CN219174943U - Full-hydraulic double-steel-wheel vibratory roller - Google Patents

Full-hydraulic double-steel-wheel vibratory roller Download PDFInfo

- Publication number

- CN219174943U CN219174943U CN202320364288.5U CN202320364288U CN219174943U CN 219174943 U CN219174943 U CN 219174943U CN 202320364288 U CN202320364288 U CN 202320364288U CN 219174943 U CN219174943 U CN 219174943U

- Authority

- CN

- China

- Prior art keywords

- sliding groove

- groove

- sliding block

- sliding

- roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A30/00—Adapting or protecting infrastructure or their operation

- Y02A30/60—Planning or developing urban green infrastructure

Landscapes

- Road Paving Machines (AREA)

Abstract

The utility model relates to the technical field of road rollers and discloses a full-hydraulic double-steel-wheel vibratory roller, which comprises a road roller frame, wherein a supporting frame is fixedly arranged at one end of the bottom of the road roller frame, a driving mechanism is arranged at the other end of the bottom of the road roller frame, a first sliding groove, a rectangular groove and a second sliding groove are formed in the inner wall of one side, far away from the driving mechanism, of the supporting frame, the first sliding groove and the second sliding groove are oppositely arranged, the rectangular groove is positioned between the first sliding groove and the second sliding groove, the rectangular groove is respectively communicated with the first sliding groove and the second sliding groove, and a first sliding block is slidably arranged in the first sliding groove; the utility model uses a rotating mechanism, a screw rod and a first sliding block. The setting of second slider and stand board can be according to waiting the height of the required height adjustment stand board on the compaction road, paves the pitch on the road surface, need not extra manpower and paves pitch, and is labour saving and time saving relatively, has improved work efficiency.

Description

Technical Field

The utility model relates to the technical field of road rollers, in particular to a full-hydraulic double-steel-wheel vibratory road roller.

Background

Vibratory rollers are engineering machines that utilize their own weight and vibration to compact a variety of building and road construction materials. In highway construction, vibratory rollers are widely used for compacting various non-cohesive soil, broken stone mixtures and various asphalt concretes, and the dual-steel-wheel vibratory rollers are suitable for roads and other large paving projects

Traditional full hydraulic double steel wheel vibratory roller utilizes gravity and vibrations of itself to compact the road surface, but traditional full hydraulic double steel wheel vibratory roller presses the road surface in real time, and the pitch on the road surface is through artifical paving pitch, then compacts the road surface again, needs extra manpower to pave the road surface, and is more time consuming and laborious, has reduced work efficiency.

Therefore, it is necessary to provide an all-hydraulic dual steel wheel vibratory roller to solve the above technical problems.

Disclosure of Invention

The utility model aims to provide a full-hydraulic double-steel-wheel vibratory roller, which has the effects of paving and improving the working efficiency.

The technical aim of the utility model is realized by the following technical scheme: the utility model provides a full hydraulic pressure double steel wheel vibratory roller, includes the road roller frame, the one end fixed mounting of road roller frame bottom has the carriage, the other end of road roller frame bottom sets up actuating mechanism, first spout, rectangular channel and second spout have been seted up to one side inner wall that actuating mechanism was kept away from to the carriage, first spout and second spout set up relatively, the rectangular channel is located between first spout and the second spout, the rectangular channel is linked together with first spout and second spout respectively, slidable mounting has first slider in the first spout, first spout internal rotation is connected with the screw rod, the screw rod runs through first slider, screw rod and first slider threaded connection, slidable mounting has the second slider in the second spout, fixed mounting has the slide bar in the second spout, the slide bar runs through the second slider, slidable mounting has the stand board in the rectangular channel, the both ends of stand board are paved with first slider and second slider fixed connection respectively, the top of screw rod is provided with slewing mechanism.

Through adopting above-mentioned technical scheme, through slewing mechanism, screw rod, first slider. The setting of second slider and stand board can be according to waiting the height of the required height adjustment stand board on the compaction road, paves the pitch on the road surface, need not extra manpower and paves pitch, and is labour saving and time saving relatively, has improved work efficiency.

The utility model is further provided with: the support frame is internally provided with a first connecting column, two ends of the first connecting column are rotationally connected with the inner wall of the support frame, and the outer side of the second connecting column is sleeved with a first compression roller.

By adopting the technical scheme, the pavement is convenient to compact.

The utility model is further provided with: the driving mechanism comprises two fixing plates, the tops of the two fixing plates are fixedly connected with the road roller frame, a second connecting column is arranged at the bottom of the road roller frame, two ends of the second connecting column are respectively connected with the two fixing plates in a rotating mode, and a second compression roller is sleeved on the outer side of the second connecting column.

Through adopting above-mentioned technical scheme, carry out the secondary compaction to the road surface when conveniently removing whole device.

The utility model is further provided with: the rotating mechanism comprises a first fixed column, an installation groove is formed in the inner wall of the supporting frame, the installation groove is located at the top of the first sliding groove, a first bevel gear and a second bevel gear are arranged in the installation groove and meshed with each other, the first fixed column is fixedly connected with the inner wall of the first bevel gear, a motor is arranged on one side of the supporting frame, the output end of the motor penetrates through the supporting frame, the output end of the motor is fixedly connected with the first fixed column, a second fixed column is fixedly connected with the inner wall of the second bevel gear, the second fixed column penetrates through the supporting frame, and the bottom of the second fixed column is fixedly connected with the top end of the screw rod.

By adopting the technical scheme, the height of the spreading plate is convenient to adjust.

The utility model is further provided with: one side of the supporting frame, which is close to the motor, is fixedly provided with an installation box, and the motor is fixedly connected with the installation box.

By adopting the technical scheme, the bottom of the paving plate is provided with the inclined plane.

The utility model is further provided with: and asphalt is conveniently paved.

In summary, the utility model has the following beneficial effects: through slewing mechanism, screw rod, first slider. The setting of second slider and stand board can be according to waiting the height of the required height adjustment stand board on the compaction road, paves the pitch on the road surface, need not extra manpower and paves pitch, and is labour saving and time saving relatively, has improved work efficiency.

Drawings

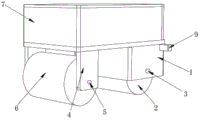

FIG. 1 is a schematic three-dimensional structure of the present utility model;

FIG. 2 is a schematic view of a three-dimensional structure from another perspective of the present utility model;

FIG. 3 is a schematic elevational view of the present utility model;

FIG. 4 is a schematic cross-sectional view of a support frame of the present utility model;

fig. 5 is an enlarged schematic view of the structure of fig. 4 at a.

In the figure: 1. a support frame; 2. a first press roller; 3. a first connection post; 4. a fixing plate; 5. a second connection post; 6. a second press roller; 7. a road roller frame; 9. a mounting box; 10. spreading and paving; 11. a first slider; 12. a screw; 13. a first bevel gear; 14. a second bevel gear; 15. a slide bar; 16. a second slider; 17. a motor; 18. a mounting groove; 19. rectangular grooves; 20. an inclined surface; 21. a second fixing column; 22. and a first fixing column.

Detailed Description

The present utility model will be further described with reference to the drawings in the embodiments of the present utility model.

Referring to fig. 1 to 5, in an embodiment of the present utility model, a full hydraulic dual steel wheel vibratory roller includes a roller frame 7, one end of the bottom of the roller frame 7 is fixedly provided with a supporting frame 1, the other end of the bottom of the roller frame 7 is provided with a driving mechanism, a side inner wall of the supporting frame 1 far away from the driving mechanism is provided with a first sliding groove, a rectangular groove 19 and a second sliding groove, the first sliding groove and the second sliding groove are oppositely arranged, the rectangular groove 19 is located between the first sliding groove and the second sliding groove, the rectangular groove 19 is respectively communicated with the first sliding groove and the second sliding groove, a first sliding block 11 is slidably mounted in the first sliding groove, a screw 12 is rotatably connected in the first sliding groove, the screw 12 penetrates through the first sliding block 11, the screw 12 is in threaded connection with the first sliding block 11, a second sliding block 16 is slidably mounted in the second sliding groove, a sliding rod 15 penetrates through the second sliding block 16, the rectangular groove 19 is slidably connected with the second sliding plate 16, the first sliding plate 10 is rotatably mounted in the second sliding plate, and the two ends of the sliding rod 16 are respectively fixedly connected with the first sliding rod 11 and the sliding rod 12; the screw rod 12 in the first chute is rotated by the driving force of the rotating mechanism, so that the first sliding block 11 moves in the first chute, the paving plate 10 is driven to move in the supporting frame 1, the second sliding block 16 is driven to move on the sliding rod 15, after the paving plate 10 is adjusted to a corresponding position, the driving mechanism is started, the whole road roller is driven to move, asphalt on the road surface is paved at the bottom of the paving plate 10 while moving, and then the asphalt road surface is compacted; by means of a rotation mechanism, a screw 12, a first slider 11. The setting of second slider 16 and paving board 10 can be according to the height adjustment of waiting to compact the required height on the road and spread the board 10, need not extra manpower and spread the pitch on the road, and is labour saving and time saving relatively, has improved work efficiency.

In this embodiment, preferably, a first connecting column 3 is disposed in the supporting frame 1, two ends of the first connecting column 3 are rotatably connected with the inner wall of the supporting frame 1, and a first pressing roller 2 is sleeved on the outer side of the first connecting column 3; the pavement is convenient to compact.

In this embodiment, preferably, the driving mechanism includes two fixing plates 4, the tops of the two fixing plates 4 are fixedly connected with the road roller frame 7, a second connecting column 5 is disposed at the bottom of the road roller frame 7, two ends of the second connecting column 5 are respectively rotatably connected with the two fixing plates 4, and a second press roller 6 is sleeved on the outer side of the second connecting column 5; the whole device is convenient to move and simultaneously performs secondary compaction on the road surface.

In this embodiment, preferably, the rotating mechanism includes a first fixed column 22, an inner wall of the supporting frame 1 is provided with a mounting groove 18, the mounting groove 18 is located at the top of the first sliding groove, a first bevel gear 13 and a second bevel gear 14 are disposed in the mounting groove 18, the first bevel gear 13 is meshed with the second bevel gear 14, the first fixed column 22 is fixedly connected with the inner wall of the first bevel gear 13, a motor 17 is disposed at one side of the supporting frame 1, an output end of the motor 17 penetrates through the supporting frame 1, an output end of the motor 17 is fixedly connected with the first fixed column 22, an inner wall of the second bevel gear 14 is fixedly connected with a second fixed column 21, the second fixed column 21 penetrates through the supporting frame 1, and a bottom of the second fixed column 21 is fixedly connected with a top end of the screw 12; starting a motor 17, wherein the motor 17 drives the first bevel gear 13 to rotate so as to drive the second bevel gear 14 to rotate so as to drive the screw 12 to rotate, and adjusting the paving plate 10; the height of the spreader plate 10 is conveniently adjusted.

In this embodiment, preferably, an installation box 9 is fixedly installed on one side, close to the motor 17, of the support frame 1, and the motor 17 is fixedly connected with the installation box 9; has a protective effect on the motor 17.

In this embodiment, preferably, the bottom of the paving board 10 is provided with an inclined surface 20; and asphalt is conveniently paved.

Working principle: starting the motor 17, the motor 17 drives the first bevel gear 13 to rotate, and then drives the second bevel gear 14 to rotate, so that the screw rod 12 in the first chute rotates, and then drives the first sliding block 11 to move in the first chute, and then drives the paving plate 10 to move in the supporting frame 1, and further drives the second sliding block 16 to move on the sliding rod 15, so that after the position of the paving plate 10 is conveniently adjusted, the whole full-hydraulic double-steel-wheel vibratory roller is started through the remote control after the position of the paving plate 10 is adjusted, so that the whole roller moves, asphalt on the road surface is paved at the bottom of the paving plate 10 when moving, the first compression roller 2 firstly compacts the asphalt road surface, and the second compression roller 6 secondarily compacts the asphalt road surface.

The foregoing description is only of the preferred embodiments of the utility model, and all changes and modifications that come within the meaning and range of equivalency of the structures, features and principles of the utility model are therefore intended to be embraced therein.

Claims (6)

1. The utility model provides a full hydraulic pressure double steel wheel vibratory roller, includes road roller frame (7), its characterized in that: the road roller is characterized in that a supporting frame (1) is fixedly arranged at one end of the bottom of the road roller frame (7), a driving mechanism is arranged at the other end of the bottom of the road roller frame (7), a first sliding groove, a rectangular groove (19) and a second sliding groove are formed in the inner wall of one side of the supporting frame (1) away from the driving mechanism, the first sliding groove and the second sliding groove are oppositely formed, the rectangular groove (19) is located between the first sliding groove and the second sliding groove, the rectangular groove (19) is respectively communicated with the first sliding groove and the second sliding groove, a first sliding block (11) is slidably mounted in the first sliding groove, a screw rod (12) is connected in an inner rotating mode, the screw rod (12) penetrates through the first sliding block (11), a second sliding block (16) is slidably mounted in the second sliding groove, a sliding rod (15) penetrates through the second sliding block (16), the rectangular groove (19) is slidably connected with the second sliding block (16), and the first sliding block (10) is rotatably connected with the first sliding block (11), and the second sliding block (10) are rotatably connected with the second sliding block (16), and the first sliding block (10) are rotatably connected with the first sliding block (10).

2. The fully hydraulic dual steel wheel vibratory roller of claim 1, wherein: the novel support is characterized in that a first connecting column (3) is arranged in the support frame (1), two ends of the first connecting column (3) are rotatably connected with the inner wall of the support frame (1), and a first compression roller (2) is sleeved on the outer side of the first connecting column (3).

3. The fully hydraulic dual steel wheel vibratory roller of claim 1, wherein: the driving mechanism comprises two fixing plates (4), the tops of the two fixing plates (4) are fixedly connected with a road roller frame (7), a second connecting column (5) is arranged at the bottom of the road roller frame (7), two ends of the second connecting column (5) are respectively connected with the two fixing plates (4) in a rotating mode, and a second pressing roller (6) is sleeved on the outer side of the second connecting column (5).

4. The fully hydraulic dual steel wheel vibratory roller of claim 1, wherein: the rotating mechanism comprises a first fixing column (22), a mounting groove (18) is formed in the inner wall of the supporting frame (1), the mounting groove (18) is located at the top of the first sliding groove, a first bevel gear (13) and a second bevel gear (14) are arranged in the mounting groove (18), the first bevel gear (13) is meshed with the second bevel gear (14), the first fixing column (22) is fixedly connected with the inner wall of the first bevel gear (13), a motor (17) is arranged on one side of the supporting frame (1), the output end of the motor (17) penetrates through the supporting frame (1), the output end of the motor (17) is fixedly connected with the first fixing column (22), a second fixing column (21) is fixedly connected with the inner wall of the second bevel gear (14), and the second fixing column (21) penetrates through the supporting frame (1) and is fixedly connected with the top end of the screw rod (12).

5. The fully hydraulic dual steel wheel vibratory roller of claim 4, wherein: one side of the supporting frame (1) close to the motor (17) is fixedly provided with an installation box (9), and the motor (17) is fixedly connected with the installation box (9).

6. The fully hydraulic dual steel wheel vibratory roller of claim 1, wherein: the bottom of the spreading plate (10) is provided with an inclined surface (20).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202320364288.5U CN219174943U (en) | 2023-03-02 | 2023-03-02 | Full-hydraulic double-steel-wheel vibratory roller |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202320364288.5U CN219174943U (en) | 2023-03-02 | 2023-03-02 | Full-hydraulic double-steel-wheel vibratory roller |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN219174943U true CN219174943U (en) | 2023-06-13 |

Family

ID=86660229

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202320364288.5U Active CN219174943U (en) | 2023-03-02 | 2023-03-02 | Full-hydraulic double-steel-wheel vibratory roller |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN219174943U (en) |

-

2023

- 2023-03-02 CN CN202320364288.5U patent/CN219174943U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN206693011U (en) | One kind paves uniform bituminous concrete paver | |

| CN113897942B (en) | Soft soil foundation rolling compaction device in municipal road construction and use method | |

| CN219174943U (en) | Full-hydraulic double-steel-wheel vibratory roller | |

| CN113186773B (en) | Road construction method based on building energy conservation | |

| CN221192856U (en) | Adjustable tamper | |

| CN211689767U (en) | Asphalt paver for road construction | |

| CN219908472U (en) | Multistage compacted waterproof material paver | |

| CN113463472B (en) | A vibrocompaction device for public road bridge roof beam construction | |

| CN213681615U (en) | Road brick laying device | |

| CN212111427U (en) | Soil plug effect simulation device of concrete pipe pile | |

| CN114108428A (en) | Asphalt laying equipment for municipal engineering building | |

| CN211472466U (en) | Tamping device for building construction | |

| CN221052315U (en) | Road roller for road repair | |

| CN220813789U (en) | Practical leveling device for foundation ramming | |

| CN221918864U (en) | Leveling structure | |

| CN215758395U (en) | Ironing device with compaction function | |

| CN221480764U (en) | Building foundation compaction device for highway engineering | |

| CN219157328U (en) | Full-hydraulic single-drive vibratory roller | |

| CN219527260U (en) | Asphalt road flattening device for municipal engineering | |

| CN219195550U (en) | Road administration road construction equipment of flattening | |

| CN220908091U (en) | Asphalt paving device for highway maintenance construction | |

| CN221877632U (en) | Pavement paving device for municipal construction | |

| CN111576154B (en) | Automatic compaction equipment of laying of pitch | |

| CN219240232U (en) | Trowelling equipment for small municipal road | |

| CN219490925U (en) | Hydraulic rammer device for bench back backfill soil compaction |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |