CN214525458U - Dampproofing composite packaging bag - Google Patents

Dampproofing composite packaging bag Download PDFInfo

- Publication number

- CN214525458U CN214525458U CN202022646222.4U CN202022646222U CN214525458U CN 214525458 U CN214525458 U CN 214525458U CN 202022646222 U CN202022646222 U CN 202022646222U CN 214525458 U CN214525458 U CN 214525458U

- Authority

- CN

- China

- Prior art keywords

- water

- fixedly connected

- paper

- collecting box

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Bag Frames (AREA)

- Drying Of Gases (AREA)

- Packages (AREA)

Abstract

The utility model discloses a dampproofing composite packaging bag belongs to wrapping bag technical field, including the sack body, the top fixedly connected with sealing strip of sack body, the bottom fixedly connected with of sack body separates damp pad, the water sucking mouth has been seted up in the front of sack body, the inside fixedly connected with water-collecting box of water sucking mouth, the inside fixedly connected with dust screen and the paper that locks of water-collecting box. The utility model discloses a, it is bigger to distribute the area of contact who makes dry paper and inside air through setting up to zigzag shape, thereby make drying effect better, and the active carbon of filling has the effect that the degerming removed the flavor in the space, can adsorb the toxic substance, prevent that the wrapping bag is inside mouldy, thereby make the whole of sack body can all play fine dampproofing effect, make sack from the top down homoenergetic receive the effect of dry paper, do not worry that the drier buries in powdery material, influence the result of use, make the dampproofing effect of whole wrapping bag better.

Description

Technical Field

The utility model relates to a wrapping bag technical field, more specifically say, relate to a dampproofing composite packaging bag.

Background

The composite package is made up by using two or more than two kinds of materials through one-time or several-time dry-type compounding process, so that it can be formed into composite package with a certain function, generally divided into base layer, functional layer and heat-sealing layer, in which the base layer mainly can be used for making the functions of beautiful appearance, printing and resisting humidity, the functional layer mainly can be used for making the functions of resisting light and shielding light, and the heat-sealing layer can be directly contacted with packaged article, and possesses the functions of adaptability, permeability resistance, good heat-sealing property and transparency, etc.

The prior packaging bag technology has the following problems: the existing packaging bag has certain defects in the application of actual life and work, has poor moisture resistance, is easy to deteriorate and rot food, medicines and the like when various foods, medicines and the like are packaged, and has low practical performance.

SUMMERY OF THE UTILITY MODEL

1. Technical problem to be solved

To the problem that exists among the prior art, the utility model aims to provide a dampproofing composite packaging bag possesses the effectual advantage of dampproofing, and it is relatively poor to have solved current wrapping bag moisture resistance, when packing various food, medicines etc. makes rotten bad, the lower problem of practicality of food, medicines etc. easily.

2. Technical scheme

In order to solve the above problems, the utility model adopts the following technical proposal.

The utility model provides a dampproofing composite packaging bag, includes the sack body, the top fixedly connected with sealing strip of sack body, the bottom fixedly connected with of sack body separates damp pad, the water absorption mouth has been seted up in the front of sack body, the inside fixedly connected with water-collecting box of water absorption mouth, the inside fixedly connected with dust screen and the lock water paper of water-collecting box, the lock water paper is located the front of dust screen, the two-layer baffle of inside fixedly connected with of water-collecting box, two the hole that leaks has all been seted up in the front of baffle, two the baffle all is located the front of lock water paper, two it has the calcium chloride granule to fill between the inner wall of baffle and water-collecting box, the sack body includes ventilative layer, dampproof course and waterproof layer, dampproof course fixed connection is in the outside of ventilative layer, waterproof layer fixed connection is in the outside of dampproof course.

Preferably, the joint of the water locking paper and the water collecting box is fixedly connected with a sealing gasket, and the water locking paper is made of a composite material of a PE film.

Preferably, the waterproof layer is made of a stretched polypropylene material, and the breathable layer is made of a polyethylene material.

Preferably, the moisture-proof layer comprises dry paper, the dry paper is uniformly distributed between the breathable layer and the waterproof layer in a folded line shape, and activated carbon is filled in gaps among the dry paper, the breathable layer and the waterproof layer.

Preferably, the inner bottom wall of the water collecting box is fixedly connected with a drain pipe, and the bottom of the drain pipe extends to the outside of the water collecting box and is in threaded connection with a sealing cover.

3. Advantageous effects

Compared with the prior art, the utility model has the advantages of:

(1) the moisture-proof composite packaging bag can seal the bag body by arranging the sealing strip, so that moisture in the outside air can not enter the bag body, the moisture-proof pad is arranged at the bottom of the bag body and can play a role of moisture insulation, when the bag is placed, the moisture on a table top can not influence the inside of the bag body, the water collecting box can play a role of dehumidification and can absorb and separately store the moisture in the air in the bag body, the internal dust-proof net can prevent articles in the bag body from blocking water-locking paper and influencing the ventilation effect of the water-locking paper, the water-locking paper is made of a composite material of a PE film and can play a role of water resistance and ventilation, so that the moisture in the packaging bag can enter the water collecting box through the water-locking paper, the moisture reacts with calcium chloride particles through the partition plate to absorb the moisture in the moisture, and the water after the absorption reaction is stored in the water collecting box, the inside that can't get into the sack body through the lock water paper, thereby play the effect of dehumidification, make the dampproofing effect of wrapping bag better, it includes the three-layer to set up the sack body, the innermost is ventilative layer, ventilative layer adopts nontoxic tasteless and water-fast polyethylene modified material, good leakproofness has, ensure the quality of wrapping bag, the waterproof layer has good mechanical strength, heat-resisting and humidity resistance, through the involution, play and bear the weight of, the effect of protection and decoration interior thing, the centre is the dampproof course, the dampproof course includes drying paper, drying paper has the dry effect of water absorption, can absorb the moisture in the inside air of wrapping bag, set up to zigzag shape distribution and make the area of contact of drying paper and inside air bigger, thereby make the drying effect better, and the active carbon that fills in the space has the effect of degerming flavor removal, can adsorb toxic substance, prevent the inside moldy of wrapping bag, thereby make the whole of sack body all can play fine dampproofing effect for sack from the top down homoenergetic can receive the effect of dry paper, does not worry that the drier buries in likepowder material, influences the result of use, makes the dampproofing effect of whole wrapping bag better.

(2) This dampproofing composite packaging bag, set up sealed the pad through the junction at lock water paper and water collection box, can guarantee that the inside water of water collection box can not leak into the packing from the junction of lock water paper and water collection box, make the water collection box have good leakproofness, it can play waterproof ventilative effect to set up the combined material that lock water paper is the PE membrane, make inside moisture of wrapping bag can get into inside the water collection box through lock water paper, adsorb moisture wherein by the calcium chloride granule, water after the absorption reaction can't see through lock water paper, thereby play the effect of dehumidification, make the dampproofing effect of wrapping bag better.

(3) This dampproofing composite packaging bag is tensile polypropylene material through setting up the waterproof layer, and the waterproof layer wraps up dampproof course and ventilative layer, and the waterproof layer has good mechanical strength, heat-resisting and moisture barrier property, through the involution, plays the effect of bearing, protection and decoration interior content, and ventilative layer adopts nontoxic tasteless and water-fast polyethylene improvement material, has good involution nature, ensures the quality of wrapping bag.

(4) This dampproofing compound packaging bag, through setting up dry paper, dry paper has the dry effect of absorbing water, can absorb the moisture in the inside air of wrapping bag, and it is bigger to set up to the area of contact that the dogleg shape distributes and make dry paper and inside air to it is better to make drying effect, and active carbon has the effect that the degerming removed the flavor, can adsorb the toxic substance, prevents that the wrapping bag is inside mouldy.

(5) This dampproofing composite packaging bag, through the interior diapire fixed connection drain pipe that sets up the water-collecting box, can outwards discharge through the drain pipe after the water storage of water-collecting box inside is full to influence the effect of absorbing water of calcium chloride granule, at the sealed lid of bottom threaded connection of drain pipe, sealed lid can be sealed with the drain pipe, makes it can outwards not leak when not the drainage.

Drawings

FIG. 1 is a schematic perspective view of the present invention;

FIG. 2 is a top cross-sectional view of the water collecting box of the present invention;

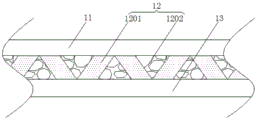

fig. 3 is a cross-sectional view of the bag body of the present invention.

The reference numbers in the figures illustrate:

1. a bag body; 2. a sealing strip; 3. a moisture-proof pad; 4. a water suction port; 5. a water collection box; 501. a drain pipe; 6. a dust screen; 7. water locking paper; 8. a partition plate; 9. a water leakage hole; 10. calcium chloride particles; 11. A breathable layer; 12. a moisture barrier; 1201. drying the paper; 1202. activated carbon; 13. and a waterproof layer.

Detailed Description

The technical solution in the embodiment of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiment of the present invention; obviously, the described embodiments are only a part of the embodiments of the present invention, and not all embodiments, and all other embodiments obtained by those skilled in the art without any inventive work are within the scope of the present invention based on the embodiments of the present invention.

Example 1:

referring to fig. 1-3, a moisture-proof composite packaging bag comprises a bag body 1, a sealing strip 2 is fixedly connected to the top of the bag body 1, a moisture-proof pad 3 is fixedly connected to the bottom of the bag body 1, a water suction opening 4 is formed in the front of the bag body 1, a water collecting box 5 is fixedly connected to the inside of the water suction opening 4, a dust screen 6 and water locking paper 7 are fixedly connected to the inside of the water collecting box 5, the water locking paper 7 is located on the front side of the dust screen 6, two layers of partition plates 8 are fixedly connected to the inside of the water collecting box 5, water leakage holes 9 are formed in the front sides of the two partition plates 8, the two partition plates 8 are located on the front side of the water locking paper 7, calcium chloride particles 10 are filled between the two partition plates 8 and the inner wall of the water collecting box 5, the bag body 1 comprises a ventilation layer 11, dampproof course 12 and waterproof layer 13, dampproof course 12 fixed connection in the outside of ventilative layer 11, waterproof layer 13 fixed connection in the outside of dampproof course 12.

In the embodiment, the bag body 1 can be sealed by arranging the sealing strip 2, so that moisture in the outside air can not enter the bag body 1, the moisture-proof pad 3 is arranged at the bottom of the bag body 1 and can play a role of moisture insulation, so that when the bag is placed, moisture on a table top can not affect the inside of the bag body 1, the water collection box 5 can play a role of dehumidification to absorb and separately store the moisture in the air in the bag body 1, the internal dust-proof net 6 can prevent articles in the bag body 1 from blocking the water locking paper 7 to affect the ventilation effect, the water locking paper 7 is made of a composite material of a PE film and can play a role of water resistance and ventilation, so that the moisture in the packaging bag can enter the water collection box 5 through the water locking paper 7 and react with the calcium chloride particles 10 through the partition plate 8 to absorb the moisture in the moisture, and the water after the absorption reaction is stored in the water collection box 5, the inside that can't permeate water-locking paper 7 and get into bag body 1, thereby play the effect of dehumidification, make the dampproofing effect of wrapping bag better, it includes the three-layer to set up bag body 1, the innermost is ventilative layer 11, ventilative layer 11 adopts nontoxic tasteless and water-fast polyethylene modified material, good leakproofness has, ensure the quality of wrapping bag, waterproof layer 13 has good mechanical strength, heat-resisting and humidity resistance, through the involution, play the effect of bearing, protection and decoration, middle dampproof course 12 that is, dampproof course 12 includes drying paper 1201, drying paper 1201 has the effect of water absorption drying, can absorb the moisture in the inside air of wrapping bag, set up to zigzag shape distribution and make the area of contact of drying paper 1201 with the inside air bigger, thereby make the drying effect better, and the active carbon 1202 who fills in the space has the effect of degerming, can adsorb toxic material, prevent that the wrapping bag is inside mouldy to make the whole of sack body 1 all can play fine dampproofing effect, make the sack from the top down homoenergetic receive dry paper 1201's effect, do not worry that the drier buries in powdery material, influence the result of use, make the dampproofing effect of whole wrapping bag better.

Furthermore, a sealing gasket is fixedly connected at the joint of the water locking paper 7 and the water collecting box 5, and the water locking paper 7 is made of a composite material of a PE film.

In this embodiment, through setting up sealed the pad in the junction of lock water paper 7 and water collection box 5, can guarantee that the inside water of water collection box 5 can not leak into the packing from the junction of lock water paper 7 and water collection box 5, make water collection box 5 have good leakproofness, it can play waterproof ventilative effect to set up the combined material that lock water paper 7 is the PE membrane, make the inside moisture of wrapping bag can get into inside the water collection box 5 through lock water paper 7, adsorb the moisture therein by calcium chloride granule 10, absorb the water after the reaction but can't see through lock water paper 7, thereby play the effect of dehumidification, make the dampproofing effect of wrapping bag better.

Further, the waterproof layer 13 is made of a stretched polypropylene material, and the breathable layer 11 is made of a polyethylene material.

In this embodiment, by setting up waterproof layer 13 as tensile polypropylene material, waterproof layer 13 wraps up dampproof course 12 and ventilative layer 11, and waterproof layer 13 has good mechanical strength, heat-resisting and humidity resistance, through the involution, plays the effect of bearing, protection and decoration interior thing, and ventilative layer 11 adopts nontoxic tasteless and waterproof polyethylene modified material, has good involution nature, ensures the quality of wrapping bag.

Further, the moisture-proof layer 12 includes dry paper 1201, the dry paper 1201 is uniformly distributed between the breathable layer 11 and the waterproof layer 13 in a zigzag shape, and activated carbon 1202 is filled in gaps among the dry paper 1201, the breathable layer 11 and the waterproof layer 13.

In this embodiment, through setting up dry paper 1201, dry paper 1201 has the dry effect of absorbing water, can absorb the moisture in the inside air of wrapping bag, and it is bigger to set up to the area of contact that dog-ear distribution made dry paper 1201 and inside air to it is better to make drying effect, and active carbon 1202 has the effect that the degerming was removed the flavor, can adsorb the toxic substance, prevents that the wrapping bag is inside mouldy.

Further, a drain pipe 501 is fixedly connected to the inner bottom wall of the water collecting box 5, and the bottom of the drain pipe 501 extends to the outside of the water collecting box 5 and is threadedly connected with a sealing cover.

In this embodiment, the drainage pipe 501 is fixedly connected to the inner bottom wall of the water collecting box 5, and after the water in the water collecting box 5 is fully stored, the water can be drained through the drainage pipe 501 to avoid affecting the water absorption effect of the calcium chloride particles 10.

The working principle is as follows: when the packaging bag is used, articles are placed inside the bag body 1, the sealing strip 2 is sealed, the moisture-proof pad 3 is arranged at the bottom of the bag body 1 and can play a role in moisture insulation, moisture in the bag body 1 and moisture generated by the articles can penetrate through the water-locking paper 7 through the dustproof net 6 and enter between the two partition plates 8, moisture in the air is absorbed by the calcium chloride particles 10 to react, generated water is left in the water collecting box 5 and cannot enter the bag body 1 through the water-locking paper 7 to play a role in dehumidification, the bag body 1 comprises three layers, the waterproof layer 13 prevents external moisture from entering the bag, the breathable layer 11 plays a role in ventilation, the moisture enters the moisture-proof layer 12 and is absorbed through the drying paper 1201, the activated carbon 1202 filled in the gap has a degerming and odor removing function, toxic substances are adsorbed, and mildew in the packaging bag is prevented, make the whole of sack body 1 play fine dampproofing effect, it is relatively poor to have solved current wrapping bag moisture resistance, when packing various food, medicine etc. makes rotten such as food, medicine easily, the lower problem of practicality.

In the description of the present invention, it should be noted that the terms "upper", "lower", "inner", "outer", "top/bottom", and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplification of description, but do not indicate or imply that the device or element referred to must have a specific orientation, be constructed in a specific orientation, and be operated, and thus, should not be construed as limiting the present invention. Furthermore, the terms "first" and "second" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance.

In the description of the present invention, it is to be noted that, unless otherwise explicitly specified or limited, the terms "mounted", "provided", "sleeved/connected", "connected", and the like are to be understood in a broad sense, such as "connected", which may be fixedly connected, detachably connected, or integrally connected; can be mechanically or electrically connected; they may be connected directly or indirectly through intervening media, or they may be interconnected between two elements. The specific meaning of the above terms in the present invention can be understood in specific cases to those skilled in the art.

The above description is only the preferred embodiment of the present invention; the scope of the present invention is not limited thereto. Any person skilled in the art should also be able to cover the technical scope of the present invention by replacing or changing the technical solution and the improvement concept of the present invention with equivalents and modifications within the technical scope of the present invention.

Claims (5)

1. A dampproofing composite packaging bag, includes bag body (1), its characterized in that: the bag comprises a bag body (1), wherein a sealing strip (2) is fixedly connected to the top of the bag body (1), a damp-proof pad (3) is fixedly connected to the bottom of the bag body (1), a water suction opening (4) is formed in the front of the bag body (1), a water collecting box (5) is fixedly connected to the inside of the water suction opening (4), a dust screen (6) and water locking paper (7) are fixedly connected to the inside of the water collecting box (5), the water locking paper (7) is located on the front of the dust screen (6), two layers of partition plates (8) are fixedly connected to the inside of the water collecting box (5), water leakage holes (9) are formed in the front of the partition plates (8), the two partition plates (8) are located on the front of the water locking paper (7), calcium chloride particles (10) are filled between the partition plates (8) and the inner wall of the water collecting box (5), and the bag body (1) comprises a ventilating layer (11), Dampproof course (12) and waterproof layer (13), dampproof course (12) fixed connection is in the outside of ventilative layer (11), waterproof layer (13) fixed connection is in the outside of dampproof course (12).

2. The moisture resistant composite packaging bag according to claim 1, wherein: the joint of the water locking paper (7) and the water collecting box (5) is fixedly connected with a sealing gasket, and the water locking paper (7) is made of a composite material of a PE film.

3. The moisture resistant composite packaging bag according to claim 1, wherein: the waterproof layer (13) is made of a stretched polypropylene material, and the breathable layer (11) is made of a polyethylene material.

4. The moisture resistant composite packaging bag according to claim 1, wherein: the moisture-proof layer (12) comprises dry paper (1201), the dry paper (1201) is uniformly distributed between the breathable layer (11) and the waterproof layer (13) in a zigzag manner, and activated carbon (1202) is filled in gaps among the dry paper (1201), the breathable layer (11) and the waterproof layer (13).

5. The moisture resistant composite packaging bag according to claim 1, wherein: the inner bottom wall of the water collecting box (5) is fixedly connected with a drain pipe (501), and the bottom of the drain pipe (501) extends to the outside of the water collecting box (5) and is in threaded connection with a sealing cover.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022646222.4U CN214525458U (en) | 2020-11-16 | 2020-11-16 | Dampproofing composite packaging bag |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202022646222.4U CN214525458U (en) | 2020-11-16 | 2020-11-16 | Dampproofing composite packaging bag |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN214525458U true CN214525458U (en) | 2021-10-29 |

Family

ID=78288204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202022646222.4U Active CN214525458U (en) | 2020-11-16 | 2020-11-16 | Dampproofing composite packaging bag |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN214525458U (en) |

-

2020

- 2020-11-16 CN CN202022646222.4U patent/CN214525458U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR890002855B1 (en) | Sheet-type deoxide material | |

| CA2305424A1 (en) | Dehumidifying pouch | |

| CN214525458U (en) | Dampproofing composite packaging bag | |

| GB2161093A (en) | Dehumidifier package | |

| JPH0783832B2 (en) | Sheet-shaped oxygen absorber | |

| JP3860547B2 (en) | Quality retainer package | |

| CN211108811U (en) | Packaging bag special for traditional Chinese medicine | |

| CN210823500U (en) | Lithium ion battery ceramic diaphragm packing plant | |

| CN209192696U (en) | Easily take off moisture absorption packaging bag | |

| CN214525482U (en) | Dry-wet separation type packaging bag for nut packaging | |

| CN212289023U (en) | Packaging composite film and packaging bag | |

| CN212149890U (en) | High-transparency back film and deoxidizer packaging bag with same | |

| CN213020574U (en) | Special desiccant bag for food and medicine | |

| CN217919083U (en) | Chrysanthemum tea packing carton with moisture absorption function | |

| CN204507606U (en) | A kind of moistureproof taste removal packaging bag | |

| JPH0235656Y2 (en) | ||

| JPH0237725Y2 (en) | ||

| CN213058212U (en) | Drying bag | |

| CN214825542U (en) | A ventilative wrapping bag for volatility solid daily chemical articles for use | |

| CN210913642U (en) | Machine deoxidizer packed in bag | |

| KR890005115Y1 (en) | A package for hygroscopic agent | |

| JP3376915B2 (en) | Deoxygenated multilayer body, packaging container using the same, and method of storing food or medicine | |

| JP3070596U (en) | Double chamber container | |

| CN221915599U (en) | Tear-off eight-edge-sealed moisture-absorbing bag | |

| CN213263661U (en) | Powder packing jar with dampproofing function |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |