CN218362130U - Lathe tool for machining valve body shaft hole - Google Patents

Lathe tool for machining valve body shaft hole Download PDFInfo

- Publication number

- CN218362130U CN218362130U CN202222468114.1U CN202222468114U CN218362130U CN 218362130 U CN218362130 U CN 218362130U CN 202222468114 U CN202222468114 U CN 202222468114U CN 218362130 U CN218362130 U CN 218362130U

- Authority

- CN

- China

- Prior art keywords

- valve body

- positioning

- main body

- shaft hole

- lathe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Turning (AREA)

Abstract

The utility model discloses a lathe frock of valve body shaft hole processing, include: the back of the main body is provided with a connecting disc connected with a lathe; an upper cover plate detachably connected with the main body; the positioning base is detachably arranged on the end face of the main body; the valve body is suitable for being positioned on the base and enables the shaft hole to face the front part of the main body; the positioning mechanism is detachably arranged on the end surface of the main body and is positioned on two sides of the valve body; the pressing mechanism is arranged on the upper cover plate in a lifting way and is matched with the positioning base to limit the up-and-down movement of the valve body; in this revolution mechanic was arranged in to the valve body, on the location base was arranged in to the valve body, the both sides of valve body were provided with positioning mechanism and realized spacing to the valve body left and right sides position, and the hold-down mechanism at valve body top and the removal of the vertical direction of location base cooperation restriction disk seat, the connection pad is connected with the rotation end of lathe, realizes that the valve body rotates around the axis direction in shaft hole, so has realized fixing the valve body through the frock.

Description

Technical Field

The utility model relates to a frock, especially lathe frock of valve body shaft hole processing are fixed to the valve body.

Background

In general, the main and auxiliary shaft holes of the main valve body of the ball valve are machined on a horizontal machining center machine tool by adopting a mandrel and a limiting part for positioning, pressing a workpiece on a workbench by a pressing plate and then machining by various rough and finish machining hole machining tools; in this way, the workbench of each machine tool can only realize the fixation of one valve body; for the working sites with limited machine tool quantity, the valve body is fixedly processed, so that the cost is high and the efficiency is low;

in conclusion, how to fix the valve body, after the last valve body is machined, the switching of the machined workpieces through the tool becomes a problem which needs to be solved urgently by researchers in the field.

SUMMERY OF THE UTILITY MODEL

The to-be-solved technical problem of the utility model is: how to fix the valve body through the tool;

in order to solve the technical problem, the utility model discloses the technical scheme who takes does:

the utility model discloses a lathe frock of valve body shaft hole processing, include: the back of the main body is provided with a connecting disc connected with a lathe; an upper cover plate detachably connected with the main body; the positioning base is detachably arranged on the end face of the main body; the valve body is suitable for the positioning base and enables the shaft hole of the valve body to face the front part of the main body; the positioning mechanism is detachably arranged on the end face of the main body, is positioned on two sides of the valve body, and is suitable for abutting against the valve body to limit the left and right movement of the valve body; the pressing mechanism is arranged on the upper cover plate in a lifting mode, is suitable for abutting against the top of the valve body and is matched with the positioning base to limit the valve body to move up and down;

in the scheme, the main body and the upper valve cover form a cylindrical rotary structure, so that the strength of the tool can be ensured, and the balance stability of the rotary centrifugal force of the tool during machining and application can be ensured, thereby being beneficial to improving the rotary stress condition of a main shaft of a numerical control lathe and the machining precision of a workpiece; in this revolution mechanic was arranged in to the valve body, on the locating base was arranged in to the valve body, the both sides of valve body were provided with positioning mechanism and realized spacing to the valve body left and right sides position, and the hold-down mechanism at valve body top and the removal of the vertical direction of locating base cooperation restriction disk seat, connection pad and the rotation end of lathe are connected, realize that the valve body rotates around the axis direction in shaft hole.

In order to explain how the positioning base is detachably arranged on the end surface of the main body, the bottom of the main body is provided with a hole body; the bottom of the positioning base is convexly provided with a positioning rod inserted into the hole body;

the positioning rod at the bottom of the positioning base is inserted into the hole body, so that the positioning of the main body and the positioning base is realized, and the positioning base is detachably connected with the main body through bolts.

In order to prevent the wearing and tearing from taking place between the hole body and the locating lever, the utility model discloses a be provided with wear-resisting cover between locating lever, the hole body.

In order to explain the concrete structure of positioning mechanism, the utility model discloses a positioning mechanism includes: the positioning seats are arranged on the end face of the main body and are positioned on two sides of the valve body; the side pressure rod is horizontally arranged at the top of the positioning seat and is in threaded connection with the positioning seat; rotating the side pressure rod to drive the end part of the side pressure rod to abut against the valve body;

the both sides of valve body all are provided with the positioning seat, and the top level of positioning seat is provided with the side depression bar, and through rotating the side depression bar, the tip that makes the side depression bar offsets with the valve body, has restricted the side-to-side motion of valve body.

In order to fix valve bodies with different specifications, the bottom of the positioning seat is provided with a slide block; a sliding groove for the sliding block to move is formed in the end face of the main body; the locking groove is formed in the end face of the main body and is parallel to the sliding groove; the bolt penetrates through the positioning seat and is connected with the T-shaped block positioned in the locking groove;

the positioning seat is arranged on the end face of the main body in a sliding mode through the matching of the sliding block and the sliding groove, and the linear motion of the positioning seat is realized; a T-shaped block is arranged in the locking groove, a bolt penetrates through the positioning seat to be connected with the T-shaped block, and the T-shaped block can be locked with the locking groove by rotating the bolt; therefore, the positioning seat can be locked after being moved; by adjusting the position of the positioning seat, the side pressure rods at the left and right positions of the valve bodies with different specifications can be abutted.

In order to explain the concrete structure of hold-down mechanism structure, the utility model discloses a hold-down mechanism includes: the thread sleeve is fixed on the upper cover plate; the compression screw is vertically connected with the threaded sleeve; the cover plate is arranged at the bottom of the compression screw and is suitable for abutting against the top of the valve body;

the pressing screw rod is rotated, the pressing screw rod descends relative to the threaded sleeve to enable the cover plate to be abutted to the top of the valve body, and the limit of the vertical direction of the valve body is limited through the matching of the positioning base, so that the fixation of the valve bodies with different heights is met.

The utility model has the advantages that: the utility model discloses a lathe frock of valve body shaft hole processing, in this revolution mechanic is arranged in to the valve body, the valve body is arranged in on the location base, the both sides of valve body are provided with positioning mechanism and realize spacing to the valve body left and right sides position, the hold-down mechanism at valve body top and the removal of the vertical direction of location base cooperation restriction disk seat, the connection pad is connected with the rotation end of lathe, realize that the valve body rotates around the axis direction in shaft hole, so realized through the frock that the valve body is fixed, need not arrange the valve body in spacing fixedly on the workstation of lathe.

Drawings

The present invention will be further explained with reference to the drawings and examples.

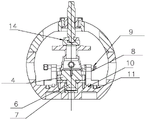

FIG. 1 is a schematic view of the present invention;

fig. 2 is a cross-sectional view of the present invention;

FIG. 3 is a schematic structural diagram of the connection pad of the present invention;

in the figure: the anti-abrasion valve comprises a main body 1, a connecting disc 2, an upper cover plate 3, a positioning base 4, a valve body 5, a positioning rod 6, a wear-resistant sleeve 7, a positioning seat 8, a lateral pressure rod 9, a sliding block 10, a T-shaped block 11, a threaded sleeve 12, a screw tightening rod 13 and a cover plate 14.

Detailed Description

The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are simplified schematic drawings and illustrate the basic structure of the present invention only in a schematic manner, and thus show only the components related to the present invention.

As shown in fig. 1-2, the utility model discloses a lathe frock of valve body shaft hole processing, include: a main body 1, the back of which is provided with a connecting disc 2 connected with a lathe; an upper cover plate 3 detachably connected to the main body 1; a positioning base 4 detachably provided on an end surface of the main body 1; a valve body 5 fitted on the positioning base 4 with its axial hole facing the front of the main body 1; the positioning mechanism is detachably arranged on the end surface of the main body 1, is positioned at two sides of the valve body 5, is suitable for abutting against the valve body 5 and limits the left and right movement of the valve body 5; the pressing mechanism is arranged on the upper cover plate 3 in a lifting mode, is suitable for abutting against the top of the valve body 5 and is matched with the positioning base 4 to limit the up-and-down movement of the valve body 5;

in the scheme, the main body and the upper valve cover form a cylindrical rotary structure, so that the strength of the tool can be ensured, and the balance stability of the rotary centrifugal force of the tool during machining and application can be ensured, thereby being beneficial to improving the rotary stress condition of a main shaft of a numerical control lathe and the machining precision of a workpiece; in this revolution mechanic was arranged in to the valve body, on the locating base was arranged in to the valve body, the both sides of valve body were provided with positioning mechanism and realized spacing to the valve body left and right sides position, and the hold-down mechanism at valve body top and the removal of the vertical direction of locating base cooperation restriction disk seat, connection pad and the rotation end of lathe are connected, realize that the valve body rotates around the axis direction in shaft hole.

As shown in fig. 1-2, in order to explain how the positioning base is detachably disposed on the end surface of the main body, the bottom of the main body 1 is provided with a hole; a positioning rod 6 inserted into the hole body is convexly arranged at the bottom of the positioning base 4;

the locating lever of location base bottom inserts to the hole internal, has realized the location of main part with the location base, adopts the bolt to dismantle the connection between location base and the main part.

As shown in fig. 1-2, in order to prevent abrasion between the hole body and the positioning rod, the utility model discloses a wear-resistant sleeve 7 is arranged between the positioning rod 6 and the hole body.

As shown in fig. 1-2, in order to illustrate the specific structure of the positioning mechanism, the positioning mechanism of the present invention comprises: positioning seats 8 which are provided on the end surface of the main body 1 and located on both sides of the valve body 5; the lateral pressure rod 9 is horizontally arranged at the top of the positioning seat 8 and is in threaded connection with the positioning seat 8; rotating the side pressure rod 9 to drive the end part of the side pressure rod 9 to abut against the valve body 5;

the both sides of valve body all are provided with the positioning seat, and the top level of positioning seat is provided with the side depression bar, through rotating the side depression bar, makes the tip and the valve body counterbalance of side depression bar, has restricted the side-to-side motion of valve body.

As shown in fig. 1-2, in order to fix valve bodies with different specifications, the utility model adopts the positioning seat bottom 4 provided with a slide block 10; a sliding groove for the sliding block 10 to move is formed in the end face of the main body 1; the locking groove is formed in the end face of the main body 1 and is parallel to the sliding groove; the bolt penetrates through the positioning seat 9 and is connected with a T-shaped block 11 positioned in the locking groove;

the positioning seat is arranged on the end face of the main body in a sliding mode through the matching of the sliding block and the sliding groove, and the linear motion of the positioning seat is realized; a T-shaped block is arranged in the locking groove, a bolt penetrates through the positioning seat to be connected with the T-shaped block, and the T-shaped block can be locked with the locking groove by rotating the bolt; therefore, the positioning seat can be locked after being moved; by adjusting the position of the positioning seat, the side pressure rods at the left and right positions of the valve bodies with different specifications can be abutted.

As shown in fig. 1-2, in order to illustrate the specific structure of the pressing mechanism structure, the present invention adopts a pressing mechanism comprising: a threaded sleeve 12 fixed to the upper cover plate 3; a compression screw 13 vertically connected with the threaded sleeve 12; a cover plate 14 arranged at the bottom of the compression screw 13 and suitable for abutting against the top of the valve body 5;

the pressing screw rod is rotated, the pressing screw rod descends relative to the threaded sleeve to enable the cover plate to be abutted to the top of the valve body, and the limit of the vertical direction of the valve body is limited through the matching of the positioning base, so that the fixation of the valve bodies with different heights is met.

The utility model discloses a lathe frock of valve body shaft hole processing, in this revolution mechanic is arranged in to the valve body, the valve body is arranged in on the location base, the both sides of valve body are provided with positioning mechanism and realize spacing to the valve body left and right sides position, the hold-down mechanism at valve body top and the removal of the vertical direction of location base cooperation restriction disk seat, the connection pad is connected with the rotation end of lathe, realize that the valve body rotates around the axis direction in shaft hole, so realized through the frock that the valve body is fixed, need not arrange the valve body in spacing fixedly on the workstation of lathe.

The connecting disc in the tool can be connected with two numerically controlled lathes, namely a Shenyang machine tool CAK6385d and a Baoji machine tool CBK63, and the tool is designed into a structural form capable of being connected with the two lathes. As shown in fig. 3, the left end is the part connected with the machine tool, and the connection disc at the left end is used as a boundary, if the connection disc at the left end is installed, the connection disc can be connected with a Shenyang CAK6385d numerical control lathe by using a short conical surface of 7.73 degrees and six installation locking columns; if the connecting disc at the left end of the A datum is removed, a phi 260 (+ 0.052, 0) short cylindrical surface can be used for directly connecting with a Baoji CBK63 numerically controlled lathe; due to the design, the connecting feasibility of the tool and numerically controlled lathes with different spindle forms is enhanced, and the tool is higher in applicability.

In light of the foregoing, it will be apparent to those skilled in the art from this disclosure that various changes and modifications can be made without departing from the spirit and scope of the invention. The technical scope of the present invention is not limited to the content of the specification, and must be determined according to the scope of the claims.

Claims (6)

1. Lathe frock of valve body shaft hole processing, its characterized in that includes:

the back of the main body is provided with a connecting disc connected with a lathe;

an upper cover plate detachably connected with the main body;

the positioning base is detachably arranged on the end face of the main body;

the valve body is suitable for the positioning base and enables the shaft hole of the valve body to face the front part of the main body;

the positioning mechanisms are detachably arranged on the end surface of the main body, are positioned on two sides of the valve body, and are suitable for abutting against the valve body to limit the left and right movement of the valve body;

and the pressing mechanism is arranged on the upper cover plate in a lifting manner, is suitable for abutting against the top of the valve body and is matched with the positioning base to limit the valve body to move up and down.

2. The lathe tool for machining the shaft hole of the valve body according to claim 1, wherein a hole body is formed in the bottom of the main body;

and a positioning rod inserted into the hole body is convexly arranged at the bottom of the positioning base.

3. The lathe tool for machining the shaft hole of the valve body according to claim 2, wherein a wear-resistant sleeve is arranged between the positioning rod and the hole body.

4. The lathe tool for machining the shaft hole of the valve body according to claim 1, wherein the positioning mechanism comprises:

the positioning seats are arranged on the end face of the main body and are positioned on two sides of the valve body;

the side pressure rod is horizontally arranged at the top of the positioning seat and is in threaded connection with the positioning seat;

and rotating the side pressure rod to drive the end part of the side pressure rod to abut against the valve body.

5. The lathe tooling for machining the shaft hole of the valve body according to claim 4, wherein a sliding block is arranged at the bottom of the positioning seat;

a sliding groove for the sliding block to move is formed in the end face of the main body;

the locking groove is formed in the end face of the main body and is parallel to the sliding groove;

the bolt penetrates through the positioning seat and is connected with the T-shaped block positioned in the locking groove.

6. The lathe tool for machining the shaft hole of the valve body according to claim 1, wherein the pressing mechanism comprises:

the threaded sleeve is fixed on the upper cover plate;

the compression screw is vertically connected with the threaded sleeve;

and the cover plate is arranged at the bottom of the compression screw and is suitable for abutting against the top of the valve body.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202222468114.1U CN218362130U (en) | 2022-09-16 | 2022-09-16 | Lathe tool for machining valve body shaft hole |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202222468114.1U CN218362130U (en) | 2022-09-16 | 2022-09-16 | Lathe tool for machining valve body shaft hole |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN218362130U true CN218362130U (en) | 2023-01-24 |

Family

ID=84952461

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202222468114.1U Active CN218362130U (en) | 2022-09-16 | 2022-09-16 | Lathe tool for machining valve body shaft hole |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN218362130U (en) |

-

2022

- 2022-09-16 CN CN202222468114.1U patent/CN218362130U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108480923B (en) | Method for precisely machining large thin-wall revolving body part | |

| CN112264920A (en) | Vertical inner hole and outer circle honing integrated machine tool | |

| CN100441372C (en) | Circular guide rail bench | |

| CN110091186B (en) | Mosaic direct-drive rotary workbench using hydrostatic guideway | |

| CN112091621A (en) | Vertical grinding and turning combined machine tool | |

| CN218362130U (en) | Lathe tool for machining valve body shaft hole | |

| CN209868001U (en) | Machining tool for electric door pump reducer shell | |

| CN110303355B (en) | Cylindrical workpiece lateral turning tool and processing method | |

| CN218983317U (en) | CNC cylinder work piece compresses tightly and mills rotatory tray device of location | |

| CN206952224U (en) | Fixture for shift fork drilling | |

| CN214186194U (en) | Positioning tool for local casting machining | |

| CN211489749U (en) | Lathe is used in processing of piston pin hole | |

| CN202278402U (en) | Process equipment for machining bearing block by utilizing lathe | |

| CN2614100Y (en) | Bucket triaxial rigid boring lathe | |

| CN2144560Y (en) | Planetary grinding device for vertical machine tool | |

| CN112571091A (en) | Tool position refitting method of economical numerical control lathe | |

| CN221911166U (en) | Chamfering machine for metal product processing | |

| CN218169424U (en) | High-precision numerical control rotary table | |

| CN219818944U (en) | Gun turret mills 3HG cross nut seat car Y to hole anchor clamps | |

| CN215035538U (en) | Boring machine fixture | |

| CN220006855U (en) | Multifunctional fixing clamp | |

| CN214134857U (en) | Vertical drilling and milling machining center structure | |

| CN217776317U (en) | Drilling and milling tool for lower valve body of anti-slip device | |

| CN215510233U (en) | Lightweight high-speed horizontal machining center | |

| CN218533627U (en) | Special fixture for drilling process of top drive rotary head |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |