CN217025645U - High-salinity wastewater treatment system - Google Patents

High-salinity wastewater treatment system Download PDFInfo

- Publication number

- CN217025645U CN217025645U CN202120963844.1U CN202120963844U CN217025645U CN 217025645 U CN217025645 U CN 217025645U CN 202120963844 U CN202120963844 U CN 202120963844U CN 217025645 U CN217025645 U CN 217025645U

- Authority

- CN

- China

- Prior art keywords

- waste

- unit

- waste gas

- outlet

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Heat Treatment Of Water, Waste Water Or Sewage (AREA)

Abstract

The utility model discloses a high-salinity wastewater treatment system, which comprises a filtering unit and a condensation collecting unit, wherein the filtering unit comprises a wastewater collecting box, a filter and a waste residue collecting box, and an inlet and an outlet of the filter are respectively connected with the wastewater collecting box and the waste residue collecting box; the advantage is that utilize domestic waste gas and light heat energy source evaporation, crystallization treatment high salt waste water, when avoiding waste gas energy waste, rational utilization solar energy, resources are saved greatly, clean environmental protection.

Description

Technical Field

The utility model relates to the field of wastewater treatment, in particular to a high-salinity wastewater treatment system.

Background

The high-salinity wastewater is wastewater with the total salt content of more than 1 percent and mainly comes from chemical plants, petroleum and natural gas collection and processing and other processes. The wastewater mainly contains various salts, organic matters and other substances, has high treatment difficulty, and can cause serious pollution to the environment and water bodies if directly discharged. With the continuous development of petrochemical industry, the generation way of high-salt wastewater is increasingly wide, the water amount is increased year by year, how to reasonably and optimally treat the high-salt wastewater becomes a serious problem, most of the existing high-salt wastewater evaporative crystallization modes adopt a mode of multi-effect evaporation and then crystallization or a mode of direct evaporation and then crystallization, but the energy consumption for treating the wastewater by using the modes is higher, and the cost is high.

Disclosure of Invention

The utility model aims to solve the technical problem of providing a high-salinity wastewater treatment system which can reduce resource waste, energy consumption and cost and is cleaner and more environment-friendly.

The technical scheme adopted by the utility model for solving the technical problems is as follows: the utility model provides a processing system of high salt waste water, includes filter unit and condensation collection unit, filter unit include waste water collecting box, filter and waste residue collecting box, the entry of filter, export respectively with waste water collecting box waste residue collecting box be connected, filter unit with the condensation collect and be provided with waste gas preheating unit and light and heat evaporation unit between the unit, filter unit waste gas preheating unit light and heat evaporation unit with condensation collect the unit and connect gradually, light and heat evaporation unit be connected with waste gas waste heat evaporation crystallization unit.

Preferably, the exhaust gas preheating unit comprises an exhaust gas conveying pipe and a tubular heat exchanger, an outlet of the filter is connected with an inlet of an inner pipe of the tubular heat exchanger, an outlet of the inner pipe of the tubular heat exchanger is connected with the photothermal evaporation unit, the exhaust gas conveying pipe is connected with an inlet of an outer pipe of the tubular heat exchanger, and an outlet of the outer pipe of the tubular heat exchanger is connected with an exhaust gas discharge pipe.

Preferably, a safety valve is arranged between the waste gas conveying pipe and an inlet of an outer pipe of the pipe type heat exchanger.

Preferably, the photothermal evaporation unit comprises a photosensitive electromagnetic valve, an arc-shaped reflecting plate and a solar heat collecting tube, the solar heat collecting tube is fixedly arranged in the arc-shaped reflecting plate, the solar heat collecting tube comprises a glass inner tube and a glass outer tube which are concentrically arranged, the glass outer tube is fixed with the glass inner tube, a heat absorbing layer is arranged on the outer surface of the glass inner tube, a vacuum layer is arranged between the glass outer tube and the glass inner tube, a steam outlet and a high-pressure spray head which are communicated with the glass inner tube are arranged on the solar heat collecting tube, the inlet of the glass inner tube is connected with the outlet of the inner tube of the tube heat exchanger through the photosensitive electromagnetic valve, and the outlet of the glass inner tube is connected with the waste gas afterheat evaporation crystallization unit.

Preferably, the arc-shaped reflector is a CPC reflector.

Preferably, the condensation collection unit comprises a condenser, a distilled water container and a fresh water pool, wherein an inlet of the condenser is connected with the steam outlet, an outlet of the condenser is connected with the distilled water container, and an outlet of the distilled water container is respectively connected with the high-pressure spray head and the fresh water pool.

Preferably, the waste gas waste heat evaporation crystallization unit comprises a crystallization tank and a reciprocating vacuum pump, a first water inlet valve is arranged between an outlet of the glass inner pipe and the crystallization tank, the bottom of the crystallization tank is fixed with the waste gas conveying pipe, a temperature sensor and an electric auxiliary heater are arranged at the inner bottom of the crystallization tank, a pressure release valve and a liquid level sensor are connected to the crystallization tank, an air suction valve of the reciprocating vacuum pump is connected with the crystallization tank, an exhaust valve of the reciprocating vacuum pump is connected with the condenser, and the reciprocating vacuum pump is electrically connected with a motor.

Preferably, a pressurizing water valve is arranged between the outlet of the distilled water container and the high-pressure spray head, and a second water inlet valve is arranged between the outlet of the distilled water container and the fresh water pool.

Preferably, a high-density filter screen is fixedly arranged in the filter.

Compared with the prior art, the utility model has the advantages that the high-salinity wastewater is evaporated and crystallized by utilizing the waste gas and the light heat energy source, the waste of the waste gas energy is avoided, simultaneously, the solar energy is reasonably utilized, the resources can be greatly saved, and the utility model is clean and environment-friendly; part of fresh water collected by the distilled water container is flushed to the inner pipe of the solar heat collecting pipe through the high-pressure nozzle, so that the scaling of the pipeline is avoided, the service life of the heat collecting pipe is prolonged, and a good heat collecting effect is ensured; crystallizing in the crystallizing pond, collecting inorganic salt in the high-salinity wastewater, and recycling resources.

Drawings

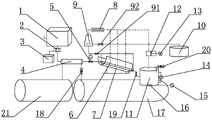

FIG. 1 is a schematic view of the structure of the present invention;

FIG. 2 is a schematic view of the structure of the photothermal evaporation unit;

FIG. 3 is a cross-sectional view of a solar collector tube;

fig. 4 is a schematic perspective view of a solar heat collecting tube.

Detailed Description

The utility model is described in further detail below with reference to the accompanying examples.

As shown in fig. 1-4, a high-salinity wastewater treatment system comprises a filtering unit and a condensation collecting unit, wherein a waste gas preheating unit and a photothermal evaporation unit are arranged between the filtering unit and the condensation collecting unit, the filtering unit, the waste gas preheating unit and the photothermal evaporation unit are sequentially connected with the condensation collecting unit, the photothermal evaporation unit is connected with a waste gas waste heat evaporation crystallization unit, the filtering unit comprises a wastewater collection box 1, a filter 2 and a waste residue collection box 3, an inlet and an outlet of the filter 2 are respectively connected with the wastewater collection box 1 and the waste residue collection box 3, and a high-density filter screen is fixedly arranged in the filter 2; the waste gas preheating unit comprises a waste gas conveying pipe 17 and a tubular heat exchanger 4, an outlet of the filter 2 is connected with an inlet of an inner pipe of the tubular heat exchanger 4, an outlet of the inner pipe of the tubular heat exchanger 4 is connected with the photothermal evaporation unit, the waste gas conveying pipe 17 is connected with an inlet of an outer pipe of the tubular heat exchanger 4, the temperature of waste gas is generally 70-200 ℃, waste gas can be utilized to preheat waste water, an outlet of the outer pipe of the tubular heat exchanger 4 is connected with a waste gas discharging pipe 21, and a safety valve 18 is arranged between the waste gas conveying pipe 17 and the inlet of the outer pipe of the tubular heat exchanger 4; the photothermal evaporation unit comprises a photosensitive electromagnetic valve 5, a CPC reflecting plate 7 and a solar heat collecting pipe 6, the solar heat collecting pipe 6 is fixedly arranged in the CPC reflecting plate 7, the solar heat collecting pipe 6 comprises a glass inner pipe 61 and a glass outer pipe 62 which are concentrically arranged, the glass outer pipe 62 is fixed with the glass inner pipe 61, the outer surface of the glass inner pipe 61 is provided with a heat absorbing layer, and a vacuum layer is arranged between the glass outer tube 62 and the glass inner tube 61, the inlet of the glass inner tube 61 is connected with the outlet of the inner tube of the tube heat exchanger 4 through the photosensitive electromagnetic valve 5, the photosensitive electromagnetic valve 5 can control the flow of the wastewater flowing into the solar heat collecting tube 6 according to the intensity of sunlight, high-salinity wastewater in the solar heat collecting tube 6 is fully evaporated, a steam outlet 63 and a high-pressure nozzle 64 which are communicated with the glass inner tube 61 are arranged on the solar heat collecting tube 6, and the outlet of the glass inner tube 61 is connected with a waste gas waste heat evaporation crystallization unit; the condensation collection unit comprises a condenser 8, a distilled water container 9 and a fresh water pool 10, wherein the inlet of the condenser 8 is connected with a steam outlet 63, the outlet of the condenser 8 is connected with the distilled water container 9, the outlet of the distilled water container 9 is respectively connected with a high-pressure spray head 64 and the fresh water pool 10, the pipeline is easy to scale and cause blockage after long-term use, the solar heat collection pipe 6 is washed by the high-pressure spray head 64, and the heat collection effect and the service life of the heat collection pipe are improved; the waste gas waste heat evaporation crystallization unit comprises a crystallization tank 11 and a reciprocating vacuum pump 12, a first water inlet valve 19 is arranged between an outlet of a glass inner tube 61 and the crystallization tank 11, the bottom of the crystallization tank 11 is fixed with a waste gas conveying pipe 17, a temperature sensor 15 and an electric auxiliary heater 16 are arranged at the inner bottom of the crystallization tank 11, the temperature sensor 15 monitors the temperature of the crystallization tank 11, the electric auxiliary heater 16 is controlled to heat waste water in the crystallization tank 11 when the temperature is low, a pressure release valve 20 and a liquid level sensor 14 are connected to the crystallization tank 11, an air suction valve of the reciprocating vacuum pump 12 is connected to the crystallization tank 11, an exhaust valve of the reciprocating vacuum pump 12 is connected to a condenser 8, and the reciprocating vacuum pump 12 is electrically connected to a motor 13.

In the above embodiment, a pressurizing water valve 91 is arranged between the outlet of the distilled water container 9 and the high-pressure nozzle 64, and a second inlet valve 92 is arranged between the outlet of the distilled water container 9 and the fresh water tank 10.

The process of treating the wastewater by using the treatment system comprises the following steps: after being filtered by a filter 2, the waste water in a waste water collecting box 1 is conveyed into an inner pipe of a tubular heat exchanger 4, waste residues are input into a waste residue collecting box 3, meanwhile, waste gas is conveyed into an outer pipe of the tubular heat exchanger 4 through a waste gas conveying pipe 17, the waste water is preheated by the waste gas, the preheated waste water flows into a solar heat collecting pipe 6 through a photosensitive electromagnetic valve 5, sunlight irradiates a CPC reflecting plate 7, the solar heat collecting pipe 6 collects heat to enable the temperature of the waste water in a glass inner pipe 61 to rise, a large amount of water vapor is discharged into a condenser 8 through a steam outlet 63 and is condensed into fresh water which is stored in a distilled water container 9, one part of the fresh water in the distilled water container 9 flows into a fresh water tank 10, the other part of the fresh water is used for flushing the glass inner pipe 61, the evaporated high-concentration waste water flows into a crystallization tank 11, and because the bottom of the crystallization tank 11 is fixed with the waste gas conveying pipe 17, the crystallization rate of the waste water in the crystallization tank 11 is accelerated by the waste gas waste heat, the crystallization tank 11 is connected with a liquid level sensor 14 for detecting the water level change in the crystallization tank 11, the water level change exceeds a limit value, the first water inlet valve 19 is closed, the motor 13 drives the reciprocating vacuum pump 12 to operate, the pressure in the crystallization tank 11 is reduced, the evaporation and crystallization speed is accelerated, and meanwhile, the water vapor in the crystallization tank 11 is pumped into the condenser 8 to be condensed into fresh water.

The scope of the present invention includes, but is not limited to, the above embodiments, and the present invention is defined by the appended claims, and any alterations, modifications, and improvements that may occur to those skilled in the art are all within the scope of the present invention.

Claims (9)

1. The utility model provides a processing system of high salt waste water, includes filter unit and condensation collecting element, filter unit include waste water collecting box, filter and waste residue collecting box, the entry of filter, export respectively with waste water collecting box, the waste residue collecting box be connected its characterized in that: the filter unit with the condensation collect and be provided with waste gas preheating unit and light and heat evaporation unit between the unit, the filter unit waste gas preheating unit light and heat evaporation unit with the condensation collect the unit and connect gradually, light and heat evaporation unit be connected with waste gas waste heat evaporation crystallization unit.

2. The high salinity wastewater treatment system of claim 1, wherein: the waste gas preheating unit comprises a waste gas conveying pipe and a tubular heat exchanger, the outlet of the filter is connected with the inlet of the inner pipe of the tubular heat exchanger, the outlet of the inner pipe of the tubular heat exchanger is connected with the photo-thermal evaporation unit, the waste gas conveying pipe is connected with the inlet of the outer pipe of the tubular heat exchanger, and the outlet of the outer pipe of the tubular heat exchanger is connected with a waste gas discharging pipe.

3. The high salinity wastewater treatment system of claim 2, wherein: and a safety valve is arranged between the waste gas conveying pipe and an inlet of the outer pipe of the pipe type heat exchanger.

4. The high salinity wastewater treatment system of claim 2, wherein: the solar-thermal evaporation unit comprises a photosensitive electromagnetic valve, an arc-shaped reflecting plate and a solar heat collecting tube, the solar heat collecting tube is fixedly arranged in the arc-shaped reflecting plate, the solar heat collecting tube comprises a glass inner tube and a glass outer tube which are concentrically arranged, the glass outer tube is fixed with the glass inner tube, a heat absorbing layer is arranged on the outer surface of the glass inner tube, a vacuum layer is arranged between the glass outer tube and the glass inner tube, the solar heat collecting tube is provided with a steam outlet and a high-pressure spray head which are communicated with the glass inner tube, the inlet of the glass inner tube is connected with the outlet of the inner tube of the tubular heat exchanger through the photosensitive electromagnetic valve, and the outlet of the glass inner tube is connected with the waste gas waste heat evaporation crystallization unit.

5. The high salinity wastewater treatment system of claim 4, wherein: the arc-shaped reflector is a CPC reflector.

6. The high salinity wastewater treatment system of claim 4, wherein: the condensation collection unit comprises a condenser, a distilled water container and a fresh water pool, wherein an inlet of the condenser is connected with the steam outlet, an outlet of the condenser is connected with the distilled water container, and an outlet of the distilled water container is respectively connected with the high-pressure spray head and the fresh water pool.

7. The high salinity wastewater treatment system of claim 6, wherein: waste gas waste heat evaporation crystallization unit include crystallizing pond and reciprocating vacuum pump, the glass inner tube the export with the crystallizing pond between be provided with first water intaking valve, the crystallizing pond the bottom with the waste gas conveyer pipe fixed mutually, the crystallizing pond the interior bottom be provided with temperature sensor and electric auxiliary heater, the crystallizing pond on be connected with relief valve and level sensor, reciprocating vacuum pump's suction valve with the crystallizing pond be connected, reciprocating vacuum pump's discharge valve with the condenser be connected, reciprocating vacuum pump electricity be connected with the motor.

8. The high salinity wastewater treatment system of claim 6, wherein: a pressurizing water valve is arranged between the outlet of the distilled water container and the high-pressure spray head, and a second water inlet valve is arranged between the outlet of the distilled water container and the fresh water tank.

9. The high salinity wastewater treatment system of claim 1, wherein: the filter is internally and fixedly provided with a high-density filter screen.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120963844.1U CN217025645U (en) | 2021-05-07 | 2021-05-07 | High-salinity wastewater treatment system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120963844.1U CN217025645U (en) | 2021-05-07 | 2021-05-07 | High-salinity wastewater treatment system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN217025645U true CN217025645U (en) | 2022-07-22 |

Family

ID=82410370

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202120963844.1U Active CN217025645U (en) | 2021-05-07 | 2021-05-07 | High-salinity wastewater treatment system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN217025645U (en) |

-

2021

- 2021-05-07 CN CN202120963844.1U patent/CN217025645U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108423732B (en) | Solar sea water desalination and pollutant removal dual-function device | |

| CN106277608B (en) | A kind of sewage-treatment plant with rainwater-collecting | |

| CN113816454B (en) | Brackish water evaporation desalting device | |

| US20240083794A1 (en) | Saline wastewater treatment system using solar-assisted heat pump | |

| CN2814305Y (en) | Textile dyeing waste water residual heat recovering apparatus | |

| CN211339167U (en) | Purification device for treating industrial wastewater containing floaters | |

| CN108328685A (en) | A kind of solar energy biogas slurry evaporation concentration device | |

| CN217025645U (en) | High-salinity wastewater treatment system | |

| CN104276710A (en) | Purification device of domestic wastewater | |

| CN212283470U (en) | Secondary steam purification system | |

| CN113354011A (en) | High-rise fall negative pressure evaporation environment-friendly water purifying device | |

| CN209143740U (en) | Sewage evaporation enrichment facility | |

| CN210855650U (en) | Movable sewage treatment device for sewage treatment | |

| CN205419833U (en) | Cell type solar -powered seawater desalination device | |

| CN109502868B (en) | Control method for sewage treatment with three-in-one structure | |

| CN103232083A (en) | Solar wind energy low-pressure sea water desalinating apparatus | |

| CN106745431A (en) | A kind of total heat recovery solar energy sea water desalination apparatus | |

| CN106186132A (en) | Low cost power plant zeroth order value waste water evaporation and concentration processing system and method | |

| CN106219855A (en) | Direct Air-cooled Unit recuperation of heat and water treatment facilities and recuperation of heat and method for treating water | |

| CN109502869B (en) | Trinity treatment device for urban sewage | |

| CN212644662U (en) | Flue gas reheating device with modular desalting function | |

| CN218781670U (en) | Self-warming mechanism of DTRO (delay tolerant reverse osmosis) equipment | |

| CN220976760U (en) | Wastewater recycling system | |

| CN203890083U (en) | System for desalinating seawater through absorbing solar energy by using liquid-solid fluidized bed | |

| CN221217261U (en) | Negative pressure treatment system for evaporating and crystallizing strong brine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |