EP0149386B1 - Urgent-venting device for pneumatic actuators - Google Patents

Urgent-venting device for pneumatic actuators Download PDFInfo

- Publication number

- EP0149386B1 EP0149386B1 EP84402581A EP84402581A EP0149386B1 EP 0149386 B1 EP0149386 B1 EP 0149386B1 EP 84402581 A EP84402581 A EP 84402581A EP 84402581 A EP84402581 A EP 84402581A EP 0149386 B1 EP0149386 B1 EP 0149386B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pneumatic

- fluid

- bolt

- orifice

- drain device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000013022 venting Methods 0.000 title description 2

- 239000012530 fluid Substances 0.000 claims description 31

- 238000009434 installation Methods 0.000 claims description 13

- 238000010926 purge Methods 0.000 description 33

- 238000006073 displacement reaction Methods 0.000 description 4

- 235000021183 entrée Nutrition 0.000 description 3

- 230000006870 function Effects 0.000 description 3

- 229920001971 elastomer Polymers 0.000 description 2

- 239000000806 elastomer Substances 0.000 description 2

- 210000000056 organ Anatomy 0.000 description 2

- 238000012795 verification Methods 0.000 description 2

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000008034 disappearance Effects 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 229920002457 flexible plastic Polymers 0.000 description 1

- 230000008571 general function Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/20—Other details, e.g. assembly with regulating devices

- F15B15/202—Externally-operated valves mounted in or on the actuator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/08—Characterised by the construction of the motor unit

- F15B15/14—Characterised by the construction of the motor unit of the straight-cylinder type

- F15B15/1423—Component parts; Constructional details

- F15B15/1433—End caps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B15/00—Fluid-actuated devices for displacing a member from one position to another; Gearing associated therewith

- F15B15/08—Characterised by the construction of the motor unit

- F15B15/14—Characterised by the construction of the motor unit of the straight-cylinder type

- F15B15/149—Fluid interconnections, e.g. fluid connectors, passages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B20/00—Safety arrangements for fluid actuator systems; Applications of safety devices in fluid actuator systems; Emergency measures for fluid actuator systems

- F15B20/004—Fluid pressure supply failure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B21/00—Common features of fluid actuator systems; Fluid-pressure actuator systems or details thereof, not covered by any other group of this subclass

- F15B21/008—Reduction of noise or vibration

Definitions

- Such devices can be used in all pneumatic installations, either to stop the displacement of the rods of jacks, for example when a danger appears, or to make possible manual actuation of the rod of this jack, in order execute a verification or adjustment operation.

- a cylinder can only be stopped and placed in an indifferent state if the pressures exerted on the two faces of its piston disappear after having decreased simultaneously.

- a 3/2 modular pneumatic disconnector can be used to operate the venting of a pressure supply line serving a multiplicity of distributors, each associated with a respective jack; such a disconnector, which simultaneously operates the interruption of the arrival of the pressurized fluid from the source in the general line and connects the latter to the atmosphere, is always placed at the head of this line, so that one must take into account the purge time from the line lengths, distributors and flow limiters mentioned above.

- the invention therefore proposes to provide an inexpensive and space-saving simple purge device for an actuator which is capable of rapidly evacuating the air which it contains when, exceptionally, a signal of opening, controlling the interruption of the supply of compressed air is applied to an installation, and in particular when this opening signal which switches a pneumatic switch capable of connecting the general distribution line to an exhaust after having disconnected it of the compressed air source, is represented by the disappearance of a pressure.

- this device has fixing means which are screwed directly onto the body of the jack and comprises an internal channel connected to the supply inlet, to the fluid outlet and to an orifice communicating with an exhaust, this orifice being closed by a valve placed opposite when a closing force is exerted on it created by the pressure of the fluid on the control input and this orifice being opened by the fluid escaping from the chamber when the control pressure and the supply pressure disappear simultaneously.

- Rapid purge devices have already been used between the cylinders and the distributors to accelerate the movement of a cylinder when the circuit which supplies it does not have a sufficient size to ensure rapid displacement of the fluid, or when the distributor is located away from the jack; such a device which is located near the cylinder, connects the chamber of the cylinder, discharging its fluid, directly to the exhaust as soon as the distributor operates its switching; these devices use a valve which is placed opposite an orifice communicating with the atmosphere, and which is either applied against the latter when the cylinder is supplied with pressure, or lifted by the fluid of the cylinder when the latter is being evacuated. Such a rapid purge device therefore operates continuously.

- the compressed air source 2 of pressure “P is connected by the pipe 3 to a general pneumatic disconnector 4 which is represented here in its on state, where it allows the fluid to circulate towards a general distribution pipeline 5.

- the general distribution line is connected at certain points to distributors such as 8 and 9 which are also connected to an exhaust manifold 10.

- the first 8 of these distributors supplies for example a first cylinder 11, without one or more speed adjustment devices being placed on one of the supply lines 12 or 13 so that the speed of movement of the piston of this cylinder is essentially determined by the characteristics of the load 14 that it displaces, and by the pressure P.

- the second distributor 9 is connected to a second jack 17 by lines 15 and 16 which have speed regulators 18 respectively 19 on their path. These each comprise at least one throttle of adjustable value, such as 21, which is frequently placed in parallel on a one-way valve such as 20.

- a purge device according to the invention 24, 24 'whose internal constitution is described below. below and whose function is to connect the chamber 23, respectively 22, either to the speed regulator 18 respectively 19 in its active state, or to a vent 25 respectively 25 'opening to the atmosphere in its passive state.

- the pipe portion 15 'shown in FIG. 1a between the chamber 23 and the purge device is therefore as short as the material embodiment allows.

- the active state of the purge device 24 represented in FIG. 1a is obtained by the application to an input 26 of a pressure control signal "P •, which is conveyed by the same line 27 as that leading to the input 6 of the general disconnector.

- the displacement speed of the piston belonging to the jack 17 is determined not only by the nature of the load 28 but also by the speed regulators 18 and 19 which impose restrictions on the passage of fluids from the chambers and going to the exhaust manifold 10.

- the state of rapid purging of the jack does not impose slow circulation on the air contained in the chambers 22 and 23 through the speed regulator (s) 20, 21 when the piston rod 29 must be actuated by hand, for example to carry out an adjustment or a verification of the positions that this rod can take, because on the one hand, the aspiration towards a chamber takes place in the direction of passage of the non-return valve , and on the other hand, the backflow coming from the other chamber escapes directly to the atmosphere.

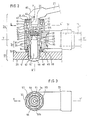

- a purge device in accordance with a first embodiment such as 24, is in particular visible in FIG. 2 where, to reduce as much as possible the length of pipe 15 'mentioned above, a controlled valve 30 for setting The exhaust has been combined with a known type swivel fitting 31 which is fixed directly to the wall of the cylinder 32 of a jack 17.

- the swivel fitting essentially comprises a body 33 having a first through bore 34 of axis XX 'and a second bore 35 of perpendicular axis YY' which communicates internally with the first and which presents externally association means 36 with a pipe such that 15, or such as 15 ", if a speed regulating device (not shown) is placed between it and the distributor 9.

- the bore 34 is traversed by a hollow bolt 37 which cooperates with the bore in leaktight manner thanks to seals 38, 39 and one end 40 of which has a thread 41 capable of cooperating in leaktight manner with a corresponding thread 42 of the wall 32, for example by means of a seal 45 or a conical thread, while an opposite end 43 has a clamping head 44, for example polygonal.

- the bolt has an axial through channel XX '46 connected by openings 47 to an annular space 48 placed between it and the bore 34.

- the region of this channel 46 opposite the thread 41 opens out through an orifice 49 in a cylindrical housing 50a, 50b which is hollowed out in the head 44 and which receives a part of revolution 51.

- the latter has an internal housing 52 which is placed opposite the orifice 49 and which receives a valve 30 capable of closing the latter by axial sliding XX ' in the housing 52.

- the external surface 53 of this part 51 circulates parallel to the housing 50a and has radial extensions 54 which are centered in the housing 50b to make the axis of the part 51 coaxial with XX ', see FIG. 3.

- a first annular space 55 existing between the bottom of the housing 50a and the part 51 as well as a second annular space 56 existing between the housing 50a and the part 51 make it possible to connect the orifice 49 to the atmosphere 63 through radial spaces 57 placed between the radial extensions, see Figure 3.

- the region of the part 51 opposite the housing 52 has a second housing 58 which is connected to the latter and which receives a small orientable connector 60 materializing the inlet 26 visible in FIG. 1a; this connector 60 is therefore connected to an external pipe 27 taking, for example, the form of a flexible plastic tube.

- the operation of the rapid purge device results from the chosen arrangement, the presence or absence of pressures in the lines 27 and 15, 15 "respectively in the chamber 23 of the jack 17 and the ratio of the diameters of the orifice 49 and housing 52.

- the purge device 70 comprises a body 72 and a fixing bolt 73, on which a bent connection 71 can appear, containing, for example, a one-way flow regulator 100 , 101.

- the body 72 has, in a tab 72 ', a bore 74 of axis XX' which passes right through it, and in a lateral extension 72 ", a bore 110 of axis YY ', perpendicular to XX', which opens out on the one hand, in the first bore and, on the other hand, through an orifice 76, towards a concentric housing 77 communicating with the outside.

- this housing is fixed a cylindrical part 79, for example by means of radial projections 89, which are applied to the internal surface 77 of the housing, and which leave between them and the external surface 80 of this part passages 81, 91.

- This part has an internal end 85, which is located at a certain distance from the bottom 78 of the housing, and which has a cylindrical housing 83 in which is housed in a sliding and sealed manner, a valve 84 made of elastomer.

- An internal channel 82 of the part 79 communicates with the housing 83 and with a quick pneumatic connector 86, which is fitted at the opposite end 90 to receive a pipe 27, for example flexible.

- the bore 74 is crossed by a hollow fixing bolt 73 which has an internal channel 111 concentric with XX '.

- This channel which communicates by lateral openings 95 with an annular space 96 situated between the bore 74 and the external surface of the bolt placed opposite, has a thread 92 at a first upper end.

- the bolt has an upper head 94, for example provided with hexagonal flaps 93 for a tightening tool, and an end 99 carrying a thread 98.

- the bolt can be tightly tightened in an opening 42 in the wall 32 of a jack 17.

- the bores 110 and 111 respectively represent portions 75 ′ and 75 "of an internal channel 75 of the purge device.

- the points mentioned in 15 ", 15 'and 26 correspond to those of FIG. 1a, and correspond respectively to the pressure inlet, the pressure outlet and the control inlet.

- a conventional elbow fitting 71 itself having a hollow connecting bolt 71 ′ can be screwed and tightly fixed by the latter in the thread 92 of the bolt 73.

- a pipe 112 is connected to this connection at a point 15, which corresponds to that mentioned in FIG. 1a, and which is therefore supplied by a pneumatic distributor such as 9.

- a filter 62 ′ can be placed between the passages 81, 91 and the exhaust 89; alternatively, the exhaust 89 can be protected, as in the previous mode, by a flexible annular part 88, similar to 62.

- the operation of the second embodiment is identical to the previous one, namely that, when a control signal pressure is applied to point 26, the valve 84 closes the orifice 76 due to the fact that the diameter of the housing 83 has been chosen large enough compared to that of the orifice, to resist the force applied to it on the surface of the orifice.

- a pressure applied at 15 therefore flows through the unidirectional valve 100 and passes through points 15 "and 15 'to supply the jack; when to obtain a reverse movement of the piston of the jack, point 15 is connected to the exhaust, the chamber 113 of the cylinder is emptied by 15 'and 15 "through the speed regulator 101.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Fluid-Pressure Circuits (AREA)

- Multiple-Way Valves (AREA)

Description

L'invention se rapporte à un dispositif de purge d'urgence pour vérin pneumatique, qui est destiné à provoquer l'arrêt de celui-ci et qui comporte :

- une entrée d'alimentation de fluide sous pression, qui est reliée directement ou indirectement à un distributeur pneumatique,

- une sortie de fluide, qui est reliée à une chambre du vérin,

- et une entrée de commande, qui reçoit un signal de commande agissant sur un organe de commutation interne apte à relier ou non la sortie de fluide à l'atmosphère, l'entrée et la sortie étant en communication lorsque ce signal est absent (FR-A-1 400 535).

- a pressurized fluid supply inlet, which is connected directly or indirectly to a pneumatic distributor,

- a fluid outlet, which is connected to a chamber of the jack,

- and a control input, which receives a control signal acting on an internal switching device capable of connecting the fluid outlet to the atmosphere or not, the input and the output being in communication when this signal is absent (FR- A-1 400 535).

De tels dispositifs peuvent être utilisés dans toutes les installations pneumatiques, soit pour arrêter le déplacement des tiges de vérins, par exemple lors de l'apparition d'un danger, soit pour rendre possible l'actionnement manuel de la tige de ce vérin, afin d'exécuter une opération de vérification ou de réglage.Such devices can be used in all pneumatic installations, either to stop the displacement of the rods of jacks, for example when a danger appears, or to make possible manual actuation of the rod of this jack, in order execute a verification or adjustment operation.

On connaît déjà des circuits de purge rapide pour vérin qui, pour obtenir la possibilité de purge mentionnée ci-dessus, mettent en oeuvre un distributeur monostable 3/2 (FR-A-2 352188) ; ce distributeur 3/2 est placé entre une chambre du vérin et un distributeur pneumatique normal de façon que, en présence d'un signal de commande, la chambre du vérin soit reliée au distributeur, tandis que, en l'absence de ce signal, la chambre est reliée à l'échappement, et que la conduite venant du distributeur normal est obturée.There are already known rapid purge circuits for cylinders which, to obtain the purge possibility mentioned above, use a 3/2 monostable distributor (FR-A-2 352188); this 3/2 distributor is placed between a cylinder chamber and a normal pneumatic distributor so that, in the presence of a control signal, the cylinder chamber is connected to the distributor, while, in the absence of this signal, the chamber is connected to the exhaust, and that the pipe coming from the normal distributor is closed.

On ne peut ici véritablement pas parler d'un dispositif particulièrement adapté à la fonction recherchée dans la mesure où ce distributeur 3/2 est étudié pour des fonctions plus générales, et présente une forme adaptée à celles-ci.We cannot really speak here of a device particularly suited to the desired function insofar as this 3/2 distributor is studied for more general functions, and has a shape adapted to these.

Le montage et la mise en oeuvre d'un tel distributeur présentent l'inconvénient, d'une part, de nécessiter un temps important et, d'autre part, d'aboutir à des ensembles encombrants. Lorsque le montage mentionné est terminé, la présence de ce distributeur 3/2 au voisinage du vérin est peu appréciée par les utilisateurs dans la mesure où il en résulte un empilage d'organes qui, de toute évidence, n'ont pas été conçus à cette fin.The assembly and the implementation of such a distributor have the disadvantage, on the one hand, of requiring a significant time and, on the other hand, of leading to bulky assemblies. When the aforementioned assembly is completed, the presence of this 3/2 distributor in the vicinity of the jack is not appreciated by users insofar as this results in a stack of organs which, obviously, were not designed to this end.

Par ailleurs, le montage de ces distributeurs 3/2, qui se justifie lorsque l'on associe au vérin des régleurs de vitesse, implique que ceux-ci soient placés entre les vérins et lesdits régleurs. Par suite de la tendance moderne à généraliser l'utilisation de régleurs de vitesse incorporés dans des raccords implantés directement sur le corps du vérin, l'utilisation de ces distributeurs 3/2 aux fins mentionnées ci-dessus, est devenue caduque.Furthermore, the mounting of these 3/2 distributors, which is justified when one associates the speed regulators with the cylinder, implies that these are placed between the cylinders and said regulators. As a result of the modern trend to generalize the use of speed regulators incorporated in fittings located directly on the cylinder body, the use of these 3/2 distributors for the purposes mentioned above has become obsolete.

La préoccupation d'arrêter instantanément un vérin ou celle de le rendre manoeuvrable à la main se présente fréquemment dans les installations industrielles où il est soit indispensable de limiter les dégâts et les risques que peuvent provoquer des fonctionnements défectueux, soit encore nécessaire d'effectuer avant une mise en route ou après une réparation.The concern of instantaneously stopping a jack or that of making it maneuverable by hand occurs frequently in industrial installations where it is either essential to limit the damage and the risks that can cause faulty operations, or is still necessary to perform before a start-up or after a repair.

Un vérin ne peut être arrêté et placé dans un état indifférent que si les pressions qui s'exercent sur les deux faces de son piston disparaissent après avoir décru de façon simultanée.A cylinder can only be stopped and placed in an indifferent state if the pressures exerted on the two faces of its piston disappear after having decreased simultaneously.

Comme les vérins sont alimentés par l'intermédiaire de canalisations qui les relient à des distributeurs et que ceux-ci sont eux-mêmes reliés à une source d'air comprimé, souvent éloignée, par une ligne générale et à un collecteur d'échappement, il est parfois difficile de vider ou de purger rapidement le vérin en interrompant l'arrivée du fluide sur la ligne générale et en purgeant cette dernière.As the cylinders are supplied via pipes which connect them to distributors and these are themselves connected to a source of compressed air, often distant, by a general line and to an exhaust manifold, it is sometimes difficult to quickly empty or purge the cylinder by interrupting the arrival of the fluid on the general line and by purging the latter.

Une telle vidange symétrique est encore plus longue et plus difficile à obtenir si, comme le cas se présente fréquemment, l'air s'échappe du vérin vers le distributeur à travers un ou plusieurs organes limiteurs de débit. Dans ce dernier cas, on observe que les masses d'air comprimé contenues de part et d'autre du piston s'échappant à des vitesses différentes, continuent à exercer sur ce piston des pressions différentes qui en prolongent le mouvement après l'ouverture du sectionneur pneumatique.Such a symmetrical emptying is even longer and more difficult to obtain if, as is the case frequently, air escapes from the jack to the distributor through one or more flow limiting members. In the latter case, it is observed that the masses of compressed air contained on either side of the piston escaping at different speeds, continue to exert on this piston different pressures which prolong the movement thereof after the opening of the pneumatic disconnector.

On sait également que l'on peut mettre en oeuvre un sectionneur pneumatique modulaire 3/2 pour opérer la mise à l'atmosphère d'une ligne d'alimentation sous pression desservant une multiplicité de distributeurs, associés chacun à un vérin respectif ; un tel sectionneur, qui opère simultanément l'interruption de l'arrivée du fluide sous pression de la source dans la ligne générale et relie cette dernière à l'atmosphère, se trouve toujours placé en tête de cette ligne, de sorte que l'on doit tenir compte du délai de purge provenant des longueurs de ligne, distributeurs et limiteurs de débit mentionnés ci-dessus.It is also known that a 3/2 modular pneumatic disconnector can be used to operate the venting of a pressure supply line serving a multiplicity of distributors, each associated with a respective jack; such a disconnector, which simultaneously operates the interruption of the arrival of the pressurized fluid from the source in the general line and connects the latter to the atmosphere, is always placed at the head of this line, so that one must take into account the purge time from the line lengths, distributors and flow limiters mentioned above.

L'invention se propose, par suite, de fournir un dispositif de purge simple peu coûteux et peu encombrant pour vérin qui soit susceptible de faire évacuer très rapidement l'air qu'il contient au moment où, de façon exceptionnelle, un signal d'ouverture, commandant l'interruption de la fourniture d'air comprimé est appliqué à une installation, et en particulier lorsque ce signal d'ouverture qui commute un sectionneur pneumatique apte à relier la ligne générale de distribution à un échappement après avoir déconnecté celle-ci de la source d'air comprimé, est représenté par la disparition d'une pression.The invention therefore proposes to provide an inexpensive and space-saving simple purge device for an actuator which is capable of rapidly evacuating the air which it contains when, exceptionally, a signal of opening, controlling the interruption of the supply of compressed air is applied to an installation, and in particular when this opening signal which switches a pneumatic switch capable of connecting the general distribution line to an exhaust after having disconnected it of the compressed air source, is represented by the disappearance of a pressure.

Selon l'invention, le but visé est atteint grâce au fait que ce dispositif présente des moyens de fixation se vissant directement sur le corps du vérin et comporte un canal interne relié à l'entrée d'alimentation, à la sortie de fluide et à un orifice communiquant avec un échappement, cet orifice étant obturé par un clapet placé en regard lorsque s'exerce sur lui une force d'obturation créée par la pression du fluide sur l'entrée de commande et cet orifice étant ouvert par le fluide s'échappant de la chambre lorsque la pression de commande et la pression d'alimentation disparaissent simultanément.According to the invention, the aim is achieved thanks to the fact that this device has fixing means which are screwed directly onto the body of the jack and comprises an internal channel connected to the supply inlet, to the fluid outlet and to an orifice communicating with an exhaust, this orifice being closed by a valve placed opposite when a closing force is exerted on it created by the pressure of the fluid on the control input and this orifice being opened by the fluid escaping from the chamber when the control pressure and the supply pressure disappear simultaneously.

On a déjà utilisé entre les vérins et les distributeurs des dispositifs de purge rapide pour accélérer le mouvement d'un vérin lorsque le circuit qui l'alimente ne présente pas un calibre suffisant pour assurer un déplacement rapide du fluide, ou lorsque le distributeur se trouve loin du vérin ; un tel dispositif qui est implanté près du vérin, relie la chambre du vérin, évacuant son fluide, directement à l'échappement dès que le distributeur opère sa commutation ; ces dispositifs mettent en oeuvre un clapet qui est placé en regard d'un orifice communiquant avec l'atmosphère, et qui est soit appliqué contre celui-ci lorsque le vérin est alimenté en pression, soit soulevé par le fluide du vérin lorsque celui-ci est en cours d'évacuation. Un tel dispositif de purge rapide fonctionne donc en permanence.Rapid purge devices have already been used between the cylinders and the distributors to accelerate the movement of a cylinder when the circuit which supplies it does not have a sufficient size to ensure rapid displacement of the fluid, or when the distributor is located away from the jack; such a device which is located near the cylinder, connects the chamber of the cylinder, discharging its fluid, directly to the exhaust as soon as the distributor operates its switching; these devices use a valve which is placed opposite an orifice communicating with the atmosphere, and which is either applied against the latter when the cylinder is supplied with pressure, or lifted by the fluid of the cylinder when the latter is being evacuated. Such a rapid purge device therefore operates continuously.

L'objectif visé par ces dispositifs de purge rapide, ainsi que son mode de réalisation, n'ont rien de commun avec ceux de l'invention.The objective sought by these rapid purge devices, as well as its embodiment, have nothing in common with those of the invention.

D'autres particularités de l'invention ainsi qu'un système d'arrêt du fonctionnement d'une installation pneumatique mettant en oeuvre le dispositif de l'invention, seront mieux compris à la lecture de la description ci-dessous et à l'examen des figures annexées parmi lesquelles :

- La figure 1a représente schématiquement une installation pneumatique mettant en oeuvre le dispositif de purge selon l'invention dans une phase de fonctionnement normal.

- La figure 1b montre une partie des organes de la figure 1a lors de l'apparition d'une panne.

- La figure 2 illustre dans une coupe par un plan PP' une vue en élévation d'un premier mode de réalisation du dispositif de purge.

- La figure 3 représente en coupe par un plan QQ' de la figure 2 une vue de dessus du dispositif selon cette figure.

- La figure 4 illustre un détail du clapet utilisé à la figure 2.

- La figure 5 représente en coupe une vue en élévation d'un second mode de réalisation du dispositif de purge.

- FIG. 1a schematically represents a pneumatic installation implementing the purge device according to the invention in a normal operating phase.

- Figure 1b shows part of the bodies of Figure 1a when a fault occurs.

- Figure 2 illustrates in a section through a plane PP 'an elevational view of a first embodiment of the purge device.

- 3 shows in section through a plane QQ 'of Figure 2 a top view of the device according to this figure.

- Figure 4 illustrates a detail of the valve used in Figure 2.

- Figure 5 shows in section an elevational view of a second embodiment of the purge device.

Dans l'installation 1 visible à la figure ia, la source d'air comprimé 2 de pression « P est reliée par la canalisation 3 à un sectionneur pneumatique général 4 qui est représenté ici dans son état passant, où il permet au fluide de circuler vers une canalisation générale de distribution 5.In the

Cet état passant du sectionneur, qui est maintenu lorsqu'un signal de commande de pression « P est appliqué à son entrée de commande 6, est commuté lorsque ce signal disparaît pour qu'une liaison soit établie entre la ligne 5 et un évent 7 débouchant à l'atmosphère A (voir figure 1b, dans un état non passant).This passing state of the disconnector, which is maintained when a pressure control signal “P is applied to its

La ligne de distribution générale, dont la longueur peut être importante, est reliée en certains de ses points à des distributeurs tels que 8 et 9 qui sont également reliés à un collecteur d'échappement 10. Le premier 8 de ces distributeurs alimente par exemple un premier vérin 11, sans qu'un ou plusieurs dispositifs de réglage de vitesse soit placé sur l'une des canalisations d'alimentation 12 ou 13 de sorte que la vitesse de déplacement du piston de ce vérin est essentiellement déterminée par les caractéristiques de la charge 14 qu'il déplace, et par la pression P.The general distribution line, the length of which can be significant, is connected at certain points to distributors such as 8 and 9 which are also connected to an

Le second distributeur 9 est relié à un second vérin 17 par des canalisations 15 et 16 qui présentent sur leur trajet des régleurs de vitesse 18 respectivement 19. Ceux-ci comprennent chacun au moins un étranglement de valeur ajustable, tel que 21, qui est fréquemment placé en parallèle sur une valve unidirectionnelle telle que 20.The second distributor 9 is connected to a

Il est rappelé que la fonction d'un tel régleur de vitesse est de permettre au fluide de se déplacer, soit sans entrave depuis le distributeur vers le cylindre, soit avec un certain ralentissement lorsque le fluide s'échappe du cylindre vers le distributeur.It is recalled that the function of such a speed regulator is to allow the fluid to move, either without hindrance from the distributor towards the cylinder, or with a certain slowing down when the fluid escapes from the cylinder towards the distributor.

Dans l'état du distributeur illustré sur la figure 1a, le piston tend à se déplacer vers la gauche car un fluide pénètre dans la chambre droite 22.In the state of the distributor illustrated in FIG. 1a, the piston tends to move to the left because a fluid enters the

Entre la chambre gauche 23 et/ou droite 22 du cylindre et le régleur de vitesse 18 et/ou 19, est placé directement sur le vérin, un dispositif de purge conforme à l'invention 24, 24' dont la constitution interne est décrite ci-dessous et dont la fonction est de relier la chambre 23, respectivement 22, soit au régleur de vitesse 18 respectivement 19 dans son état actif, soit à un évent 25 respectivement 25' débouchant à l'atmosphère dans son état passif. La portion de canalisation 15' représentée sur la figure 1a entre la chambre 23 et le dispositif de purge est donc aussi courte que le permet la réalisation matérielle. L'état actif du dispositif de purge 24 représenté à la figure 1a, est obtenu par l'application sur une entrée 26 d'un signal de commande de pression « P •, qui est véhiculé par la même ligne 27 que celle aboutissant à l'entrée 6 du sectionneur général.Between the

Lorsque l'installation fonctionne normalement, la vitesse de déplacement du piston appartenant au vérin 17 est déterminée non seulement par la nature de la charge 28 mais encore par les régleurs de vitesse 18 et 19 qui imposent des restrictions de passage aux fluides issus des chambres et allant vers le collecteur d'échappement 10.When the installation is operating normally, the displacement speed of the piston belonging to the

Si un incident se produit dans l'installation, et qu'il soit nécessaire d'interrompre l'alimentation de celle-ci, la pression de commande « PjLSur la ligne 27 est interrompue, et devient « P par exemple à l'aide d'un interrupteur pneumatique d'arrêt d'urgence non représenté, et le sectionneur général 4 relie la canalisation 5 à l'atmosphère. Compte tenu de la proximité immédiate du distributeur 8, du sectionneur 4, et du vérin 11, ce dernier purge très rapidement ses chambres à travers les canalisations 12, 10 et 13, 5 de sorte que l'arrêt du mouvement du piston est pratiquement instantané.If an incident occurs in the installation, and it is necessary to interrupt its supply, the control pressure "PjL On

Par contre, si l'on examine le fonctionnement du vérin 17 qui est éloigné du sectionneur 4, on constate que le seul fait de relier la ligne 5 à l'atmosphère à travers le sectionneur général 4 ne suffirait pas en l'absence du dispositif de purge 24, à provoquer un arrêt instantané du piston correspondant, d'une part en raison de l'existence des pertes de charge dans la ligne 5, et d'autre part en raison de la présence des régleurs de vitesse 18 et 19. En effet, le fluide qui est enfermé dans la chambre 22 se trouve comprimé à une valeur très supérieure à celle qui existe dans la chambre 23 et, si ces pressions ne décroissent pas en conservant des valeurs identiques, ce qui est rarement le cas en raison des vitesses différentes que doivent prendre les vérins à l'aller et au retour, il en résulte que le piston continue de se déplacer en raison de la différence de ces pressions après que la ligne de distribution ait été reliée à l'atmosphère.On the other hand, if we examine the operation of the

Grâce à la mise en place directement à l'entrée ou aux entrées du vérin d'un ou de deux dispositifs de purge tels que 24, 24', on établit simultanément et instantanément une courte liaison à l'atmosphère de la ligne 5 et des chambres 22 et 23 ; il en résulte que le piston s'arrête quasi instantanément dans la position qui est la sienne au moment où la pression du signal de commande « P disparaît, voir figure 1 b.Thanks to the installation directly at the inlet or at the inlets of the jack of one or two purge devices such as 24, 24 ', a short connection to the atmosphere of

On constate, par ailleurs, que l'état de purge rapide du vérin n'impose pas à l'air contenu dans les chambres 22 et 23 une lente circulation à travers le ou les régleurs de vitesse 20, 21 lorsque la tige 29 du piston doit être actionnée à la main, par exemple pour effectuer un réglage ou une vérification des positions que peut prendre cette tige, car d'une part, l'aspiration vers une chambre s'opère dans le sens de passage de la valve anti- retour, et d'autre part, le refoulement venant de l'autre chambre s'échappe directement à l'atmosphère.It can also be seen that the state of rapid purging of the jack does not impose slow circulation on the air contained in the

Il est clair que le circuit pneumatique de l'installation qui vient d'être décrit, garde tout son intérêt si un seul régleur de débit est utilisé et même si, en l'absence de régleurs de débit, l'une ou les deux canalisations 15, 16 présentent une longueur telle, que les pertes de charge propres ajoutées à celles de la ligne 5 et du collecteur 10 ralentissent sensiblement la vitesse de vidange du vérin.It is clear that the pneumatic circuit of the installation which has just been described retains its interest if only one flow regulator is used and even if, in the absence of flow regulators, one or both

Un dispositif de purge, conforme à un premier mode de réalisation tel que 24, est en particulier visible à la figure 2 où, pour réduire autant que possible la longueur de canalisation 15' mentionnée ci-dessus, une valve commandée 30 de mise à l'échappement a été combinée avec un raccord orientable de type connu 31 qui se fixe directement sur la paroi du cylindre 32 d'un vérin 17.A purge device, in accordance with a first embodiment such as 24, is in particular visible in FIG. 2 where, to reduce as much as possible the length of pipe 15 'mentioned above, a controlled

Le raccord orientable comprend essentiellement un corps 33 ayant un premier alésage traversant 34 d'axe XX' et un second alésage 35 d'axe YY' perpendiculaire qui communique intérieurement avec le premier et qui présente extérieurement des moyens d'association 36 avec une canalisation telle que 15, ou telle que 15", si un dispositif régleur de vitesse (non représenté) est placé entre lui et le distributeur 9. L'alésage 34 est traversé par un boulon creux 37 qui coopère avec l'alésage de façon étanche grâce à des joints 38, 39 et dont une extrémité 40 possède un filetage 41 apte à coopérer de façon étanche avec un filetage correspondant 42 de la paroi 32, par exemple grâce à un joint 45 ou à un filetage conique, tandis qu'une extrémité opposée 43 présente une tête de serrage 44 par exemple polygonale.The swivel fitting essentially comprises a

Le boulon possède un canal traversant axial XX' 46 relié par des ouvertures 47 à un espace annulaire 48 placé entre lui et l'alésage 34. La région de ce canal 46 opposée au filetage 41 débouche par un orifice 49 dans un logement cylindrique 50a, 50b qui est creusé dans la tête 44 et qui reçoit une pièce de révolution 51. Cette dernière possède un logement interne 52 qui est placé en regard de l'orifice 49 et qui reçoit un clapet 30 apte à obturer ce dernier par coulissement axial XX' dans le logement 52. La surface extérieure 53 de cette pièce 51 circule parallèlement au logement 50a et présente des prolongements radiaux 54 qui viennent se centrer dans le logement 50b pour rendre l'axe de la pièce 51 coaxial à XX', voir figure 3.The bolt has an axial through channel XX '46 connected by

. Un premier espace annulaire 55 existant entre le fond du logement 50a et la pièce 51 ainsi qu'un second espace annulaire 56 existant entre le logement 50a et la pièce 51 permettent de relier l'orifice 49 à l'atmosphère 63 à travers des espaces radiaux 57 placés entre les prolongements radiaux, voir figure 3. . A first

La région de la pièce 51 opposée au logement 52 possède un second logement 58 qui est relié à ce dernier et qui reçoit un petit connecteur orientable 60 matérialisant l'entrée 26 visible sur la figure 1a ; ce connecteur 60 est donc relié à une canalisation externe 27 prenant par exemple la forme d'un tube souple en matière plastique.The region of the

Le fonctionnement du dispositif de purge rapide résulte de la disposition choisie, de la présence ou de l'absence de pressions dans les canalisations 27 et 15, 15" respectivement dans la chambre 23 du vérin 17 et du rapport des diamètres de l'orifice 49 et du logement 52.The operation of the rapid purge device results from the chosen arrangement, the presence or absence of pressures in the

Si l'on suppose, ce qui est le cas le plus fréquent, que lors du remplissage de la chambre 23 la pression présente dans la canalisation 27 est égale à la pression dans cette chambre, on obtiendra une fermeture de l'orifice 49 par le choix d'un diamètre du logement 52 supérieur au diamètre de cet orifice. Dans ces conditions, le dispositif de purge se comporte comme un raccord classique.If it is assumed, which is the most frequent case, that during filling of the

Si, conformément au principe de fonctionnement exposé ci-dessus, on interrompt la fourniture de fluide vers la canalisation 15, 15" et que l'on interrompe simultanément la pression sur la ligne de commande 27, une purge du fluide présent dans la chambre 23 va s'effectuer vers l'atmosphère à travers les espaces 55, 56, 57 grâce au soulèvement du clapet 30 hors de l'orifice 49 qui lui servait de siège.If, in accordance with the operating principle set out above, the supply of fluid to the

Afin de diminuer l'intensité des bruits lors d'une purge et la pénétration de corps étrangers dans le dispositif de purge par la voie des passages 55, 56 et 57, on peut placer dans ce dernier passage un filtre 61 présentant une très faible perte de charge pour le fluide de purge. Au cas où cette perte de charge devrait être encore plus faible, un clapet annulaire de protection 62 pourrait remplacer le filtre et être disposé au-dessus de la sortie 63 du passage 57. Un tel clapet, qui peut être réalisé à partir d'une feuille d'élastomère, est avantageusement fixé dans une gorge 64 de la pièce 51, de façon à s'appuyer élastiquement sur la périphérie 65 de la tête 44 et à s'écarter de celle-ci lorsque le fluide de purge vient la soulever.In order to reduce the intensity of the noises during a purge and the penetration of foreign bodies into the purge device through the

Les déplacements du clapet libre 30 qui, dans le mode de réalisation de la figure 2, ne sont guidés que par sa jupe élastique, pourraient également être guidés par une tige 66 de section cruciforme solidaire du clapet 30' et mobile dans le canal 46, voir figure 4.The displacements of the

Il doit être compris que pour réduire les dimensions extérieures du dispositif, on dispose de préférence un certain nombre de ses éléments dans la tige 67 du boulon 37; l'encombrement mis à part, les avantages du dispositif restent les mêmes si, par exemple le clapet 30 se trouve placé axialement au niveau de la tête 44 ; le sens de la tête de boulon doit donc s'entendre comme la région opposée à celle qui présente le filetage.It should be understood that to reduce the external dimensions of the device, there are preferably a number of its elements in the

Dans un second mode de réalisation, visible à la figure 5, le dispositif de purge 70 comprend un corps 72 et un boulon de fixation 73, sur lequel peut se montrer un raccord coudé 71, contenant, par exemple, un régleur de débit unidirectionnel 100, 101.In a second embodiment, visible in FIG. 5, the

Le corps 72 présente dans une patte 72', un alésage 74 d'axe XX' qui la traverse de part en part, et dans un prolongement latéral 72", un alésage 110 d'axe YY', perpendiculaire à XX', qui débouche d'une part, dans le premier alésage et, d'autre part, par un orifice 76, vers un logement concentrique 77 communiquant avec l'extérieur.The

Dans ce logement est fixée une pièce cylindrique 79, par exemple à l'aide de saillies radiales 89, qui s'appliquent sur la surface interne 77 du logement, et qui laissent entre elles et la surface externe 80 de cette pièce des passages 81, 91.In this housing is fixed a

Cette pièce présente une extrémité interne 85, qui se trouve à une certaine distance du fond 78 du logement, et qui présente un logement cylindrique 83 dans lequel est logé de façon coulissante et étanche, un clapet 84 en élastomère.This part has an

Un canal interne 82 de la pièce 79 communique avec le logement 83 et avec un connecteur pneumatique rapide 86, qui est emmanché à l'extrémité opposée 90 pour recevoir une canalisation 27, par exemple souple.An

L'alésage 74 est traversé par un boulon de fixation creux 73 qui possède un canal interne 111 concentrique à XX'. Ce canal, qui communique par des lumières latérales 95 avec un espace annulaire 96 situé entre l'alésage 74 et la surface externe du boulon placée en regard, possède à une première extrémité supérieure un filetage 92.The

Le boulon comporte une tête supérieure 94, par exemple munie de pans hexagonaux 93 pour un outil de serrage, et une extrémité 99 portant un filetage 98.The bolt has an

Grâce à l'interposition de joints tels que 97', 97", le boulon peut être serré de façon étanche dans une ouverture 42 de la paroi 32 d'un vérin 17. Les alésages 110 et 111 représentent respectivement des portions 75' et 75" d'un canal interne 75 du dispositif de purge.Thanks to the interposition of seals such as 97 ′, 97 ″, the bolt can be tightly tightened in an

Les points mentionnés en 15", 15' et 26 correspondent à ceux de la figure 1a, et correspondent respectivement à l'entrée de pression, à la sortie de pression et à l'entrée de commande.The points mentioned in 15 ", 15 'and 26 correspond to those of FIG. 1a, and correspond respectively to the pressure inlet, the pressure outlet and the control inlet.

Un raccord coudé classique 71 possédant lui- même un boulon creux de raccordement 71', peut être vissé et fixé de façon étanche par ce dernier dans le taraudage 92 du boulon 73.A conventional elbow fitting 71 itself having a hollow connecting

Ces raccords présentent fréquemment aujourd'hui, un régleur de débit tel que 101, ajusté par le bouton de réglage 102 et un clapet unidirectionnel 100, ces organes étant ici représentés de façon symbolique.These connections frequently present today, a flow regulator such as 101, adjusted by the

Un tuyau 112 est relié à ce raccord en un point 15, qui correspond à celui mentionné à la figure 1a, et qui est donc alimenté par un distributeur pneumatique tel que 9.A

Comme dans le précédent mode de réalisation, un filtre 62' peut être disposé entre les passages 81, 91 et l'échappement 89 ; en variante, on peut protéger l'échappement 89, comme dans le mode précédent, par une pièce annulaire souple 88, analogue à 62.As in the previous embodiment, a

Le fonctionnement du second mode de réalisation est identique au précédent, à savoir que, lorsqu'une pression de signal de commande est appliquée au point 26, le clapet 84 obture l'orifice 76 en raison du fait que le diamètre du logement 83 a été choisi suffisamment grand par rapport à celui de l'orifice, pour résister à la force qui lui est appliquée sur la surface de l'orifice.The operation of the second embodiment is identical to the previous one, namely that, when a control signal pressure is applied to point 26, the

Une pression appliquée en 15 circule donc à travers le clapet unidirectionnel 100 et traverse les points 15" et 15' pour alimenter le vérin ; lorsque pour obtenir un mouvement inverse du piston du vérin, le point 15 est relié à l'échappement, la chambre 113 du vérin se vide par 15' et 15" à travers le régleur de vitesse 101.A pressure applied at 15 therefore flows through the

Si la pression du signal de commande et celle qui est présente en 15 disparaissent simultanément, le fluide présent dans la chambre 113 ne pouvant s'échapper rapidement à travers le régleur de vitesse, ou en raison de tout autre perte de charge sur la conduite 112 et sur ses prolongements, sa pression soulève le clapet 84 et relie donc cette chambre à l'atmosphère par la voie 25 la plus courte.If the pressure of the control signal and that present at 15 disappear simultaneously, the fluid present in the chamber 113 cannot escape quickly through the speed regulator, or due to any other pressure drop on the

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8400652 | 1984-01-17 | ||

| FR8400652A FR2558216B1 (en) | 1984-01-17 | 1984-01-17 | EMERGENCY PURGE DEVICE FOR PNEUMATIC CYLINDER |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0149386A1 EP0149386A1 (en) | 1985-07-24 |

| EP0149386B1 true EP0149386B1 (en) | 1987-03-04 |

Family

ID=9300187

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84402581A Expired EP0149386B1 (en) | 1984-01-17 | 1984-12-13 | Urgent-venting device for pneumatic actuators |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4690035A (en) |

| EP (1) | EP0149386B1 (en) |

| JP (1) | JPS60234102A (en) |

| DE (1) | DE3462542D1 (en) |

| FR (1) | FR2558216B1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2575526B1 (en) * | 1984-12-28 | 1987-02-13 | Telemecanique Electrique | ASSEMBLY OF FUNCTIONAL CONNECTIONS FOR PNEUMATIC CYLINDER WITH COMBINATION MOUNT TO PROVIDE AT LEAST TWO FUNCTIONS |

| JP2613150B2 (en) * | 1992-03-19 | 1997-05-21 | エスエムシー株式会社 | Pneumatic actuator shock absorber |

| US6715403B2 (en) | 2001-10-12 | 2004-04-06 | Caterpillar Inc | Independent and regenerative mode fluid control system |

| US6701822B2 (en) | 2001-10-12 | 2004-03-09 | Caterpillar Inc | Independent and regenerative mode fluid control system |

| EP1369633B1 (en) * | 2002-06-07 | 2006-07-12 | FESTO AG & Co | Connecting device for fluid conduits |

| CN105351262A (en) * | 2015-11-20 | 2016-02-24 | 李晓勤 | Pneumatic mechanism for manufacturing and pressing of inkstone die |

| RU194506U1 (en) * | 2019-06-04 | 2019-12-12 | Общество с ограниченной ответственностью "Камоцци Пневматика" | Pneumatic actuator with double acting cylinder |

| CN113339566B (en) * | 2021-05-19 | 2022-09-30 | 合肥金星智控科技股份有限公司 | Power-off and gas-off protection device for sampling equipment |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1506012A (en) * | 1921-10-13 | 1924-08-26 | Westinghouse Air Brake Co | Quick-release valve |

| US1726102A (en) * | 1927-09-24 | 1929-08-27 | Nat Pneumatic Co | Quick-release valve |

| US2888909A (en) * | 1953-12-24 | 1959-06-02 | Gratzmuller Jean Louis | Liquid dumping valve arrangement for a hydraulic jack |

| US3099136A (en) * | 1960-05-19 | 1963-07-30 | Honeywell Regulator Co | Fluid actuator |

| US3187637A (en) * | 1962-06-05 | 1965-06-08 | Westinghouse Air Brake Co | Multi-position cylinder apparatus and control therefor |

| FR1400535A (en) * | 1964-04-15 | 1965-05-28 | Renault | Control device for pneumatic device |

| US3960059A (en) * | 1974-12-09 | 1976-06-01 | Caterpillar Tractor Co. | Fast exhaust circuit for hydraulic jacks |

| FR2352188A1 (en) * | 1976-05-18 | 1977-12-16 | Bouteille Daniel | Fast emptying for pneumatic cylinder chamber - is performed using inner distributor chamber which is connected with three lines |

| JPS6037443Y2 (en) * | 1976-10-08 | 1985-11-08 | 焼結金属工業株式会社 | Cylinder with quick exhaust valve |

| JPS5526616U (en) * | 1978-08-01 | 1980-02-21 | ||

| FR2455231A1 (en) * | 1979-04-27 | 1980-11-21 | Telemecanique Electrique | LOCKING DEVICE FOR CYLINDER |

| JPS58134205A (en) * | 1982-02-05 | 1983-08-10 | Ckd Corp | Remaining pressure exhaust device |

| US4475442A (en) * | 1982-02-08 | 1984-10-09 | Vickers, Incorporated | Power transmission |

-

1984

- 1984-01-17 FR FR8400652A patent/FR2558216B1/en not_active Expired

- 1984-12-13 EP EP84402581A patent/EP0149386B1/en not_active Expired

- 1984-12-13 DE DE8484402581T patent/DE3462542D1/en not_active Expired

-

1985

- 1985-01-17 JP JP60007339A patent/JPS60234102A/en active Granted

-

1986

- 1986-09-29 US US06/912,700 patent/US4690035A/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| US4690035A (en) | 1987-09-01 |

| FR2558216B1 (en) | 1988-05-20 |

| FR2558216A1 (en) | 1985-07-19 |

| DE3462542D1 (en) | 1987-04-09 |

| JPH0423128B2 (en) | 1992-04-21 |

| JPS60234102A (en) | 1985-11-20 |

| EP0149386A1 (en) | 1985-07-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FR2657138A1 (en) | RAPID CONNECTION PART WITH PRESSURE REDUCING MEMBER. | |

| EP0149386B1 (en) | Urgent-venting device for pneumatic actuators | |

| EP0272176A1 (en) | Hydraulic rotary vane actuator, especially for aircraft rudder control | |

| FR2557253A1 (en) | VALVE OPENING AT DEPRESSION | |

| EP0504032B1 (en) | Redundant closing valve | |

| FR2693248A1 (en) | Ball or plug type valve fitted with an insert. | |

| FR2509831A1 (en) | RE-POSITION CONTROL FOR HYDRAULIC WATER SUPPORT, AS WELL AS HYDRAULIC CONTROL NON-RETURN VALVE | |

| FR2834016A1 (en) | Jet pump for transferring fuel between different compartments in multi-compartment fuel tanks, has sealing elements each adapted to open when pressure of injected fluid exceeds predetermined level | |

| EP3599408B1 (en) | Quick coupling for removable connection of two pipes containing pressurised fluid | |

| FR2748298A1 (en) | PNEUMATIC CYLINDER DEVICE | |

| EP0330575A1 (en) | Hydraulic circuit comprising a safety valve for a hydraulic actuator | |

| FR2629557A1 (en) | NON-RETURN VALVE | |

| EP0328472B1 (en) | Coupling incorporating a start-up valve for the gradual pressurisation of pneumatic installations | |

| FR2658578A1 (en) | STOP VALVE DEVICE TO AVOID LEAKS. | |

| FR2658580A1 (en) | PILOT PRESSURE CUT-OFF VALVE AND PILOTAGE VALVE. | |

| WO2002057672A1 (en) | Pneumatically-controlled needle valve | |

| BE1009338A3 (en) | Hydraulic valve pilot. | |

| FR2591706A1 (en) | INTEGRATED PILOTAGE SAFETY VALVE | |

| FR2660726A1 (en) | Connector - distributor for controlling pneumatic actuators | |

| EP0116500A1 (en) | Fluid distributors | |

| FR2524580A1 (en) | Distributor for compressed air circuit - has drive chambers cross connected to reduce air consumption | |

| FR2666634A1 (en) | PNEUMATIC VALVE. | |

| FR2561798A1 (en) | Pressure reducing valve with progressive pressurising | |

| EP0833013B1 (en) | Hydraulic control device for a lifting cylinder of an arm of an agricultural loader | |

| FR2915786A1 (en) | Blocker type connection for connecting actuator e.g. jack, has flap valve connected to piston sling along central axis in piloting chamber, and burging unit arranged on channel of side of seat oriented toward one of joining units |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19841214 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB IT LI SE |

|

| 17Q | First examination report despatched |

Effective date: 19860527 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE GB IT LI SE |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 3462542 Country of ref document: DE Date of ref document: 19870409 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 84402581.7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19991119 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19991207 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19991217 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19991218 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20001213 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84402581.7 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011002 |