CN219024121U - Coating production mixing equipment - Google Patents

Coating production mixing equipment Download PDFInfo

- Publication number

- CN219024121U CN219024121U CN202223122344.9U CN202223122344U CN219024121U CN 219024121 U CN219024121 U CN 219024121U CN 202223122344 U CN202223122344 U CN 202223122344U CN 219024121 U CN219024121 U CN 219024121U

- Authority

- CN

- China

- Prior art keywords

- stirring

- mixing box

- paint

- wall

- cylinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 18

- 239000011248 coating agent Substances 0.000 title claims description 16

- 238000000576 coating method Methods 0.000 title claims description 16

- 238000003756 stirring Methods 0.000 claims abstract description 91

- 239000003973 paint Substances 0.000 claims abstract description 42

- 238000007790 scraping Methods 0.000 claims abstract description 6

- 238000007599 discharging Methods 0.000 claims description 11

- 238000009434 installation Methods 0.000 claims description 7

- 235000017166 Bambusa arundinacea Nutrition 0.000 claims description 3

- 235000017491 Bambusa tulda Nutrition 0.000 claims description 3

- 241001330002 Bambuseae Species 0.000 claims description 3

- 235000015334 Phyllostachys viridis Nutrition 0.000 claims description 3

- 239000011425 bamboo Substances 0.000 claims description 3

- 238000003754 machining Methods 0.000 abstract description 2

- 239000000463 material Substances 0.000 description 8

- 239000002994 raw material Substances 0.000 description 3

- 238000010586 diagram Methods 0.000 description 2

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/10—Greenhouse gas [GHG] capture, material saving, heat recovery or other energy efficient measures, e.g. motor control, characterised by manufacturing processes, e.g. for rolling metal or metal working

Landscapes

- Mixers Of The Rotary Stirring Type (AREA)

- Coating Apparatus (AREA)

Abstract

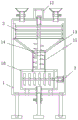

The utility model provides paint production mixing equipment which comprises a mixing box, wherein feeding funnels are arranged on two sides of the top of the mixing box, a mounting frame is fixedly arranged in the middle of the top of the mixing box, a first stirring assembly is arranged at the bottom of the mounting frame, an arc plate is fixedly arranged on the inner wall of the mixing box, a through hole is formed in the bottom of the arc plate, a mounting cylinder is fixedly arranged at the edge of the inner wall of the through hole, a stirring cylinder is fixedly arranged at the bottom of the mounting cylinder, and a second stirring assembly is arranged on one side of the stirring cylinder. The utility model comprises the following steps: the first motor is matched with the rotating shaft to drive the plurality of connecting rods to rotate, the plurality of connecting rods drive the two scraping plates to rotate, so that residual paint on the inner wall of the mixing box is scraped while paint in the mixing box is stirred, paint residue is avoided, the rotating shaft drives the spiral stirring blade to rotate, the paint flows down from the through hole on the arc plate, the paint is conveyed and stirred in the mounting cylinder to enter the stirring cylinder, stirring efficiency is improved, and the influence on machining efficiency caused by overlong manual force application time can be avoided.

Description

Technical Field

The utility model belongs to the technical field of paint processing, and particularly relates to paint production mixing equipment.

Background

The utility model provides a need use mixing arrangement in the paint produce, mixing arrangement is used for mixing the coating raw materials with article such as water, additive, in order to prevent to mix the process coating caking, need stir it, through retrieving, "a paint production mixing arrangement" that application number is "CN201920028992.7" discloses, it is recorded "through the improvement to stirring structure," under the condition of applying the same effort to the handle, can wait to mix the coating to carry out more thorough stirring mixing connecting rod outer end fixedly connected with rectangular plate in this coating mixing arrangement, the one end fixedly connected with handle of connecting rod is kept away from to the rectangular plate, make things convenient for the staff to apply force through the handle, drive connecting rod and main pivot and rotate, main pivot outer end fixedly connected with a plurality of extension bars, a plurality of extension bars are from last down evenly distributed in the outer end of main pivot, the rotation of the extension bar that drives its outer end through main pivot, make the coating in the coating mixing arrangement can mix, utilize to apply force the connecting rod and the driving shaft rotation to drive a plurality of extension bar rotation really can be to the coating stirring more even, but this paint production mixing equipment is when using, the manual stirring efficiency is not needed to be influenced by the manual stirring device, the high-speed is realized in the design time, the practical production efficiency is not is convenient for mix to carry out to the coating production efficiency.

Disclosure of Invention

The utility model aims to provide paint production mixing equipment, which aims to solve the problems that when the existing paint production mixing equipment in the prior art is used, the stirring is inconvenient to be carried out for a long time by manually applying force by a worker, so that the working efficiency is influenced, and meanwhile, the stirring efficiency is inconvenient to be improved.

In order to achieve the above purpose, the present utility model provides the following technical solutions:

the coating production mixing equipment comprises a mixing box, wherein feeding funnels are arranged on two sides of the top of the mixing box, a mounting frame is fixedly arranged in the middle of the top of the mixing box, a first stirring assembly is arranged at the bottom of the mounting frame, an arc plate is fixedly arranged on the inner wall of the mixing box, a through hole is formed in the bottom of the arc plate, a mounting cylinder is fixedly arranged at the edge of the inner wall of the through hole, a stirring cylinder is fixedly arranged at the bottom of the mounting cylinder, and a second stirring assembly is arranged on one side of the stirring cylinder;

the first stirring assembly comprises a first motor arranged at the bottom of the mounting frame, an output shaft of the first motor extends to the inside of the mixing box and is fixedly connected with a rotating shaft, a plurality of connecting rods are fixedly arranged on the surface of the rotating shaft, the other ends of the connecting rods are fixedly connected with the scraping plates, and spiral stirring blades are arranged on the surface of the lower end of the rotating shaft.

Moreover, the second stirring assembly comprises a fixing seat arranged on one side of the stirring cylinder, a second motor is fixedly arranged on one side of the fixing seat, an output shaft of the second motor extends to the inner wall of the stirring cylinder and is fixedly connected with a rotating rod, the other end of the rotating rod is rotationally connected with the inner wall of the stirring cylinder, and a plurality of stirring rods are arranged on the surface of the rotating rod.

And the bottom end of the rotating shaft extends on the inner wall of the mounting cylinder, and the width of the spiral stirring blade is smaller than the radius of the inner wall of the mounting cylinder.

Moreover, the top of churn has seted up the through-hole, the inner wall of through-hole and the bottom fixed connection of installation section of thick bamboo, the guide mouth has been seted up to the bottom of churn, the bottom fixedly connected with discharging pipe of guide mouth, the bottom of discharging pipe extends to the bottom of mixing box.

And the surface of the feeding funnel is provided with a first electromagnetic valve, and the surface of the discharging pipe is provided with a second electromagnetic valve.

And moreover, the discharging pipe is fixedly provided with a plurality of supporting columns at the bottom of the mixing box, and supporting pads are arranged at the bottoms of the supporting columns.

And the surface of the mixing box is provided with a control panel, and the first electromagnetic valve, the second electromagnetic valve, the first motor and the second motor are all connected with the control panel.

Compared with the prior art, the utility model has the beneficial effects that:

1) The first motor on the mounting frame is matched with the rotating shaft to drive the plurality of connecting rods to rotate, the plurality of connecting rods drive the two scraping plates to rotate, so that residual paint on the inner wall of the mixing box is scraped while paint in the mixing box is stirred, paint residues are avoided, the rotating shaft drives the spiral stirring blade to rotate, the paint flows down from the through hole on the arc plate, is conveyed and stirred in the mounting cylinder and enters the stirring cylinder, the stirring efficiency is improved, and the processing efficiency is prevented from being influenced by overlong manual force application time compared with the prior art;

2) The second motor on the fixing base is matched with the rotating rod to drive the stirring rods to rotate, the stirring rods stir the paint inside the stirring barrel again, the stirring efficiency of the paint is further improved, and the stirring efficiency is more uniform than that of the paint in the prior art.

Drawings

FIG. 1 is a schematic diagram of the structure of the present utility model;

FIG. 2 is a schematic diagram of the structure of the present utility model;

FIG. 3 is a schematic view of a portion of the structure of the present utility model;

FIG. 4 is a schematic view of a first stirring assembly according to the present utility model;

fig. 5 is a schematic structural view of a second stirring assembly according to the present utility model.

Description of the reference numerals

1. A mixing box; 11. a feed hopper; 111. a first electromagnetic valve; 12. a mounting frame; 13. an arc-shaped plate; 14. a through hole; 15. a mounting cylinder; 16. a stirring cylinder; 161. a through hole; 162. a material guiding port; 163. a discharge pipe; 164. a second electromagnetic valve; 17. a support column; 171. a support pad; 18. a control panel; 2. a first stirring assembly; 21. a first motor; 22. a rotating shaft; 23. a connecting rod; 24. a scraper; 25. spiral stirring blades; 3. a second stirring assembly; 31. a fixing seat; 32. a second motor; 33. a rotating lever; 34. stirring rod.

Detailed Description

The following description of the embodiments of the present utility model will be made clearly and completely with reference to the accompanying drawings, in which it is apparent that the embodiments described are only some embodiments of the present utility model, but not all embodiments. All other embodiments, which can be made by those skilled in the art based on the embodiments of the utility model without making any inventive effort, are intended to be within the scope of the utility model.

Referring to fig. 1-5, the present utility model provides the following technical solutions: the paint production mixing equipment comprises a mixing box 1, wherein feeding hoppers 11 are arranged on two sides of the top of the mixing box 1, a mounting frame 12 is fixedly arranged in the middle of the top of the mixing box 1, a first stirring assembly 2 is arranged at the bottom of the mounting frame 12, an arc-shaped plate 13 is fixedly arranged on the inner wall of the mixing box 1, a through hole 14 is formed in the bottom of the arc-shaped plate 13, a mounting cylinder 15 is fixedly arranged at the edge of the inner wall of the through hole 14, a stirring cylinder 16 is fixedly arranged at the bottom of the mounting cylinder 15, and a second stirring assembly 3 is arranged on one side of the stirring cylinder 16;

the first stirring assembly 2 comprises a first motor 21 arranged at the bottom of the mounting frame 12, an output shaft of the first motor 21 extends to the inside of the mixing box 1 and is fixedly connected with a rotating shaft 22, a plurality of connecting rods 23 are fixedly arranged on the surface of the rotating shaft 22, the other ends of the plurality of connecting rods 23 are fixedly connected with scraping plates 24, and spiral stirring blades 25 are arranged on the surface of the lower end of the rotating shaft 22.

During specific use, get into mixing box 1 with the raw materials from two feed hoppers 11, drive a plurality of connecting rod 23 through the first motor 21 cooperation axis of rotation 22 on the mounting bracket 12 and rotate, a plurality of connecting rod 23 drives two scraper blades 24 and rotates, thereby scrape the residual coating on the inner wall of mixing box 1 when stirring the coating in mixing box 1, avoid the coating to remain, simultaneously axis of rotation 22 drive spiral stirring leaf 25 rotate, flow down the coating from the through-hole 14 on the arc 13, carry the stirring in the installation section of thick bamboo 15, get into in the churn 16, thereby improve stirring efficiency, can avoid artifical application of force time overlength to influence machining efficiency.

In this embodiment, the second stirring assembly 3 includes a fixed seat 31 installed at one side of the stirring barrel 16, a second motor 32 is fixedly installed at one side of the fixed seat 31, an output shaft of the second motor 32 extends to an inner wall of the stirring barrel 16, and is fixedly connected with a rotating rod 33, the other end of the rotating rod 33 is rotationally connected with the inner wall of the stirring barrel 16, and a plurality of stirring rods 34 are arranged on the surface of the rotating rod 33.

When the stirring device is specifically used, the second motor 32 on the fixed seat 31 is matched with the rotating rod 33 to drive the stirring rods 34 to rotate, the stirring rods 34 stir the paint inside the stirring barrel 16 again, the stirring efficiency of the paint is further improved, and the stirring of the paint is more uniform.

In this embodiment, the bottom end of the rotation shaft 22 extends on the inner wall of the installation cylinder 15, and the width of the spiral stirring vane 25 is smaller than the radius of the inner wall of the installation cylinder 15.

When the device is particularly used, the spiral stirring blade 25 is used for stirring and conveying the paint, so that the conveying speed of the paint is convenient to slow down.

In this embodiment, the top of the mixing drum 16 is provided with a through hole 161, the inner wall of the through hole 161 is fixedly connected with the bottom of the mounting drum 15, the bottom of the mixing drum 16 is provided with a material guiding opening 162, the bottom of the material guiding opening 162 is fixedly connected with a material discharging pipe 163, and the bottom end of the material discharging pipe 163 extends to the bottom of the mixing box 1.

In specific use, paint in the mounting cylinder 15 enters the stirring cylinder 16 from the through hole 161, is stirred, enters the discharge pipe 163 from the material guide opening 162, and is discharged out of the mixing box 1.

In this embodiment, the surface of the feeding funnel 11 is provided with a first electromagnetic valve 111, and the surface of the discharging pipe 163 is provided with a second electromagnetic valve 164.

In particular, the first solenoid valve 111 controls the flow of material into the hopper 11 and the second solenoid valve 164 controls the discharge of paint from the discharge tube 163.

In this embodiment, a plurality of support columns 17 are fixedly installed at the bottom of the mixing box 1, and support pads 171 are respectively arranged at the bottoms of the plurality of support columns 17.

In particular use, the plurality of support columns 17 cooperate with the plurality of support pads 171 to facilitate support of the mixing tank 1.

In this embodiment, the surface of the mixing box 1 is provided with a control panel 18, and the first electromagnetic valve 111, the second electromagnetic valve 164, the first motor 21 and the second motor 32 are all electrically connected with an external power supply through the control panel 18.

When the device is specifically used, the control panel 18 is used for controlling the first electromagnetic valve 111, the second electromagnetic valve 164, the first motor 21 and the second motor 32, so that the device is convenient for mixing and stirring the paint, and the stirring efficiency is improved.

Working principle: when the device is used, the device is connected with an external power supply, raw materials firstly enter the mixing box 1 from two feeding hoppers 11, a first motor 21 on a mounting frame 12 is matched with a rotating shaft 22 to drive a plurality of connecting rods 23 to rotate, the plurality of connecting rods 23 drive two scraping plates 24 to rotate, residual paint on the inner wall of the mixing box 1 is scraped while the paint in the mixing box 1 is stirred, meanwhile, the rotating shaft 22 drives a spiral stirring blade 25 to rotate, the paint flows down from a through hole 14 on an arc plate 13 and is conveyed and stirred in a mounting cylinder 15, the paint in the mounting cylinder 15 enters a stirring cylinder 16 from a through hole 161, a second motor 32 on a fixing seat 31 is matched with a rotating rod 33 to drive a plurality of stirring rods 34 to rotate, the plurality of stirring rods 34 stir the paint in the stirring cylinder 16 again, the stirring efficiency of the paint is further improved, the paint enters a discharging pipe 163 from a material guide opening 162 after stirring, and then is discharged out of the mixing box 1.

Although the embodiments of the present utility model and the accompanying drawings have been disclosed for illustrative purposes, those skilled in the art will appreciate that: various substitutions, changes and modifications are possible without departing from the spirit and scope of the utility model and the appended claims, and therefore the scope of the utility model is not limited to the embodiments and the disclosure of the drawings.

Claims (7)

1. Coating production mixing equipment, including mixing box (1), its characterized in that: both sides at the top of the mixing box (1) are provided with a feeding funnel (11), a mounting frame (12) is fixedly mounted in the middle of the top of the mixing box (1), a first stirring assembly (2) is arranged at the bottom of the mounting frame (12), an arc plate (13) is fixedly mounted on the inner wall of the mixing box (1), a through hole (14) is formed in the bottom of the arc plate (13), an installation cylinder (15) is fixedly mounted at the edge of the inner wall of the through hole (14), a stirring cylinder (16) is fixedly mounted at the bottom of the installation cylinder (15), and a second stirring assembly (3) is arranged at one side of the stirring cylinder (16);

the first stirring assembly (2) comprises a first motor (21) arranged at the bottom of the mounting frame (12), an output shaft of the first motor (21) extends to the inside of the mixing box (1), and is fixedly connected with a rotating shaft (22), a plurality of connecting rods (23) are fixedly arranged on the surface of the rotating shaft (22), the other ends of the connecting rods (23) are fixedly connected with scraping plates (24), and spiral stirring blades (25) are arranged on the surface of the lower end of the rotating shaft (22).

2. The paint production mixing apparatus of claim 1 wherein: the second stirring assembly (3) comprises a fixing seat (31) arranged on one side of the stirring barrel (16), a second motor (32) is fixedly arranged on one side of the fixing seat (31), an output shaft of the second motor (32) extends to the inner wall of the stirring barrel (16), a rotating rod (33) is fixedly connected with the output shaft, the other end of the rotating rod (33) is rotatably connected with the inner wall of the stirring barrel (16), and a plurality of stirring rods (34) are arranged on the surface of the rotating rod (33).

3. The paint production mixing apparatus of claim 1 wherein: the bottom end of the rotating shaft (22) extends on the inner wall of the mounting cylinder (15), and the width of the spiral stirring blade (25) is smaller than the radius of the inner wall of the mounting cylinder (15).

4. The paint production mixing apparatus as claimed in claim 2, wherein: the top of churn (16) has seted up through hole (161), the inner wall of through hole (161) and the bottom fixed connection of installation section of thick bamboo (15), guide mouth (162) have been seted up to the bottom of churn (16), the bottom fixedly connected with discharging pipe (163) of guide mouth (162), the bottom of discharging pipe (163) extends to the bottom of mixing box (1).

5. The paint production mixing apparatus of claim 4 wherein: the surface of feed hopper (11) is equipped with first solenoid valve (111), the surface of discharging pipe (163) is equipped with second solenoid valve (164).

6. The paint production mixing apparatus of claim 1 wherein: the bottom of mixing box (1) is fixedly mounted with a plurality of support column (17), and the bottom of a plurality of support column (17) all is equipped with supporting pad (171).

7. A paint producing mixing apparatus as claimed in claim 5 wherein: the surface of the mixing box (1) is provided with a control panel (18), and the first electromagnetic valve (111), the second electromagnetic valve (164), the first motor (21) and the second motor (32) are all connected with the control panel (18).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202223122344.9U CN219024121U (en) | 2022-11-24 | 2022-11-24 | Coating production mixing equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202223122344.9U CN219024121U (en) | 2022-11-24 | 2022-11-24 | Coating production mixing equipment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN219024121U true CN219024121U (en) | 2023-05-16 |

Family

ID=86275667

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202223122344.9U Active CN219024121U (en) | 2022-11-24 | 2022-11-24 | Coating production mixing equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN219024121U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116621315A (en) * | 2023-07-24 | 2023-08-22 | 尚丰智星(天津)环境有限公司 | Sewage combined type advanced oxidation device |

-

2022

- 2022-11-24 CN CN202223122344.9U patent/CN219024121U/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116621315A (en) * | 2023-07-24 | 2023-08-22 | 尚丰智星(天津)环境有限公司 | Sewage combined type advanced oxidation device |

| CN116621315B (en) * | 2023-07-24 | 2023-10-20 | 尚丰智星(天津)环境有限公司 | Sewage combined type advanced oxidation device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN215539924U (en) | High efficiency powder mixer | |

| CN219024121U (en) | Coating production mixing equipment | |

| CN210946389U (en) | Fly ash prevention continuous asphalt concrete cleaning hot mixing device | |

| CN220696543U (en) | Pulp stirring device | |

| CN213611156U (en) | High-speed dispersion machine with good stability for chemical production | |

| CN220919040U (en) | Oily paint pulping device | |

| CN219596498U (en) | Raw material pretreatment device convenient to clean and used for UV glue production | |

| CN219788881U (en) | Material mixer for plastic processing | |

| CN221619111U (en) | Efficient and uniform paint stirrer | |

| CN220245888U (en) | Coal slime drying device of coal washery | |

| CN112844153A (en) | Agitating unit is used in bean vermicelli raw materials processing | |

| CN219294343U (en) | Feeding and compounding device for production | |

| CN218962309U (en) | Variable-frequency high-speed stirrer | |

| CN217962279U (en) | Sealant automatic production line mixing device | |

| CN221244712U (en) | Material mixing device for hydraulic engineering construction | |

| CN221832108U (en) | Material stirring device | |

| CN220159229U (en) | Feeding and discharging continuous stable quaternary ammonium alkaline aqueous solution concentrating device | |

| CN217189068U (en) | Powder concentrator material dispersion equipment | |

| CN219729849U (en) | Quantitative discharging device for powder coating | |

| CN220345575U (en) | Automatic batching machine | |

| CN220715544U (en) | Mixing device for mixing stone paint imitation putty powder | |

| CN215996298U (en) | Pretreatment device for gypsum | |

| CN220634114U (en) | Wastewater treatment device for industrial chemicals production | |

| CN220026873U (en) | Horizontal spiral ribbon stainless steel mixer | |

| CN220009186U (en) | Additive control amount injection device for printing equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| EE01 | Entry into force of recordation of patent licensing contract |

Assignee: TIANJIN RUBBER INDUSTRY INSTITUTE CO.,LTD. Assignor: TIANJIN BOHAI VOCATIONAL TECHNICAL College Contract record no.: X2024980000356 Denomination of utility model: A coating production mixing equipment Granted publication date: 20230516 License type: Common License Record date: 20240109 |

|

| EE01 | Entry into force of recordation of patent licensing contract |