkali metal silicate, however, it is usually necessary to include alkali metal hydroxide, e.g. NaOH or KOH, to achieve the desired high alkalinity. Amounts of alkali metal hydroxide in the range of from 0.5 to 8%, preferably from 1 to 6%, more preferably from 1.2 to 4%, by weight of the composition will be sufficient to achieve the desired pH level and/or to adjust the K/Na weight ratio.

-

While as stated above, high alkalinity is desired with regard to improved cleaning performance, it has now additionally been discovered that the pH of the composition during processing is highly important for product stability, e.g. viscosity, and bleach stability and phase stability. Specifically, it has been found that, especially for the Carbopol class of thickening agents, the amount of basic neutralizing agent, preferably NaOH, should be sufficient to provide the neutralized thickening agent with a pH of at least 11, preferably at least 11.5. Furthermore, these high alkalinity levels should be maintained throughout the product formulation steps, namely, the pH value of at least 11, preferably at least 11.5, should be maintained during the successive additions of the other ingredients of the competition.

-

As will be shown by the examples given below, if the pH drops to a lower value, there is a loss in viscosity, as well as stability (as manifested by liquid phase separation) over time.

-

Other alkali metal salts, such as alkali metal carbonate may also be present in the compositions in minor amounts, for example from 0 to 4%, preferably 0 to 2%, by weight of the composition.

-

Another often beneficial additive for the present liquid automatic dishwasher detergent compositions is a relatively low molecular weight, non-cross-linked polyacrylic acid or neutralized with caustic, such as the commercial product Acrysol LMW=45N, which has a molecular weight of 4,500. The low m.w. polyacrylic acids can provide additional thickening characteristics but are primarily introduced for their ability to function as a builder or chelating agent. In this capacity, the low m.w. polyacrylic acids can contribute to reduced spotting or streaking and reduced filming on dishes, glassware, pots, pans, and other utensils and appliances.

-

Generally, a suitable molecular weight ranges for the non-cross-linked polyacrylic acid is from 800 to 200,000, preferably 1000 to 150,000, especially from 2,000 to 100,000. When present in the formulation, the non-cross-linked polyacrylic acid can be used in amounts up to 10% by weight, preferably from 1% to 8% by weight, especially 2 to 6% by weight of the composition.

-

Other conventional ingredients may be included in these compositions in small amounts, generally less than about 3 weight percent, such as perfume, hydrotropic agents such as the sodium benzene, toluene, xylene and cumene sulphonates, preservatives, dyestuffs and pigments and the like, all of course being stable to chlorine bleach compound and high alkalinity. Especially preferred for coloring are the chlorinated phthalocyanines and polysulphides of aluminosilicate which provide, respectively, pleasing green and blue tints. To achieve stable yellow colored products, the bleach stable mixed dyes C.I. Direct Yellow 28 (C.I. 19555) or C.I. Direct Yellow 29 (C.I. 19556) can be added to the compositions. These colors meet stability criteria described in Table A. TiO₂ may be employed for whitening or neutralizing off-shades.

-

Although for the reasons previously discussed excessive air bubbles are not often desirable in the invention compositions, depending on the amounts of dissolved solids and liquid phase densities, incorporation of small amounts of finely divided air bubbles, generally up to about 10% by volume, preferably up to 4% by volume, more preferably up to 2% by volume, can be incorporated to adjust the visual appearance, product density and flowability. The incorporated air bubbles should be finely divided, such as up to 100 microns in diameter, preferably from 20 to 40 microns in diameter. Other inert gases can also be used, such as nitrogen, carbon dioxide, helium, oxygen, etc.

-

The amount of water contained in these compositions should, of course, be neither so high as to produce unduly low viscosity and fluidity, nor so low as to produce unduly high viscosity and low flowability, linear viscoelastic properties in either case being diminished or destroyed by increasing tan 1. Such amount is readily determined by routine experimentation in any particular instance, and generally will range from 30 to 75 weight percent, preferably 35 to 65 weight percent. Preferably, the water should also be deionized or softened.

-

The manner of formulating the invention compositions is also important. As discussed above, the order of mixing the ingredients as well as the manner in which the mixing is performed will generally have a significant effect on the properties of the composition, and in particular on product density (by incorporation of more or less air), viscosity and physical stability (e.g. phase separation). Thus, according to the preferred practice of this invention the compositions are prepared by forming a dispersion of the polycarboxylate type thickener in heated water, e.g. 35° to 60°C (95° to 140°F), preferably 40°C to 50°C (104° to 122°F), under moderate to high shear conditions, neutralizing the dissolved polymer to a pH of at least 11, preferably at least 11.5, such as from 11.5 to 13.0, to cause gelation. After transferring the thickener dispersion to a main mixing tank processing is continued by introducing, while continuing mixing, the detergent builder salts, alkali metal silicates, chlorine bleach compound and remaining detergent additives, including any previously unused alkali metal hydroxide, if any, other than the surface-active compounds. All of the additional ingredients can be added simultaneously or sequentially. Preferably, the ingredients are added sequentially, with mixing continued for from 2 to 10 minutes for each ingredient, although it is not necessary to complete the addition of one ingredient before beginning to add the next ingredient. Furthermore, one or more of these ingredients can be divided into portions and added at different times. These mixing steps should also be performed under moderate to high shear rates to achieve complete and uniform mixing. These additional ingredient mixing steps may be carried out at room temperature, but preferably the elevated temperature of the thickener slurry is maintained. The composition may be allowed to age, if necessary, to cause dissolved or dispersed air to dissipate out of the composition.

-

The remaining surface active ingredients, including the anti-foaming agent, optionally, organic detergent compound, and fatty acid or fatty acid salt stabilizer is post-added to the previously formed mixture in the form of an aqueous emulsion (using from 1 to 10%, preferably from 2 to 4% of the total water added to the composition other than water added as carrier for other ingredients or water of hydration) which is pre-heated to a temperature in the range of from Tm-5 to Tm+20, preferably from about Tm to Tm+10, where Tm is the melting point temperature of the fatty acid or fatty acid salt. For the stearic acid stabilizer the heating temperature is in the range of 150° to 170°F (65° to 77°C). For the high chain length fatty acids and mixtures C₁₈-C₃₆, correspondingly higher temperatures may be used, such as from about 160° to 200°F (ca. 70° to 95°C). However, if care is taken to avoid excessive air bubble incorporation during the gelation step or during the mixing of the detergent builder salts and other additives, for example, by operating under vacuum, or using low shearing conditions, or special mixing apparatus, etc., the order of addition of the surface active ingredients should be less important.

-

In accordance with an especially preferred embodiment, the thickened linear viscoelastic aqueous automatic dishwasher detergent composition of this invention includes, on a weight basis:

- (a)

- (i) 8 to 25%, preferably 10 to 20%, potassium tripolyphosphate detergent builder;

- (ii) 2 to 10%, preferably 4 to 8%, sodium tripolyphosphate detergent builder, at an (i)/(ii) weight ratio of from 1.4/1 to 10/1, preferably 2/1 to 6/1;

- (b) 5 to 15, preferably 8 to 12%, alkali metal silicate;

- (c) 1 to 6%, preferably 1.2 to 4%, alkali metal hydroxide;

- (d) 0 to 5%, preferably 0.1 to 3%, chlorine bleach stable, water-dispersible, low-foaming organic detergent active material, preferably non-soap anionic detergent;

- (e) 0 to 1.5%, preferably 0.1 to 0.5%, chlorine bleach stable foam depressant;

- (f) chlorine bleach compound in an amount to provide 0.2 to 4%, preferably 0.8 to 1.6%, of available chlorine;

- (g) at least one non-linear, water-dispersible polyacrylic acid thickening agent comprising at least one high molecular weight hydrophilic polycarboxylate having a molecular weight of from 750,000 to 4,000,000, preferably 800,000 to 3,000,000, thickening agent is present at a concentration of 0.1 to 2%, more preferably from 0.2 to 1.5%, and most preferably from 0.4 to 1.5%;

- (h) a long chain fatty acid or a metal salt of a long chain fatty acid in an amount effective to increase the physical stability of the compositions, preferably from 0.01 to 0.2%, more preferably from 0.1 to 1.5%;

- (i) 0 to 10%, preferably 1 to 8%, especially 2 to 6% of non-cross-linked polyacrylic acid having a molecular weight in the range of from 800 to 200,000, preferably 1000 to 150,000, especially 2,000 to 100,000; and

- (j) balance water, preferably from 30 to 75%, more preferably from 35 to 65%; and wherein at least 95 weight % of the water is tightly bound to the crosslinked polyacrylic acid thickening agent. The compositions may also have an amount of air incorporated therein such that the bulk density of the composition is from 1.28 to 1.42 g/cc, preferably from 1.32 to 1.42 g/cc, more preferably from 1.35 to 1.40 g/cc.

-

The compositions will be supplied to the consumer in suitable dispenser containers preferably formed of molded plastic, especially polyolefin plastic, and most preferably opaque or translucent polyethylene, for which the invention compositions appear to have particularly favorable slip characteristics. In addition to their linear viscoelastic character, the compositions of this invention may also be characterized as pseudoplastic gels (non-thixotropic) which are typically near the borderline between liquid and solid viscoelastic gel, depending, for example, on the amount of the polymeric thickener. The invention compositions can be readily poured from their containers without any shaking or squeezing, i.e. have a sufficiently low yield stress value to flow under their own weight (gravity), although squeezable containers are often convenient and accepted by the consumer for gel-like products.

-

The liquid aqueous linear viscoelastic automatic dishwasher compositions of this invention are readily employed in know manner for washing dishes, other kitchen utensils and the like in an automatic dishwasher, provided with a suitable detergent dispenser, in an aqueous wash bath containing an effective amount of the composition, generally sufficient to fill or partially fill the automatic dispenser cup of the particular machine being used.

-

The invention also provides a method for cleaning dishware in an automatic dishwashing machine with an aqueous wash bath containing an effective amount of the liquid linear viscoelastic automatic dishwasher detergent composition as described above. The composition can be readily poured from the polyethylene container with little or no squeezing or shaking into the dispensing cup of the automatic dishwashing machine and will be sufficiently viscous and cohesive to remain securely within the dispensing cup until shear forces are again applied thereto, such as by the water spray from the dishwashing machine.

-

The invention may be put into practice in various ways and a number of specific embodiments will be described to illustrate the invention with reference to the accompanying examples.

-

All amounts and proportions referred to herein are by weight of the composition unless otherwise indicated.

Example 1

-

The following formulations A-C were prepared as described below:

Table 1 | FORMULATION | A | B | C |

| INGREDIENT | | | |

| Water | Q.A | Q.A | Q.A |

| Carbopol 941 | 0.9 | - | - |

| Carbopol 940 | - | 0.9 | - |

| Carbopol 614 | - | - | 0.9 |

| NaOH (50%) | 2.4 | 4.5 | 4.5 |

| Na-Silicate (47.5%)(1:2.4) | 21 | 21 | 20.83 |

| TKPP | 15 | 15 | - |

| KTPP | - | - | 20.35 |

| NaTPP (anhydrous) | 13 | 13 | 5.26 |

| DOWFAX3B2 | 1 | 0.8 | 0.8 |

| LPKN 1,58 (anti-foaming agent) | 0.16 | 0.16 | 0.16 |

| Fatty acid | 0.10² | 0.20¹ | 0.15² |

| Bleach (13.1%) | 8.1 | 11.1 | 10.13 |

| Grapthol green | 0.0025 | 0.003 | - |

| CI Direct Yellow 28 | - | - | 0.003 |

| Air (Vol. %) approx. | 2 | 2 | 2 |

| Acrysol LMW 45-N (45.0%) | - | - | - |

| Highlights (fragrance) | - | - | 0.05 |

| K/Na | 0.98 | 0.98 | 1.61 |

| Density | 1.35 | 1.37 | 1.37 |

| Stability ambient | 8 wks | 8 wks | 4 wks |

| Stability |

| 100°F | 2 wks | 2 wks | 4 wks |

| Stability 120°F | - | - | 4 wks |

| Stability 140°F | - | - | 2 wks |

| Crystal growth (100°F) | Yes | Yes | No |

| Rheogram | Fig. 1 | Fig. 2 | Fig. 3 |

| ² Stearic acid |

| ¹ Syncrowax C₂₄₋₂₆ |

| ³ Syncrowax C₁₈₋₃₆ |

-

Formulations A, B, and C are prepared by first forming a uniform dispersion of the Carbopol 614 or 940 thickener in about 97% of the water of the total formula water. The Carbopol is slowly added by sprinkling it into the vortex of previously colored deionized water preheated to a temperature of 105°F using a mixer equipped with a premier blade, with agitation set at a medium shear rate, as recommended by the manufacturer. After mixing for about 15 minutes, the dispersion is then neutralized by addition, under the same mixing, of the caustic soda (50% NaOH) component until a thickened product of gel-like consistency is formed (about 10 minutes).

-

To the resulting gelled dispersion the silicate, sodium tripolyphosphate (NaTPP), tetrapotassium pyrophosphate (TKPP), or potassium tripolyphosphate (KTPP), the surfactant emulsion (described below) and bleach and color, added sequentially, in the order stated, with the mixing continued at medium shear for several minutes before adding the next ingredient. After the addition of the surfactant emulsion (at 160°F), the mixture is cooled to from 90°-95°F before the bleach is added.

-

Separately, the surfactant emulsion of the phosphate anti-foaming agent (LPKN), stearic acid or fatty acid mixture and detergent (Dowfax 3B2) is prepared by adding these ingredients to the remaining 3% of water and heating the resulting mixture to a temperature in the range of 160°F (71°C).

-

The rheograms for the formulations A, B and C are shown in Figures 1-3, respectively.

-

These rheograms are obtained with the System 4 Rheometer from Rheometrics equipped with a Fluid Servo with a 100 grams-centimeter torque transducer and a 50 millimeter parallel plate geometry having an 0.8 millimeter gap between plates. All measurements are made at room temperature (25°±1°C) in a humidity chamber after a 5 minute or 10 minute holding period of the sample in the gap. The measurements are made by applying a frequency of 10 radians per second.

Example 2

-

The following formulas were prepared according to the procedure of Example 1 and tested.