CN216518887U - Silencer of draught fan - Google Patents

Silencer of draught fan Download PDFInfo

- Publication number

- CN216518887U CN216518887U CN202220018619.5U CN202220018619U CN216518887U CN 216518887 U CN216518887 U CN 216518887U CN 202220018619 U CN202220018619 U CN 202220018619U CN 216518887 U CN216518887 U CN 216518887U

- Authority

- CN

- China

- Prior art keywords

- silencer

- draft fan

- exhaust duct

- shell

- top surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

The utility model provides a draught fan muffler, which comprises an outer shell body, the shell body top is sealed, open the bottom has the air current entry, the inside noise elimination portion that is equipped with of shell body, noise elimination portion and shell body top surface are connected, the inside exhaust duct that is equipped with of noise elimination portion, exhaust duct includes the third wind channel, second air current entry and gas vent, exhaust duct's outer pipe wall and top surface are connected, noise elimination portion has the convex part, the lateral surface of noise elimination portion and the medial surface of shell body form first wind channel, the lateral surface of noise elimination portion is close to top surface department and opens there is the ventilation hole, the medial surface of noise elimination portion and exhaust duct's lateral surface form the second wind channel. The induced draft fan silencer has the following advantages: simple structure, fixed effectual, the noise cancelling effect is good.

Description

Technical Field

The utility model relates to powder material treatment equipment, in particular to a silencer of a draught fan.

Background

In the current industry, the powder material treatment is required to reach the environmental protection standard, a high-speed high-pressure draught fan is required to be used during working, the high-speed high-pressure draught fan can generate strong noise during operation, the environmental silence can be seriously influenced, the normal production and life of workers are hindered, the normal production and life of the workers are hindered, and occupational diseases are easily caused.

Chinese patent CN103341382A discloses a superfine pulverizing system, which comprises a pulverizing main body further connected with a pulverizing motor and a grading electrode, the pulverizing main body is further connected with a vortex cyclone collector, a pulse belt type dust collector and a high-pressure induced draft fan in sequence, and the high-pressure induced draft fan is further provided with a silencer; smash the main part and grind the superfine impact mill that the motor is connected through the belt pulley including setting up in the lower extreme, still be fixed with the grader in superfine impact upper end, this grader passes through belt pulley and hierarchical motor necklace.

The prior art has the following problems: the structure is complicated, the fixation is inconvenient, and the silencing effect is poor.

SUMMERY OF THE UTILITY MODEL

The utility model aims to provide a silencer of a draught fan, which aims to solve the problems that: the problems of incapability of eliminating strong noise and controlling air flow are complex structure, inconvenient fixation and poor silencing effect.

In order to achieve the purpose, the specific technical scheme of the utility model is as follows:

the utility model provides a draught fan muffler includes the shell body, the shell body top is sealed, open the bottom has the air current entry, the inside noise elimination portion that is equipped with of shell body, noise elimination portion and shell body top surface are connected, the inside exhaust duct that is equipped with of noise elimination portion, exhaust duct includes the third wind channel, second air current entry and gas vent, exhaust duct's outer pipe wall and top surface are connected, noise elimination portion has the convex part, the lateral surface of noise elimination portion and the medial surface of shell body form first wind channel, the lateral surface of noise elimination portion is close to top surface department and opens there is the ventilation hole, the medial surface of noise elimination portion and exhaust duct's lateral surface form the second wind channel.

Further, the projection faces the first airflow inlet.

Furthermore, the silencing part is provided with a concave part facing the second airflow inlet of the exhaust pipeline.

Furthermore, the outer shell is a hollow cylinder on the upper half part and a hollow round table on the lower half part.

Furthermore, the convex part is in a hollow spherical shape.

Further, the total cross-sectional area of the vent holes is greater than the cross-sectional area of the first airflow inlet.

Furthermore, the first air duct and the second air duct have the same width.

Furthermore, the top surface of the top of the outer shell is provided with a first annular bulge, the first annular bulge is provided with a first fixing hole, and a reinforcing rib is fixed between the first annular bulge and the outer shell.

Further, the top of the exhaust duct has a third annular projection having a third fixing hole.

Furthermore, the first air flow inlet at the bottom of the outer shell is provided with a second annular bulge, and the second annular bulge is provided with a second fixing hole.

In conclusion, the induced draft fan silencer has the following advantages: simple structure, fixed effectual, the noise cancelling effect is good.

Drawings

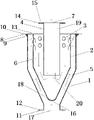

FIG. 1 is a cross-sectional view of a first embodiment;

the notation in the figure is: 1. an outer housing; 2. a sound deadening section; 3. a vent hole; 4. an exhaust pipe; 5. a first air duct; 6. a second air duct; 7. an airflow outlet; 8. a first fixing hole; 9. reinforcing ribs; 10. a first annular projection; 11. a second fixing hole; 12. a second annular projection; 13. a top surface; 14. a third annular projection; 15. a third fixing hole; 16. a convex portion; 17. a first gas flow inlet; 18. a recess; 19. a third air duct; 20. a second gas flow inlet.

Detailed Description

For better understanding of the objects, structure and operation of the utility model, reference will now be made to the following detailed description of the preferred embodiments taken in conjunction with the accompanying drawings.

A draught fan silencer comprises three parts, namely an outer shell 1, a silencing part 2 and an exhaust pipe 4, wherein the top of the outer shell is closed, and the bottom of the outer shell is provided with a first airflow inlet 17; a silencing part 2 is arranged in the outer shell 1, the silencing part 2 is connected with the top surface 13 of the outer shell 1, an exhaust pipeline 4 is arranged in the silencing part 2, the exhaust pipeline 4 comprises a third air duct 19, a second air flow inlet 20 and an exhaust port 7, and the outer wall of the exhaust pipeline 4 is connected with the top surface 13; the sound-deadening portion 2 has a convex portion 16 facing the first airflow inlet 17, and the convex portion 16 functions to split airflow and reflect sound waves, thereby reducing noise; a first air channel 5 is formed on the outer side surface of the sound-deadening part 2 and the inner side surface of the outer shell 1, a vent hole 3 is formed on the outer side surface of the sound-deadening part 2 close to the top surface 13, and a second air channel 6 is formed on the inner side surface of the sound-deadening part 2 and the outer side surface of the exhaust pipeline 4; because the sound wave enters the first air channel 5 in an inclined mode, the sound wave is randomly reflected in the first air channel, the air flow and the sound wave are divided and reflected into the second channel 6 from the air vent 3, the sound wave entering the second channel touches the outer side face of the exhaust pipeline 4 to be reflected, and finally the sound wave enters the third air channel and is exhausted from the exhaust port 7. The sound waves are reflected multiple times in the device and are therefore gradually attenuated and the noise is reduced.

The sound-deadening portion 2 may be further provided with a concave portion 18 facing the second air flow inlet 20, and when the sound wave reaches the concave portion 18, the sound wave and the air flow are reflected again, the sound wave is inclined into the third passage 19, and is reflected randomly in the third passage 19, thereby reducing noise.

As shown in fig. 1, the present invention proposes a first embodiment. A draught fan silencer comprises an outer shell 1, the upper half part of which is a hollow cylinder and the lower half part of which is a hollow round table; the outer shell 1 comprises a top surface 13 and a first air inlet 17, the top of the outer shell is closed, an inner sleeve is arranged in the outer shell 1, the upper half part of the inner sleeve is a hollow cylinder, the lower half part of the inner sleeve is a hollow cone, the inner sleeve is connected with the top surface 13 of the outer shell 1, an exhaust pipeline 4 with a hollow inner part is arranged in the inner sleeve, and the outer pipe wall of the exhaust pipeline 4 is connected with the top surface 13 of the outer shell 1; a first air channel 5 is formed on the outer side surface of the inner sleeve and the inner side surface of the outer shell, a ventilation hole 3 is formed in the position, close to the top surface, of the outer side surface of the inner sleeve, a second air channel 6 is formed on the inner side surface of the inner sleeve and the outer side surface of the exhaust pipeline, and a third air channel 19 is formed in the exhaust pipeline 4 in a hollow mode.

The convex part 16 of the hollow conical top of the lower half part of the inner sleeve is in a hollow spherical shape, and the convex surface of the hollow spherical shape is opposite to the first air inlet 17, so that the wind resistance can be reduced, and the wind noise can be further reduced. The hollow of the hollow spherical shape may be used as a recess 18 just opposite the second airflow inlet 20 of the exhaust duct 4.

The ventilation holes 3 are round holes with the diameter of 8cm-10cm, the number of the round holes is determined according to ventilation quantity, the total cross sectional area of all the round holes is larger than that of the first airflow inlet 17, airflow can better pass through, and otherwise, the ventilation quantity is influenced.

The distance of the lateral surface of noise reduction part 2 and the medial surface of shell body 1 is the road width of first wind channel 5, and the distance of the medial surface of noise reduction part 2 and the lateral surface of exhaust duct 4 is equal and more than or equal to 8cm for the road width of second wind channel 6, the road width of first wind channel 3 and second wind channel four to guarantee sufficient air volume and noise reduction effect.

The top surface 13 of the top of the outer casing 1 has a first annular projection 10, and the first annular projection 10 has a first fixing hole 8. Be fixed with strengthening rib 9 between first annular protrusion 10 and the shell body 1, strengthening rib 9 is right triangle, and a right-angle side of right triangle's strengthening rib 9 is being fixed to the lower surface of first annular protrusion 10, and another right-angle side of strengthening rib 9 is fixed at the lateral surface of shell body 1 to it is vertical fixed to strengthen. The bottom of the outer shell 1 is provided with a second annular bulge 12 at the first air inlet 17, the second annular bulge 12 is provided with a second fixing hole 11 on the second annular bulge 12, and the fixing is convenient.

The top of the exhaust pipe 4 is provided with a third annular projection 14, and the third annular projection 14 is provided with a third fixing hole 15 for facilitating the fixing.

During the use, will draught fan muffler fixes on mechanical equipment, and air current and sound wave get into from the first air inlet 17 of this draught fan muffler, touch the circular cone top and carry out the reposition of redundant personnel and the reflection of sound wave of air current, and air current and sound wave follow first wind channel 5 and get into second wind channel 6 from ventilation hole 3, reflect into third wind channel 19 by the concave part 18 of 16 inside on circular cone tops at last, discharge in the air outlet 7 of follow exhaust duct, thereby the sound wave is through multiple reflection noise reduction.

In summary, the induced draft fan silencer provided by the utility model has the following effects: simple structure, fixed effectual, the noise cancelling effect is good.

It is to be understood that the present invention has been described with reference to certain embodiments and that various changes in form and details may be made therein by those skilled in the art without departing from the spirit and scope of the utility model. In addition, many modifications may be made to adapt a particular situation or material to the teachings of the utility model without departing from the essential scope thereof. Therefore, it is intended that the utility model not be limited to the particular embodiment disclosed, but that the utility model will include all embodiments falling within the scope of the appended claims.

Claims (10)

1. A silencer of a draught fan comprises a shell (1) and is characterized in that a first air inlet (17) is formed in the bottom of the shell (1), a silencing part (2) is arranged inside the shell (1), the silencing part (2) is connected with the top surface (13) of the shell (1), an exhaust pipeline (4) is arranged inside the silencing part (2), the exhaust pipeline (4) comprises a third air duct (19), second air inlet (20) and gas vent (7), the outer pipe wall and top surface (13) of exhaust duct (4) are connected, noise damping portion (2) have convex part (16), the lateral surface of noise damping portion (2) and the medial surface of shell body form first wind channel (5), the lateral surface of noise damping portion (2) is close to top surface (13) department and is opened ventilation hole (3), the medial surface of noise damping portion (2) and the lateral surface of exhaust duct (4) form second wind channel (6).

2. A silencer for an induced draft fan according to claim 1, wherein the protrusion (16) faces the first air flow inlet (17).

3. A draft fan silencer according to claim 1, characterized in that the silencer component (2) further has a recess (18) facing the second flow inlet (20) of the exhaust duct (4).

4. The silencer according to claim 1, characterized in that the upper half of the outer casing (1) is a hollow cylinder, and the lower half is a hollow circular truncated cone.

5. The silencer of the induced draft fan according to claim 1, wherein the convex portion (16) is in the shape of a hollow sphere.

6. A draft fan silencer according to claim 1, characterized in that the total cross-sectional area of the ventilation holes (3) is larger than the cross-sectional area of the first gas flow inlet (17).

7. The silencer of claim 1, wherein the first air duct and the second air duct have the same duct width.

8. The silencer of the induced draft fan according to claim 1, wherein the top surface (13) of the top of the outer casing (1) is provided with a first annular bulge (10), the first annular bulge (10) is provided with a first fixing hole (8), and a reinforcing rib (9) is fixed between the first annular bulge (10) and the outer casing (1).

9. The silencer of the induced draft fan according to claim 1, wherein the top of the exhaust duct (4) is provided with a third annular protrusion (14), and the third annular protrusion (14) is provided with a third fixing hole (15).

10. The silencer of the induced draft fan according to claim 1, wherein the bottom of the outer shell (1) is provided with a second annular bulge (12) at the first airflow inlet (17), and the second annular bulge (12) is provided with a second fixing hole (11).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220018619.5U CN216518887U (en) | 2022-01-06 | 2022-01-06 | Silencer of draught fan |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202220018619.5U CN216518887U (en) | 2022-01-06 | 2022-01-06 | Silencer of draught fan |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN216518887U true CN216518887U (en) | 2022-05-13 |

Family

ID=81518592

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202220018619.5U Active CN216518887U (en) | 2022-01-06 | 2022-01-06 | Silencer of draught fan |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN216518887U (en) |

-

2022

- 2022-01-06 CN CN202220018619.5U patent/CN216518887U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017133371A1 (en) | Ceiling-mounted exhaust hood | |

| CN206207518U (en) | A kind of noise reduction impeller and application have the range hood of the impeller | |

| CN216518887U (en) | Silencer of draught fan | |

| CN205582478U (en) | Simple silencer | |

| CN110439864B (en) | Air inlet current collector and centrifugal fan with same | |

| CN207420981U (en) | Denoising device and cooking apparatus | |

| CN213270383U (en) | Noise reduction ventilator | |

| CN206207517U (en) | A kind of noise reduction impeller and application have the range hood of the impeller | |

| CN214501371U (en) | Smoke collecting hood and range hood | |

| CN217354902U (en) | Air blower and automobile | |

| CN212361221U (en) | Multifunctional silencer | |

| CN212376959U (en) | Volute of centrifugal fan | |

| CN108386889A (en) | Range hood | |

| CN106949099A (en) | Dust catcher motor air pump | |

| CN211264950U (en) | High-efficient steam noise silencing device | |

| CN112762494A (en) | Smoke collecting hood and range hood | |

| CN209818252U (en) | Buffer tank inlet silencing pipe capable of reducing noise | |

| CN208720485U (en) | A kind of silencer for Heating,Ventilating and Air Conditioning ventilating system | |

| CN105526197A (en) | Noise reduction and oil filtering device of centrifugal fan | |

| CN111006092A (en) | Multifunctional silencer | |

| CN215892408U (en) | Auxiliary smoke exhaust device | |

| CN219911301U (en) | Noise reduction structure for air outlet of centrifugal fan | |

| TWI789237B (en) | Fan housing of kitchen ventilator with a wind guide structure | |

| JPH0842499A (en) | Flow straightening silencer device in air blasting and exhausting device | |

| CN215214109U (en) | Compressor amortization spiral case |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |