EP0208247A1 - Air brushing apparatus - Google Patents

Air brushing apparatus Download PDFInfo

- Publication number

- EP0208247A1 EP0208247A1 EP19860108989 EP86108989A EP0208247A1 EP 0208247 A1 EP0208247 A1 EP 0208247A1 EP 19860108989 EP19860108989 EP 19860108989 EP 86108989 A EP86108989 A EP 86108989A EP 0208247 A1 EP0208247 A1 EP 0208247A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- gas

- gas flow

- valve

- section

- bomb

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/24—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device

- B05B7/2402—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device

- B05B7/2405—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device using an atomising fluid as carrying fluid for feeding, e.g. by suction or pressure, a carried liquid from the container to the nozzle

- B05B7/2416—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device using an atomising fluid as carrying fluid for feeding, e.g. by suction or pressure, a carried liquid from the container to the nozzle characterised by the means for producing or supplying the atomising fluid, e.g. air hoses, air pumps, gas containers, compressors, fans, ventilators, their drives

- B05B7/2421—Gas containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/24—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device

- B05B7/2402—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device

- B05B7/2459—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device a liquid being fed by capillarity from the container to the nozzle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B43—WRITING OR DRAWING IMPLEMENTS; BUREAU ACCESSORIES

- B43K—IMPLEMENTS FOR WRITING OR DRAWING

- B43K8/00—Pens with writing-points other than nibs or balls

- B43K8/006—Pens with writing-points other than nibs or balls using a spraying system, e.g. airbrushes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B44—DECORATIVE ARTS

- B44D—PAINTING OR ARTISTIC DRAWING, NOT OTHERWISE PROVIDED FOR; PRESERVING PAINTINGS; SURFACE TREATMENT TO OBTAIN SPECIAL ARTISTIC SURFACE EFFECTS OR FINISHES

- B44D3/00—Accessories or implements for use in connection with painting or artistic drawing, not otherwise provided for; Methods or devices for colour determination, selection, or synthesis, e.g. use of colour tables

- B44D3/22—Implements or apparatus for special techniques, e.g. for painting lines, for pouring varnish; Batik pencils

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D34/00—Containers or accessories specially adapted for handling liquid toiletry or cosmetic substances, e.g. perfumes

- A45D34/04—Appliances specially adapted for applying liquid, e.g. using roller or ball

Definitions

- This invention relates to an air brushing apparatus for spraying ink, paint or any other liquid for drawing a picture by use of high pressure gas to thereby perform brushing, and more particularly to a portable air brushing apparatus.

- the conventional air brushing apparatus using compressed air is of such an arrangement that air compressed by an air compressor is fed into a main body of brushing apparatus through an air hose and blown out of the forward end of a nozzle to spray ink or paint in a container.

- high pressure gas filled in a gas bomb is fed into the main body of brushing apparatus through an air hose and blown out of the forward end of the nozzle to spray ink or paint in the container.

- the air compressor and the gas bomb are provided separately of the nozzle portion for spraying compressed air or high pressure gas and the aforesaid compressed air or the like is delivered into the main body of air brushing apparatus to be blown out, whereby the apparatus is large-sized and it is difficult to use the apparatus in portable condition.

- the through-hole is formed in the seal plate of the high pressure gas bomb by the plug opening mechanism, to thereby open the plug.

- the high pressure gas flows out into the gas flow-out control section through the through-hole formed in this seal plate.

- the high pressure gas which has flowed out into the gas flow-out control section, is delivered into the gas pressure regulating mechanism and flows out into the nozzle section, while being regulated in gas pressure thereof.

- the high pressure gas is discharged from the forward end of the nozzle section.

- the liquid storage wherein ink or paint is stored is opposed to the forward end of the nozzle, whereby the liquid such as the ink or paint is sprayed from the liquid storing section.

- the gas pressure regulating mechanism interposed between the gas bomb and the nozzle section is provided with a valve for performing the shut-off the flow of gas from the gas bomb to the nozzle section and the regulation of gas pressure by its axial dispacement, and both the shut-off of the flow of gas to the nozzle section and the regulation of the gas pressure by the displacement of the valve are controlled by a push button, whereby the density of the liquid sprayed from the liquid storing member having the liquid storing section facing the forward end portion of the nozzle section is made variable, so that the workability can be improved, and an action of constant pressure applied to the downstream side of the gas pressure regulating mechanism can be avoided, thus enabling to render the apparatus light in weight.

- a further characteristic feature of the present invention resides in that the on-off condition of the gas flow path controlled by the valve mechanism can be reliably set and grasped from the outside by an on-off position holding mechanism for holding an on or off position of the valve mechanism, so that the operations of starting and stopping the brushing and the like due to the gas flow fed to the nozzle through the gas flow path can be-reliably carried out, and, even when the brushing is continuously performed for a relatively long period of time, the burden on a worker can be reduced and the workability can be improved because there is no need of continuously operating the gas flow-out path on-off operating section for controlling the valve mechanism.

- one embodiment of the air brushing apparatus is integrally assembled thereonto with: a gas flow-out path on-off operation section 5 for controlling the flow-out of high pressure C0 2 gas flowing out of a gas flow-out control section 3, to one end of which is detachably secured a bomb holder 2 housing therein a gas bomb 1 filled up with liquefied C0 2 ; a nozzle section 6 for blowing out C0 2 fed from the gas bomb 1; and a liquid storing member supporting section 8 for detachably supporting a liquid storing section for storing liquid such as ink or paint to be sprayed by C0 2 gas through this nozzle section 6.

- the gas flow-out control section 3, to one end of which the bomb holder 2 is detachably secured, includes, in its tubular main body 9 formed of molded synthetic resin:

- the plug opening mechanism 12 has a plug opening member 15 formed at one end thereof with a plug opening needle 14 to pierce the seal plate 10 sealing a through-hole formed at the forward end of the gas bomb 1 when the bomb holder 2 housing therein the gas bomb 1 is secured to the main body of control section 9.

- This plug opening member 15 is threadably coupled to one end of the main body of control section 9, with the plug opening needle 14 formed therein with a through-hole 14a tapered toward the forward end thereof, facing the mounted side of the bomb holder 2.

- the plug opening member 15 is formed therein with a valve seat coupling hole 15a communicated with the through-hole 14a of the plug opening member 14.

- valve seat coupling hole 15 a filter made of porous Cu alloy is provided at the inner side of this valve seat coupling hole 15a, an 0-ring 19 is interposed between a valve seat 18 slidably coupled thereinto with a gas pressure regulating pin 17 constituting a gas pressure regulating mechanism 13 and the valve seat coupling hole 15a, and the valve seat 18 is closely fitted into the valve seat coupling hole 15a to thereby prevent the gas leakage.

- an 0-ring 20 for the seat made of synthetic resin such as urethane, for guiding the slide of the gas pressure regulating pin 17 is coupled to an end portion of the valve seat coupling hole 15a on the outer side thereof.

- An end portion of the valve seat 18 is coupled to one side surface of a piston control plate 22 previously inserted and secured into the main body of control section 9 during its forming, for controlling the sliding position of a piston 21.

- the forward end face of the gas bomb 1 housed in the bomb holder 2 is abutted against the end face of the plug opening member 15 on the side where the plug opening needle 14 is formed and a packing 23 is secured therebetween so as to prevent the gas leakage through the through-hole 11 formed by the plug opening needle 14.

- This packing 23 is mounted to be supported by a packing lock nut 24 threadably coupled into one end of the main body of control section 9.

- Designated at 23a is an insertion hole for a jig to threadably couple the plug opening member 15 into the main body of control section 9.

- the gas pressure regulating mechanism 13 includes: a pressure regulating spring 25 for biasing the piston 21 secured thereto with the gas regulating pin 17 coupled into and sliding in the valve seat 18 against the piston control plate 22; and a coupling member 27 for a gas flow-out port, formed integrally with a gas flow-out pipe 26, and supporting this pressure regulating spring 25.

- a proximal end portion 17a of the gas pressure regulating pin 17 is coupled and brazed into a coupling recess formed on an end face a cup-shaped piston nut 29 threadably coupled into a coupling hole 28 formed on one end of the piston 21. Furthermore, a plurality of gas flow holes 30 are formed in the end face of the piston nut 29.

- the piston 21 inserts the gas pressure regulating pin 17 into the O-ring 20 for the seat through a through-hole 22a formed in the piston control plate 22 and couples the same into the valve seat 18, whereby a cylinder portion 9a formed in the main body of control section 9 is slidably coupled to the piston 21.

- a V-shaped packing 31 for the piston, for preventing the gas leakage is coupled onto the outer periphery of one end of the piston 21.

- the piston 21 is biased toward the piston control plate 22 by a coil-shaped pressure regulating spring 25 having a low biasing force rendered by pressure of gas discharged from the gas bomb 1.

- This pressure regulating spring 25 is urgingly supported by the coupling member 27 threadably coupled to the other end of the main body of control section 9.

- the coupling member 27 is threadably coupled to the other end of the main body of control section 9, with one end of the gas flow-out pipe 26 being coupled into a through-hole 33 formed in the piston 21. Additionally, a packing 34 for sealing is coupled to the forward end of the gas flow-out pipe 26. A lock nut 35 is coupled onto the outer periphery of the coupling member 27 so as to prevent a shift in position of the coupling member 27 relative to the main body of control section 9.

- a tubular outer casing 36 as being a grip portion is coupled onto the outer periphery of the main body of control section 9 provided with the plug opening mechanism 12 and the gas pressure regulating mechanism 13 as described above.

- a holder coupling portion 37 to which an open end of the bomb holder 2 is threadably coupled, is formed on one end of the main body of control section 9.

- the bomb holder 2 has a coupling portion 38 having a coupling value within which the seal plate 10 is pierced by the plug opening needle 14 of the gas bomb 1 housed in the bomb holder 2 when the bomb holder 2 is coupled to the holder coupling portion 37.

- a gas escaping slit 39 is formed on the peripheral surface at the side of the proximal end of the bomb holder 2 so as to prevent the bomb-holder 2 from being excessively filled up with high pressure gas.

- the gas flow-out path control section 5 for on-off controlling the blow-out of gas, which is discharged from the gas bomb 1 and flows into the main body of control section 9, through the nozzle section 6 is secured to the other end of the main body of control section 9.

- This gas flow-out path on-off operation section 5 includes: a coupling portion 41 coupled to a coupling recess 40 formed on the coupling member 27; and a main body of operation section 47 formed therein with a gas flow path 43 communicated with a gas flow-out port 42 provided at the other end of the gas flow-out pipe 26 provided in the coupling member 27 when this coupling portion 41 is coupled into the coupling recess 40 and further a coupling hole 46 communicated with this gas flow path 43 and coupled to an on-off valve mechanism 45.

- This main body of operation section 47 threadably couples the coupling portion 41 into the coupling recess 40 of the coupling member 27, with an 0-ring 49 for sealing being interposed therebetween, whereby the gas flow path 43 is communicated with the gas flow-out port 42, so that the main body of operation section 47 can be connected to the main body of control section 9.

- a needle valve having an operating pin 52 provided with a valve 51 secured into a tubular valve housing 50 by being biased by a plectrum, for covering an opening formed at the forward end of the valve housing 50.

- a push button 53 for urging an operating pin 52 of the valve mechanism 45 to on-off operate the valve mechanism 45 is slidably coupled to the top end portion of the valve coupling hole 46.

- This push button 53 is constructed such that a shaft portion 53a of the push button 53 is coupled thereonto with a packing 54 for preventing the gas leakage and inserted into the valve coupling hole 46, and a cap 55 coupled onto the top end portion of the main body of operation section 47 engages a flange portion 53b of the push button 53 to thereby lock the push button 53 against dislodging. Furthermore, a cap 57 coupled thereonto with an 0-ring 56 is coupled onto the bottom end portion of the valve coupling hole 46 so as to seal the vlave coupling hole 46.

- a nozzle 60 is coupled to the forward end of a nozzle housing 59, which is linearly movably provided with a nozzle opening valve regulating valve 58.

- This nozzle 60 is closely coupled to the forward end of the nozzle housing 59 through an 0-ring 61.

- the nozzle opening value regulating valve 58 is mounted into the nozzle housing 59, with a tapered forward end portion thereof projecting to the proximal end of the nozzle 60.

- this nozzle opening value regulating valve 58 is rotated by use of a driver or the like to be linearly moved relative to the nozzle 60, thereby adjusting the opening value of the nozzle 60.

- the nozzle section 6 is rotatably mounted such that a flange portion 64 provided on one end of a connecting pipe 63 extended from the nozzle housing 59 is engaged with an engageable portion 65 formed on one side surface of the main body of operation section 47.

- the nozzle section 6 and the gas flow-out path on-off operation section 5 are connected to each other through a joining pipe 66 made of a flexible material such as vinyl chloride.

- This joining pipe 66 is coupled at one end thereof with a joining hole 67 facing the top end of the valve mechanism 45 coupled into the valve coupling hole 46 of the main body of operation sectin 47,extended through a connecting pipe 63, and coupled at the other end thereof into a joining hole 68 communicated with the nozzle 60 formed in the nozzle housing 59.

- the nozzle section 6 is rotatably mounted to the gas flow-out path on-off operation section 5 and the flexible joining pipe 66 joins therebetween, so that the nozzle section 6 is variable in position within a range from a position shown in Fig. 3 to a position shown in Fig. 6.

- the position of the nozzle section 6 can be selected relative to the gas flow-out path on-off operation section 5.

- the gas flow-out path on-off operation section 5 can be operated by either index finger or thumb and be used by anyone of right-handed and left-handed persons.

- the liquid storing member supporting section 8 including a pair of curved and flexibly displaceable support arms 71 and 72 is provided at one side of the joining pipe 66 of the nozzle section 6.

- a so-called felt pen, etc. is used, in which, for example, aqueous ink is stored in a tubular container and a liquid storing section 74 consisting of felt, etc. for sucking ink by capillarity is provided at the forward end of the container.

- the liquid storing member 73 is coupled between the pair of support arms 71 and 72 and controlled in position by a ring 75 coupled to the liquid storing member 73 and the liquid (ink) storing section 74 is mounted, facing the forward end of the nozzle 60.

- any liquid such as paint or cosmetic liquid can be used if only the liquid can be sprayed.

- the bomb holder 2 is threadably coupled to the main body of control section 9, however, a mere coupling may be adopted.

- any gas may be used only if a predetermined pressure can be obtained by it.

- the gas bomb is integrally mounted to the gas flow-out control section secured thereto with the nozzle section, so that a small-sized air brushing apparatus can be provided.

- the air brushing apparatus is usable in portable condition and easily handled, so that one easily used even by an infant can be provided.

- Fig. 7 is a sectional view showing another embodiment of the air brushing apparatus according to the present invention.

- Fig. 8 is a side view thereof.

- a valve housing (gas pressure regulating mechanism) 102 and a filter 103 made of sintered metal are provided, all of which are fixed by a plug opening member (plug opening mechanism) 104 threadably coupled to the main body 101.

- a plug opening needle 105 having a sharply tapered forward end portion is projected from an end face of this plug opening member 104.

- a through-hole 106 is formed through the plug opening needle 105 in the axial direction thereof.

- a packing 107 surrounding the plug opening needle 105 is provided on an end face of the plug opening member 104 and fixed by a packing gland 108 threadably coupled to the main body 101.

- a bomb holder 109 is threadably coupled to the outer periphery of an end portion of the main body 101, a seal plate 111 of a gas bomb 110 filled up with liquefied C0 2 , for example, and held in the bomb holder 109 is closely attached to the packing 107, and plug opening of the seal plate 111 by the plug opening needle 105 can be performed.

- an axially movable valve ll2 is provided, one end of which is projected from an end face of the main body 101 through a through-hole 113 formed in the end face of the main body 101.

- the valve 112 is formed with a large diameter portion 114, a tapered portion 115 and a small diameter portion 116, which are arranged in the axial direction thereof. Further, between the valve housing 102 and the main body 101, a valve seat 0-ring 117 whose inner diameter is smaller than the large diameter portion 114 is provided at a position surrounding the valve body 112.

- valve seat 0-ring 117 and the outer peripheral portion of the large diameter portion 114 of the valve 112 are closely attached to each other due to an axial displacement of the valve 112 constantly biased to the left in Fig. 7 by a valve spring 118 provided in the valve housing 102, whereby the gas flowing through the through-hole 106 of the plug opening needle 105, the filter 103, further, a space formed between the valve housing 102 and the outer peripheral portion of the valve ll2 and flowing out of the through-hole 113 of the main body is shut off, and the valve ll2 is displaced in a direction of pushing the valve 112 into the valve housing 102 against the biasing force of the valve spring 118, whereby an orifice is formed between the tapered portion 115 and the valve seat 0-ring 117 and variable in sectional area as commensurate to the axial displacement of the valve 112, so that high pressure gas acting from the gas bomb 110 is reduced to a desirable value and flows out of the through-hole 113 of the main body 101.

- an 0-ring 104a is provided between the plug opening member 109 and the valve housing 102 so as to hold air tightness of the connecting portion between the valve housing 102 and the plug opening member 104, and an air escaping hole 101a is provided, which is communicated with a portion of the main body 101, where the valve housing 102 and the plug opening member 104 are housed, so that rise of internal pressure in the main body 101, caused by deteriorated O-ring 104a and valve seat 0-ring 117 is prevented, for example.

- the end portion of the main body 101, in which the through-hole 113 is formed, is inserted into a main body of operation section 119, and a diaphragm 120 made of a flexible material such as rubber and a diaphragm gland 121 for fixing the diaphragm 120 are provided between an end portion of the main body 101 and the main body of operation section 119.

- a large diameter piston 122 is axially movably provided, which is abutted against an end portion of the valve 112, said end portion being projected to the outside of the main body 101, an axial displacement of the large diameter piston 122 is imparted to the valve 112, and a fluid chamber A is defined by the diaphragm gland 121, the large diamter piston 122 and an end face portion of the main body 101, said fluid chamber A being communicated with the through-hole 113 of the main body 101.

- An O-ring 123 is provided between the outer peripheral portion of the main body 101 and the main body of operation section 119, whereby the fluid chamber A is held air tight.

- the main body 101 is fixed to the main body of operation section 119 by a spring pin 124 penetratingly provided in a direction perpendicular to the paper surface.

- the main body of operation section 119 is provided with a cylinder 125 at a predetermined angle to the axial direction, one end of the cylinder 125 is communicated with a fluid chamber B formed between the diaphragm 120 and the main body of operation section 119, and the other end thereof is inserted thereinto with a small diameter piston 127 formed integrally with a push button 126.

- the cylinder 125 and the fluid chamber B are filled up with silicone oil 128 as being incompressible fluid, whereby an axial displacement of the push button 126 is imparted to the large diameter piston 122 through silicone oil 128 and the diaphragm 120.

- An 0-ring 129 is coupled to the outer peripheral portion of the small diameter piston 127, whereby the cylinder 125 is held air tight.

- a push button spring 130 is provided, which biases the push button 126 to project to the outside of the main body of operation section 119, and the push button 126 is locked against dislodging from the main body of operation section l19 by a push button keeper 131.

- a fluid path 132 is formed on the side surface portion of the main body of operation section 119, whereby a nozzle (nozzle section) 133 is communicated with the fluid chamber A.

- a pen (liquid storing member) 135 is provided at a position where a pen point (liquid storing section) 134 faces the forward end portion of the nozzle 133, and detachably fixed by a pen guide (liquid storing member supporting section) 136, one end of which is connected to the main body of operation section 119.

- the push button 126 is in the released state, the valve 112 to be displaced by the push button 126 is projected out of the valve housing 102 by the biasing force of the valve spring 118, and the outer peripheral portion of the large diameter portion 114 of the valve 112 and the inner peripheral portion of the valve seat 0-ring 117 provided in the valve housing 102 are closely attached to each other, to thereby shut off the flow of gas in the valve housing 102.

- the orifice variable in sectional area as commensurate to a displacement value of the valve 112 is formed between the inner peripheral portion of the valve seat O-ring 117 and the tapered portion 115 of the valve 112, high pressure C0 2 gas acting on the interior of the valve housing 102 from the gas bomb 110 through the orifice is reduced to a desirable pressure commensurate to the sectional area of the orifice, and flows into the fluid chamber A.

- C0 2 gas which has flowed into the fluid chamber A, is passed through the fluid path 132 and blown out of the forward end portion of the nozzle 133 toward the pen point 134, whereby ink,paint or the like stored in the pen point 134 is sprayed in a density commensurate to a flow rate of gas blown out of the nozzle 133.

- the flow rate of gas blown out of the nozzle 133 i.e. the density of ink, paint or the like can be set to a desired value by regulating the displacement value of the push button 126, so that a shade of color can be adjusted without changing a distance to the sprayed surface, and the workability in a relatively small space can be improved.

- valve 112 when the operation of pressing the push button 126 is released, the valve 112 is projected in the direction of the fluid chamber A by the biasing force of the valve spring 118, and the inner peripheral portion of the valve seat O-ring 117 and the outer peripheral portion of the large diameter portion 114 of the valve 112 are closely attached to each other, whereby the flow of gas in the valve housing 102 is immediately shut off, so that pressurizing given to the fluid chamber A formed in the main body of operation section 119 can be released.

- pressurizing of the fluid chamber A formed in the main body of operation section 119 is performed only when necessary, and further, in the main body 101, high pressure gas from the gas bomb 110 acts only on the plug opening member 104 and the valve housing 102, whereby the main body 101 and the main body of operation section 119 can be formed of synthetic resin lighter in weight and more inexpensive than metal, so that the apparatus as a whole can be rendered light in weight and reduced in costs.

- imparting of the displacement from the push botton 126 to the valve 112 is performed through incompressible oil 128 sealed in the cylinder 125, whereby the displacement of the push button 126 is reliably imparted to the valve 112 and communication between the interior of the cylinder 125 and the fluid chamber B makes it possible to disirably set the position of the push button 126 relative to the valve 112 and the large diameter piston for displacing the valve 112, so that the degree of freedom in design and manufacture of the apparatus can be improved.

- the push button 126 is provided with the small diameter piston 127 and the displacement of the valve 112 is effected by the large diameter piston 122, acting of a relatively slight pressing force on the push button 126 makes it possible to render a high displacing force to the large diameter piston 122 for displacing the valve 112, so that a smooth displacement motion of the valve 112 by the push button 126 can be made without being affected by a resisting force and the like caused to the large diameter piston 122 due to the biasing force of the valve spring 118 and gas pressure acting on the fluid chamber A.

- Fig. 9 is a sectional view showing a further embodiment of the air brushing apparatus according to the present invention.

- Figs. 10 and 11 are enlarged sectional views showing the essential portions thereof.

- the gas flow-out control section 201 formed of a tubular member made of synthetic resin or the like is threadably coupled at one end thereof to a bomb holder 202, and assembled at the other end thereof with a liquid storing member supporting section 206 for detachably supporting a nozzle section 204 and a liquid storing member 205 facing the forward end portion of the nozzle section 204 through a gas flow-out path on-off operation section 203.

- a plug opening mechanism 208 projectingly provided at an end face thereof with a piercing needle 207 is threadably coupled into an end portion of the gas flow-out control section 201, to which the bomb holder 202 is threadably coupled, and a packing 209 surrounding the piercing needle 207 is fixed by a packing gland 210.

- a seal plate 211a of a gas bomb 211 held by the bomb holder 202 is closely attached to the packing 209, whereby plug opening in the seal plate 211a is effected by the piercing needle 207 and the plug opened portion is held air tight.

- a slit 202a Formed in one side surface of the bomb holder 202 is a slit 202a, through which is discharged to the outside the gas leaking into the bomb holder 202 until the seal plate 211a is closely attached to the packing 209 during cutting of the seal plate 2lla.

- a gas pressure regulating mechanism 216 including: a pin housing 213 mounted between a partition plate 212 engaged with the inner periphery of the gas flow-out control section 201 and the inner end portion of the plug opening mechanism 208; a gas pressure regulating pin 214 movable in a direction of an internal shaft of this pin housing 213; a pressure regulating piston 215, to which is engaged one end of the gas pressure regulating pin 214 through the partition plate 212 and constituting a fluid chamber A between the partition plate 212 and itself; and the like.

- the gas pressure regulating pin 214 has a large diameter portion 214b and a small diameter portion 214c, a tapered portion 214a being interposed therebetween, when displaced in the direction of the pressure regulating piston 215 and the inner peripheral portion of an 0-ring 217 held in the pin housing 213. And the large diameter portion 214b are closely attached to each other, a flow path starting from a through-hole 207a formed in the piercing needle 207, passing through the pin housing 213 and reaching the fluid chamber A is blocked.

- an orifice variable in sectional area as commensurate to a displacement of the gas pressure regulating pin 214 is formed between the tapered portion 214a, the small diameter portion 214C and the 0-ring 217, so that pressure of gas flowing into the fluid chamber A from the interior of the gas bomb 211 can be regulated.

- a filter 218 made of sintered metal is interposed between the plug opening mechanism 208 and the pin housing 213, so that dust contained in gas passing through a flow path starting from the through-hole 207a, passing through the pin housing 213 and reaching the fluid chamber A can be removed.

- a piston nut 219 having a recess 219a is threadably coupled to an end face of the pressure regulating piston 215 on the side of the fluid chamber A.

- One end of the gas pressure regulating pin 214 is engaged with the central portion of this piston nut 219, and a plurality of communicating holes 219b for communicating the fluid chamber A and the recess 219a are formed around the engaged portion of the gas pressure regulating pin 214.

- a pressure regulating spring 221 abutted at one end thereof against the pressure regulating piston 215 and abutted at the other end thereof with a pressure regulating plate 220, for supporting a biasing force generated in the pressure regulating piston 215 due to gas pressure acting on the fluid chamber A.

- Portions of the outer periphery of the pressure regulating plate 220 are projected outwardly through a plurality of slits 202 formed on the wall surface of the gas flow-out control section 201 and engaged with a pressure regulating screw 223 threadably coupled to the outer periphery of the gas flow-out control section 201.

- This pressure regulating screw 223 is suitably rotated from the outside in a desired direction to displace the pressure regulating plate 220 in the axial direction thereof, so that the biasing force acting on the pressure regulating piston 215 from the pressure regulating spring 221 can be regulated.

- a boss 224 is threadably coupled to the end portion of the gas flow-out control section 201, to which the gas flow-out path on-off operation section 203 is connected.

- a gas flow-out pipe 225 is projected which extends through the pressure regulating plate 220 and the pressure regulating piston 215 and is inserted into a recess 219a of the piston nut 219 threadably coupled to the pressure regulating piston 215. Gas flowing into the recess 219a through the plurality of communicating holes 219b is fed into the gas flow-out path on-off operation section 203.

- a gas flow path 226 extending in the axial direction is formed.

- a valve mechanism 227 is disposed in the axial direction.

- the gas flow path 226 is blocked.

- a cam (on-off position holding mechanism) 228 displaceable in a direction crossing the gas flow path 226 is provided.

- a spherical body (on-off position holding mechanism) 229 is interposed between this cam 228 and the pin 227a of the valve mechanism 227.

- a V-groove 228A and a flat portion 228b are formed on a side surface of this cam 228, on which the spherical body 229 slides.

- a displacement of the cam 228 in the direction crossing the gas flow path 226 is imparted as a displacement of the pin 227a of the valve mechanism 227 in the axial direction of the gas flow path 226, so that on-off operation of the valve mechanism 227 can be controlled.

- the side surface of the cam 228, where the V-groove 228a and the flat portion 228b are formed is reduced in length in a direction normal to the paper surface, so that the flow of gas in the gas flow path 226 crossing the cam 228 can be smoothly effected.

- One end of the cam 228 is projected toward a recess 231 of the gas flow-out path on-off operation section 203 and biased by a spring 230 to thereby be abutted against a portion of a rocking switch (on-off position holding mechanism) 233 to be rocked about a shaft 232 supported at opposite ends thereof by side wall portions of the recess 231.

- Elastically deformable engaging pieces 233a and 233b are provided at the opposite ends of this rocking switch 233, respectively, and engaged with cut-away portions 231a and 231b formed in the side wall portions of the recess 231 of the gas flow-out path on-off operation section 203, respectively, so that positions of opposite rocking ends of the rocking switch, i.e. an on or off state of the valve mechanism 227 driven by the rocking switch 233 through the cam 228 and the spherical body 229 can be stably held.

- a malfunction preventive cover 234 for closably shielding the rocking switch 233 located in the recess 231, so that malfunction caused by an accidental contact of the rocking switch 233 with a neighboring object can be prevented.

- the nozzle section 204 is rotatably connected to the outlet of the gas flow path 226 of the gas flow-out path on-off operation section 203 by engaging a flange portion 235a of a connecting pipe 235 with a side surface portion of the gas flow-out path on-off operation section 203.

- a nozzle 236 is mounted onto the forward end of the nozzle section 204, and a tapered nozzle opening value regulating valve 237 threadably coupled and inserted into the other end portion of the nozzle section 204 is inserted into the inner end portion of this nozzle 236, whereby an orifice 238 is formed.

- the upstream side of the orifice 238 is connected to the gas flow path 226 of the gas flow-out path on-off operation section 203 through a flexible gas pipe 239 provided in the connecting pipe 235.

- a cap 239' detachably mounted to the top end portion of the nozzle section 204 is removed and the nozzle opening value regulating valve 237 is suitably rotated to vary the sectional area of the orifice 238, so that the flow rate of gas passing through the gas flow-out path on-off operation section 203 and being blown out of the forward end portion of the nozzle 236 can be regulated.

- the liquid storing member 205 Detachably supported by the liquid storing member supporting section 206 formed integrally with the nozzle section 204 is the liquid storing member 205, which includes, for example, a tubular container 240 for storing aqueous ink or the like, felt 241 extended from the interior of the container 240 to the forward end portion thereof, etc.

- this felt 241 is caused to face the forward end portion of the nozzle section 204 and positioned in the flow of gas blown out of the nozzle 236, whereby ink or the like fed from the container to the felt at the forward end portion by capillarity is sprayed.

- the cam 228 is raised by the biasing force of the spring 230, whereby the spherical body 229 being in sliding contact with the cam 228 is coupled into the V-groove 228a, whereby the spherical body 229 is displaced in a direction of going away from the valve mechanism 227, so that the pin 227a of the valve mechanism 227, which is abutted against the spherical body 229 is projected to the outside, thereby closing the gas flow path 226.

- the displacement of the pressure regulating piston 215, i.e. the displacement of the gas pressure regulating pin 214 is stopped at a position where the biasing force by fluidal pressure acting on the fluid chamber A and the biasing force of the pressure regulating spring 221 are balanced, whereby gas leaving from the gas bomb 211, passing through the gas flow-out control section 201 and the fluid chamber A and flowing into the gas flow path 226 is regulated to a predetermined level of pressure.

- the pressure regulating plate 220 supporting one end of the pressure regulating spring 221 is displaced by suitably rotating the pressure regulating screw 223 in a desired direction, whereby the biasing force of the pressure regulating spring 221 to the pressure regulating piston 215 is varied, so that gas pressure fed to the gas flow path 226 in the preceding process can be regulated to a desired value.

- gas fed to the gas flow path 226, which has been regulated to the desired level of pressure, is passed through the valve mechanism 227 in the opened state, flows into the nozzle section 204 through the gas pipe 239, blown out of the forward end portion of the nozzle 236 at a flow rate commensurate to the sectional area of the orifice 238 regulated by the nozzle 236 and the rotating value of the nozzle opening value regulating valve 237, the forward end portion of which is inserted into the nozzle 236, and liquid such as ink impregnated in the felt 241 at the forward end portion of the liquid storing member 240 facing the forward end portion of the nozzle 236 is sprayed together with the flow of gas to the outside, so that the predetermined brushing operation can be performed.

- the rocking switch 233 capable of controlling the on-off operation of the valve mechanism 227 through the spherical body 229 and the cam 228 and stably holding the on or off position of the valve mechanism by use of the engaging pieces 233a and 233b is provided on the gas flow-out path on-off operation section 203 interposed between the gas flow-out control section 201 and the nozzle section 204, for controlling the supply and the shut-off of gas from the gas flow-out control section 201 to the nozzle section 204, whereby the on-off condition of the valve mechanism 227 can be accurately grasped from the outside and the on or off condition of the valve mechanism 227 can be stably held by only one pushing operation to the rocking switch 233, so that, for example, when a relatively large area is continuously brushed, necessity of continuously pushing the rocking switch 233 is eliminated and the worker is protected from fatigue, thus improving the workability of the brushing.

- the displacement of the cam 228 crossing the direction of the displacement of the pin 227a of the valve mechanism 227 is imparted to the pin 227a through the spherical body 229, whereby, for example, the biasing force acting on the pin 227a by gas pressure is not imparted to the rocking switch 233 through the spherical body 229 and the cam 228, so that the burden on the worker operating the rocking switch can be reduced.

- the provision of the malfunction preventive cover 234 for closably shielding the rocking switch 233 makes it possible to prevent a malfunction caused by an accidental contact of the rocking switch 233 with a neighboring object during storing the air brushing apparatus, for example.

- pressure of gas leaving from the gas bomb 211, passing through the gas flow-out path on-off operation section 203 and being fed to the nozzle section 204 is regulated to the desired value by the pressure regulating screw 223 threadably coupled to the outer periphery of the gas flow-out control section 201 from the outside in the gas pressure regulating mechanism 216, so that the particle diameter and the flow rate of the sprayed ink or the like can be varied in a wide variety by combining the above-described regulation with the regulation of the flow rate of gas blown out of the nozzle 236 by the nozzle opening value control valve 237 of the nozzle section 204, thus obtaining brushing results in a wide variety.

- Fig. 12 is a sectional view showing the essential portions of a still further embodiment of the air brushing apparatus according to the present invention.

- This embodiment is different from the preceding embodiment in that the displacement of the cam 228 for on-off operating the valve mechanism 227 through the spherical body 229 is performed by a sliding switch 240 rectilinearly movable in a direction crossing the direction of displacement of the cam 228.

- a portion of the sliding switch 240 which slides on the cam 228 is formed with stepped portions 240a and 240b, which are stepped in the direction of displacement of the cam 228, an engaging piece 241 projected through a wall surface of the gas flow-out path on-off operation section 203a is provided integrally with one end of the sliding switch 240, and further, a spring 243 is provided at the other end of the sliding switch 240.

- Recesses 241a of this engaging piece 241 is coupled to coupling pawls 242 provided on the outer surface of the gas flow-out path on-off operation section 203a, whereby, as shown in Fig. 12, the cam 228 is pushed down by the stepped portion 240a to hold the valve mechanism 227 in the opened state through the spherical body 229. Alternatively, when the sliding switch 240 is pushed to the left in Fig.

- the sliding switch 240 is moved by the biasing force of the spring 243, and the cam 228 is projected to a position of being abutted against the stepped portion 240b, whereby the spherical body 229 is coupled into the groove portion 228a of the cam 228 to close the valve mechanism 227, so that this state can be stably maintained.

- the linear displacement of the sliding switch 240 makes it possible to reliably grasp and set the on or off condition of the valve mechanism 227 through the cam 228 and the spherical body 229.

- the gas pressure regulating pin 214 is separated from the pressure regulating piston 215, a collar, not shown, is provided at the rear end of the large diameter portion 214b of the gas pressure regulating pin 214, and a spring, not shown, is interposed between the filter 218 and the collar.

- This embodiment can achieve the following outstanding functional effects.

Landscapes

- Filling Or Discharging Of Gas Storage Vessels (AREA)

Abstract

A portable air brushing apparatus wherein ink, paint or any other liquid is sprayed to perform brushing by use of high pressure gas blown out of a small-sized gas bomb (1). This air brushing apparatus includes: a gas flow-out control section (3) having a plug opening mechanism (12) for forming a through-hole (11) in a seal plate (10) of the small-sized gas bomb (1) to open a plug and a gas pressure regulating mechanism (13) for controlling pressure of high pressure gas blown out of the gas bomb (1); a a gas flow-out path on-off operation section (5) having a valve mechanism for on-off operating a gas flow path communicated with a gas flow-out port of the gas flow-out control section (3): a nozzle section (6) communicated with a gas flow-out path of the gas flow-out path on-off operation section (5); and a liquid storing member facing a liquid storing section to a gas blow-out port of the nozzle section (6) and detachably supported. The gas pressure regulating mechanism (13) performs the shut-off of the flow of the high pressure gas from the gas bomb (1) to the nozzle section (6) and the regulation of gas pressure by pressing a push button to displace a valve in the axial direction through liquid pressure. The gas flow-out path on-off operation section (5) has an on-off position holding mechanism including: a cam (228); a spherical body (229) for imparting a displacement of the cam (228) to the valve mechanism (227); and an engageable rocking (233) switch for displacing the cam (228).

Description

- This invention relates to an air brushing apparatus for spraying ink, paint or any other liquid for drawing a picture by use of high pressure gas to thereby perform brushing, and more particularly to a portable air brushing apparatus.

- There have heretofore been used air brushing apparatuses for spraying ink, paint or the like by use of compressed air, fleon or propane gas under high pressure, etc. to thereby draw a picture and so on.

- The conventional air brushing apparatus using compressed air is of such an arrangement that air compressed by an air compressor is fed into a main body of brushing apparatus through an air hose and blown out of the forward end of a nozzle to spray ink or paint in a container.

- Furthermore, also in the air brushing apparatuses using fleon, propane or any other gas under high pressure, high pressure gas filled in a gas bomb is fed into the main body of brushing apparatus through an air hose and blown out of the forward end of the nozzle to spray ink or paint in the container.

- In each of the above-described conventional air brushing apparatuses, the air compressor and the gas bomb are provided separately of the nozzle portion for spraying compressed air or high pressure gas and the aforesaid compressed air or the like is delivered into the main body of air brushing apparatus to be blown out, whereby the apparatus is large-sized and it is difficult to use the apparatus in portable condition.

- Since the air hose extends from the main body of air brushing apparatus, this air hose interferes with the operation, so that it is difficult to use the apparatus in a small space and fine brushing works cannot be performed.

- Further, in the air brushing apparatus using the air compressor, a driving source for this air compressor is needed, whereby it is difficult not only to use the apparatus outdoors but also to handle the components. Moreover, in the air brushing apparatus using the air compressor, noises from the air compressor is considerably high, so that the apparatus cannot be used in a very quite picture gallery and the like.

- It is an object of the present invention to provide an air brushing apparatus usable in portable condition and easily usable even by an infant and the like because of easy handling.

- It is another object of the present invention to provide an air brushing apparatus wherein fine works and use in a small space are made possible, so that high value of utility can be achieved.

- It is a further object of the present invention to provide air brushing apparatus wherein the workability is improved and the weight of the apparatus is rendered light.

- It is a still further object of the present invention to provide an air brushing apparatus which can be reliably controlled and the workability is improved.

- It is a yet further object of the present invention to provide an air brushing apparatus wherein malfunction can be avoided.

- A characteristic feature of the present invention resides in that an air brushing apparatus includes:

- a gas flow-out control section provided in a tubular member thereof, to one end of which a bomb holder housing therein a gas bomb is connected, with a plug opening mechanism for forming a through-hole in a seal plate of the gas bomb to open a plug of the gas bomb and a gas pressure regulating mechanism for controlling pressure of gas discharged from the gas bomb through the plug opening mechanism;

- a gas flow-out path on-off operation section having a gas flow path communicated with a gas flow-out port of this gas flow-out control section, for on-off operating this gas flow path;

- a nozzle section mounted to be communicated with a gas flow-out path of this gas flow-out path on-off operation section; and

- a liquid storing member supporting section for detachably supporting a liquid storing member, said liquid storing member having a liquid storing section facing a gas discharge port disposed at the forward end of this nozzle section.

- According to the present invention, when the bomb holder housing therein the high pressure gas bomb is secured to the gas flow-out control section provided thereon with the plug opening mechanism, the through-hole is formed in the seal plate of the high pressure gas bomb by the plug opening mechanism, to thereby open the plug. The high pressure gas flows out into the gas flow-out control section through the through-hole formed in this seal plate. The high pressure gas, which has flowed out into the gas flow-out control section, is delivered into the gas pressure regulating mechanism and flows out into the nozzle section, while being regulated in gas pressure thereof. When the gas blow-out path on-off operation section provided in the intermediate portion of the gas flow path for communicating the gas pressure regulating mechanism with the nozzle portion is on-operated, the high pressure gas is discharged from the forward end of the nozzle section. When the high pressure gas is discharged, the liquid storage wherein ink or paint is stored is opposed to the forward end of the nozzle, whereby the liquid such as the ink or paint is sprayed from the liquid storing section.

- Another characteristic feature of the present invention resides in that the gas pressure regulating mechanism interposed between the gas bomb and the nozzle section is provided with a valve for performing the shut-off the flow of gas from the gas bomb to the nozzle section and the regulation of gas pressure by its axial dispacement, and both the shut-off of the flow of gas to the nozzle section and the regulation of the gas pressure by the displacement of the valve are controlled by a push button, whereby the density of the liquid sprayed from the liquid storing member having the liquid storing section facing the forward end portion of the nozzle section is made variable, so that the workability can be improved, and an action of constant pressure applied to the downstream side of the gas pressure regulating mechanism can be avoided, thus enabling to render the apparatus light in weight.

- A further characteristic feature of the present invention resides in that the on-off condition of the gas flow path controlled by the valve mechanism can be reliably set and grasped from the outside by an on-off position holding mechanism for holding an on or off position of the valve mechanism, so that the operations of starting and stopping the brushing and the like due to the gas flow fed to the nozzle through the gas flow path can be-reliably carried out, and, even when the brushing is continuously performed for a relatively long period of time, the burden on a worker can be reduced and the workability can be improved because there is no need of continuously operating the gas flow-out path on-off operating section for controlling the valve mechanism.

- Other objects and advantages of the present invention will become apparent from the following detailed description taken in conjunction with preferred embodiments shown in the accompanying drawings, in which:

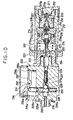

- Fig. 1 is a longitudinal sectional view showing an embodiment of the air brushing apparatus according to the present invention;

- Fig. 2 is a side view thereof;

- Fig. 3 is a front view thereof;

- Fig. 4 is a longitudinal sectional view showing the essential portions of the state of gas flow-in;

- Fig. 5 is a longitudinal sectional view showing the essential portions of the stopped state of gas flow-in;

- Fig. 6 is a front view showing the state of rotating operation of the nozzle section;

- Fig. 7 is a sectional view showing another embodiment of the air brushing apparatus according to the present invention;

- Fig. 8 is a side view thereof;

- Fig. 9 is a sectional view showing a further embodiment of the air brushing apparatus according to the present invention;

- Figs. 10 and 11 are enlarged sectional views showing the essential portions thereof; and

- Fig. 12 is an enlarged sectional view showing the essential portions of a still further embodiment of the air brushing apparatus according to the present invention.

- As shown in Figs. 1 and 2, for example, one embodiment of the air brushing apparatus according to the present invention is integrally assembled thereonto with: a gas flow-out path on-off

operation section 5 for controlling the flow-out of high pressure C02 gas flowing out of a gas flow-outcontrol section 3, to one end of which is detachably secured abomb holder 2 housing therein a gas bomb 1 filled up with liquefied C02; anozzle section 6 for blowing out C02 fed from the gas bomb 1; and a liquid storingmember supporting section 8 for detachably supporting a liquid storing section for storing liquid such as ink or paint to be sprayed by C02 gas through thisnozzle section 6. - The gas flow-out

control section 3, to one end of which thebomb holder 2 is detachably secured, includes, in its tubularmain body 9 formed of molded synthetic resin: - a

plug opening mechanism 12 having a through-hole 11 formed in aseal plate 10 of the gas bomb 1 housed in and secured to thegas bomb holder 2, for opening a plug of the gas bomb 1; and a gaspressure regulating mechanism 13 for controlling high pressure C02 gas discharged from the gas bomb 1 through thisplug opening mechanism 12. - The

plug opening mechanism 12 has aplug opening member 15 formed at one end thereof with aplug opening needle 14 to pierce theseal plate 10 sealing a through-hole formed at the forward end of the gas bomb 1 when thebomb holder 2 housing therein the gas bomb 1 is secured to the main body ofcontrol section 9. Thisplug opening member 15 is threadably coupled to one end of the main body ofcontrol section 9, with theplug opening needle 14 formed therein with a through-hole 14a tapered toward the forward end thereof, facing the mounted side of thebomb holder 2. Theplug opening member 15 is formed therein with a valveseat coupling hole 15a communicated with the through-hole 14a of theplug opening member 14. In this valveseat coupling hole 15, a filter made of porous Cu alloy is provided at the inner side of this valveseat coupling hole 15a, an 0-ring 19 is interposed between avalve seat 18 slidably coupled thereinto with a gaspressure regulating pin 17 constituting a gaspressure regulating mechanism 13 and the valveseat coupling hole 15a, and thevalve seat 18 is closely fitted into the valveseat coupling hole 15a to thereby prevent the gas leakage. Furthermore, an 0-ring 20 for the seat, made of synthetic resin such as urethane, for guiding the slide of the gaspressure regulating pin 17 is coupled to an end portion of the valveseat coupling hole 15a on the outer side thereof. An end portion of thevalve seat 18 is coupled to one side surface of apiston control plate 22 previously inserted and secured into the main body ofcontrol section 9 during its forming, for controlling the sliding position of apiston 21. - Further, the forward end face of the gas bomb 1 housed in the

bomb holder 2 is abutted against the end face of theplug opening member 15 on the side where theplug opening needle 14 is formed and apacking 23 is secured therebetween so as to prevent the gas leakage through the through-hole 11 formed by theplug opening needle 14. Thispacking 23 is mounted to be supported by apacking lock nut 24 threadably coupled into one end of the main body ofcontrol section 9. Designated at 23a is an insertion hole for a jig to threadably couple theplug opening member 15 into the main body ofcontrol section 9. - Furthermore, the gas

pressure regulating mechanism 13 includes: apressure regulating spring 25 for biasing thepiston 21 secured thereto with the gas regulatingpin 17 coupled into and sliding in thevalve seat 18 against thepiston control plate 22; and acoupling member 27 for a gas flow-out port, formed integrally with a gas flow-outpipe 26, and supporting thispressure regulating spring 25. - A

proximal end portion 17a of the gaspressure regulating pin 17 is coupled and brazed into a coupling recess formed on an end face a cup-shaped piston nut 29 threadably coupled into acoupling hole 28 formed on one end of thepiston 21. Furthermore, a plurality ofgas flow holes 30 are formed in the end face of thepiston nut 29. Thepiston 21 inserts the gaspressure regulating pin 17 into the O-ring 20 for the seat through a through-hole 22a formed in thepiston control plate 22 and couples the same into thevalve seat 18, whereby acylinder portion 9a formed in the main body ofcontrol section 9 is slidably coupled to thepiston 21. - Additionally, a V-

shaped packing 31 for the piston, for preventing the gas leakage is coupled onto the outer periphery of one end of thepiston 21. Further, thepiston 21 is biased toward thepiston control plate 22 by a coil-shapedpressure regulating spring 25 having a low biasing force rendered by pressure of gas discharged from the gas bomb 1. Thispressure regulating spring 25 is urgingly supported by thecoupling member 27 threadably coupled to the other end of the main body ofcontrol section 9. When gas discharged from the gas bomb 1 and stored in thecylinder portion 9a of the main body ofcontrol section 9 is used to lower the pressure in thecylinder portion 9a, thepiston 21 is urged against thepiston control plate 22 by thepressure regulating spring 25. When thepiston 21 is urged, asmall diameter portion 17a at the proximal end of the gaspressure regulating pin 17 reaches the O-ring 20 portion for the seat as shown in Fig. 4, whereby the sealed state between this O-ring 20 and the gaspressure regulating pin 17 is released, so that gas flows into thecylinder portion 9a. Furthermore, when gas flows into thecylinder portion 9a to raise gas pressure, thepiston 21 is caused to slide toward thecoupling member 27 against the biasing force of thepressure regulating spring 25 due to this gas pressure. When thepiston 21 is caused to slide as described above, alarge diameter portion 17b of the gaspressure regulating pin 17 reaches the 0-ring 20 portion for the seat to thereby seal the gas flow-out as shown in Fig. 5. The above-described sliding operation of thepiston 21 is repeated, whereby the gas pressure in thecylinder portion 9a is held at a predetermined value. - Furthermore, the

coupling member 27 is threadably coupled to the other end of the main body ofcontrol section 9, with one end of the gas flow-outpipe 26 being coupled into a through-hole 33 formed in thepiston 21. Additionally, a packing 34 for sealing is coupled to the forward end of the gas flow-outpipe 26. Alock nut 35 is coupled onto the outer periphery of thecoupling member 27 so as to prevent a shift in position of thecoupling member 27 relative to the main body ofcontrol section 9. - A tubular

outer casing 36 as being a grip portion is coupled onto the outer periphery of the main body ofcontrol section 9 provided with theplug opening mechanism 12 and the gaspressure regulating mechanism 13 as described above. - Furthermore, a

holder coupling portion 37, to which an open end of thebomb holder 2 is threadably coupled, is formed on one end of the main body ofcontrol section 9. Thebomb holder 2 has acoupling portion 38 having a coupling value within which theseal plate 10 is pierced by theplug opening needle 14 of the gas bomb 1 housed in thebomb holder 2 when thebomb holder 2 is coupled to theholder coupling portion 37. Agas escaping slit 39 is formed on the peripheral surface at the side of the proximal end of thebomb holder 2 so as to prevent the bomb-holder 2 from being excessively filled up with high pressure gas. - The gas flow-out path control

section 5 for on-off controlling the blow-out of gas, which is discharged from the gas bomb 1 and flows into the main body ofcontrol section 9, through thenozzle section 6 is secured to the other end of the main body ofcontrol section 9. This gas flow-out path on-offoperation section 5 includes: acoupling portion 41 coupled to acoupling recess 40 formed on thecoupling member 27; and a main body ofoperation section 47 formed therein with agas flow path 43 communicated with a gas flow-out port 42 provided at the other end of the gas flow-outpipe 26 provided in thecoupling member 27 when thiscoupling portion 41 is coupled into thecoupling recess 40 and further acoupling hole 46 communicated with thisgas flow path 43 and coupled to an on-offvalve mechanism 45. - This main body of

operation section 47 threadably couples thecoupling portion 41 into thecoupling recess 40 of thecoupling member 27, with an 0-ring 49 for sealing being interposed therebetween, whereby thegas flow path 43 is communicated with the gas flow-out port 42, so that the main body ofoperation section 47 can be connected to the main body ofcontrol section 9. - In the on-off

valve mechanism 45 coupled into thevalve coupling hole 46 of the main body ofoperation section 47, there is used a needle valve having an operatingpin 52 provided with avalve 51 secured into atubular valve housing 50 by being biased by a plectrum, for covering an opening formed at the forward end of thevalve housing 50. Apush button 53 for urging anoperating pin 52 of thevalve mechanism 45 to on-off operate thevalve mechanism 45 is slidably coupled to the top end portion of thevalve coupling hole 46. Thispush button 53 is constructed such that ashaft portion 53a of thepush button 53 is coupled thereonto with a packing 54 for preventing the gas leakage and inserted into thevalve coupling hole 46, and acap 55 coupled onto the top end portion of the main body ofoperation section 47 engages aflange portion 53b of thepush button 53 to thereby lock thepush button 53 against dislodging. Furthermore, acap 57 coupled thereonto with an 0-ring 56 is coupled onto the bottom end portion of thevalve coupling hole 46 so as to seal thevlave coupling hole 46. - Secured to the gas flow-out path on-off

operation section 5 is thenozzle section 6. In thisnozzle section 6, anozzle 60 is coupled to the forward end of anozzle housing 59, which is linearly movably provided with a nozzle openingvalve regulating valve 58. Thisnozzle 60 is closely coupled to the forward end of thenozzle housing 59 through an 0-ring 61. The nozzle openingvalue regulating valve 58 is mounted into thenozzle housing 59, with a tapered forward end portion thereof projecting to the proximal end of thenozzle 60. After acap 62 coupled to the top end of thenozzle housing 59 is removed therefrom, this nozzle openingvalue regulating valve 58 is rotated by use of a driver or the like to be linearly moved relative to thenozzle 60, thereby adjusting the opening value of thenozzle 60. - The

nozzle section 6 is rotatably mounted such that aflange portion 64 provided on one end of a connectingpipe 63 extended from thenozzle housing 59 is engaged with anengageable portion 65 formed on one side surface of the main body ofoperation section 47. - The

nozzle section 6 and the gas flow-out path on-offoperation section 5 are connected to each other through a joiningpipe 66 made of a flexible material such as vinyl chloride. This joiningpipe 66 is coupled at one end thereof with a joininghole 67 facing the top end of thevalve mechanism 45 coupled into thevalve coupling hole 46 of the main body ofoperation sectin 47,extended through a connectingpipe 63, and coupled at the other end thereof into a joining hole 68 communicated with thenozzle 60 formed in thenozzle housing 59. - As described above, the

nozzle section 6 is rotatably mounted to the gas flow-out path on-offoperation section 5 and the flexible joiningpipe 66 joins therebetween, so that thenozzle section 6 is variable in position within a range from a position shown in Fig. 3 to a position shown in Fig. 6. As a consequence, the position of thenozzle section 6 can be selected relative to the gas flow-out path on-offoperation section 5. According to the selection of a user, the gas flow-out path on-offoperation section 5 can be operated by either index finger or thumb and be used by anyone of right-handed and left-handed persons. - The liquid storing

member supporting section 8 including a pair of curved and flexiblydisplaceable support arms pipe 66 of thenozzle section 6. As aliquid storing member 73 mounted on this liquid storingmember supporting section 8, a so-called felt pen, etc. is used, in which, for example, aqueous ink is stored in a tubular container and aliquid storing section 74 consisting of felt, etc. for sucking ink by capillarity is provided at the forward end of the container. Theliquid storing member 73 is coupled between the pair ofsupport arms ring 75 coupled to theliquid storing member 73 and the liquid (ink)storing section 74 is mounted, facing the forward end of thenozzle 60. - The operation of the air brushing apparatus constructed as above will now be described. When the

bomb holder 2 housing therein the gas bomb 1 is coupled to theholder coupling section 37 of the gas flow-outcontrol section 3, the through-hole 11 is formed in theseal plate 10 of the gas bomb 1 by theplug opening needle 14 of theplug opening mechanism 12, whereby the plug of the gas bomb 1 is opened. When the plug of the gas bomb 1 is opened, liquefied C02 in the gas bomb 1, while being evaporated, flows out into the gaspressure regulating mechanism 13 through theplug opening mechanism 12. Here, when thepush button 53 of the gas flow-out path on-offoperation section 5 is pressed to release thevalve mechanism 45, C02 gas is blown out of the forward end of thenozzle 60 of thenozzle section 6 to thereby spray ink stored in theliquid storing section 74. - Additionally, as the liquid stored in the

liquid storing section 74 for spraying, in addition to ink described above, any liquid such as paint or cosmetic liquid can be used if only the liquid can be sprayed. - Furthermore, in the above embodiment, the

bomb holder 2 is threadably coupled to the main body ofcontrol section 9, however, a mere coupling may be adopted. - Further, as the gas filled in the gas bomb 1, in addition to C02 gas, any gas may be used only if a predetermined pressure can be obtained by it.

- According to the present invention, as described above, as the means for spraying ink, paint or the like, C02 gas or the like filled in the gas bomb is used and the gas bomb is integrally mounted to the gas flow-out control section secured thereto with the nozzle section, so that a small-sized air brushing apparatus can be provided.

- As a consequence, the air brushing apparatus is usable in portable condition and easily handled, so that one easily used even by an infant can be provided.

- Further, necessity for air supplying hose and the like as in the conventional air brushing apparatuses is eliminated, so that fine picture drawing works can be easily performed and the use in a small space is made possible, thereby enabling to provide the air brushing apparatus having a high value of utility.

- Fig. 7 is a sectional view showing another embodiment of the air brushing apparatus according to the present invention. Fig. 8 is a side view thereof.

- In a main body (tubular member) 101, a valve housing (gas pressure regulating mechanism) 102 and a

filter 103 made of sintered metal are provided, all of which are fixed by a plug opening member (plug opening mechanism) 104 threadably coupled to themain body 101. - A

plug opening needle 105 having a sharply tapered forward end portion is projected from an end face of thisplug opening member 104. A through-hole 106 is formed through theplug opening needle 105 in the axial direction thereof. - Further, a packing 107 surrounding the

plug opening needle 105 is provided on an end face of theplug opening member 104 and fixed by apacking gland 108 threadably coupled to themain body 101. - A

bomb holder 109 is threadably coupled to the outer periphery of an end portion of themain body 101, aseal plate 111 of agas bomb 110 filled up with liquefied C02, for example, and held in thebomb holder 109 is closely attached to the packing 107, and plug opening of theseal plate 111 by theplug opening needle 105 can be performed. - On the other hand, in the

valve housing 102, an axially movable valve ll2 is provided, one end of which is projected from an end face of themain body 101 through a through-hole 113 formed in the end face of themain body 101. - In this case, the valve 112 is formed with a

large diameter portion 114, a taperedportion 115 and asmall diameter portion 116, which are arranged in the axial direction thereof. Further, between thevalve housing 102 and themain body 101, a valve seat 0-ring 117 whose inner diameter is smaller than thelarge diameter portion 114 is provided at a position surrounding the valve body 112. - The inner peripheral portion of the valve seat 0-ring 117 and the outer peripheral portion of the

large diameter portion 114 of the valve 112 are closely attached to each other due to an axial displacement of the valve 112 constantly biased to the left in Fig. 7 by avalve spring 118 provided in thevalve housing 102, whereby the gas flowing through the through-hole 106 of theplug opening needle 105, thefilter 103, further, a space formed between thevalve housing 102 and the outer peripheral portion of the valve ll2 and flowing out of the through-hole 113 of the main body is shut off, and the valve ll2 is displaced in a direction of pushing the valve 112 into thevalve housing 102 against the biasing force of thevalve spring 118, whereby an orifice is formed between thetapered portion 115 and the valve seat 0-ring 117 and variable in sectional area as commensurate to the axial displacement of the valve 112, so that high pressure gas acting from thegas bomb 110 is reduced to a desirable value and flows out of the through-hole 113 of themain body 101. - Furthermore, an 0-

ring 104a is provided between theplug opening member 109 and thevalve housing 102 so as to hold air tightness of the connecting portion between thevalve housing 102 and theplug opening member 104, and anair escaping hole 101a is provided, which is communicated with a portion of themain body 101, where thevalve housing 102 and theplug opening member 104 are housed, so that rise of internal pressure in themain body 101, caused by deteriorated O-ring 104a and valve seat 0-ring 117 is prevented, for example. - Further, the end portion of the

main body 101, in which the through-hole 113 is formed, is inserted into a main body ofoperation section 119, and adiaphragm 120 made of a flexible material such as rubber and adiaphragm gland 121 for fixing thediaphragm 120 are provided between an end portion of themain body 101 and the main body ofoperation section 119. - In the

diaphragm gland 121, alarge diameter piston 122 is axially movably provided, which is abutted against an end portion of the valve 112, said end portion being projected to the outside of themain body 101, an axial displacement of thelarge diameter piston 122 is imparted to the valve 112, and a fluid chamber A is defined by thediaphragm gland 121, thelarge diamter piston 122 and an end face portion of themain body 101, said fluid chamber A being communicated with the through-hole 113 of themain body 101. - An O-

ring 123 is provided between the outer peripheral portion of themain body 101 and the main body ofoperation section 119, whereby the fluid chamber A is held air tight. Themain body 101 is fixed to the main body ofoperation section 119 by aspring pin 124 penetratingly provided in a direction perpendicular to the paper surface. - Further, the main body of

operation section 119 is provided with acylinder 125 at a predetermined angle to the axial direction, one end of thecylinder 125 is communicated with a fluid chamber B formed between thediaphragm 120 and the main body ofoperation section 119, and the other end thereof is inserted thereinto with asmall diameter piston 127 formed integrally with apush button 126. - The

cylinder 125 and the fluid chamber B are filled up with silicone oil 128 as being incompressible fluid, whereby an axial displacement of thepush button 126 is imparted to thelarge diameter piston 122 through silicone oil 128 and thediaphragm 120. - An 0-

ring 129 is coupled to the outer peripheral portion of thesmall diameter piston 127, whereby thecylinder 125 is held air tight. - Furthermore, between the

push button 126 and the main body ofoperation section 119, apush button spring 130 is provided, which biases thepush button 126 to project to the outside of the main body ofoperation section 119, and thepush button 126 is locked against dislodging from the main body of operation section l19 by apush button keeper 131. - Further, a

fluid path 132 is formed on the side surface portion of the main body ofoperation section 119, whereby a nozzle (nozzle section) 133 is communicated with the fluid chamber A. - In the proximity of the

nozzle 133, a pen (liquid storing member) 135 is provided at a position where a pen point (liquid storing section) 134 faces the forward end portion of thenozzle 133, and detachably fixed by a pen guide (liquid storing member supporting section) 136, one end of which is connected to the main body ofoperation section 119. - The action of this embodiment will hereunder be described.

- First, the

push button 126 is in the released state, the valve 112 to be displaced by thepush button 126 is projected out of thevalve housing 102 by the biasing force of thevalve spring 118, and the outer peripheral portion of thelarge diameter portion 114 of the valve 112 and the inner peripheral portion of the valve seat 0-ring 117 provided in thevalve housing 102 are closely attached to each other, to thereby shut off the flow of gas in thevalve housing 102. - Subsequently, when the

bomb holder 109 is threadably coupled to themain body 101 and theseal plate 111 of thegas bomb 110 housed in thebomb holder 109 is pierced by theplug opening needle 105, theseal plate 111 is closely attached to the packing 107 and high pressure C02 gas stored in thegas bomb 110 flows into thevalve housing 102 through the through-hole 106 of theplug opening needle 105 and thefilter 103. - Then, when the worker or the like presses the

pushbutton 126 into the main body ofoperation section 119, a displacement of thepush button 126 is imparted to the valve 112 through oil 128 sealed in thecylinder 125 and the fluid chamber B, the diaphragm l20 and further thelarge diameter piston 122. With this operation, the valve 112 is displaced in a direction, in which the valve 112 is pushed into thevalve housing 102, whereby the blocked state brought about by the outer periphery of the large diameter portion of the valve l12 and the valve seat O-ring 117 is released. Then, the orifice variable in sectional area as commensurate to a displacement value of the valve 112 is formed between the inner peripheral portion of the valve seat O-ring 117 and the taperedportion 115 of the valve 112, high pressure C02 gas acting on the interior of thevalve housing 102 from thegas bomb 110 through the orifice is reduced to a desirable pressure commensurate to the sectional area of the orifice, and flows into the fluid chamber A. - Further, C02 gas, which has flowed into the fluid chamber A, is passed through the

fluid path 132 and blown out of the forward end portion of thenozzle 133 toward thepen point 134, whereby ink,paint or the like stored in thepen point 134 is sprayed in a density commensurate to a flow rate of gas blown out of thenozzle 133. - As described above, the flow rate of gas blown out of the

nozzle 133, i.e. the density of ink, paint or the like can be set to a desired value by regulating the displacement value of thepush button 126, so that a shade of color can be adjusted without changing a distance to the sprayed surface, and the workability in a relatively small space can be improved. - Further, when the operation of pressing the