CN214983781U - PVC polyester taffeta - Google Patents

PVC polyester taffeta Download PDFInfo

- Publication number

- CN214983781U CN214983781U CN202121161406.XU CN202121161406U CN214983781U CN 214983781 U CN214983781 U CN 214983781U CN 202121161406 U CN202121161406 U CN 202121161406U CN 214983781 U CN214983781 U CN 214983781U

- Authority

- CN

- China

- Prior art keywords

- coating

- layer

- retardant

- taff

- taffeta

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Professional, Industrial, Or Sporting Protective Garments (AREA)

- Details Of Garments (AREA)

Abstract

The utility model discloses a PVC polyester taffeta, including washing taffeta, the front end intermediate position that washes taffeta is provided with the second coating, the front end intermediate position of second coating is provided with high temperature resistant layer, the front end top that washes taffeta is provided with first coating, the intermediate position of first coating is provided with the fire-retardant precoat of aramid fiber, the one end of first coating is provided with the fire-retardant layer of cotton entirely, the other end of first coating is provided with the fire-retardant precoat of nylon cotton, the front end bottom that washes taffeta is provided with the third coating, the intermediate position of third coating is provided with the moisture absorption fibrous layer that generates heat. The utility model discloses in, be provided with the third coating in the front end bottom of washing the taff, the one end of third coating is provided with the heat preservation, is provided with the moisture absorption fibrous layer that generates heat at the intermediate position of third coating, is provided with the hollow fiber layer at the other end of third coating, realizes washing the holistic heat preservation effect of taff, and convenient and practical is worth wideling popularize.

Description

Technical Field

The utility model relates to a surface fabric technical field especially relates to a PVC washes taff.

Background

Polyester taffeta, also known as taffeta, refers to a silk fabric woven by high-quality degummed mulberry silk and a plain weave, the name of the silk fabric is from the English taffeta, and the silk fabric contains the meaning of the plain weave.

As disclosed in chinese patent document (CN206796711U), a polyester taffeta composite fabric includes an inner layer located at the inner side, an outer layer located at the outer side, and a breathable waterproof layer disposed between the inner side and the outer side; the inner layer comprises a first polyester taffeta layer, a first yarn cotton net layer, a fiber layer and a second yarn cotton net layer, wherein the first polyester taffeta layer, the first yarn cotton net layer, the fiber layer and the second yarn cotton net layer are sequentially stacked from inside to outside on the inner layer, although the use range of the existing polyester taffeta is wider, the problems still exist in the use process, namely the existing polyester taffeta is single in function, poor in fireproof and flame retardant performance, meanwhile, the heat preservation effect of the existing polyester taffeta is also poor, and the performance needs to be improved.

SUMMERY OF THE UTILITY MODEL

The utility model aims at solving the defects existing in the prior art and providing a PVC polyester taffeta.

In order to achieve the above purpose, the utility model adopts the following technical scheme: the utility model provides a PVC washes taff, includes washing taff, the front end intermediate position that washes taff is provided with the second coating, the front end intermediate position of second coating is provided with high temperature resistant layer, the front end top that washes taff is provided with first coating, the intermediate position of first coating is provided with the fire-retardant precoat of aramid fiber, the one end of first coating is provided with the fire-retardant layer of all-cotton, the other end of first coating is provided with the fire-retardant precoat of nylon wool, the front end bottom that washes taff is provided with the third coating, the intermediate position of third coating is provided with the moisture absorption fibre layer that generates heat.

As a further description of the above technical solution:

and a PVC layer is arranged at the top of the front end of the second coating.

As a further description of the above technical solution:

and a wear-resistant layer is arranged at the bottom of the front end of the second coating.

As a further description of the above technical solution:

the all-cotton flame-retardant layer and the nylon flame-retardant fabric layer are centrosymmetric with respect to the aramid flame-retardant fabric layer.

As a further description of the above technical solution:

and one end of the third coating is provided with a heat-insulating layer.

As a further description of the above technical solution:

and the other end of the third coating is provided with a hollow fiber layer.

The utility model discloses following beneficial effect has:

1. the utility model discloses in, at first be provided with the fire-retardant layer of all cotton in the one end of first coating, be provided with the fire-retardant precoat of aramid fiber and be provided with the fire-retardant precoat of nylon cotton at the other end of first coating in the intermediate position of first coating, when using when washing taff, if when meetting naked light, utilize the intraformational material of first coating to prevent fires fire-retardant to washing taff, it is fire-retardant to protect washing taff, be provided with the second coating simultaneously at washing taff front end intermediate position, be provided with the PVC layer at second coating top and be provided with high temperature resistant layer at the intermediate position of second coating, be provided with the wearing layer in the bottom of second coating, realize washing taff's multifunctionality, the performance obtains improving.

2. The utility model discloses in, be provided with the third coating in the front end bottom of washing the taff, the one end of third coating is provided with the heat preservation, is provided with the moisture absorption fibrous layer that generates heat at the intermediate position of third coating, is provided with the hollow fiber layer at the other end of third coating, realizes washing the holistic heat preservation effect of taff, and convenient and practical is worth wideling popularize.

Drawings

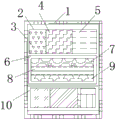

Fig. 1 is a schematic structural view of a PVC polyester taffer provided by the present invention;

fig. 2 is a schematic structural view of a third coating layer of the PVC polyester taff.

Illustration of the drawings:

1. washing Taff; 2. a first coating layer; 3. an all-cotton flame-retardant layer; 4. an aramid fiber flame-retardant fabric layer; 5. a nylon cotton flame-retardant fabric layer; 6. a second coating layer; 7. a PVC layer; 8. a high temperature resistant layer; 9. a wear layer; 10. a third coating layer; 11. a heat-insulating layer; 12. a moisture-absorbing heat-generating fiber layer; 13. a hollow fiber layer.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

In the description of the present invention, it should be noted that the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplification of description, but do not indicate or imply that the device or element referred to must have a specific orientation, be constructed and operated in a specific orientation, and thus, should not be construed as limiting the present invention; the terms "first," "second," and "third" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance, and furthermore, unless otherwise explicitly stated or limited, the terms "mounted," "connected," and "connected" are to be construed broadly and may be, for example, fixedly connected, detachably connected, or integrally connected; can be mechanically or electrically connected; they may be connected directly or indirectly through intervening media, or they may be interconnected between two elements. The specific meaning of the above terms in the present invention can be understood in specific cases to those skilled in the art.

Referring to fig. 1-2, the present invention provides an embodiment: a PVC polyester taffeta comprises a polyester taffeta 1, a second coating 6 is arranged in the middle of the front end of the polyester taffeta 1, a high-temperature resistant layer 8 is arranged in the middle of the front end of the second coating 6, a first coating 2 is arranged on the top of the front end of the polyester taffeta 1, an aramid flame-retardant fabric layer 4 is arranged in the middle of the first coating 2, the aramid flame-retardant fabric layer 4 has excellent high-temperature resistance and flame-retardant performance, has good dimensional stability and mechanical performance, and becomes one of the most widely used fibers at present, an all-cotton flame-retardant layer 3 is arranged at one end of the first coating 2, a nylon-cotton flame-retardant fabric layer 5 is arranged at the other end of the first coating 2, when the polyester taffeta is used, if open fire is met, the polyester taffeta is subjected to flame retardance by using materials in the first coating 2 to protect the polyester taffeta, and the second coating 6 is arranged in the middle of the front end of the polyester taffeta, the multifunctional polyester taffeta comprises a second coating 6, a PVC layer 7, a high-temperature resistant layer 8, a wear-resistant layer 9, a third coating 10, a moisture-absorbing and heating fiber layer 12, a third coating 10 and a third coating, wherein the PVC layer 7 is arranged on the top of the second coating 6, the high-temperature resistant layer 8 is arranged in the middle of the second coating 6, the high-temperature resistant coating is arranged at the bottom of the second coating 6, the multifunctional polyester taffeta is realized, the performance is improved, the third coating 10 is arranged at the bottom of the front end of the polyester taffeta 1, the moisture-absorbing and heating fiber layer 12 is arranged in the middle of the third coating 10, fiber molecules and water molecules attract each other and are combined when the fibers in the moisture-absorbing and heating fiber 12 absorb water, the kinetic energy of the water molecules is reduced and is converted into heat to be released, in addition, in order to enhance the heating effect, a certain substance can be added into the fibers or coated on the surfaces of the fibers, and after the fibers absorb the water, the substance is triggered to perform chemical reaction to release more heat.

The front end top of second coating 6 is provided with PVC layer 7, the front end bottom of second coating 6 is provided with wearing layer 9, prolong whole the life of washing the taff, all cotton fire-retardant layer 3 and nylon wool fire-retardant precoat 5 are central symmetry about the fire-retardant precoat of aramid fiber 4, set the two to central symmetry and make things convenient for whole washing the taff to prevent fires fire-retardant, the one end of third coating 10 is provided with heat preservation 11, heat preservation 11 can realize heat retaining effect to washing the taff, the other end of third coating 10 is provided with hollow fiber layer 13, hollow fiber layer 13's inside has a large amount of static air, can bring light elasticity for the fabric, good moisture permeability has been through comfortable cold-proof effect.

The working principle is as follows: when the polyester taffeta is used, firstly, one end of a first coating layer 2 is provided with an all-cotton flame-retardant layer 3, the middle position of the first coating layer 2 is provided with an aramid flame-retardant fabric layer 4, the other end of the first coating layer 2 is provided with a nylon flame-retardant fabric layer 5, when the polyester taffeta is used, if open fire occurs, the polyester taffeta is subjected to fireproof flame-retardant by using materials in the first coating layer 2 to protect the polyester taffeta, meanwhile, the middle position of the front end of the polyester taffeta is provided with a second coating layer 6, the top of the second coating layer 6 is provided with a PVC layer 7, the middle position of the second coating layer 6 is provided with a high-temperature resistant layer 8, the bottom of the second coating layer 6 is provided with a wear-resistant layer 9 to realize the multifunctional performance of the polyester taffeta and improve the performance, meanwhile, the bottom of the front end of the polyester taffeta is provided with a third coating layer 10, one end of the third coating layer 10 is provided with a heat-insulating layer 11, the middle position of the third coating layer 10 is provided with a moisture-absorbing and heating fiber layer 12, the hollow fiber layer 13 is arranged at the other end of the third coating 10, a large amount of static air can bring light elasticity to the fabric, good moisture permeability is comfortable, the overall heat preservation effect of the polyester taffeta is realized, and the polyester taffeta is convenient and practical.

Finally, it should be noted that: although the present invention has been described in detail with reference to the foregoing embodiments, it will be apparent to those skilled in the art that modifications and variations can be made in the embodiments or in part of the technical features of the embodiments without departing from the spirit and the scope of the invention.

Claims (6)

1. The utility model provides a PVC is washed taff, includes washing taff (1), its characterized in that: the front end intermediate position of washing taffeta (1) is provided with second coating (6), the front end intermediate position of second coating (6) is provided with high temperature resistant layer (8), the front end top of washing taffeta (1) is provided with first coating (2), the intermediate position of first coating (2) is provided with the fire-retardant surface fabric layer of aramid fiber (4), the one end of first coating (2) is provided with all-cotton flame retardant layer (3), the other end of first coating (2) is provided with the fire-retardant surface fabric layer of nylon wool (5), the front end bottom of washing taffeta (1) is provided with third coating (10), the intermediate position of third coating (10) is provided with moisture-absorbing heating fiber layer (12).

2. The PVC polyester taff according to claim 1, wherein: and a PVC layer (7) is arranged at the top of the front end of the second coating (6).

3. The PVC polyester taff according to claim 1, wherein: and a wear-resistant layer (9) is arranged at the bottom of the front end of the second coating (6).

4. The PVC polyester taff according to claim 1, wherein: the all-cotton flame-retardant layer (3) and the nylon flame-retardant fabric layer (5) are centrosymmetric with respect to the aramid flame-retardant fabric layer (4).

5. The PVC polyester taff according to claim 1, wherein: and one end of the third coating (10) is provided with a heat-insulating layer (11).

6. The PVC polyester taff according to claim 1, wherein: the other end of the third coating (10) is provided with a hollow fiber layer (13).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121161406.XU CN214983781U (en) | 2021-05-27 | 2021-05-27 | PVC polyester taffeta |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121161406.XU CN214983781U (en) | 2021-05-27 | 2021-05-27 | PVC polyester taffeta |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN214983781U true CN214983781U (en) | 2021-12-03 |

Family

ID=79087796

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202121161406.XU Active CN214983781U (en) | 2021-05-27 | 2021-05-27 | PVC polyester taffeta |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN214983781U (en) |

-

2021

- 2021-05-27 CN CN202121161406.XU patent/CN214983781U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109664582B (en) | Efficient flame-retardant heat-insulation composite fabric and application | |

| CN102499501A (en) | Anti-corrosion high-temperature-resistance thermal-insulation composite fabric for protective clothing | |

| CN214983781U (en) | PVC polyester taffeta | |

| CN210309290U (en) | Novel waterproof and breathable composite fabric | |

| CN210611074U (en) | Protective fabric | |

| CN210362767U (en) | High-temperature-resistant flame-retardant antibacterial chemical fiber fabric | |

| CN211075005U (en) | Ceramic heat-insulating cotton | |

| CN215243362U (en) | High-flame-retardant glass fiber knitted fabric | |

| CN215360254U (en) | Novel anti-solarization curtain fabric | |

| CN215473696U (en) | Textile fabric with flame-retardant and antibacterial functions | |

| CN215551403U (en) | PVC composite knitted fabric | |

| CN215662207U (en) | High-strength flexible garment fabric | |

| CN217863205U (en) | Waterproof textile fabric | |

| CN220588761U (en) | Fireproof garment made of fireproof fabric | |

| CN215662264U (en) | Breathable wear-resistant waterproof fabric | |

| CN216993404U (en) | High-wear-resistance flame-retardant polyester fabric | |

| CN218876505U (en) | Portable medical protective clothing fabric | |

| CN210590844U (en) | Terylene double-polyester double-heterochromatic silk | |

| CN211808203U (en) | High-temperature-resistant and radiation-proof fabric | |

| CN216153263U (en) | Novel foam TC mixed fabric | |

| CN220785106U (en) | High-flame-retardance polyester-cotton-hemp blended yarn | |

| CN213472401U (en) | High-barrier non-woven fabric | |

| CN221794094U (en) | Strong acid and alkali resistant special flame-retardant fiber laminated fabric | |

| CN221518991U (en) | Macroporous viscose-based activated carbon fiber felt | |

| CN215152487U (en) | Fabric with good stretch-resistant effect |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |