CN215763696U - Pipeline positioning device - Google Patents

Pipeline positioning device Download PDFInfo

- Publication number

- CN215763696U CN215763696U CN202120521558.XU CN202120521558U CN215763696U CN 215763696 U CN215763696 U CN 215763696U CN 202120521558 U CN202120521558 U CN 202120521558U CN 215763696 U CN215763696 U CN 215763696U

- Authority

- CN

- China

- Prior art keywords

- plate

- tile

- positioning

- assembly

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn - After Issue

Links

- 238000005452 bending Methods 0.000 claims description 15

- 229910001220 stainless steel Inorganic materials 0.000 claims description 7

- 239000010935 stainless steel Substances 0.000 claims description 7

- 238000003466 welding Methods 0.000 claims description 5

- 239000013013 elastic material Substances 0.000 claims description 2

- 239000011248 coating agent Substances 0.000 abstract description 2

- 238000000576 coating method Methods 0.000 abstract description 2

- 230000007797 corrosion Effects 0.000 abstract description 2

- 238000005260 corrosion Methods 0.000 abstract description 2

- 238000009434 installation Methods 0.000 abstract description 2

- 230000000694 effects Effects 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000011900 installation process Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000007790 scraping Methods 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Landscapes

- Supports For Pipes And Cables (AREA)

Abstract

The embodiment of the utility model provides a pipeline positioning device, which comprises a tile plate assembly and a positioning plate; the size of the tile plate assembly is matched with that of the tube row; the size of the positioning plate is matched with that of the tile plate assembly; the tile plate assembly is connected with the positioning plate; the positioning plate and the tile plate assembly are used for fixing a pipeline. The device has the high-temperature tensile property of 16Rp0.2/MPa at 1200 ℃, and the high-temperature endurance property of the device has the breaking time of 856 tau/h at 1000 ℃; the coating has high temperature resistance, wear resistance and corrosion resistance, never falls off, has extremely low wear, and can ensure the service life of 10 years at least; the contact surface of the device and the pipe is large, the pipe row is not damaged at all, and the device is fixed reliably and is not easy to fall off; the device can effectively prevent or treat the phenomenon of pipe panel toppling and collision; the device has simple structure and convenient field installation, and is suitable for various occasions needing to fix the tube panel.

Description

Technical Field

The utility model relates to the technical field of pipeline fixing, in particular to a pipeline positioning device.

Background

In a large-scale thermal power generating unit boiler, phenomena of disordered tube screens, mutual scraping and mutual abrasion among tubes can be caused due to long-term heating in the operation process. The air flow around the tubes after being discharged forms vortex flow to cause uneven heat transfer, over-burning phenomenon and tube explosion of the boiler, so the tube rows must be well positioned.

The common fixture on the market has the following defects: the traditional clamp has low comprehensive grade including technical level, and the damage to the pipe caused by the structural problem of the clamp often occurs. A stainless steel plate strip with the thickness of 10-12 mm, the width of 40mm and the length of 1-2 m is generally adopted to be clamped at two sides of a tube bank and form point or line contact with a superheater tube, the contact area is small, and the stainless steel plate strip is easy to slip. The stainless steel plate strips are clamped on two sides of the tube bank, the upper end and the lower end of each stainless steel plate strip are abutted against the tube wall, and when the tube vibrates, the upper end and the lower end of each stainless steel plate strip are easy to scratch the tube, so that the tube is broken. The traditional clamp has complicated installation process and uneven load distribution of the clamp, and is easy to cause damage to a certain part of the clamp due to large stress, so that the pipe is discharged.

The existing fixture is made of materials with poor high temperature resistance, short service life and unsatisfactory fixation and discharge effects.

SUMMERY OF THE UTILITY MODEL

The utility model provides a pipeline positioning device, and aims to solve the problems that an existing clamp is short in service life and not ideal in fixing effect. In order to achieve the purpose, the utility model adopts the following technical scheme:

the utility model provides a pipeline positioning device, which comprises a tile plate assembly and a positioning plate; the tile plate assembly is connected with the positioning plate; the size of the positioning plate is matched with that of the tile plate assembly; the positioning plate and the tile plate assembly are used for fixing a pipeline, and the size of the tile plate assembly is matched with that of the pipeline.

Preferably: the tile plate assembly comprises an upper comb plate, a lower comb plate and a vertical bent plate, wherein the upper comb plate and the lower comb plate are respectively arranged on the vertical bent plate; the comb plate is provided with a connecting block; the positioning plate is provided with a hole, and the tile plate assembly is inserted into the hole and connected with the tile plate assembly; the connecting block on the comb plate is matched with the hole on the positioning plate.

Preferably: a plurality of semicircular holes are formed in the vertical bending plate; elastic materials are arranged in the semi-arc-shaped holes; the comb plate and the positioning plate are connected in a welding mode.

Preferably: the comb plate is connected with the positioning plate through bolts.

Preferably: the vertical bending plate is provided with a bulge, and the bulge is arranged on the inner wall of the vertical bending plate.

Preferably: the convex objects on the vertical bending plate are any one of point convex objects and line convex objects.

Preferably: the tile plate assembly and the positioning plate are made of stainless steel.

Compared with the prior art, the utility model has the following advantages: the device has the high-temperature tensile property of 16Rp0.2/MPa at 1200 ℃, and the high-temperature endurance property of the device has the breaking time of 856 tau/h at 1000 ℃; the coating has high temperature resistance, wear resistance and corrosion resistance, never falls off, has extremely low wear, and can ensure the service life of 10 years at least; the contact surface of the device and the pipe is large, the pipe row is not damaged at all, and the device is fixed reliably and is not easy to fall off; the device can effectively prevent or treat the phenomenon of pipe panel toppling and collision; the device has simple structure and convenient field installation, and is suitable for various occasions needing to fix the tube panel.

In addition to the technical problems addressed by the present invention, the technical features constituting the technical solutions, and the advantageous effects brought by the technical features of the technical solutions described above, other technical problems that the present invention can solve, other technical features included in the technical solutions, and advantageous effects brought by the technical features will be described in further detail in the detailed description.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the description of the embodiments or the prior art will be briefly described below.

FIG. 1 is a schematic structural diagram of a pipe positioning device according to an embodiment of the present invention;

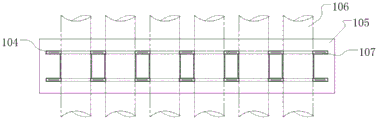

FIG. 2 is a front view of a pipe positioner according to an embodiment of the present invention;

fig. 3 is a schematic structural diagram of a positioning plate according to an embodiment of the present invention.

Reference numerals:

101-tile assembly, 102-positioning plate, 103-bulge, 104-comb plate, 105-vertical bending plate, 106-pipeline, 107-connecting block, 108-hole.

Detailed Description

In order to make the aforementioned objects, features and advantages of the present invention comprehensible, embodiments accompanied with figures are described in detail below. It is to be understood that the described embodiments are merely a few embodiments of the utility model, and not all embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

The utility model provides a pipeline positioning device, which comprises a tile plate assembly 101 and a positioning plate 102; the size of the tile assembly 101 is matched with that of the tube row; the size of the locating plate 102 is matched with the size of the tile assembly 101; the tile plate assembly 101 is connected with the positioning plate 102; the locating plate 102 and the shingle assembly 101 are used to secure a conduit 106. The tile plate assembly 101 and the positioning plate 102 are made of 0cr18ni11nb material;

the tile plate assembly 101 comprises an upper comb plate 104, a lower comb plate 104 and a vertical bent plate 105, wherein the upper comb plate 104 and the lower comb plate 104 are respectively arranged on the vertical bent plate 105; the comb plates 104 may be connected by way of integral molding, and may be connected by way of welding.

The comb plate 104 is provided with a bulge; the protrusion of the comb plate 104 is matched with the through hole 108 of the positioning plate 102, and the length of the protrusion may be smaller than the length of the hole 108, equal to the length of the hole 108, or longer than the length of the hole 108.

A hole 108 is formed in the positioning plate 102, and the tile plate assembly 101 is inserted into the hole 108 of the positioning plate 102 and connected with the tile plate assembly 101; the protrusions on the comb plate 104 fit into the holes 108 on the positioning plate 102.

A plurality of semicircular holes 108 are formed in the vertical bending plate 105; a flexible wrapping material is arranged in the semicircular hole 108 and used for protecting the pipeline 106; the comb plate 104 is connected to the positioning plate 102 by welding.

The comb plate 104 is connected to the positioning plate 102 by bolts.

The vertical bending plate 105 is provided with protrusions 103, and the protrusions 103 are arranged on the left side and the right side of the inner wall of the vertical bending plate 105.

The protrusions 103 on the vertical bent plate 105 are point protrusions.

The protrusions 103 on the vertical bent plate 105 are line protrusions.

The tile assembly 101 and the positioning plate 102 are made of 0cr18ni11nb material.

The tile assembly 101 is provided with a set, and the tile assembly 101 is arranged up and down.

Referring to fig. 1, it can be seen from fig. 1 that the tile assembly 101 cooperates with the locating plate 102 to fix the pipe 106 in the tile assembly 101, and a protrusion 103 is provided in the tile assembly 101, the protrusion 103 is used to locate the pipe 106 before the locating plate 102 is installed, and the protrusion 103 can also play a certain role of fixing and clamping after the locating plate 102 is installed.

Referring to fig. 2, it can be seen from fig. 2 that the comb plate 104 is disposed on the vertical bending plate 105, and the comb plate 104 can be fixedly disposed on the vertical bending plate 105 by riveting, welding, etc.; and the two comb plates 104 are provided with bulges, and the vertical bent plate 105 is provided with a plurality of semi-circular holes 108, the size of which is matched with that of the pipeline 106. And a plurality of connecting blocks 107 are provided on the comb plate 104, the connecting blocks 107 being used to limit the position of the positioning plate 102.

Referring to fig. 3, it can be seen from fig. 3 that a plurality of holes 108 are disposed on the positioning plate 102 in the apparatus, the holes 108 may be through holes or blind holes, and the size of the holes 108 is adapted to the size of the connecting block 107; the hole 108 is adapted to fit the connection block 107.

Finally, it should be noted that: the above embodiments are only used to illustrate the technical solution of the present invention, and not to limit the same; while the utility model has been described in detail and with reference to the foregoing embodiments, it will be understood by those skilled in the art that: the technical solutions described in the foregoing embodiments may still be modified, or some or all of the technical features may be equivalently replaced; and the modifications or the substitutions do not make the essence of the corresponding technical solutions depart from the scope of the technical solutions of the embodiments of the present invention.

Claims (7)

1. A pipeline positioning device is characterized by comprising a tile plate assembly and a positioning plate; the tile plate assembly is connected with the positioning plate; the size of the positioning plate is matched with that of the tile plate assembly; the positioning plate and the tile plate assembly are used for fixing a pipeline, and the size of the tile plate assembly is matched with that of the pipeline.

2. The pipe positioning device of claim 1, wherein the shoe assembly comprises two comb plates and one vertical bending plate, wherein the two comb plates are respectively arranged on the vertical bending plate; the comb plate is provided with a connecting block; the positioning plate is provided with a hole, and the size of the connecting block on the comb plate is matched with the size of the hole on the positioning plate.

3. The pipe positioning device of claim 2, wherein the vertical bending plate is provided with a plurality of semi-circular holes; elastic materials are arranged in the semi-arc-shaped holes; the comb plate and the positioning plate are connected in a welding mode.

4. The pipe positioning device of claim 2, wherein the comb plate is connected to the positioning plate by bolts.

5. The pipe positioning device according to claim 2 or 3, wherein the vertical bending plate is provided with a protrusion, and the protrusion is arranged on the inner wall of the vertical bending plate.

6. The pipe positioning device of claim 3, wherein the protrusions on the bend plate are any one of point protrusions and line protrusions.

7. The pipe positioner of claim 1, wherein the tile assembly and the positioning plate are made of stainless steel.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120521558.XU CN215763696U (en) | 2021-03-12 | 2021-03-12 | Pipeline positioning device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120521558.XU CN215763696U (en) | 2021-03-12 | 2021-03-12 | Pipeline positioning device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN215763696U true CN215763696U (en) | 2022-02-08 |

Family

ID=80093915

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202120521558.XU Withdrawn - After Issue CN215763696U (en) | 2021-03-12 | 2021-03-12 | Pipeline positioning device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN215763696U (en) |

-

2021

- 2021-03-12 CN CN202120521558.XU patent/CN215763696U/en not_active Withdrawn - After Issue

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102032587B (en) | Plate type air preheater with glass as heat exchange plate | |

| CN215763696U (en) | Pipeline positioning device | |

| CN204574097U (en) | Air preheater and hot junction radial seal structure thereof | |

| CN215637116U (en) | Use moisture separator reheater tube bank of antivibration strip | |

| CN215293893U (en) | Pipeline for building heating | |

| CN201828179U (en) | Tube bank for tube box-free air cooler | |

| CN205383926U (en) | Heat exchanger stringing structure | |

| CN105444605A (en) | Impact-resistant fluoroplastic heat exchanger | |

| CN221961580U (en) | Corrosion-resistant fire-resistant bus duct | |

| CN212080332U (en) | Novel pipe clamp for support hanger | |

| CN216408141U (en) | Firm pipe bracket of circular pipeline installation | |

| CN218916060U (en) | Heat exchanger tube bundle capable of improving heat exchange efficiency | |

| CN213118033U (en) | Anti-corrosion pipeline protection structure | |

| CN210379477U (en) | Flange grounding connection device | |

| CN221444934U (en) | Heat exchange tube fixing clamping plate structure for evaporative cooler | |

| CN104913330A (en) | Air preheater and hot-end radial sealing device thereof | |

| CN216346373U (en) | Novel glass tube air preheater | |

| CN221037016U (en) | Hanger rod structure of coal economizer | |

| CN217358221U (en) | Tube bundle supporting plate of cooling device | |

| CN217763494U (en) | Water guide groove structure for preventing tube explosion of boiler heating surface | |

| CN219734631U (en) | Stainless steel pipe cap convenient to dismantle | |

| CN205841983U (en) | Combined pipeline support | |

| CN214743824U (en) | Mounting structure of PPH environmental protection equipment | |

| CN211549779U (en) | Adjustable tunnel pipe wall hanging piece device | |

| CN215675261U (en) | Clamp formula scraper of coking is arranged to boiler heating surface tube |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| AV01 | Patent right actively abandoned |

Granted publication date: 20220208 Effective date of abandoning: 20231227 |

|

| AV01 | Patent right actively abandoned |

Granted publication date: 20220208 Effective date of abandoning: 20231227 |

|

| AV01 | Patent right actively abandoned | ||

| AV01 | Patent right actively abandoned |