CN217500323U - Safety well lid with air exhaust function - Google Patents

Safety well lid with air exhaust function Download PDFInfo

- Publication number

- CN217500323U CN217500323U CN202220911601.8U CN202220911601U CN217500323U CN 217500323 U CN217500323 U CN 217500323U CN 202220911601 U CN202220911601 U CN 202220911601U CN 217500323 U CN217500323 U CN 217500323U

- Authority

- CN

- China

- Prior art keywords

- exhaust fan

- well

- lid

- exhaust

- cover body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Sewage (AREA)

Abstract

The utility model relates to an underground piping maintains technical field, concretely relates to safety well lid of function of airing exhaust in area. The utility model provides a safety well lid of function of airing exhaust in area, includes: the cover body is assembled at the position of a well opening in an openable and closable manner, and a harmful gas detection device is further arranged in the well; an exhaust fan liftably fitted in the wellhead; the transmission assembly, the lid passes through the transmission assembly drives the exhaust fan goes up and down, works as when the lid is opened, the lid passes through the transmission assembly drives the exhaust fan descends to the well depths. The vertical gag lever post that is equipped with in the well head, the exhaust fan sliding assembly is in on the gag lever post, it is equipped with the elastic component still to overlap on the gag lever post, elastic component elastic support the exhaust fan. The technical problems that natural ventilation and exhaust effects of the shaft are poor, ventilation time is long, and whether residual toxic gas in the shaft reaches the safety standard or not can not be confirmed in the prior art are solved.

Description

Technical Field

The utility model relates to an underground piping maintains technical field, concretely relates to safety well lid of function of airing exhaust in area.

Background

With the rapid development of cities, various underground pipelines are arranged more and more densely. Various pipelines such as power, heating, tap water, rain and sewage, communication and the like in urban centers are arranged in a star and checkered manner and complicated, and wells are often arranged at turning positions or branch positions for underground pipelines so as to facilitate the operation and maintenance of the pipelines. Sealed wells located in the subsurface for long periods of time typically collect harmful gases. After the well lid is opened, the deeper well, the more difficult harmful gas in it is got rid of through the natural draft mode under natural conditions, and fortune dimension personnel are sometime in uncertain well harmful gas content the trade down well operation, and remaining harmful gas will threaten pipeline fortune dimension personnel's personal safety. In recent years, when the underground limited space works, harmful gas poisoning incidents occur occasionally, and the alarm clock is sounded when underground operators carry out the work.

In order to remove harmful gas in the well and facilitate the operation and maintenance personnel to enter the well for maintenance, in the prior art, an exhaust fan is assembled at the well cover to discharge the toxic gas in the well. As the application document with the application number of CN201920874833.9, the utility model discloses a safe explosion-proof automatic air discharge formula well lid of sewer to specifically disclose: the well cover is provided with a cavity, and the exhaust fan comprises an exhaust fan motor arranged in the cavity, a rotating shaft extending out of the cavity and connected with the exhaust fan motor and a fan blade part, and a fan blade part connected with the rotating shaft; the top of the cavity is provided with a sealing cover plate, and the well cover is provided with an exhaust hole for exhausting gas. The exhaust fan of the exhaust type well lid is assembled on the well lid, and when the well lid is opened outwards, the exhaust fan is also positioned outside the well mouth, so that the exhaust effect of the exhaust type well lid on the well is weak; when the well lid covers, the exhaust fan is located within the well head, but the well lid can block the well head, even be formed with the exhaust hole on the well lid, nevertheless because area of ventilation is little, its exhaust effect is also relatively weak.

SUMMERY OF THE UTILITY MODEL

The natural draft exhaust effect in order to solve the well among the prior art is poor, and the ventilation time is long, and can't confirm in the well whether remain the technical problem below the toxic gas reaches the safety standard, the utility model provides a take safety well lid of function of airing exhaust for above-mentioned technical problem has been solved. The technical scheme of the utility model as follows:

the utility model provides a safety well lid of function of airing exhaust in area, includes:

the cover body is assembled at the position of a well opening in an openable and closable manner, and a harmful gas detection device is further arranged in the well;

an exhaust fan liftably fitted in the wellhead;

the transmission assembly, the lid passes through the transmission assembly drives the exhaust fan goes up and down, works as when the lid is opened, the lid passes through the transmission assembly drives the exhaust fan descends to the well depths.

The utility model provides a take safety well lid of exhaust function sets up the exhaust fan in the well mouth, rather than the assembly on the lid, then the exhaust fan can not be because of the lid is opened and be located outside the well mouth, also can not only be located the well mouth when the lid covers the well mouth, in this application, the exhaust fan will be located the well mouth all the time, when the lid is opened, the exhaust fan work, can drive the flow of gas in the well, get rid of the harmful gas in the well as early as possible. In addition, the cover body drives the exhaust fan to lift through the transmission assembly, and when the cover body is opened, the exhaust fan can be driven to descend to the deep part of the well, so that on one hand, the exhaust fan can effectively drive gas inside the well to circulate, harmful gas in the well is discharged, and the personal safety of operating personnel is guaranteed; on the other hand, the exhaust fan descends, and can avoid the well mouth, so that operation and maintenance personnel can conveniently go into the well for operation.

According to the utility model discloses an embodiment, the vertical gag lever post that is equipped with in the well head, the exhaust fan sliding assembly is in on the gag lever post, it is equipped with the elastic component still to overlap on the gag lever post, elastic component elastic support the exhaust fan.

According to the utility model discloses an embodiment, the gag lever post is two at least, two piece at least gag lever posts parallel arrangement.

According to the utility model discloses an embodiment, the periphery of exhaust fan extends there is connecting portion, the exhaust fan passes through connecting portion sliding assembly is in on the gag lever post, elastic component elastic support connecting portion.

According to the utility model discloses an embodiment, transmission assembly includes stay cord and direction subassembly, the one end of stay cord with the lid is connected, the other end warp of stay cord the direction subassembly with the exhaust fan is connected, works as when the lid is opened, the stay cord pulling the exhaust fan compression the elastic component downstream to the well depths.

According to the utility model discloses an embodiment, the direction subassembly includes leading wheel and fixed pulley, the leading wheel sets up on the well lateral wall, the fixed pulley sets up on the well bottom surface, the stay cord passes through earlier the leading wheel, passes through again behind the fixed pulley with the exhaust fan is connected.

According to the utility model discloses an embodiment, the stay cord warp vertical upwards extension behind the fixed pulley, the stay cord with the bottom middle part of exhaust fan is connected.

According to the utility model discloses an embodiment, the leading wheel is two, two the leading wheel is located same vertical direction, and the leading wheel that is located the top is close to the lid sets up, the leading wheel that is located the below with the fixed pulley is located same level.

According to the utility model discloses an embodiment, the articulated assembly of lid is in well head department, the stay cord with the tie point of lid with the pin joint of lid is relative.

Based on the technical scheme, the utility model discloses the technological effect that can realize does:

1. the utility model discloses a take safety well lid of exhausting function, go up and down to set up the exhaust fan in the well head, rather than the assembly on the lid, then the exhaust fan can not be located outside the well head because of the lid is opened, also can not only just be located the well head when the lid covers the well head, in this application, the exhaust fan will be located the well head all the time, when the lid is opened, the exhaust fan work, can drive the flow of gas in the well, get rid of the harmful gas in the well as early as possible, and simultaneously, both ends well head department at the well all is equipped with harmful gas detection device, when the harmful gas detection device's of well both ends well head department detection result all reaches the requirement, the operation personnel just allow the operation of going into the well. In addition, the cover body drives the exhaust fan to lift through the transmission assembly, and when the cover body is opened, the exhaust fan is driven to descend to the deep part of the well, so that on one hand, the exhaust fan can effectively drive the gas inside the well to circulate; on the other hand, the exhaust fan descends to avoid the wellhead, so that operation and maintenance personnel can conveniently go into the well for operation; when the cover body is closed, the exhaust fan is positioned at a position close to a well mouth, so that the exhaust fan can be prevented from contacting harmful gas or internal liquid as far as possible, and the exhaust fan is prevented from being damaged;

2. the safety well lid with the air exhaust function is provided with the limiting rod which is vertically assembled, the exhaust fan is assembled on the limiting rod in a sliding mode, the exhaust fan is elastically supported by the elastic piece, when the well lid is closed, the exhaust fan can be located at a higher position in a well head under the supporting effect of the elastic piece, and when the well lid is opened, the exhaust fan can be driven to compress the elastic piece to move downwards, so that the lifting motion of the exhaust fan is realized; the limiting rods are at least two, so that the exhaust fan can be ensured to do lifting motion only in the vertical direction, and deflection cannot occur;

3. the utility model discloses a take safety well lid of exhausting function sets up drive assembly and includes stay cord and direction subassembly, and opening of well lid can pull the stay cord, and then overcomes the effect downstream of elastic component through stay cord pulling exhaust fan. The pull rope is further arranged to vertically extend upwards through the guide assembly to be connected with the bottom of the exhaust fan, so that the well cover is opened to pull the pull rope, and the pull rope can pull the exhaust fan to overcome the action of the elastic piece to slide downwards stably along the vertical downward direction;

4. the safety well lid with the air exhaust function of the utility model is provided with the connecting point of the stay cord and the well lid opposite to the hinge point of the well lid, so that when the well lid is opened, the stay cord is pulled to a larger extent to drive the exhaust fan to descend to a deeper position; all be provided with gaseous detection device at the both ends wellhead department of well, the harmful gas concentration in the detectable well, when the harmful gas detection device's of well both ends wellhead department's testing result all reached the requirement, the operation personnel just allowed the operation of going into the well. Effectively reduces the risk of harmful gas poisoning of underground pipeline operation and maintenance personnel and ensures personal safety.

Drawings

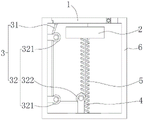

Fig. 1 is a schematic structural view of the safety well lid with the ventilation function of the utility model;

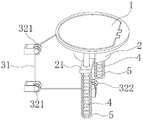

FIG. 2 is a schematic view of the exhaust fan assembly;

FIG. 3 is a diagram of the exhaust fan with the cover open;

in the figure: 1-a cover body; 2-an exhaust fan; 21-a connecting part; 3-a transmission assembly; 31-a pull rope; 32-a guide assembly; 321-a guide wheel; 322-a fixed pulley; 4-a limiting rod; 5-an elastic member; 6-well; 61-well head.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. The following description of at least one exemplary embodiment is merely illustrative in nature and is in no way intended to limit the invention, its application, or uses. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative efforts belong to the protection scope of the present invention.

It is noted that the terminology used herein is for the purpose of describing particular embodiments only and is not intended to be limiting of example embodiments according to the present application. As used herein, the singular forms "a", "an" and "the" are intended to include the plural forms as well, and it should be understood that when the terms "comprises" and/or "comprising" are used in this specification, they specify the presence of stated features, steps, operations, devices, components, and/or combinations thereof, unless the context clearly indicates otherwise.

Unless specifically stated otherwise, the relative arrangement of the components and steps, the numerical expressions, and numerical values set forth in these embodiments do not limit the scope of the present invention. Meanwhile, it should be understood that the sizes of the respective portions shown in the drawings are not drawn in an actual proportional relationship for the convenience of description. Techniques, methods, and apparatus known to those of ordinary skill in the relevant art may not be discussed in detail but are intended to be part of the specification where appropriate. In all examples shown and discussed herein, any particular value should be construed as merely illustrative, and not limiting. Thus, other examples of the exemplary embodiments may have different values. It should be noted that: like reference numbers and letters refer to like items in the following figures, and thus, once an item is defined in one figure, further discussion thereof is not required in subsequent figures.

In the description of the present invention, it should be understood that the orientation or positional relationship indicated by the orientation words such as "front, back, up, down, left, right", "horizontal, vertical, horizontal" and "top, bottom" etc. are usually based on the orientation or positional relationship shown in the drawings, and are only for convenience of description and simplification of description, and in the case of not making a contrary explanation, these orientation words do not indicate and imply that the device or element referred to must have a specific orientation or be constructed and operated in a specific orientation, and therefore, should not be interpreted as limiting the scope of the present invention; the terms "inner and outer" refer to the inner and outer relative to the profile of the respective component itself.

Spatially relative terms, such as "above … …", "above … …", "above … …, on a surface", "above", and the like, may be used herein for ease of description to describe one device or feature's spatial relationship to another device or feature as illustrated in the figures. It will be understood that the spatially relative terms are intended to encompass different orientations of the device in use or operation in addition to the orientation depicted in the figures. For example, if a device in the figures is turned over, devices described as "above" or "on" other devices or configurations would then be oriented "below" or "under" the other devices or configurations. Thus, the exemplary term "above … …" can include both an orientation of "above … …" and "below … …". The device may be otherwise variously oriented (rotated 90 degrees or at other orientations) and the spatially relative descriptors used herein interpreted accordingly.

It should be noted that the terms "first", "second", and the like are used to define the components, and are only used for convenience of distinguishing the corresponding components, and if not stated otherwise, the terms have no special meaning, and therefore, the scope of the present invention should not be construed as being limited.

As shown in fig. 1-3, the present embodiment provides a safety well lid with an air exhaust function, which is disposed at a wellhead 61 of a hoistway 6, specifically, the safety well lid with an air exhaust function of the present embodiment includes a lid body 1 and an air exhaust fan 2, the lid body 1 is openably and closably assembled at the wellhead 61, the air exhaust fan 2 is assembled in a liftable manner, the lid body 1 is connected with the air exhaust fan 2 through a transmission assembly 3, and the air exhaust fan 2 is pulled by the transmission assembly 3 to descend to the deep part of the hoistway 6 when the lid body 1 is opened.

The articulated assembly of lid 1 is at well head 61, and the switching can be rotated along the pin joint to lid 1. The cover body 1 is connected with the transmission assembly 3, and when the cover body 1 is opened, the transmission assembly 3 can be pulled, so that the exhaust fan 2 is driven to move.

As a preferred solution of this embodiment, the connection point of the cover body 1 and the transmission assembly 3 is opposite to the hinge point of the cover body 1. Preferably, the connecting point of the cover body 1 and the transmission assembly 3 and the hinge point of the cover body 1 are located on the same straight line passing through the center point of the cover body 1.

As a preferred technical scheme of this embodiment, the number of the limiting rods 4 is at least two, and the at least two limiting rods 4 are vertically arranged; correspondingly, the periphery of the exhaust fan 2 extends with a connecting part 21, the exhaust fan 2 is slidably assembled on the limiting rod 4 through the connecting part 21, and the elastic piece 5 elastically supports the connecting part 21. Preferably, gag lever post 4 evenly distributed is in exhaust fan 2's periphery, and exhaust fan 2 goes up to extend has at least two, and evenly distributed's connecting portion 21, and connecting portion 21 and gag lever post 4 one-to-one correspond sliding fit. The elastic member 5 may be selected from, but not limited to, a spring. In this embodiment, the number of the limiting rods 4 is two, and the two limiting rods 4 are symmetrically arranged on two sides of the exhaust fan 2.

The cover body 1 drives the exhaust fan 2 to slide downwards by overcoming the acting force of the elastic piece 5 through the transmission component 3. The transmission assembly 3 comprises a pull rope 31 and a guide assembly 32, one end of the pull rope 31 is connected with the cover body 1, the other end of the pull rope 31 is connected with the exhaust fan 2 through the guide assembly 32, and when the cover body 1 is opened, the pull rope 31 pulls the exhaust fan 2 from the lower part of the exhaust fan 2 to overcome the acting force of the elastic part 5 and slide downwards along the limiting rod 4; when the cover 1 is closed, the pull rope 31 is loosened, and the exhaust fan 2 is lifted back to the lower part of the cover 1 under the action of the elastic member 5.

As a preferable configuration of the present embodiment, one end of the pull cord 31 is connected to the lower surface of the lid body 1, and the other end of the pull cord 31 is connected to the bottom end of the exhaust fan 2. Preferably, the other end of the pulling rope 31 is connected to the middle of the bottom end of the exhaust fan 2.

In this embodiment, the guiding assembly 32 includes a guiding wheel 321 and a fixed pulley 322, and the pulling rope 31 can extend downwards along the sidewall of the hoistway 6 to the lower side of the exhaust fan 2 through the guiding wheel 321, and then vertically extend upwards through the fixed pulley 322 to be connected with the bottom end of the exhaust fan 2. Preferably, the number of the guide wheels 321 is at least two, the guide wheels 321 are mounted on the side wall of the hoistway 6, the at least two guide wheels 321 are located on the same vertical line, the pulling rope 31 extends to a position close to the bottom surface of the hoistway 6 through the guide wheels 321, the fixed pulley 322 is one, the fixed pulley 322 is mounted on the bottom surface of the hoistway 6, the fixed pulley 322 is located right below the exhaust fan 2, and the pulling rope 31 extends vertically upwards after passing through the fixed pulley 322 and is connected with the middle part of the bottom end of the exhaust fan 2.

As a preferable embodiment of the present invention, two guide wheels 321 are provided, the two guide wheels 321 are located in the same vertical direction, the upper guide wheel 321 is located near the cover body 1 of the wellhead 61, and the lower guide wheel 321 and the fixed pulley 322 are located at the same horizontal height. The pulling rope 31 firstly passes through the upper guide wheel 321, then passes through the lower guide wheel 321, and then horizontally extends to the fixed pulley 322, and after passing through the fixed pulley 322, the pulling rope 31 vertically extends to be connected with the middle part of the bottom end of the exhaust fan 2.

As a preferable technical solution of the present embodiment, a harmful gas detection device is further provided in the hoistway 6, and is configured to detect a concentration of a harmful gas. Specifically, harmful gas detection devices may be disposed at both end wellheads 61 of the hoistway 6, and when detection results of the harmful gas detection devices at both end wellheads 61 of the hoistway 6 meet requirements, the operator may allow the operation of going into the well.

Based on the technical scheme, the use method of the safety well lid with the air exhaust function in the embodiment comprises the following steps:

s1, when the pipeline operation and maintenance personnel prepare for descending the well, only the cover bodies 1 of the safety well covers on the two sides of the well 6 need to be opened, an exhaust fan switch of the safety well cover is triggered, and the exhaust fan 2 is started;

s2, after a period of time, the harmful gas in the hoistway 6 is reduced. Harmful gas detection devices at well mouths at two ends of the well 6 are started to perform timing detection functions. When the content of the harmful gas is continuously lower than the standard value for three times and the descending trend is gradually flat, the harmful gas in the well 6 is completely discharged, and workers can safely go into the well for work;

s3, after the work is finished, covering the cover body 1, stopping the work of the exhaust fan 2, and returning to the lower part of the cover body 1 under the action of the elastic piece 5; and (4) the harmful gas detection devices at the well mouths at the two ends of the well 6 enter a dormant state.

The embodiments of the present invention have been described in detail with reference to the drawings, but the present invention is not limited to the above embodiments, and various changes can be made without departing from the spirit of the present invention within the knowledge of those skilled in the art.

Claims (9)

1. The utility model provides a safety well lid of function of airing exhaust in area which characterized in that includes:

the cover body (1), the cover body (1) can be assembled at the well head (61) of the well (6) in an opening and closing way, and a harmful gas detection device is also arranged in the well (6);

an exhaust fan (2), the exhaust fan (2) being elevatably fitted within the wellhead (61);

drive assembly (3), lid (1) passes through drive assembly (3) drive exhaust fan (2) go up and down, work as when lid (1) is opened, lid (1) passes through drive assembly (3) drive exhaust fan (2) descend to the well depths.

2. The safety well lid with the air exhaust function according to claim 1, wherein a limiting rod (4) is vertically assembled in the well head (61), the exhaust fan (2) is slidably assembled on the limiting rod (4), an elastic part (5) is further sleeved on the limiting rod (4), and the exhaust fan (2) is elastically supported by the elastic part (5).

3. The safety well lid with the air exhaust function according to claim 2, characterized in that the limiting rods (4) are at least two, and at least two limiting rods (4) are arranged in parallel.

4. The manhole cover with the air exhausting function according to claim 3, wherein a connecting portion (21) extends from the periphery of the air exhausting fan (2), the air exhausting fan (2) is slidably assembled on the limiting rod (4) through the connecting portion (21), and the elastic member (5) elastically supports the connecting portion (21).

5. The manhole cover with the air exhaust function according to any one of claims 2 to 4, wherein the transmission assembly (3) comprises a pull rope (31) and a guide assembly (32), one end of the pull rope (31) is connected with the cover body (1), the other end of the pull rope (31) is connected with the exhaust fan (2) through the guide assembly (32), and when the cover body (1) is opened, the pull rope (31) pulls the exhaust fan (2) to compress the elastic member (5) to move downwards to the deep part of a hoistway.

6. The manhole cover with the air exhausting function according to claim 5, wherein the guiding assembly (32) comprises a guiding wheel (321) and a fixed pulley (322), the guiding wheel (321) is arranged on the side wall of the hoistway (6), the fixed pulley (322) is arranged on the bottom surface of the hoistway (6), and the pulling rope (31) passes through the guiding wheel (321) and then the fixed pulley (322) and then is connected with the exhaust fan (2).

7. The manhole cover with the air exhausting function according to claim 6, wherein the pulling rope (31) passes through the fixed pulley (322) and then extends vertically upwards, and the pulling rope (31) is connected with the middle part of the bottom end of the exhaust fan (2).

8. The manhole cover with the air exhaust function according to any one of claims 6 to 7, wherein the number of the guide wheels (321) is two, the two guide wheels (321) are located in the same vertical direction, the upper guide wheel (321) is arranged close to the cover body (1), and the lower guide wheel (321) and the fixed pulley (322) are located at the same horizontal height.

9. The manhole cover with air exhaust function according to claim 5, wherein the cover body (1) is hinged to the well head (61), and the connection point of the pull rope (31) and the cover body (1) is opposite to the hinge point of the cover body (1).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220911601.8U CN217500323U (en) | 2022-04-19 | 2022-04-19 | Safety well lid with air exhaust function |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220911601.8U CN217500323U (en) | 2022-04-19 | 2022-04-19 | Safety well lid with air exhaust function |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN217500323U true CN217500323U (en) | 2022-09-27 |

Family

ID=83350407

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202220911601.8U Active CN217500323U (en) | 2022-04-19 | 2022-04-19 | Safety well lid with air exhaust function |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN217500323U (en) |

-

2022

- 2022-04-19 CN CN202220911601.8U patent/CN217500323U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN217500323U (en) | Safety well lid with air exhaust function | |

| CN111521444B (en) | Water sample detecting system | |

| CN203732312U (en) | In-situ sampler for spilling oil in sediment | |

| JP2008095411A (en) | Manhole cover operating method, manhole cover operating device, and manhole cover operating device assembling method | |

| KR101201998B1 (en) | Floodgate winch | |

| CN219493605U (en) | Municipal administration pipeline water environment detector | |

| CN208917253U (en) | Well formula glowing furnace organic exhaust gas collection device | |

| CN214667885U (en) | Ship ballast water sampling device | |

| CN206418921U (en) | The sliding door device and the vent cabinet of use for laboratory of a kind of vent cabinet for laboratory | |

| CN208140407U (en) | A kind of water sample acquisition device | |

| CN113751455B (en) | Low-carbon emission-reducing type low-air-volume intelligent laboratory ventilation equipment | |

| CN201423286Y (en) | Controllable volatile solvent environment-friendly operating room | |

| CN112051110B (en) | Industrial sewage sampling device | |

| CN215973207U (en) | Container with test bed | |

| CN206827390U (en) | Container with a lid | |

| KR20210042056A (en) | Rubber sealed sliding open type manhole cover | |

| CN215395325U (en) | High-safety environment-friendly operation table for detection | |

| CN219389752U (en) | Emergency emptying device of incinerator | |

| CN218784775U (en) | Oscillation device for detecting toxicity of wastewater | |

| CN111791789A (en) | Intelligent safety type multifunctional chemical detection fire truck | |

| CN221942433U (en) | Push-pull type sealing disc well lid door | |

| CN216771158U (en) | Sewage treatment plant sampling equipment | |

| CN214471983U (en) | Sampling device suitable for shallow water stereoplasm bed mud | |

| CN216955292U (en) | Sampling device for hydrogeology convenient to carry | |

| CN218725592U (en) | Sampling device for sludge treatment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |