CN216037707U - Cotton rod rolling machine - Google Patents

Cotton rod rolling machine Download PDFInfo

- Publication number

- CN216037707U CN216037707U CN202121399955.0U CN202121399955U CN216037707U CN 216037707 U CN216037707 U CN 216037707U CN 202121399955 U CN202121399955 U CN 202121399955U CN 216037707 U CN216037707 U CN 216037707U

- Authority

- CN

- China

- Prior art keywords

- roller

- cotton

- conveying

- pressing plate

- silver

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229920000742 Cotton Polymers 0.000 title claims abstract description 128

- 238000005096 rolling process Methods 0.000 title claims abstract description 13

- 238000003825 pressing Methods 0.000 claims abstract description 65

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims abstract description 54

- 229910052709 silver Inorganic materials 0.000 claims abstract description 54

- 239000004332 silver Substances 0.000 claims abstract description 54

- 230000007246 mechanism Effects 0.000 claims abstract description 24

- 238000005520 cutting process Methods 0.000 claims abstract description 10

- 238000004804 winding Methods 0.000 claims abstract description 9

- 239000000463 material Substances 0.000 claims description 39

- 230000007704 transition Effects 0.000 claims description 22

- 238000003756 stirring Methods 0.000 claims description 15

- 230000006835 compression Effects 0.000 claims description 7

- 238000007906 compression Methods 0.000 claims description 7

- 238000005452 bending Methods 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 abstract description 2

- 238000007599 discharging Methods 0.000 description 9

- 230000005540 biological transmission Effects 0.000 description 7

- 238000001125 extrusion Methods 0.000 description 5

- 238000000034 method Methods 0.000 description 3

- 238000009434 installation Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

Images

Landscapes

- Preliminary Treatment Of Fibers (AREA)

Abstract

A cotton stick rolling machine belongs to the technical field of cotton stick production equipment. Including silver input device, silver that set gradually cut device, cotton swab stick doffer and silver winding device, its characterized in that: the cotton sliver cutting device comprises a pressing device, a conveying pair roller and a power device, wherein the pressing device and the conveying pair roller are sequentially arranged along the conveying direction of the cotton sliver, the power device is connected with the conveying pair roller and drives the conveying pair roller to move, and the power device is connected with the pressing device through a cam mechanism and enables the pressing device to work intermittently. This cotton stick cotton winder's power device passes through cam mechanism and links to each other with closing device, makes closing device intermittent type nature compress tightly the silver, and power device links to each other with carrying the pair roller to drive and carry the pair roller work, realized the transport of silver, when closing device compresses tightly the silver, carry the pair roller and cooperate and tear the silver with closing device, in order to cut the silver, cut more stable, reliable to the silver, and then make equipment work more stable.

Description

Technical Field

A cotton stick rolling machine belongs to the technical field of cotton stick production equipment.

Background

The cotton swab is a common daily and medical consumable material, comprises a cotton swab rod, and clean cotton is wound at one end or two ends of the cotton swab rod. The utility model discloses a chinese utility model patent of application number 201620852090.5 discloses a novel cotton swab winder, its transport that has realized the silver through the claw wheel to cut off the silver through cutter and the cooperation of block rubber, then will cut off on the winding cotton swab stick of silver after. The problem that the cotton sliver is hard to cut off through the cutter and the rubber block because the cotton sliver is soft in the working process, so that the equipment is unstable in working.

Disclosure of Invention

The technical problem to be solved by the utility model is as follows: the cotton rod cotton winder overcomes the defects of the prior art, breaks the cotton sliver, ensures the reliable truncation of the cotton sliver and further ensures the stable working of the equipment.

The technical scheme adopted by the utility model for solving the technical problems is as follows: this cotton stick rolls up cotton machine, including silver input device, the silver that sets gradually cut device, cotton swab stick doffer and silver winding device, its characterized in that: the cotton sliver cutting device comprises a pressing device, a conveying pair roller and a power device, wherein the pressing device and the conveying pair roller are sequentially arranged along the conveying direction of the cotton sliver, the power device is connected with the conveying pair roller and drives the conveying pair roller to move, and the power device is connected with the pressing device through a cam mechanism and enables the pressing device to work intermittently.

Preferably, the pressing device comprises a transition groove and a pressing plate, the opening of the transition groove is arranged upwards, the pressing plate is arranged on the upper side of the transition groove, and the cam mechanism is connected with the pressing plate and drives the pressing plate to reciprocate along the direction close to or far away from the transition groove. The pressing plate enters the transition groove and presses the cotton sliver in the transition groove, so that the cotton sliver is reliably pressed.

Preferably, the cam mechanism comprises a cam, a connecting rod and a connecting rod guide block, the connecting rod is slidably mounted on the connecting rod guide block, one end of the connecting rod is connected with the pressing plate, the other end of the connecting rod is slidably connected with the cam, a return spring in a stretching state is arranged between the pressing plate and the connecting rod guide block to enable the connecting rod to press the cam, and the cam is connected with the power device and synchronously rotates along with the power device. Reset spring makes the connecting rod compress tightly the cam all the time, avoids the clamp plate to cause the hindrance to the normal transport of silver, has realized the drive of clamp plate through the cam, guarantees that the length of the silver of intercepting is unanimous, and the stability of the size of silver is good.

Preferably, the conveying pair roller comprises a conveying roller and a bearing roller, the conveying roller is arranged on the upper side of the bearing roller and compresses the bearing roller, and the power device is connected with the conveying roller and drives the conveying roller to rotate. The silver is passed through between conveying roller and the bearing roller, and conveying roller and bearing roller cooperate and carry the silver, carry stably, and can guarantee to cut the silver.

Preferably, one side of the conveying roller is provided with a convex boss which is in an arc shape coaxial with the conveying roller, and the boss compresses the carrier roller. The boss has realized the transport of silver with the conveying roller extrusion, has realized the transport of the intermittent type nature of silver, and then cooperatees with closing device, has realized truncating of silver, guarantees that the silver truncates reliably, can also avoid hindering each other with silver input device.

Preferably, silver wind include conveyer belt and clamp plate, the input of conveyer belt links to each other with the output that the silver cut the device to accept the silver and cut the silver of device output, cotton swab stick doffer sets gradually along the direction of delivery of conveyer belt with the clamp plate, the clamp plate interval sets up the upside at the conveyer belt, and compress tightly the cotton swab stick on the conveyer belt, the clamp plate is close to the arc of cotton swab stick doffer's one end for upwards buckling. The cotton swab stick falls on the silver that cuts, and cotton swab stick and silver enter into between clamp plate and the conveyer belt, and the clamp plate compresses tightly the cotton swab stick to make the cotton swab stick take place to rotate in transportation process, and then twine the silver on the cotton swab stick, the tip of clamp plate is the arc of upwards buckling, makes the more smooth and easy entering into between clamp plate and the conveyer belt of cotton swab stick.

Preferably, silver wind still include clamp plate guide bar, clamp plate mounting panel and pressure spring, the clamp plate setting is at clamp plate mounting panel downside, the lower extreme of clamp plate guide bar links to each other with the clamp plate, the upper end is connected with clamp plate mounting panel slidable, pressure spring cover is established outside the clamp plate guide bar between clamp plate mounting panel and the clamp plate, pressure spring is in compression state. The hold-down spring can make and maintain the state of compressing tightly between clamp plate and the conveyer belt, guarantees that the cotton swab stick twines the silver more stable.

Preferably, the cotton swab stick doffer include hopper, doffer and unloading roller, the doffer setting is between hopper and silver wind, unloading roller level sets up in the upper portion one side of doffer, the upper portion of doffer is provided with the curved striker plate coaxial with the unloading roller, is provided with the unloading groove that is used for holding the cotton swab stick on the unloading roller. The cotton swab stick in the hopper enters into the unloading inslot of unloading roller, and the striker plate blocks the lateral part of unloading roller, and then makes the cotton swab stick enter into the doffer, through the accurate silver that falls into of doffer, the blanking of cotton swab stick is accurate, stable.

Preferably, the cotton sliver input device comprises a feeding roller and a material stirring roller, the material stirring roller is arranged on the upper side of the feeding roller side by side, a plurality of stirring teeth are arranged at intervals on the side part surrounding the material stirring roller, and the power device is connected with the material stirring roller and drives the material stirring roller to rotate.

Compared with the prior art, the utility model has the beneficial effects that:

this cotton stick cotton winder's power device passes through cam mechanism and links to each other with closing device, makes closing device intermittent type nature compress tightly the silver, and power device links to each other with carrying the pair roller to drive and carry the pair roller work, realized the transport of silver, when closing device compresses tightly the silver, carry the pair roller and cooperate and tear the silver with closing device, in order to cut the silver, cut more stable, reliable to the silver, and then make equipment work more stable.

Drawings

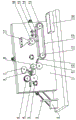

FIG. 1 is a perspective view of a cotton rod gin.

Fig. 2 is a partially enlarged view of a portion a in fig. 1.

FIG. 3 is a schematic front view of the drive mechanism of the cotton picker.

Fig. 4 is a schematic front sectional view of a cotton swab discharging device.

In the figure: 1. the device comprises a frame 2, a motor 3, a belt 4, a feed chute 5, a feed roller 6, a material stirring roller 7, a cam 8, a conveying roller 801, a boss 9, a supporting roller 10, a discharge chute 11, a driving roller 12, a conveying belt 1201, a relief chute 13, a driven roller 14, a pressure plate 15, a pressure plate mounting plate 16, a material receiving box 17, a hopper 18, a material discharging roller 1801, a material discharging chute 19, a connecting rod 20, a connecting rod guide block 21, a pressure plate 22, a transition chute 23, a blanking barrel 2301, a material blocking plate 2302, a barrel 24, an input gear 25, a material stirring gear 26, an extrusion gear 27, a cutting gear 28, a first idle gear 29, a second idle gear 30, a conveying gear 31, a blanking gear 32 and a pressure plate guide rod.

Detailed Description

Fig. 1 to 4 are preferred embodiments of the present invention, and the present invention will be further described with reference to fig. 1 to 4.

The cotton stick rolling machine comprises a cotton stick input device, a cotton stick cutting device, a cotton stick discharging device and a cotton stick winding device which are sequentially arranged, wherein the cotton stick cutting device comprises a pressing device, a conveying double-roller and a power device, the pressing device and the conveying double-roller are sequentially arranged along the conveying direction of cotton sticks, the power device is connected with the conveying double-roller and drives the conveying double-roller to move, and the power device is connected with the pressing device through a cam mechanism and enables the pressing device to work intermittently. This cotton stick cotton winder's power device passes through cam mechanism and links to each other with closing device, makes closing device intermittent type nature compress tightly the silver, and power device links to each other with carrying the pair roller to drive and carry the pair roller work, realized the transport of silver, when closing device compresses tightly the silver, carry the pair roller and cooperate and tear the silver with closing device, in order to cut the silver, cut more stable, reliable to the silver, and then make equipment work more stable.

The present invention is further described with reference to the following detailed description, however, it should be understood by those skilled in the art that the detailed description given herein with respect to the accompanying drawings is for better explanation and that the present invention is not necessarily limited to the specific embodiments, but rather, for equivalent alternatives or common approaches, may be omitted from the detailed description, while still remaining within the scope of the present application.

Specifically, the method comprises the following steps: as shown in FIGS. 1-2: the cotton stick rolling machine further comprises a rack 1 and a transmission mechanism, wherein the power device is installed on the left side of the rack 1, and the cotton sliver input device, the cotton sliver cutting device, the cotton stick discharging device and the cotton sliver winding device are sequentially installed on the rack 1 from left to right. The cotton sliver cutting device comprises a pressing device and a conveying pair roller which are sequentially arranged on the rack 1 from left to right, the transmission mechanism is arranged on the rack 1, and a driven belt wheel is arranged at the power input end of the transmission mechanism. In this embodiment, the power device is a motor 2, an output shaft of the motor 2 is provided with a driving belt wheel, and the driving belt wheel is connected with a driven belt wheel through a belt 3. The power output end of the transmission mechanism is simultaneously connected with the cotton sliver input device, the pressing device, the conveying pair rollers, the cotton swab rod blanking device and the cotton sliver winding device.

The silver input device is including dialling material roller 6, feed roll 5 and feed chute 4, dial material roller 6 and the equal rotatable installation in frame 1 of feed roll 5, and dial material roller 6 and the equal level setting of feed roll 5, dial material roller 6 and install the upside at feed roll 5, it is provided with a plurality of teeth of dialling to encircle the lateral part interval of dialling material roller 6, it cooperatees with feed roll 5 to dial the tooth, the transport of silver has been realized, drive mechanism's power take off end links to each other with dialling material roller 6, and drive its rotation. The feeding groove 4 is a groove with an upward opening, the output port of the feeding groove 4 is arranged opposite to the joint part of the material poking roller 6 and the feeding roller 5, so that the cotton sliver passing through the feeding groove 4 enters between the material poking roller 6 and the feeding roller 5, and the cotton sliver can be continuously fed.

The pressing device comprises a transition groove 22 and a pressing plate 21, the transition groove 22 is of a groove shape with an upward opening, the transition groove 22 is arranged between the feeding roller 5 and the conveying pair roller, the conveying pair roller is arranged lower than the feeding roller 5, the transition groove 22 is of an inclined shape gradually downward along the direction close to the conveying pair roller, the left end of the transition groove 22 is opposite to the joint of the feeding roller 5 and the material shifting roller 6 and is used for bearing the cotton slivers conveyed by the feeding roller 5 and the material shifting roller 6, and the right end of the transition groove 22 is opposite to the conveying pair roller. The pressing plate 21 is arranged on the upper side of the transition groove 22 in parallel, the cam mechanism is connected with the pressing plate 21 and drives the pressing plate 21 to reciprocate along the direction close to or far away from the transition groove 22, so that the pressing plate 21 intermittently enters the transition groove 22 and is matched with the transition groove 22 to press the cotton sliver.

The cam mechanism comprises a cam 7, a connecting rod 19 and a connecting rod guide block 20, the connecting rod guide block 20 is installed on the rack 1, the upper end of the connecting rod 19 is connected with the side part of the cam 7 in a sliding manner, the lower end of the connecting rod 19 penetrates through the connecting rod guide block 20 in a sliding manner and then is connected with a pressure plate 21 and drives the pressure plate 21 to lift synchronously, and a connecting rod guide hole matched with the connecting rod 19 is formed in the connecting rod guide block 20. A return spring is sleeved outside the connecting rod 19 between the connecting rod guide block 20 and the pressing plate 21 and is in a stretching state, one end of the return spring is fixedly connected with the connecting rod guide block 20, the other end of the return spring is fixedly connected with the pressing plate 21, the pressing plate 21 is enabled to be reset upwards, and therefore the upper end of the connecting rod 19 is enabled to be pressed against the side portion of the cam 7 all the time. The output end of the transmission mechanism is connected with the cam 7 and drives the cam to rotate.

The pair roller of plucking includes conveying roller 8 and bearing roller 9, the equal rotatable installation in frame 1 of conveying roller 8 and bearing roller 9, the equal level setting of conveying roller 8 and bearing roller 9, 8 intervals of conveying roller set up the upside at bearing roller 9, 8's lateral part of conveying roller is provided with boss 801, boss 801 is the arc coaxial with conveying roller 8, boss 801's the outside compresses tightly bearing roller 9, conveying roller 8 links to each other with drive mechanism's output, and then realized the clearance transport of silver, avoid causing the interference to the transport of dialling material roller 6 and feed roller 5, can also cooperate with lead to aqueduct 22 and clamp plate 21, realized intermittent type nature cut the silver.

The cotton sliver winding device comprises a conveying belt 12, a pressing plate 14, a mounting plate 15, a pressing plate guide rod 32 and a compression spring, a driving roller 11 and a driven roller 13 are rotatably mounted on the right side of the rack 1, the driving roller 11 and the driven roller 13 are horizontally arranged, the driving roller 11 and the driven roller 13 are arranged at intervals from left to right, the conveying belt 12 is arranged between the driving roller 11 and the driven roller 13, a transmission mechanism is connected with the driving roller 11 and drives the driving roller 11 to rotate, and the conveying belt 12 is horizontally arranged. The conveyer belt 12 is less than the setting of picking roller 8, is provided with blown down tank 10 at the input of conveyer belt 12, and blown down tank 10 is for from left to right decurrent slope form gradually, and the left end of blown down tank 10 is just right with the joint portion of conveying roller 8 and bearing roller 9, and the right-hand member is just right with the left end of conveyer belt 12.

Cotton swab stick doffer and clamp plate 14 all set up the upside at conveyer belt 12, and cotton swab stick doffer and clamp plate 14 set gradually along the direction of delivery of conveyer belt 12. 14 level settings of clamp plate are at the upside of conveyer belt 12, clamp plate mounting panel 15 is installed in frame 1, and the 15 intervals of clamp plate mounting panel set up the upside at clamp plate 14, the vertical setting of clamp plate guide bar 32 is at the upside of clamp plate 14, clamp plate guide bar 32 has two of symmetry setting at clamp plate 14 both ends, the lower extreme and the 14 fixed connection of clamp plate guide bar 32, upper end slidable passes clamp plate mounting panel 15 and stretches out to last, the clamp plate guide bar 32 between clamp plate 14 and clamp plate mounting panel 15 is established to the housing of compression spring, thereby make clamp plate 14 compress tightly conveyer belt 12. The equal threaded connection in upper end of each clamp plate guide bar 32 has adjusting nut, and adjusting nut is located the 15 upsides of clamp plate mounting panel, can adjust the pressure of clamp plate 14 to conveyer belt 12 through adjusting nut, guarantees that the cotton is more stable to the cotton stick roll-up.

The left end of the pressing plate 14 is in an upward arc shape, so that the cotton swab stick and the cotton swab can smoothly enter between the pressing plate 14 and the conveying belt 12.

A material receiving box 16 is arranged on the right side of the frame 1, the material receiving box 16 is a box body with an open top, and the material receiving box 16 is arranged on the lower side of the right end of the conveying belt 12 and is used for receiving the produced cotton sticks.

As shown in fig. 3: the transmission mechanism comprises an input gear 24, a material stirring gear 25, a squeezing gear 26, a cutoff gear 27, a first idle gear 28, a second idle gear 29, a conveying gear 30 and a blanking gear 31.

The input gear 24 is rotatably mounted on the frame 1, and the input gear 24 is coaxially connected with the driven pulley and keeps rotating synchronously. The material shifting gear 25 is rotatably arranged on the machine frame 1, the material shifting gear 25 is coaxially connected with the material shifting roller 6 and drives the material shifting roller 6 to rotate synchronously, and the material shifting gear 25 is meshed with the input gear 24. The extrusion gear 26 is rotatably arranged on the frame 1, the extrusion gear 26 is connected with the cam 7 and drives the cam 7 to rotate, and the extrusion gear 26 is meshed with the material shifting gear 25. The cutoff gear 27 is rotatably mounted on the frame 1, the feed roller 8 is coaxially mounted on the cutoff gear 27 and rotates synchronously therewith, and the cutoff gear 27 is engaged with the pressing gear 26. The first idle gear 28 and the second idle gear 29 are both rotatably mounted on the frame 1, the first idle gear 28 is meshed with the cutoff gear 27, the second idle gear 29 is meshed with the first idle gear 28, and the first idle gear 28 and the second idle gear 29 can adjust the position of the conveyor belt 12 to avoid mutual interference among various mechanisms. The conveying gear 30 is rotatably mounted on the frame 1, the driving roller 11 is coaxially connected with the conveying gear 30 and synchronously rotates along with the driving roller, and the conveying gear 30 is meshed with the second idle gear 29. The blanking gear 31 is rotatably arranged on the machine frame 1, the blanking gear 31 is connected with a cotton swab stick blanking device, and the blanking gear 31 is meshed with the second idle gear 29.

As shown in fig. 4: the cotton swab stick doffer comprises a hopper 17, a discharging roller 18 and a discharging barrel 23, wherein the hopper 17 is in a conical shape with the sectional area gradually reduced from top to bottom, the bottom of the hopper 17 is a discharging hole, the discharging hole of the hopper 17 is flat, and only one cotton swab stick is fed out at each time. The blanking roller 18 is arranged under the hopper 17, the axial blanking grooves 1801 are arranged on the side portion of the blanking roller 18, the blanking grooves 1801 are arranged around the blanking roller 18 at intervals, in the embodiment, the blanking grooves 1801 are uniformly distributed around the blanking roller 18 at intervals, the blanking roller 18 is coaxially connected with the blanking gear 31 and synchronously rotates along with the blanking gear, and therefore the cotton swab stick is sent out downwards through the blanking grooves 1801. The interval is provided with a plurality of grooves of stepping down 1201 on the conveyer belt 12, blanking barrel 23 includes striker plate 2301 and the barrel 2302 of downside of upside, barrel 2302 is the platykurtic, and in being used for carrying cotton swab stick to the groove of stepping down 1201 on conveyer belt 12 accurately, striker plate 2301 is the right side that sets up at unloading roller 18, and striker plate 2301 is the semicircle coaxial with unloading roller 18, striker plate 2301 and the left side laminating of unloading roller 18, avoid the cotton swab stick in unloading groove 1801 to fall out, striker plate 2301's upper end links to each other with hopper 7's bottom, the lower extreme links to each other with the barrel 2302, thereby make the cotton swab stick enter into in barrel 2302 one by one.

When the cotton rod rolling machine works, when the pressing plate 21 and the transition groove 22 are matched to compress the cotton sliver, the boss 801 just begins to compress the bearing roller 9, the cotton sliver is torn off, the torn cotton sliver enters the conveying belt 12, and the abdicating groove 1201 on the conveying belt 12 is just covered. The cotton swab stick blanking device places the cotton swab stick on the cotton sliver, and the cotton swab stick is opposite to the yielding groove 1201. The cotton swab stick moves to the lower side of the pressing plate 14 along with the conveying belt 12, the cotton swab stick rotates under the action of the pressing plate 14, then the cotton sliver is wound to form a cotton swab, and the formed cotton swab continues to move along with the conveying belt 12 and falls into the material receiving box 16.

The foregoing is directed to preferred embodiments of the present invention, other and further embodiments of the utility model may be devised without departing from the basic scope thereof, and the scope thereof is determined by the claims that follow. However, any simple modification, equivalent change and modification of the above embodiments according to the technical essence of the present invention are within the protection scope of the technical solution of the present invention.

Claims (9)

1. The utility model provides a cotton stick book cotton machine, cuts device, cotton stick doffer and cotton sliver wind including cotton sliver input device, cotton sliver that set gradually, its characterized in that: the cotton sliver cutting device comprises a pressing device, a conveying pair roller and a power device, wherein the pressing device and the conveying pair roller are sequentially arranged along the conveying direction of the cotton sliver, the power device is connected with the conveying pair roller and drives the conveying pair roller to move, and the power device is connected with the pressing device through a cam mechanism and enables the pressing device to work intermittently.

2. The cotton rod rolling machine according to claim 1, characterized in that: the pressing device comprises a transition groove (22) and a pressing plate (21), wherein an opening of the transition groove (22) is arranged upwards, the pressing plate (21) is arranged on the upper side of the transition groove (22), and the cam mechanism is connected with the pressing plate (21) and drives the pressing plate to reciprocate along the direction close to or far away from the transition groove (22).

3. The cotton rod rolling machine according to claim 1 or 2, characterized in that: the cam mechanism comprises a cam (7), a connecting rod (19) and a connecting rod guide block (20), the connecting rod (19) is slidably mounted on the connecting rod guide block (20), one end of the connecting rod (19) is connected with a pressing plate (21), the other end of the connecting rod is slidably connected with the cam (7), a return spring in a stretching state is arranged between the pressing plate (21) and the connecting rod guide block (20), the connecting rod (19) is enabled to press the cam (7), and the cam (7) is connected with a power device and synchronously rotates along with the power device.

4. The cotton rod rolling machine according to claim 1, characterized in that: the conveying pair roller comprises a conveying roller (8) and a bearing roller (9), the conveying roller (8) is arranged on the upper side of the bearing roller (9) and compresses the bearing roller (9), and the power device is connected with the conveying roller (8) and drives the conveying roller to rotate.

5. The cotton rod winder of claim 4, wherein: one side of the conveying roller (8) is provided with a convex boss (801), the boss (801) is in an arc shape coaxial with the conveying roller (8), and the boss (801) compresses the bearing roller (9).

6. The cotton rod rolling machine according to claim 1, characterized in that: the cotton sliver winding device comprises a conveying belt (12) and a pressing plate (14), wherein the input end of the conveying belt (12) is connected with the output end of the cotton sliver cutting device, the cotton sliver output by the cotton sliver cutting device is received, a cotton swab rod blanking device and the pressing plate (14) are sequentially arranged along the conveying direction of the conveying belt (12), the pressing plate (14) is arranged on the upper side of the conveying belt (12) at intervals, the cotton swab rod is pressed on the conveying belt (12), and one end, close to the cotton swab rod blanking device, of the pressing plate (14) is in an arc shape with the upward bending.

7. The cotton rod rolling machine according to claim 6, characterized in that: the cotton sliver winding device further comprises a pressing plate guide rod (32), a pressing plate mounting plate (15) and a compression spring, wherein the pressing plate (14) is arranged on the lower side of the pressing plate mounting plate (15), the lower end of the pressing plate guide rod (32) is connected with the pressing plate (14), the upper end of the pressing plate guide rod is slidably connected with the pressing plate mounting plate (15), the compression spring is sleeved outside the pressing plate guide rod (32) between the pressing plate mounting plate (15) and the pressing plate (14), and the compression spring is in a compression state.

8. The cotton rod winder according to claim 1 or 6, wherein: cotton swab stick doffer include hopper (17), doffer (23) and unloading roller (18), doffer (23) set up between hopper (17) and silver wind, unloading roller (18) level sets up in the upper portion one side of doffer (23), the upper portion of doffer (23) is provided with curved striker plate (2301) coaxial with unloading roller (18), be provided with on unloading roller (18) and be used for holding unloading silo (1801) of cotton swab stick.

9. The cotton rod rolling machine according to claim 1, characterized in that: the cotton sliver input device comprises a feed roller (5) and a material stirring roller (6), the material stirring roller (6) is arranged on the upper side of the feed roller (5) side by side, a plurality of stirring teeth are arranged at intervals on the side part surrounding the material stirring roller (6), and a power device is connected with the material stirring roller (6) and drives the material stirring roller to rotate.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121399955.0U CN216037707U (en) | 2021-06-23 | 2021-06-23 | Cotton rod rolling machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121399955.0U CN216037707U (en) | 2021-06-23 | 2021-06-23 | Cotton rod rolling machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN216037707U true CN216037707U (en) | 2022-03-15 |

Family

ID=80616347

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202121399955.0U Expired - Fee Related CN216037707U (en) | 2021-06-23 | 2021-06-23 | Cotton rod rolling machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN216037707U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115590687A (en) * | 2022-11-09 | 2023-01-13 | 深圳市建龙兴实业有限公司(Cn) | Cotton swab production and processing equipment |

-

2021

- 2021-06-23 CN CN202121399955.0U patent/CN216037707U/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115590687A (en) * | 2022-11-09 | 2023-01-13 | 深圳市建龙兴实业有限公司(Cn) | Cotton swab production and processing equipment |

| CN115590687B (en) * | 2022-11-09 | 2023-06-20 | 深圳市建龙兴实业有限公司 | Cotton swab production and processing equipment |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111232729B (en) | Corrugated board trimming and collecting equipment and production process using same | |

| CN216037707U (en) | Cotton rod rolling machine | |

| CN209078947U (en) | A kind of plastic grain cutting machine of no stationary knife | |

| CN108787939A (en) | A kind of construction site reinforcement metal straightening cutting equipment | |

| CN112868837A (en) | Automatic rolling equipment for tea processing | |

| CN211306400U (en) | Integrative device of cotton-padded slicing and discharging of makeup | |

| CN112680990A (en) | Plant fiber extraction element | |

| CN212771100U (en) | Roller type carding machine for processing carbon fiber felt | |

| CN111268358A (en) | Automatic ramie homogenizing, tip cutting, rolling and feeding conveying system | |

| CN215202361U (en) | Automatic material-separating die-cutting machine | |

| CN112140206B (en) | Waste collecting equipment for tailoring | |

| CN115161778A (en) | Full-automatic reverse-pulling type decorticator | |

| CN201032772Y (en) | Grass-feeding wiredrawing mechanism of the crop cutter filament-rubbing machine | |

| CN2456487Y (en) | Filament cutter for tobacco | |

| CN213445405U (en) | Automatic cotton storage mechanism for conveying cotton webs | |

| CN111270315B (en) | Drum-inclined reverse-pulling type ramie conveying and peeling machine | |

| CN212164236U (en) | Chinese hemp harvester | |

| CN216338126U (en) | Pure cotton hard twist yarn production line | |

| CN118542155B (en) | Crop straw crushing treatment device and method | |

| CN218278611U (en) | Oil tea fruit shell breaking mechanism | |

| CN211359157U (en) | Feed arrangement is smashed to black feather duck's fodder | |

| CN201452049U (en) | Transport mechanism of bristle combing machine | |

| CN112877788A (en) | Full-automatic re-scraping type hemp peeling equipment | |

| CN115846013B (en) | Fiber shredder | |

| CN108555186A (en) | It is a kind of to carry the bar cutter for stretching function |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20220315 |