EP0268031B2 - Stuffer box and method for making crimped synthetic fibres - Google Patents

Stuffer box and method for making crimped synthetic fibres Download PDFInfo

- Publication number

- EP0268031B2 EP0268031B2 EP87113030A EP87113030A EP0268031B2 EP 0268031 B2 EP0268031 B2 EP 0268031B2 EP 87113030 A EP87113030 A EP 87113030A EP 87113030 A EP87113030 A EP 87113030A EP 0268031 B2 EP0268031 B2 EP 0268031B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- lid

- stuffing box

- base

- inlet opening

- box section

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 29

- 229920002994 synthetic fiber Polymers 0.000 title claims description 9

- 238000002788 crimping Methods 0.000 claims description 40

- 239000000835 fiber Substances 0.000 claims description 23

- 229920002972 Acrylic fiber Polymers 0.000 claims description 21

- 239000000463 material Substances 0.000 claims description 12

- 230000001133 acceleration Effects 0.000 claims description 4

- 238000011144 upstream manufacturing Methods 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 description 12

- 238000009987 spinning Methods 0.000 description 11

- 230000006835 compression Effects 0.000 description 5

- 238000007906 compression Methods 0.000 description 5

- 239000012209 synthetic fiber Substances 0.000 description 5

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 238000002166 wet spinning Methods 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 1

- 238000011437 continuous method Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000000578 dry spinning Methods 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 229920002239 polyacrylonitrile Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920006149 polyester-amide block copolymer Polymers 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02G—CRIMPING OR CURLING FIBRES, FILAMENTS, THREADS, OR YARNS; YARNS OR THREADS

- D02G1/00—Producing crimped or curled fibres, filaments, yarns, or threads, giving them latent characteristics

- D02G1/12—Producing crimped or curled fibres, filaments, yarns, or threads, giving them latent characteristics using stuffer boxes

Definitions

- the invention relates to a process for the production of crimped synthetic fibers by the upsetting process, in particular for acrylic fibers, and to a device for carrying out the process.

- the invention relates to a method for continuous compression crimping during a continuous fiber spinning and aftertreatment process with high strip weights above 100,000 dtex and at production speeds above 200 m / min.

- the fiber cable is fed through two guide rollers to a crimping chamber in which the cable accumulates and in which it is retained under pressure, the cable laying in small turns and forming the so-called crimp, see e.g. US-A-2 862 279.

- a crimping chamber in which the cable accumulates and in which it is retained under pressure, the cable laying in small turns and forming the so-called crimp, see e.g. US-A-2 862 279.

- Three of the four walls of the crimping chamber are fixed, while the fourth is formed by a resilient plate which is resilient to pressure.

- a method for crimping synthetic fibers with a stuffer box crimp which comprises an inlet opening, a stuffer box with bottom, cover and side parts, and an outlet opening.

- the solution is indicated by the features of the characterizing part of claim 1.

- the invention further relates to a device for crimping synthetic fibers with the further features of the preamble of patent claim 5 Starting from this device, the features are specified in the characterizing part of claim 5 to achieve the object.

- the stuffer box is dimensioned such that that the area F2 of the side parts of stuffer box part 2 is at least 85% of the area F1 of the side parts of stuffer box part 1.

- the crimping method described according to the invention is therefore preferably suitable for continuously dry-spun acrylic fiber cables with high strip weights above 100,000 dtex and for production speeds of up to approximately 1,500 m / min, preferably 500-1,200 m / min.

- Fig. 1 shows a device according to the invention with a pair of squeeze rollers with the rollers (1) and (2), an inlet opening (3), a stuffer box with bottom (4), lid (5) and side parts and an outlet opening (6) in the working position.

- the stuffer box basically consists of a pair of squeeze rolls with rolls (1) and (2) and a downstream chamber.

- the side walls of this chamber are fixed, as is the chamber cover (5).

- the "chamber floor” (4) is movably mounted.

- a pressure cylinder (7) which exerts an adjustable force on the movable plate of the chamber floor.

- the exit height of the crimp chamber is between 40 and 50 mm.

- the working thrust of the printing cylinder, which is attached to the end of the movable plate, is therefore approx. 10 mm.

- the distance between the lid and the bottom of the crimping chamber inlet opening is generally greater than the distance between the lid and the bottom of the outlet opening.

- the front crimp chamber part works identically.

- the downstream second stuffer box part 2 is larger in the outlet opening between the bottom and the lid than the entry opening (cf. FIG. 1).

- the bottom could be flattened with the movable plate instead of the fixed cover.

- the upsetting process according to the invention is not only limited to a continuous production process of dry-spun acrylic fibers.

- dry or wet-spun acrylic fiber cables which have been washed and, if appropriate, drawn and dried and are present, for example, in spinning cans, can subsequently be crimped at speeds above 200 m / min using the apparatus described.

- Other synthetic fibers can also be crimped according to the invention, in particular polyester and polyamide fibers.

- the method according to the invention permits continuous stuffer box crimping at high production speeds, in particular according to the continuous methods known from, for example, EP-A-98 477.

- a 100 m / min spinning take-off and prepared acrylic fiber cable with a total denier of 626,000 dtex is stretched 1: 6-fold over heating rollers at a belt temperature of 100 ° C and fed to a stuffer box, as shown in FIG. 1.

- the tape weight presented was 10.4 g / m and the crimping speed 600 m / min.

- Crimping was performed with a force of 294 N (30 kp) on the movable plate and a force on the infeed rollers of 17640 N (1,800 kp).

- the cable was further subjected to 10 kg / h spray steam before entering the crimping chamber.

- the crimp chamber length was 510 mm, the crimp chamber width 75 mm and the crimp chamber height 40 mm.

- the enlarged opening, the crimping chamber wall opposite the movable plate, begins after a chamber length of 290 mm (see Fig.).

- the clear opening at the end of the crimping chamber is 50 mm.

- the area of the unchanged crimp part F1 is calculated to 116 cm2 and the area of the modified crimp part F2 is calculated to 99 cm2.

- the feed rollers of the stuffer box can be tempered with water.

- the roller temperature was 70 ° C.

- the crimped fiber cable is then damped without tension and cut into staple fibers 60 mm long.

- the single fiber end titer is 2.2 dtex.

- the curl the fiber is 19.5%.

- the flake has an adhesive force of 68 centi Newton Ktex.

- the processing speed on the high-performance card is 110 m min.

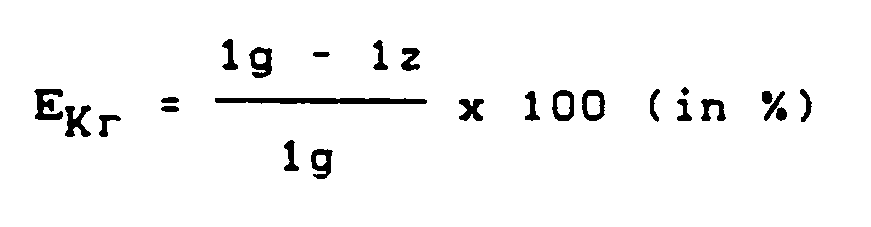

- the ratio V1 is:

- the content of the compression crimp chamber is 820 g.

- the acceleration factor V2 is accordingly.

- the ratio V3 is calculated as:

- the material density ⁇ of the fiber cable in the crimping chamber is:

- the following table shows further examples of the crimping of acrylic fiber cables with different sized crimping devices for different strip weights and crimping speeds up to 1,200 m / min.

- the values of the corresponding crimping parameters and the evaluation of the crimping are also given.

- Example 2 shows that even high strip weights of, for example, 25 g / m, corresponding to 250,000 dtex, can be crimped using the process according to the invention.

- Example 3 shows that with an acceleration factor V2 greater than 100 the material can bake.

- the area ratio V 1 should preferably be greater than 85%, because otherwise the pent-up kinetic energy in the unchanged crimp chamber part become too large and the material can become matted.

- Example 5 shows that by increasing the proportion of area F2 a perfect compression crimp can be carried out again.

- Example 7 shows that if the limit values for the parameters V2 and V3 are not adhered to, caking of the acrylic fiber cable can occur.

- Examples 8-10 show that, by appropriately dimensioning the crimping chamber, even high strip weights at very high crimping speeds can be properly crimped according to the inventive method.

- the crimping of the fiber cable was based on: (cf. Riggert: Crimping of chemical cut fibers and cables and their importance for further processing in Melliand Textile Reports 4/1977 page 274).

- the adhesive force (measured in cN / Ktex) and the processing speed of the crimped cut fibers on the high-performance card were used as further evaluation criteria.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Preliminary Treatment Of Fibers (AREA)

Description

Die Erfindung betrifft ein Verfahren zur Herstellung von gekräuselten synthetischen Fasern nach dem Stauchkräuselungsverfahren, insbesondere für Acrylfasern, sowie eine Vorrichtung zur Durchführung des Verfahrens. Insbesondere betrifft die Erfindung ein Verfahren zur kontinuierlichen Stauchkräuselung während eines kontinuierlich ablaufenden Faserspinn- und Nachbehandlungsprozesses mit hohen Bandgewichten oberhalb 100'000 dtex und bei Produktionsgeschwindigkeiten oberhalb 200 m/min.The invention relates to a process for the production of crimped synthetic fibers by the upsetting process, in particular for acrylic fibers, and to a device for carrying out the process. In particular, the invention relates to a method for continuous compression crimping during a continuous fiber spinning and aftertreatment process with high strip weights above 100,000 dtex and at production speeds above 200 m / min.

Verfahren und Vorrichtungen zur Kräuselung von Synthesefasern sind bekannt. Bei der am meisten bevorzugten Ausführungsform der Stauchkräuselung wird das Faserkabel durch zwei Führungswalzen hindurch einer Kräuselkammer zugeführt, in welcher sich das Kabel ansammelt und in welcher es unter Druck zurückgehalten wird, wobei sich das Kabel in kleine Windungen legt und sich die sogenannte Kräuselung ausbildet, Siehe z.B. US-A-2 862 279. Drei von den vier Wänden der Kräuselkammer sind fest, während die vierte durch eine mit Druck belastbare, beweglich Platte gebildet wird. Wenn der Innendruck des gekräuselten Kabels gleich dem Druck, der auf der beweglichen Platte herrscht, geworden ist, wird diese hochgedrückt und das gestauchte Kabel verläßt die Kammer durch den auf diese Weise gebildeten Schlitz.Methods and devices for crimping synthetic fibers are known. In the most preferred embodiment of the compression crimp, the fiber cable is fed through two guide rollers to a crimping chamber in which the cable accumulates and in which it is retained under pressure, the cable laying in small turns and forming the so-called crimp, see e.g. US-A-2 862 279. Three of the four walls of the crimping chamber are fixed, while the fourth is formed by a resilient plate which is resilient to pressure. When the internal pressure of the crimped cable has become equal to the pressure on the movable plate, the plate is pushed up and the compressed cable leaves the chamber through the slot thus formed.

Es hat sich nun gezeight, daß die bisher bekannten Verfahren und Vorrichtungen dieser Art insbesondere beim Kräuseln von Acrylfaserkabeln den Nachteil aufweisen, daß sich mit ihnen nur Kabel bis zu Produktionsgeschwindigkeiten von ca. 150 - 200 m/min kräuseln lassen. Bei höheren Geschwindigkeiten, oberhalb ca. 200 m/min, treten Verbackungen der Acrylfaserkabel auf. Der Grund hierfür ist, daß bei hohen Geschwindigkeiten und großen Kabelgewichten, wie sie vornehmlich bei kontinuierlich ablaufenden Spinn- und Nachbehandlungsprozessen, wie z.B. in EP-A-98 477 beschrieben sind, auftreten, sich in kürzesten Zeiten große Fasermengen in der Stauchkammer ansammeln, deren aufgebaute kinetische Energie abgeführt werden muß, um Verbackungen zu vermeiden. Es hat nicht an Versuchen gefehlt, z.B. durch Kühlung der Einzugswalzen, durch spezielle Führung des gekräuselten Kabels (DE-A-1 435 438) oder durch Benetzung des Faserkabels mit Feuchte (US-A-3 041 705) diesem Umstand Rechnung zu tragen. Durch Kühlung und spezielle Kabelführung in der Stauchkammer alleine lassen sich jedoch keine hohen Produktionsgeschwindigkeiten erreichen, wie sie bei kontinuierlichen Spinn- und Nachbehandlungspro zessen auftreten. Die Stauchkräuselung von feuchten Acrylfaserkabeln hat zudem den Nachteil, daß die Kräuselung sehr instabil ist und häufig zu sogenannten Hackstellen während der Stauchkräuselung führt. Unter Hackstellen werden Kräuselschäden im Faserkabel verstanden, die zu Löchern im gekräuselten Filamentverband führen und zu Stapeleinkürzungen und Kurzfasern Anlaß geben.It has now been shown that the previously known methods and devices of this type, in particular when crimping acrylic fiber cables, have the disadvantage that they can only crimp cables up to production speeds of approximately 150-200 m / min. At higher speeds, above approx. 200 m / min, caking of the acrylic fiber cables occurs. The reason for this is that at high speeds and large cable weights, such as those primarily used in continuous spinning and post-treatment processes, such as e.g. are described in EP-A-98 477, occur, accumulate large amounts of fibers in the stuffer box in the shortest possible time, the built-up kinetic energy of which must be dissipated in order to avoid caking. There was no lack of attempts, e.g. to take this into account by cooling the feed rollers, by special guidance of the crimped cable (DE-A-1 435 438) or by wetting the fiber cable with moisture (US-A-3 041 705). However, cooling and special cable routing in the stuffer box alone do not allow high production speeds to be achieved, such as occur in continuous spinning and post-treatment processes. The crimping of wet acrylic fiber cables also has the disadvantage that the crimping is very unstable and often leads to so-called hacking points during crimping. Hack points are understood to mean crimp damage in the fiber cable, which lead to holes in the crimped filament structure and give rise to shortening of the stack and short fibers.

Aufgabe der vorliegenden Erfindung war es daher, ein kontinuierliches Stauchkräuselverfahren, insbesondere für Acrylfaserkabel von hohen Bandgewichten, vorzugsweise oberhalb 100'000 dtex, für hohe Produktionsgeschwindigkeiten, vornehmlich größer als 200 m/min, sowie eine Vorrichtung zur Druchführung des Verfahrens zur Verfügung zu stellen.It was therefore an object of the present invention to provide a continuous crimping process, in particular for acrylic fiber cables of high strip weights, preferably above 100,000 dtex, for high production speeds, primarily greater than 200 m / min, and an apparatus for carrying out the process.

Es wurde nun ein Verfahren zur Kräuselung von synthetischen Fasern mit einer Stauchkammerkräusel gefunden, die eine Eingangsöffnung, eine Stauchkammer mit Boden, Deckel und Seitenteilen sowie eine Austrittsöffnung umfaßt. Die Lösung ist durch die Merkmale des kennzeichnenden Teils des Patentanspruches 1 angegeben.A method has now been found for crimping synthetic fibers with a stuffer box crimp, which comprises an inlet opening, a stuffer box with bottom, cover and side parts, and an outlet opening. The solution is indicated by the features of the characterizing part of claim 1.

Gegenstand der Erfindung ist weiterhin eine Vorrichtung zur Kräuselung von synthetischen Fasern mit den weiteren Merkmalen des Oberbegriffs des Patentanspruches 5

Ausgehend von dieser Vorrichtung sind zur Lösung der Aufgabe die Merkmale im kennzeichnenden Teil des Patentanspruches 5 angegeben.The invention further relates to a device for crimping synthetic fibers with the further features of the preamble of

Starting from this device, the features are specified in the characterizing part of

In einer besonders bevorzugten Ausführungsform ist die Stauchkammer so bemessen, daß die Fläche F₂ der Seitenteile von Stauchkammerteil 2 mindestens 85 % der Fläche F₁ der Seitenteile von Stauchkammerteil 1 beträgt.In a particularly preferred embodiment, the stuffer box is dimensioned such that that the area F₂ of the side parts of

Zur Beschreibung der komplexen Kräuselungsvorgänge beim Stauchkräuseln von Acrylfasern hat sich neben V₁ die Einführung folgender weiterer produkt- und prozeßspezifischer Größen bewährt:

- b) Das Verhältnis V₂ von Bandgeschwindigkeit v in (m/min) des der Stauchkammer zugeführten Faserkabels zur Verweilzeit t (in Sekunden) des Faserkabels in der Stauchkammer.

Hierfür gilt die Beziehung: - c) Das Verhältnis V₃ von Durchsatzmenge m (gemessen in g/Sekunden) an Faserkabel durch die Stauchkammer zur Verweilzeit t (gemessen in Sekunden). V₃ ist vorzugsweise kleiner 50 g/sec². Bei Überschreitung des angegebenen Grenzwertes infolge zu hohen Durchsatzes oder zu geringer Verweilzeit werden wiederum verbackene Acrylfaserkabel beobachtet.

- d) Die Dichte δ der Acrylfaserkabel in der Stauchkammer. Die Dichte δ (gemessen in g/cm³) läßt sich aus dem Verhältnis des Kräuselkammerinhaltes in Gramm zum Kräuselkammervolumen in cm³ berechnen.

Die Dichte δ, worunter defintionsgemäß nicht die eigentliche Stoffdichte von Acrylfasern, sondern die Materialdichte des Faserkabels in der Stauchkammer verstanden wird, sagt ebenfalls etwas über den Kräuselzustand des Acrylfaserkabels in der Stauchkammer aus. Beträgt die Dichte δ weniger als 0,2 g/cm³, so liegen in der Regel nur schwach gekräuselte, nahezu glatte Faserkabel vor.In addition to V₁, the introduction of the following additional product and process-specific sizes has proven useful for describing the complex crimping processes for upsetting acrylic fibers:

- b) The ratio V₂ of belt speed v in (m / min) of the fiber cable fed to the stuffer box to the residence time t (in seconds) of the fiber cable in the stuffer box.

The relationship applies here: - c) The ratio V₃ of flow rate m (measured in g / seconds) of fiber cable through the stuffer box to the residence time t (measured in seconds). V₃ is preferably less than 50 g / sec². If the specified limit value is exceeded due to too high throughput or too short a dwell time, baked acrylic fiber cables are observed.

- d) The density δ of the acrylic fiber cables in the stuffer box. The density δ (measured in g / cm³) can be calculated from the ratio of the crimp chamber content in grams to the crimp chamber volume in cm³.

The density δ, which by definition is not to be understood as the actual material density of acrylic fibers, but rather the material density of the fiber cable in the stuffer box, also says something about the state of crimp of the acrylic fiber cable in the stuffer box. If the density δ is less than 0.2 g / cm³, there are usually only slightly crimped, almost smooth fiber cables.

Bei den bisher bekannten Herstellprozessen von Acrylfasern sind Kräuselgeschwindigkeiten oberhalb von 200 m/min nicht bekannt. Während beim Naßspinnen die Spinngeschwindigkeit im Fällbad bei maximal ca. 15 m/min liegt und nach einer 1:6 bis 1:10 Verstreckung somit Produktionsgeschwindigkeiten von maximal 150 m/min erreicht werden, liegen die Geschwindigkeitsverhältnisse beim Trockenspinnen ähnlich. Hier wird aus Ringdüsen mit weit geringerer Lochzahl gegenüber dem Naßspinnen in Schächten mit höheren Spinnabzügen von ca. 200 - 300 m/min gesponnen, das Spinngut zunächst jedoch in sogenannte Spinnkannen gesammelt und anschließend gewaschen., ca. 1:4-fach verstreckt, getrocknet und gekräuselt. Hierbei werden Geschwindigkeiten von ebenfalls maximal 150 - ca. 200 m/min erreicht. Höhere Geschwindigkeiten sind unrationell, weil der zeitbestimmende Faktor die Lösungsmittelentfernung beim Waschen des Spinngutes ist. Erst mit dem Aufkommen von kontinuierlichen Spinn- und Nachbehandlungsprozessen von trockengesponnenen Acrylfaserkabeln bestand die Notwendigkeit, die Kräuselgeschwindigkeit den hohen Produktionsgeschwindigkeiten, wie sie etwa in EP-A-98 477 beschrieben sind, anzupassen. Das erfindungsgemäß beschriebene Stauchkräuselverfahren eignet sich daher vorzugsweise für kontinuierlich trockengesponnene Acrylfaserkabel von hohen Bandgewichten oberhalb 100'000 dtex und für Produktionsgeschwindigkeiten bis ca. 1.500 m/min, vorzugsweise 500-1.200 m/min.In the previously known manufacturing processes of acrylic fibers, crimping speeds above 200 m / min are not known. While in wet spinning the spinning speed in the precipitation bath is a maximum of approx. 15 m / min and after a 1: 6 to 1:10 stretching production speeds of maximum 150 m / min are reached, the speed ratios in dry spinning are similar. Here is spun from ring nozzles with a much smaller number of holes compared to wet spinning in shafts with higher spinning take-offs of approx. 200 - 300 m / min, but the spinning material is first collected in so-called spinning cans and then washed., Stretched approx. 1: 4 times, dried and curled. Here speeds of maximum 150 - approx. 200 m / min are also achieved. Higher speeds are inefficient because the time-determining factor is the solvent removal when washing the spinning material. Only with the advent of continuous spinning and post-treatment processes for dry-spun acrylic fiber cables was there a need to to adapt the crimping speed to the high production speeds as described, for example, in EP-A-98 477. The crimping method described according to the invention is therefore preferably suitable for continuously dry-spun acrylic fiber cables with high strip weights above 100,000 dtex and for production speeds of up to approximately 1,500 m / min, preferably 500-1,200 m / min.

Fig. 1 zeigt eine erfindundsgemäße Vorrichtung mit einem Quetschwalzenpaar mit den Walzen (1) und (2), einer Eingangsöffnung (3), einer Stauchkammer mit Boden (4), Dekkel (5) und Seitenteilen sowie einer Austrittsöffnung (6) in Arbeitsstellung. Die Stauchkammer besteht im Prinzip aus einem Quetschwalzenpaar mit den Walzen (1) und (2) und einer nachgeschalteten Kammer. Die Seitenwände dieser Kammer sind fest angeordnet, ebenso der Kammerdeckel (5). Der "Kammerboden" (4) ist beweglich gelagert. Am Ende des Kammerbodens befindet sich ein Druckzylinder (7), der eine einstellbare Kraft auf die bewegliche Platte des Kammerbodens ausübt.Fig. 1 shows a device according to the invention with a pair of squeeze rollers with the rollers (1) and (2), an inlet opening (3), a stuffer box with bottom (4), lid (5) and side parts and an outlet opening (6) in the working position. The stuffer box basically consists of a pair of squeeze rolls with rolls (1) and (2) and a downstream chamber. The side walls of this chamber are fixed, as is the chamber cover (5). The "chamber floor" (4) is movably mounted. At the end of the chamber floor there is a pressure cylinder (7) which exerts an adjustable force on the movable plate of the chamber floor.

Im Normalzustand bei arbeitender Kräusel liegt die Austrittshöhe der Kräuselkammer zwischen 40 und 50 mm. Der Arbeitschub des Druckzylinders, der am Ende der beweglichen Platte befestigt ist, beträgt somit ca. 10 mm.In the normal state with the crimp working, the exit height of the crimp chamber is between 40 and 50 mm. The working thrust of the printing cylinder, which is attached to the end of the movable plate, is therefore approx. 10 mm.

In Arbeitsstellung ist beim herkömmlichen Stauchkammer-Kräuselverfahren der Abstand zwischen Deckel und Boden der Kräuselkammereintrittsöffnung in der Regel größer als der Abstand zwischen Deckel und Boden der Austrittsöffnung. Bei der vorligenden Erfindung arbeitet der vordere Kräuselkammerteil identisch. Der nachgeschaltete zweite Stauchkammerteil 2 ist jedoch in der Austrittsöffnung zwischen Boden und Deckel größer als die Eintriffsöffnung (vgl. Fig. 1).In the working position in the conventional stuffer box crimping method, the distance between the lid and the bottom of the crimping chamber inlet opening is generally greater than the distance between the lid and the bottom of the outlet opening. In the present invention, the front crimp chamber part works identically. However, the downstream second

In der Fig. 1 ist im zweiten Stauchkammerteil der (feststehende) Deckel abgeflacht.In Fig. 1 the (fixed) cover is flattened in the second stuffer box part.

Ebenso könnte beispielsweise der Boden mit der beweglichen Platte anstelle des feststehenden Deckels abgeflacht sein. Eine weitere Möglichkeit ergibt sich durch Anbringung einer einstellbaren Kolbenkraft an die abgeschrägte Fläche mit einem Drehpunkt am Anfang dieser Fläche, wodurch der Stauchkammerkräuselprozeß in weiten Grenzen variabel wird. Bevorzugt ist in jedem Falle, daß das im Verhältnis V₁ definierte Flächenverhältnis von F₂:F₁ = mindestens 85 % beträgt sowie die anderen angegebenen Randbedingungen V₂ = kleiner 100, V₃ kleiner 50 und die Materialdichte δ größer 0,2 eingehalten werden.Likewise, for example, the bottom could be flattened with the movable plate instead of the fixed cover. Another possibility arises by applying an adjustable piston force to the beveled surface with a pivot point at the beginning of this surface, as a result of which the stuffer box crimping process can be varied within wide limits. It is preferred in any case that the area ratio of F₂: F₁ = at least 85% defined in the ratio V₁ and the other specified boundary conditions V₂ = less than 100, V₃ less than 50 and the material density δ greater than 0.2 are observed.

Das erfindungsgemäße Stauchkräuselverfahren ist jedoch nicht nur auf ein kontinuierliches Herstellverfahren von trockengesponnenen Acrylfasern beschränkt. Ebenso können trocken- oder naßgesponnene Acrylfaserkabel, die gewaschen und gegebenenfalls verstreckt und getrocknet worden sind und beispielsweise in Spinnkannen vorliegen, anschließend bei Geschwindigkeiten oberhalb 200 m/min mit der beschriebenen Apparatur stauchgekräuselt werden. Auch andere synthetische Fasern können erfindungsgemäß stauchgekräuselt werden, insbesondere Polyester- und Polyamidfasern. Das erfindungsgemäße Verfahren erlaubt die kontinuierliche Stauchkammerkräuselung bei hohen Produktionsgeschwindigkeiten, insbesondere nach den aus beispielsweise der EP-A-98 477 bekannten kontinuierlichen Verfahren.However, the upsetting process according to the invention is not only limited to a continuous production process of dry-spun acrylic fibers. Likewise, dry or wet-spun acrylic fiber cables, which have been washed and, if appropriate, drawn and dried and are present, for example, in spinning cans, can subsequently be crimped at speeds above 200 m / min using the apparatus described. Other synthetic fibers can also be crimped according to the invention, in particular polyester and polyamide fibers. The method according to the invention permits continuous stuffer box crimping at high production speeds, in particular according to the continuous methods known from, for example, EP-A-98 477.

Die folgenden Beispiele dienen der näheren Erläuterung der Erindung, ohne sie selbst einzuschränken.The following examples serve to explain the invention in greater detail, without restricting it itself.

Ein mit 100 m/min Spinnabzug kontinuierlich trockengesponnenes und präpariertes Acrylfaserkabel vom Gesamttiter 626'000 dtex wird über Heizwalzen bei 100°C Bandtemperatur 1:6-fach verstreckt und einer Stauchkammer, gemäß Fig. 1, zugeführt. Das vorgelegte Bandgewicht betrug 10,4 g/m und die Kräuselgeschwindigkeit 600 m/min. Gekräuselt wurde mit einer Kraft von 294 N (30 kp) auf die bewegliche Platte bei einer Kraft auf die Einlaufwalzen von 17640 N (l.800 kp). Das Kabel wurde ferner mit 10 kg/h Sprühdampf vor dem Einlauf in die Kräuselkammer beaufschlagt. Die Kräuselkammerlänge betrug 510 mm, die Kräuselkammerbreite 75 mm und die Kräuselkammerhöhe 40 mm. Die erweiterte Öffnung, die der beweglichen Platte gegenüberliegenden Kräuselkammerwand, beginnt nach 290 mm Kammerlänge (vergl. Abb.). Die lichte Öffnung am Kräuselkammerende beträgt 50 mm. Die Fläche des unveränderten Kräuselkammerteils F₁ berechnet sich zu 116 cm² und die Fläche des abgeänderten Kräuselkammerteils F₂ berechnet sich zu 99 cm². Die Einzugswalzen der Stauchkammer sind mit Wasser temperierbar. Die Walzentemperatur lag bei 70°C. Das gekräuselte Faserkabel wird anschließend spannungslos gedämpft und zu Stapelfasern von 60 mm Länge geschnitten. Der Einzelfaserendtiter beträgt 2,2 dtex. Die Einkräuselung der Fasern liegt bei 19,5 % Die Flocke besitzt eine Haftkraft von 68 centi Newton Ktex. Die Verarbeitungsgeschwindigkeit auf der Hochleistungskarde liegt bei 110 m min.A 100 m / min spinning take-off and prepared acrylic fiber cable with a total denier of 626,000 dtex is stretched 1: 6-fold over heating rollers at a belt temperature of 100 ° C and fed to a stuffer box, as shown in FIG. 1. The tape weight presented was 10.4 g / m and the crimping speed 600 m / min. Crimping was performed with a force of 294 N (30 kp) on the movable plate and a force on the infeed rollers of 17640 N (1,800 kp). The cable was further subjected to 10 kg / h spray steam before entering the crimping chamber. The crimp chamber length was 510 mm, the crimp chamber width 75 mm and the crimp chamber height 40 mm. The enlarged opening, the crimping chamber wall opposite the movable plate, begins after a chamber length of 290 mm (see Fig.). The clear opening at the end of the crimping chamber is 50 mm. The area of the unchanged crimp part F₁ is calculated to 116 cm² and the area of the modified crimp part F₂ is calculated to 99 cm². The feed rollers of the stuffer box can be tempered with water. The roller temperature was 70 ° C. The crimped fiber cable is then damped without tension and cut into staple fibers 60 mm long. The single fiber end titer is 2.2 dtex. The curl the fiber is 19.5%. The flake has an adhesive force of 68 centi Newton Ktex. The processing speed on the high-performance card is 110 m min.

Das Verhältnis V₁ beträgt:

Der Inhalt der Stauchkräuselkammer beträgt 820 g. Für ein Acrylfaserkabel von Bandgewicht 10,4 g/m ergibt sich bei einer Produktionsgeschwindigkeit von 600 m/min ein Durchsatz von 104 g Sekunde. Demnach beträgt die Verweilzeit in der Stauchkammer 820:104 = ca 7,9 Sekunden.The ratio V₁ is:

The content of the compression crimp chamber is 820 g. For an acrylic fiber cable with a tape weight of 10.4 g / m, a throughput of 104 g results at a production speed of 600 m / min. Accordingly, the dwell time in the stuffer box 820 is: 104 = approx. 7.9 seconds.

Der Beschleunigungsfaktor V₂ beträgt demnach.

Das Verhältnis V₃ errechnet sich zu:

Die Materialdichte δ des Faserkabels in der Kräuselkammer beträgt:

The ratio V₃ is calculated as:

The material density δ of the fiber cable in the crimping chamber is:

In der folgenden Tabelle sind weitere Beispiele zur Stauchkräuselung von Acrylfaserkabeln mit verschiedenen dimensionierten Stauchkräuselvorrichtungen für unterschiedliche Bandgewichte und Kräuselgeschwindigkeiten bis zu 1.200 m/min angeführt Ferner sind die Werte der entsprechenden Kräuselparameter sowie die Beurteilung der Kräuselung angegeben.The following table shows further examples of the crimping of acrylic fiber cables with different sized crimping devices for different strip weights and crimping speeds up to 1,200 m / min. The values of the corresponding crimping parameters and the evaluation of the crimping are also given.

Beispiel 2 zeigt, daß auch hohe Bandgewichte von beispielsweise 25 g/m entsprechend 250'000 dtex nach dein erfindungsgemäßen Verfahren sich stauchkräuseln lassen.Example 2 shows that even high strip weights of, for example, 25 g / m, corresponding to 250,000 dtex, can be crimped using the process according to the invention.

Beispiel 3 zeigt, daß bei einem Beschleunigungsfaktor V₂ größer 100 das Material verbacken kann.Example 3 shows that with an acceleration factor V₂ greater than 100 the material can bake.

In Beispiel 4 wird dargelegt, daß das Flächenverhaltnis V₁ vorzugsweise größer 85 % sein sollte, weil sonst die aufgestaute kinetische Energie im unveränderten Kräuselkammerteil zu groß werden und das Material verfilzen kann.In example 4 it is shown that the area ratio V 1 should preferably be greater than 85%, because otherwise the pent-up kinetic energy in the unchanged crimp chamber part become too large and the material can become matted.

Beispiel 5 zeight, daß durch Vergrößerung des Flächenanteils F₂ eine einwandfreie Stauchkräuselung wieder durchführbar ist.Example 5 shows that by increasing the proportion of area F₂ a perfect compression crimp can be carried out again.

Im Beispiel 6 wird dargelegt, daß bei niedriger Kräuselkammerfüllung und damit niedriger Materialdichte in der Kräuselkammer unter Umständen nur glatte Fasern erhalten werden.In example 6 it is shown that with low crimp chamber filling and thus low material density in the crimp chamber under certain circumstances only smooth fibers are obtained.

Beispiel 7 zeight, daß bei Nichteinhaltung der Grenzwerte für die Parameter V₂ und V₃ Verbackungen des Acrylfaserkabels eintreten können.Example 7 shows that if the limit values for the parameters V₂ and V₃ are not adhered to, caking of the acrylic fiber cable can occur.

In den Beispielen 8 - 10 wird gezeigt, daß man durch entsprechende Dimensionierung der Kräuselkammer auch hohe Bandgewichte bei sehr hohen Kräuseigeschwindigkeiten gemäß dem erfinderischen Verfahren einwandfrei stauchkräuseln kann.Examples 8-10 show that, by appropriately dimensioning the crimping chamber, even high strip weights at very high crimping speeds can be properly crimped according to the inventive method.

In den Beispielen 11 und 12 schließlich wird aufgezeigt, daß das Stauchkräuselverfahren gemäß der vorliegenden Erfindung auch für kleinere Bandgewichte unterhalb 100'000 dtex erfolgreich angewendet werden kann.Finally, in Examples 11 and 12 it is shown that the compression crimping method according to the present invention is also successfully used for smaller strip weights below 100,000 dtex can be.

In den Beispielen wurde zur kBeurteilung der Kräuselung die Einkräuselung des Faserkabels nach:

(vergl. Riggert: Kräuselung von Chemie-Schnittfasern und -Kabeln und ihre Bedeutung für die Weiterverarbeitung in Melliand Textilberichte 4/1977 Seite 274) bestimmt.In the examples, the crimping of the fiber cable was based on:

(cf. Riggert: Crimping of chemical cut fibers and cables and their importance for further processing in

Es bedeuten:

- 1g =

- Länge des gestreckten, entkräuselten Zustandes

- 1z =

- Länge des zusammengezogenen, gekräuselten Zustandes

- 1g =

- Length of the stretched, crimped state

- 1z =

- Length of the contracted, curled condition

Als weitere Beurteilungskriterien wurden die Haftkraft (gemessen in cN/Ktex) sowie die Verarbeitungsgeschwindigkeit der gekräuselten Schnittfasern auf der Hochleistungskarde (gemessen in m/min) herangezogen.

Claims (7)

- A method for crimping synthetic fibres using a device comprising an inlet opening, a stuffing box having a base, lid and side portions and an outlet opening, characterised in that a stuffing box is used in which in the operative position the distance between the lid and base is smaller in the case of the inlet opening than the distance between the lid and base in the case of the outlet opening, the synthetic fibres are pushed into the inlet opening by means of a pair of crushing rollers, the lid and/or base are movable about a pivot point in the vicinity of the inlet opening, with the parallel position of the lid and base in a stuffing box section 1 adjoining the inlet opening, an adjoining stuffing box section 2 is formed in which the distance between lid and base increases in the direction of the outlet opening, the lid of the stuffing box section 1 being arranged at an angle to the lid of the stuffing box section 2 and the base in both stuffing box sections being formed by an even surface, and the strip weight of the fibres when entering the stuffing crimping chamber exceeds 100,000 dtex with a fibre input velocity greater than or equal to 200 m/min.

- A method according to claim 1, characterised in that a stuffing box is used whose side walls and lid are immovably arranged and whose base is movable.

- A method according to claims 1 and 2, characterised in thata) the surface F₂ of the side portions of the stuffing box section 2 corresponds to at least 85% of the surface F₁ of the side portions of the stuffing box section 1,b) the acceleration faction V₂ from the ratio of strip velocity v (m/min) to dwell time t (sec) in the crimping chamber is less than 100,c) the ratio V₃ of throughput quantity m (g/sec) to dwell time t (sec) is less than 50,

- A method according to claims 1 to 3, characterised in that the synthetic cable is an acrylic fibre cable and is introduced into the stuffing box at a velocity of at least 500 m/min.

- A device for crimping synthetic fibres with a strip weight exceeding 100,000 dtex and an input velocity greater than or equal to 200 m/min, comprising an inlet opening, a stuffing box having a base, lid and side portions and an outlet opening, characterised in that in the operative position the distance between the lid and base is smaller in the case of the inlet opening than the distance between the lid and base in the case of the outlet opening, a pair of crushing rollers is arranged upstream of the inlet opening, the lid and/or base are movable about a pivot point in the vicinity of the inlet opening, with the parallel position of the lid and base in a stuffing box section 1 adjoining the inlet opening, an adjoining stuffing box section 2 is formed in which the distance between lid and base increases in the direction of the outlet opening, the lid of the stuffing box section 1 is arranged at an angle to the lid of the stuffing box section 2 and the base in both stuffing box sections is formed by an even surface.

- A device according to claim 5, characterised in that the side walls and lid of the stuffing box are immovably arranged and the base is movable.

- A device according to claims 5 and 6, characterised in that the surface F₂ of the side portions of the stuffing box section 2 corresponds to at least 85% of the surface F₁ of the side portions of the stuffing box section 1.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863631905 DE3631905A1 (en) | 1986-09-19 | 1986-09-19 | CONTAINER CHAMBER AND METHOD FOR PRODUCING CURLED SYNTHETIC FIBERS |

| DE3631905 | 1986-09-19 |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP0268031A2 EP0268031A2 (en) | 1988-05-25 |

| EP0268031A3 EP0268031A3 (en) | 1990-01-31 |

| EP0268031B1 EP0268031B1 (en) | 1992-04-22 |

| EP0268031B2 true EP0268031B2 (en) | 1995-03-15 |

Family

ID=6309935

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87113030A Expired - Lifetime EP0268031B2 (en) | 1986-09-19 | 1987-09-07 | Stuffer box and method for making crimped synthetic fibres |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4854021A (en) |

| EP (1) | EP0268031B2 (en) |

| JP (1) | JPS6392746A (en) |

| DE (2) | DE3631905A1 (en) |

| ES (1) | ES2030407T5 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3630244C2 (en) * | 1986-09-05 | 1994-06-16 | Bayer Ag | Continuous dry spinning and post-treatment process of the spun material for highly shrinkable acrylonitrile threads and fibers and corresponding threads and fibers |

| DE3823683A1 (en) * | 1988-07-13 | 1990-01-18 | Hollingsworth Gmbh | METHOD AND DEVICE FOR COMBINING FLEECES OR FLORES FROM FIBERS, ESPECIALLY TEXTILE FIBERS |

| US5020198A (en) * | 1988-08-10 | 1991-06-04 | Filter Materials Ltd. | Crimped textile fibers and stuffer box apparatus and methods for crimping textile fibers |

| DE3832870A1 (en) * | 1988-09-28 | 1990-03-29 | Bayer Ag | (CONTINUOUS) MANUFACTURE OF ACRYLNITRILE THREADS AND FIBERS FROM RESIDUAL LOW-SOLVED SPINNING MATERIAL |

| DE4212590C2 (en) * | 1992-01-29 | 2001-01-04 | Bayer Ag | Method and device for producing high crimp intensities of filament cables according to the stuffer box crimping method |

| DE19538423C2 (en) * | 1995-10-16 | 1997-08-21 | Neumag Gmbh | Device for crimping synthetic bundles of threads or tapes |

| US6134758A (en) * | 1999-03-22 | 2000-10-24 | Wellman, Inc. | Method of producing improved crimped polyester fibers |

| US6572966B1 (en) | 1999-03-22 | 2003-06-03 | Wellman, Inc. | Polyester fibers having substantially uniform primary and secondary crimps |

| US6351877B1 (en) | 2000-05-31 | 2002-03-05 | Eastman Chemical Company | Synthetic fiber crimper, method of crimping and crimped fiber produced therefrom |

| FR2833974B1 (en) * | 2001-12-21 | 2004-02-13 | Superba Sa | METHOD AND DEVICE FOR CRIMPING YARN |

| US6718603B2 (en) | 2001-12-21 | 2004-04-13 | Superba (Sa) | Apparatus and method for producing frieze yarns |

| US7163159B2 (en) * | 2003-07-15 | 2007-01-16 | Siemens Vdo Automotive Corporation | Fuel injector including a compound angle orifice disc |

| EP1512779A1 (en) * | 2003-08-28 | 2005-03-09 | Power-heat-set GmbH | Device and process for treating an elongated medium |

| EP2098622B1 (en) | 2008-03-03 | 2011-03-23 | M.A.E. S.p.A. | Apparatus for crimping chemical-fibres filaments and control methods thereof |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR924751A (en) * | 1946-03-05 | 1947-08-14 | Crins Averseng Soc D | Corrugating machine for fibers of animal, vegetable or mineral origin |

| GB808518A (en) | 1955-11-04 | 1959-02-04 | American Cyanamid Co | Tow of polyacrylonitrile filamentary material and production thereof |

| US2862279A (en) * | 1956-04-10 | 1958-12-02 | Allied Chem | Tow crimping apparatus |

| US2917784A (en) * | 1957-06-05 | 1959-12-22 | Dow Chemical Co | Crimping fibers |

| DE1877098U (en) * | 1963-06-08 | 1963-08-08 | Neumuenster Masch App | COMPRESSION CURLING DEVICE. |

| US4016632A (en) * | 1963-07-31 | 1977-04-12 | Textured Yarn Co., Inc. | Strand treatment |

| DE1435438A1 (en) | 1964-01-24 | 1968-10-31 | Eastman Kodak Co | Method for introducing a continuous thread cable into a curling device and apparatus for carrying out the method |

| JPS46864Y1 (en) * | 1966-03-15 | 1971-01-13 | ||

| US3516241A (en) * | 1968-10-30 | 1970-06-23 | Asahi Chemical Ind | Process for the manufacture of crimped spun yarn |

| DE3225266A1 (en) | 1982-07-06 | 1984-01-12 | Bayer Ag, 5090 Leverkusen | CONTINUOUS DRY SPINNING PROCESS FOR ACRYLNITRILE THREADS AND FIBERS |

| DE3332387A1 (en) * | 1983-09-08 | 1985-03-21 | Neumünstersche Maschinen- und Apparatebau GmbH (Neumag), 2350 Neumünster | DIVING CHAMBER CRUSH DEVICE |

-

1986

- 1986-09-19 DE DE19863631905 patent/DE3631905A1/en not_active Withdrawn

-

1987

- 1987-09-07 EP EP87113030A patent/EP0268031B2/en not_active Expired - Lifetime

- 1987-09-07 ES ES87113030T patent/ES2030407T5/en not_active Expired - Lifetime

- 1987-09-07 DE DE8787113030T patent/DE3778491D1/en not_active Expired - Lifetime

- 1987-09-08 US US07/093,735 patent/US4854021A/en not_active Expired - Lifetime

- 1987-09-18 JP JP62232701A patent/JPS6392746A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| EP0268031A2 (en) | 1988-05-25 |

| EP0268031B1 (en) | 1992-04-22 |

| ES2030407T3 (en) | 1992-11-01 |

| US4854021A (en) | 1989-08-08 |

| DE3631905A1 (en) | 1988-03-31 |

| ES2030407T5 (en) | 1995-08-16 |

| EP0268031A3 (en) | 1990-01-31 |

| DE3778491D1 (en) | 1992-05-27 |

| JPS6392746A (en) | 1988-04-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0268031B2 (en) | Stuffer box and method for making crimped synthetic fibres | |

| DE69116913T2 (en) | Device for crimping fiber strands, which includes crimping chamber, crimping rollers and shaping rollers | |

| DE2948298C2 (en) | ||

| DE1760771A1 (en) | Synthetic frizzy filament and process for its manufacture | |

| DE2803904C2 (en) | Open-end spinning process and spinning device | |

| DE2036856A1 (en) | Method and apparatus for the manufacture of a textured thermoplastic see yarn with high nervousness | |

| DE69420578T2 (en) | DEVICE FOR CONTINUOUSLY FEEDING AN ARBITRAL TWISTED FIBER CABLE | |

| DE1435408A1 (en) | Method for curling strands of thread | |

| EP0271677A2 (en) | Carding machine for making a fibre fleece | |

| DE2628650C2 (en) | Process for the production of a self-twisted yarn | |

| DE2551128C2 (en) | Process for crimping a continuous thread and apparatus for carrying out the process | |

| DE3336584C2 (en) | ||

| DE69221421T2 (en) | WIRE DISPERSING DEVICE | |

| DE2504079C2 (en) | Process for the production of highly shrinkable, dry-spun acrylonitrile fibers or threads | |

| DE2053854C3 (en) | Card with fixed cover | |

| EP2064377B1 (en) | Method and apparatus for producing staple fibres from a crimped sliver | |

| DE2054510C3 (en) | Method and device for the production of non-woven thread structures | |

| DE2139264B2 (en) | Device for the continuous treatment of textile threads | |

| DE19519882A1 (en) | Method of treating a cable of synthetic filaments and method of producing cables of uniformly crimped fibers with a high initial modulus | |

| DE1660242C3 (en) | Method and device for converting strands of thread into spinnable staple fiber ribbons | |

| DE102020109066A1 (en) | Method and device for guiding and wetting a crimped fiber cable | |

| DE2211691C3 (en) | Device for the production of fleeces from filaments | |

| DE1912452A1 (en) | Fleece removal device | |

| DE2239458A1 (en) | Metal fibre material - for production of anti-static fabrics | |

| EP2398945B1 (en) | Method for producing multiple fiber strips in parallel and apparatus for executing said method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19870907 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 19910930 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 3778491 Country of ref document: DE Date of ref document: 19920527 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: NEUMAG - NEUMUENSTERISCHE MASCHINEN- UND ANLAGENBA Effective date: 19930116 |

|

| ITTA | It: last paid annual fee | ||

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19950315 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): DE ES FR GB IT |

|

| ITF | It: translation for a ep patent filed | ||

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) |

Effective date: 19950531 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Kind code of ref document: T5 Effective date: 19950816 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19950913 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960814 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960829 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960919 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970907 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19970908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19970930 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970907 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980603 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20001204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050907 |