CN2598540Y - Thin film - Google Patents

Thin film Download PDFInfo

- Publication number

- CN2598540Y CN2598540Y CNU032197276U CN03219727U CN2598540Y CN 2598540 Y CN2598540 Y CN 2598540Y CN U032197276 U CNU032197276 U CN U032197276U CN 03219727 U CN03219727 U CN 03219727U CN 2598540 Y CN2598540 Y CN 2598540Y

- Authority

- CN

- China

- Prior art keywords

- thin film

- layer

- pores

- muscle

- pore

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Laminated Bodies (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Abstract

The utility model discloses a thin film, which is provided with at least two layers with pores, all layers except the utmost interior layer are provided with pores with the size larger manyfold than that of the pores arranged on the utmost interior layer. In the two-layer or more-than-two-layer structure with pores of the film with pores, the pores in the outer layers form an anti-leakage wall structure, which effectively prevents the liquid from flowing out of the sanitary towel when the thin file with pores are used for the sanitation products such as the sanitation towels, etc, in order to make the liquid flow towards the absorbing material through the pores.

Description

Technical field

This utility model relates to a kind of perforated film that is applied on hygienic article such as sanitary towel, protective pad.

Background technology

The plastic sheeting of punching has multiple use, it is used in gardening and the agricultural, to prevent the growth of grass and weeds, but allow dampness to enter in the following soil by thin film, perforated film has very many isolated regularly apertures, they allow liquid and air or other fluidic infiltration, and this thin film is also in a large number as on the disposable sanitary articles such as women use sanitary napkin, protective pad, urine trousers.

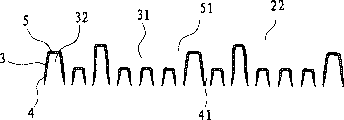

Prior art, perforated film as shown in Figure 1 are the monolayer open-celled structure substantially, and promptly the front of perforated film does not possess the open-celled structure of anti-pierced wall, therefore when this thin film is used for the purposes of menstruation or incontinence, when the body fluid flow is excessive, the phenomenon of " side leakage " can occur.

The utility model content

The purpose of this utility model provides a kind of when being used for the menstruation or the purposes of incontinence, can prevent the thin film of body fluid " side leakage ".

For achieving the above object, solution of the present utility model is: a kind of thin film, and wherein this thin film has at least two layers of open-celled structure, and the perforated area in the single hole of each layer of all the other except that innermost layer is exponentially greater than the perforated area in the single hole of innermost layer.

Described thin film has trilaminar open-celled structure.

The perforated area in the single hole of described formation each except that internal layer layer is 1mm

2To 80000mm

2

The height of the muscle that forms between the Kong Yukong on described formation each except that internal layer layer is 0.05mm to 5.0mm, and the width on muscle top is 0.05mm to 4mm, and the width of muscle bottom is 0.05mm to 5mm.

The perforated area in the hole of described formation each except that internal layer layer is identical, also can be different.

Offer pore on the described muscle.

Described pore is funnel type, and the pore bore size is 0.1mm to 2.0mm, and the width of muscle is 0.1mm to 1.5mm between pore.

The percent opening of described pore is 5% to 50%.

After adopting such scheme, because the open-celled structure more than two layers or two layers that the front of perforated film forms, and the perforated area except that internal layer is bigger, then outer field hole just can form a leakproof wall construction, this leakproof wall construction can prevent effectively when being used for menstruation hygienic article such as sanitary towel at perforated film that liquid from flowing around sanitary towel, liquid can be moved to absorber by the hole, surround the anti-pierced wall of solid of various geometries from skin, constitute outer field perforate and form a passage by skin arrival internal layer, the passage that internal layer provides liquid to pass through.

Description of drawings

Fig. 1 is the partial enlarged drawing of overlooking of commonly using product;

Fig. 2 is that the I-I of Fig. 1 is to cutaway view;

Fig. 3 is the schematic flow sheet of film holed technique equipment;

Fig. 4 is the partial enlarged drawing of Fig. 3;

Fig. 5 is the partial enlarged drawing of overlooking of the present utility model;

Fig. 6 is that the II-II of Fig. 5 analyses and observe partial enlarged drawing;

Fig. 7 is processing screen cloth (two-layer structure) sketch map of Fig. 6;

Fig. 8 is the partial enlarged drawing of analysing and observe of this utility model embodiment 2;

Fig. 9 is processing screen cloth (three-decker) sketch map of Fig. 8;

Figure 10 is the partial enlarged drawing of analysing and observe of this utility model embodiment 3;

Figure 11 is processing screen cloth (three-decker) sketch map of Figure 10;

Figure 12 is the partial enlarged drawing of overlooking of this utility model embodiment 4;

Figure 13 is that the III-III of Figure 12 is to cutaway view;

Figure 14 is the processing screen cloth sketch map of Figure 13;

Figure 15 is the menopad fabric of thin film fabrication of the present utility model;

Figure 16 is the IV-IV cutaway view of Figure 15.

The specific embodiment

Shown in Fig. 3,4, the perforating apparatus of thermoplastic film of the present utility model comprises that screen cloth 10 is fixed on the rotatable spindle nose B, this spindle nose B is supported by central shaft, and central shaft is fixed on the support, the spindle nose B of fixed grit 10 is by one group of gear or belt transmission, and contain corresponding mechanism, and guarantee the synchronized movement at two ends, screen cloth 10 left and right sides, prevent screen cloth 10 distortions.Utilize the suction of vacuum chamber C to make the thermoplastic film of heat flow in the aperture of screen cloth 10 and pulled open, thus get on the thin film 22 with screen cloth 10 on the aperture that is complementary of aperture.

The production technology of perforated film shown in Figure 3 only is a kind of in numerous known perforated film production technologies, adopting the thin film drilling technology shown in this figure is thermoplastic film 22 to be attached on the cylindrical screen 10 move along clockwise direction with screen cloth 10, thin film 22 above the suction mouth by hot-air D that hot air nozzle sprayed heating and in suction mouth under the effect of negative pressure, thin film 22 is drawn in the aperture of screen cloth 10 by eyeletting, the thin film 22 of punching is after suitable mode is cooled off, through deflector roll E, sided corona treatment roller F, processing is cut operations such as cutting of a G and be wound into perforated film 22 to Scroll H.

Shown in Fig. 5,6,7, the thin film 22 that utilizes double-deck screen cloth 10 productions is for having the double-layer drilling structure, and the skin 3 of thin film 22 is made up of the bigger perforate 31 of perforated area, and the perforated area of perforate 31 is at 1mm

2To 80000mm

2, the geometric figure of perforate 31 can be circle, ellipse or polygon, also can be the combination of multiple shape figure, and geometric setting of perforate 31 can be identical, also can be different; And form these thin film 22 internal layers 4 single hole 41 perforated area only for outer 3 hole 31 1/2 or littler.

The height H 1 of the muscle 32 that forms between hole 31 on the skin 3 of thin film 22 and the hole 31 is 0.05mm to 5.0mm, and the width W 2 on muscle 32 tops is 0.05mm to 4.0mm; The width W 2 of muscle 32 bottoms is 0.05mm to 5.0mm; Perforate 31 formation one of outer surface layer 3 are arrived the bigger passage of area of internal layers 4 by the skin 3 of thin film 22.

The perforate 41 of above-mentioned thin film 22 internal layers 4 forms the fluid passage of outer surface to inner surface.Outer 3 perforate 31 surrounds the anti-pierced wall (being muscle 32) of solid of various geometries on internal layer 4.

Shown in Fig. 8,9, utilize the thin film 22 of screen cloth 10 productions of three-decker, it also has the structure of three layers of perforate, middle level 5 and outer 3 is made up of the bigger perforate 51,31 of perforated area, the geometric figure of perforate 51,31 can be circle, ellipse or polygon, also can be the combination of multiple shape figure, the geometric setting of perforate 51,31 can be identical, also can be different; And form these thin film 22 internal layers 4 single hole 41 perforated area only for the hole 51,31 of middle level 5 and outer 3 1/2 or littler.

Shown in Figure 10,11, utilize the thin film 22 of screen cloth 10 productions of different structure, it also can form the open-celled structure of different structure, it is the open-celled structure that forms more than three layers or three layers substantially, is to add the multilamellar open-celled structure to form " anti-pierced wall " on the basis of the single layer hole of located by prior art thin film.

Shown in Figure 12,13,14, utilize again on the muscle 32 that forms between the hole 31 and hole 31 on thin film 22 skins 3 that the screen cloth 10 of another kind of form produces and perforate has pore 321, this pore 321 is funnel type, the bore size of pore 321 is 0.1mm to 2.0mm, the width of muscle 322 is 0.1mm to 1.5mm between pore, and the percent opening of this pore 321 is 5% to 50%.

Cooperate Figure 15, shown in 16, when thin film 22 described in the utility model is used for menstruation hygienic article J such as sanitary towel, can prevent effectively that liquid from flowing around sanitary towel, liquid can be moved in absorber J1 by the punching of thin film 22, on thin film 22 skins 3, surround the anti-pierced wall (being muscle 32) of solid of various geometries, the perforate 31 that constitutes skin 3 forms a passage (being hole 31) by outer 3 internal layers 4 that arrive, the skin 3 of this thin film 33 constitutes the anti-pierced wall of the solid that prevents the liquid side leakage, because the setting of pore 321 on the muscle 32, then can on " anti-pierced wall ", be formed with the overflow effect, therefore the more effective phenomenon that prevents liquid " side leakage " that played is safe and reliable.

Claims (8)

1, a kind of thin film is characterized in that: this thin film has at least two layers of open-celled structure, and the perforated area in the single hole of each layer of all the other except that innermost layer is exponentially greater than the perforated area in the single hole of innermost layer.

2, a kind of thin film as claimed in claim 1, it is characterized in that: this thin film has trilaminar open-celled structure.

3, a kind of thin film as claimed in claim 1 or 2 is characterized in that: the perforated area that constitutes the single hole of each layer except that internal layer is 1mm

2To 80000mm

2

4, a kind of thin film as claimed in claim 1 or 2, it is characterized in that: the height that constitutes the muscle that forms between the Kong Yukong on each layer except that internal layer is 0.05mm to 5.0mm, and the width on muscle top is 0.05mm to 4mm, and the width of muscle bottom is 0.05mm to 5mm.

5, a kind of thin film as claimed in claim 1 is characterized in that: the perforated area in the hole of formation each layer except that internal layer is identical, also can be different.

6, a kind of thin film as claimed in claim 4 is characterized in that: offer pore on the described muscle.

7, a kind of thin film as claimed in claim 6, it is characterized in that: this pore is funnel type, and the pore bore size is 0.1mm to 2.0mm, and the width of muscle is 0.1mm to 1.5mm between pore.

8, a kind of thin film as claimed in claim 6 is characterized in that: the percent opening of this pore is 5% to 50%.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU032197276U CN2598540Y (en) | 2003-01-28 | 2003-01-28 | Thin film |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU032197276U CN2598540Y (en) | 2003-01-28 | 2003-01-28 | Thin film |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN2598540Y true CN2598540Y (en) | 2004-01-14 |

Family

ID=34161415

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNU032197276U Expired - Lifetime CN2598540Y (en) | 2003-01-28 | 2003-01-28 | Thin film |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN2598540Y (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101732134A (en) * | 2008-11-10 | 2010-06-16 | 屈德加薄膜产品股份有限公司 | Transfer layer for absorbent article |

| CN102525747A (en) * | 2012-01-30 | 2012-07-04 | 厦门延江工贸有限公司 | Punched thermoplastic plastic film coiled material |

-

2003

- 2003-01-28 CN CNU032197276U patent/CN2598540Y/en not_active Expired - Lifetime

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101732134A (en) * | 2008-11-10 | 2010-06-16 | 屈德加薄膜产品股份有限公司 | Transfer layer for absorbent article |

| CN101732134B (en) * | 2008-11-10 | 2014-07-09 | 屈德加薄膜产品股份有限公司 | Transfer layer for absorbent article |

| CN102525747A (en) * | 2012-01-30 | 2012-07-04 | 厦门延江工贸有限公司 | Punched thermoplastic plastic film coiled material |

| CN102525747B (en) * | 2012-01-30 | 2013-08-07 | 厦门延江工贸有限公司 | Punched thermoplastic plastic film coiled material |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69007566T2 (en) | Nonwoven fabric and process for its manufacture. | |

| AU602866B2 (en) | Macroscopically expanded three-dimensional polymeric web for transmitting both dynamically deposited & statically contacted fluids from one surface to the other | |

| US8415524B2 (en) | Three-dimensional apertured film for transmitting dynamically-deposited and statically retained fluids | |

| EP1911577B1 (en) | Dry top formed film | |

| KR940000807B1 (en) | Apertured macroscopically expanded three-dimensional polymeric web exhibiting breatheability and resistance to fluid transmission and use thereof in an absorbent article | |

| US5591510A (en) | Layered fabric material having angled capillaries | |

| US5718928A (en) | Screen for producing a perforated film | |

| US5562932A (en) | Screen for producing a perforated film | |

| EP0859700B1 (en) | Film with angled capillaries | |

| CN1375266A (en) | Disposable excreta-treatment wear products | |

| US5897543A (en) | Film | |

| EP2359790B1 (en) | Three-dimensional apertured film for transmitting dynamically-deposited and statically-retained fluids | |

| US6544625B2 (en) | Flexible sheet used for disposable sanitary article | |

| CN2598540Y (en) | Thin film | |

| JP3461826B2 (en) | Elastic plastic web with small skin contact area and excellent fluid transfer performance | |

| CN2598539Y (en) | Thin film structure | |

| CN2592350Y (en) | Screen mesh for film perforating | |

| CN2635062Y (en) | Punched thin film | |

| CN2664633Y (en) | Composite perforating film | |

| JP2809480B2 (en) | Surface sheet for absorbent articles | |

| CN2734465Y (en) | Screen mesh for manufacturing perforated plastic rubber membrane | |

| EP1033122A2 (en) | Liquid impervious backsheet for body fluids disposable absorbent article | |

| CN1520793A (en) | Thin film structure | |

| DE19728328C1 (en) | Absorbent initial product for nappies, sanitary towels, etc. | |

| JPH0670956A (en) | Face material for absorptive article and manufacture thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CX01 | Expiry of patent term |

Expiration termination date: 20130128 Granted publication date: 20040114 |