CN214375854U - Processing box - Google Patents

Processing box Download PDFInfo

- Publication number

- CN214375854U CN214375854U CN202120345471.1U CN202120345471U CN214375854U CN 214375854 U CN214375854 U CN 214375854U CN 202120345471 U CN202120345471 U CN 202120345471U CN 214375854 U CN214375854 U CN 214375854U

- Authority

- CN

- China

- Prior art keywords

- driving force

- photosensitive drum

- gear

- developing roller

- process cartridge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Electrophotography Configuration And Component (AREA)

Abstract

The utility model discloses a processing box, detachable install in the electrophotographic image forming apparatus that has drive power component, include: a housing configured to accommodate a developer; a developing roller; a photosensitive drum rotatable about a photosensitive drum rotation axis extending in an axial direction thereof; a power receiving part that can receive a driving force of the driving force member; and a regulating portion provided on one side in a longitudinal direction of the housing, the regulating portion urging the driving force member to a position of engagement with a power receiving member which receives the driving force from the driving force member and which can drive the developing roller and the photosensitive drum to rotate when the process cartridge is mounted in the electrophotographic image forming apparatus. The developing roller, the photosensitive drum and the stirring frame can be driven to rotate simultaneously by receiving the driving force in the electrophotographic image forming device only through the developing roller gear, compared with the prior art, the transmission structure of the processing box is simplified, the mounting and meshing precision of the processing box and the driving force component is reduced, and meanwhile, the mounting interference is reduced.

Description

Technical Field

The utility model relates to an electrophotographic imaging technical field especially relates to a processing box.

Background

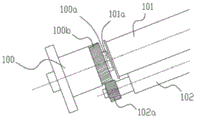

As shown in fig. 1, there is disclosed in the prior art a process cartridge detachably mountable to an electrophotographic image forming apparatus having a driving force member 100, the driving force member 100 being capable of transmitting a driving force, comprising: a coupling recess 100a and a plurality of driving force member gear teeth 100 b. The process cartridge includes: a photosensitive drum 101 provided with a coupling projection 101a at one side in the longitudinal direction, the coupling projection 101a being engageable with the coupling recess 100a to receive the driving force transmitted from the driving force member 100 and rotate the photosensitive drum 101; a developing roller 102 provided with a developing roller gear 102a at one side in a longitudinal direction thereof, the developing roller gear 102a being engageable with the driving force member gear teeth 100b to receive the driving force transmitted from the driving force member 100 and rotate the developing roller 102.

The coupling convex portion 101a of the photosensitive drum 101 and the developing roller gear 102a of the developing roller 102 are both engaged with the driving force member 100, and the process cartridge can normally operate, that is, the process cartridge adopts a dual-drive technical scheme.

SUMMERY OF THE UTILITY MODEL

In order to solve the above problems, the present invention provides a novel processing box, which is mainly realized by the following technical solution:

a process cartridge detachably mountable to an electrophotographic image forming apparatus having a driving force member, comprising:

a housing configured to accommodate a developer;

a developing roller;

a photosensitive drum rotatable about a photosensitive drum rotation axis extending in an axial direction thereof;

a power receiving part that can receive a driving force of the driving force member;

further comprising a regulating portion provided on one side of the longitudinal direction of the housing, the regulating portion urging the driving force member to a position to engage with the power receiving member which can receive the driving force from the driving force member and can drive the developing roller and the photosensitive drum to rotate when the process cartridge is mounted to the electrophotographic image forming apparatus.

Further, the positioning device comprises a positioning part arranged on one side of the longitudinal direction of the shell, and the positioning part and the photosensitive drum are coaxially arranged.

Further, the positioning portion is configured to have an inner circumference, and the driving force member is configured to have an outer circumference, the inner circumference being engageable with the outer circumference.

Further, the power receiving member is configured as a developing roller gear mounted at an axial end of the developing roller and configured to drive the developing roller to rotate.

Further, still including installing the sensitization drum gear of sensitization drum axial end, sensitization drum gear is used for the drive the sensitization drum is rotatory, the developer roll gear with sensitization drum gear direct mesh.

Further, still include the stirring frame and install stirring frame gear at stirring frame axial end, stirring frame gear is used for the drive the stirring frame is rotatory, it still includes middle transmission gear to handle the box, the stirring frame gear passes through middle transmission gear with developer roll gear engagement.

Further, the electrophotographic image forming apparatus includes a photosensitive drum gear installed at an axial end of the photosensitive drum, the photosensitive drum gear being configured to drive the photosensitive drum to rotate, and the developing roller gear being simultaneously engaged with the driving force member, the photosensitive drum gear, and the intermediate transmission gear when the process cartridge is installed in the electrophotographic image forming apparatus.

In one aspect of the present invention, the first and second,

the utility model discloses in adopted single driven technical scheme, processing box just can drive developer roll, sensitization drum, stirring frame rotation after just receiving the drive power of electrophotography image forming apparatus by the developer roll gear promptly, compares in prior art, has simplified the transmission structure who handles the box, has reduced the installation meshing precision of processing box and drive power component, has reduced the installation simultaneously and has interfered.

On the other hand, by adopting a structure in which the developing roller gear having a smaller addendum circle is engaged with the driving force member having a larger addendum circle, so that the torque of the driving force member is reduced when the driving force is transmitted, the electrophotographic image forming apparatus requires only a small torque to drive the rotating member in the process cartridge, and the mechanical strength requirement of the driving force member is reduced after the torque of the driving force member is reduced.

Drawings

FIG. 1 is a schematic view showing a driving force member engaging with a process cartridge in the prior art;

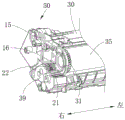

FIG. 2 is a partial schematic view of an electrophotographic imaging apparatus according to the present invention;

fig. 3 is a partially enlarged schematic view of a in fig. 1 according to the present invention;

FIG. 4 is a schematic view of a driving force member of the present invention;

FIG. 5 is a schematic view of the present invention with the driving force member in a first position;

FIG. 6 is a schematic view of the present invention with the driving force member in a second position;

FIG. 7 is a schematic view of the cartridge of the present invention;

FIG. 8 is an exploded view of the cartridge of the present invention;

FIG. 9 is a partial right side view of the cartridge of the present invention;

fig. 10 is a schematic view of the engagement relationship between the driving force member, the developing roller gear and the photosensitive drum gear according to the present invention.

Detailed Description

In order to make the object, technical solution and technical effect of the embodiment of the present invention clearer, the following will clearly and completely describe the technical solution of the process cartridge of the present invention with reference to the accompanying drawings. It should be apparent that the described embodiment is only one preferred embodiment of the present invention, not all embodiments, and other embodiments obtained by those skilled in the art without inventive efforts based on the embodiments of the present invention belong to the protection scope of the present invention.

The longitudinal direction of the process cartridge 50 is the left-right direction, and the developing roller gear 21 is located on the right side of the process cartridge 50 in the left-right direction.

Electrophotographic image forming apparatus

As shown in fig. 2 to 6, an electrophotographic image forming apparatus, which can be used to mount a process cartridge, includes a side plate 150, a driving force member 100; the side plate 150 includes a side plate main body 151 and a cover portion 101, the cover portion 101 protrudes outward from the side plate main body 151, the cover portion 101 has an accommodating portion 101c capable of accommodating the driving force member 100, the cover portion 101 can also be used to restrain the driving force member 100 at a specific position within the accommodating portion 101c, the cover portion 101 further includes a first opening 101a, a second opening 101b, the first opening 101a and the second opening 101b are disposed at a certain distance along an outer circumferential surface of the cover portion 101, and a portion of the driving force member 100 is exposed through the first opening 101a and the second opening 101 b; the driving force member 100 may receive a driving force from a motor (not shown) in the electrophotographic image forming apparatus and rotate about a predetermined driving force member rotation axis a, the driving force member 100 having a plurality of driving force member gear teeth 100a having a spiral shape in tooth form, the driving force being transmittable from the motor to the driving force member gear teeth 100a, the driving force member 100 further including a positioned portion 100b, the positioned portion 100b being configured to have an outer circumference.

The driving force member 100 of the electrophotographic image forming apparatus of the present invention is movable by an external force other than the electrophotographic image forming apparatus, that is, the driving force member 100 has two positions, a first position shown in fig. 5 and a second position shown in fig. 6. Specifically, in the first position, the driving force member 100 has two states, i.e., an inclined state and a retracted state, and in the second position, the driving force member 100 also has two states, i.e., a righting state in which the maximum angle of the driving force member rotation axis a with respect to the inclined state is smaller and in which the driving force member rotation axis a substantially coincides with the photosensitive drum rotation axis of the photosensitive drum in the process cartridge, and an extended state in which the driving force member 100 is farther from the side plate 150 with respect to the retracted state. In the process from the start of mounting to the completion of mounting of the process cartridge, the process cartridge is configured such that the driving force member 100 can be urged so that the driving force member 100 is gradually moved from the first position to the second position, so that the driving force member 100 and the process cartridge can be properly engaged.

Processing box

As shown in fig. 3 to 10, the present invention provides a process cartridge 50, including a power receiving part, the process cartridge 50 being detachably mountable to an electrophotographic image forming apparatus having a driving force member 100, the power receiving part being engageable with the driving force member 100 and receiving a driving force transmitted from the driving force member 100, the process cartridge further including: the device comprises a shell 30, a protective cover 39, a photosensitive drum 35, a photosensitive drum gear 31, a developing roller 25, a developing roller gear 21, a first intermediate transmission gear 22, a second intermediate transmission gear 23, an agitating frame (not shown), an agitating frame gear 24, a regulating part 15 and a positioning part 16. The power receiving part can receive the driving force from the driving force component 100 to drive the developing roller 25 and the photosensitive drum 35 to rotate, and further, the power receiving part is configured as a developing roller gear 21, and after the developing roller gear 21 is directly meshed with the driving force component 100 to receive the driving force from the driving force component 100, the developing roller 25 can be driven to rotate, and the photosensitive drum 35 can also be driven to rotate, so that the transmission structure of the processing box 50 is simplified.

The casing 30 is configured to accommodate a developer;

a protective cover 39 is mounted on the right side of the housing 30;

the photosensitive drum 35, which can generate an electrostatic latent image, is supported on the housing 30 and is rotatable about a photosensitive drum rotation axis B extending in the left-right direction; the drum gear 31 is mounted on the right side of the drum 35 and directly engages with the developing roller gear 21, and by adopting the above-described gear-and-gear engagement transmission structure, while the transmission structure of the process cartridge 50 is simplified, the transmission is also more stable because the drum 35 does not directly engage with the driving force member 100.

The developing roller 25, which can carry developer, is supported on the casing 30 and is rotatable about a developing roller rotation axis C extending in the left-right direction; the developing roller gear 21 is installed at the right side of the developing roller 25, the developing roller gear 21 has a plurality of developing roller gear teeth 21a, the tooth profile of the developing roller gear teeth 21a is configured in a spiral shape and can be engaged with the driving force member gear teeth 100a of the driving force member 100 to receive and transmit the driving force, and the developing roller gear 21 is also engaged with the first intermediate transmission gear 22 at the same time.

The agitating bracket is supported inside the first casing 30 and is operable to agitate the developer inside the casing 30 to convey the developer onto the developing roller 25; the stirring frame gear 24 is arranged on the right side of the stirring frame and meshed with the second middle transmission gear 23, the stirring frame gear 24 is meshed with the developing roller gear 21 through the first middle transmission gear 22 and the second middle transmission gear 23, and the first middle transmission gear 22 and the second middle transmission gear 23 are arranged between the developing roller gear 21 and the stirring frame gear 24, so that the rotating speed of the stirring frame can be adjusted by adjusting parameters such as the tooth number, the tooth direction and the outer diameter of the gear teeth of the first middle transmission gear 22 and the second middle transmission gear 23, and the rotating speed, the direction and the like of the stirring frame can be adjusted according to actual requirements. Alternatively, the agitation frame gear 24 may be directly engaged with the developing roller gear 21.

The first intermediate transmission gear 22 and the second intermediate transmission gear 23 are mounted on the right side of the housing 30, and the first intermediate transmission gear 22 and the second intermediate transmission gear 23 are engaged.

The regulating portion 15 is located on the right side of the housing 30, the regulating portion 15 has a curved surface portion which is provided to face the photosensitive drum rotation axis B, and during mounting of the process cartridge 50, the regulating portion 15 can come into contact with the driving force member 100 through the first opening 101a of the lid portion 101 and generate an urging force F1 to urge the driving force member 100 so that the driving force member 100 is gradually moved from the inclined state at the first position to the righted state at the second position.

The positioning portion 16 is located on the right side of the housing 30, the positioning portion 16 is located farther from the right side end portion of the housing 30 relative to the regulating portion 15, the positioning portion 16 is disposed coaxially with the photosensitive drum 35, further, the positioning portion 16 is configured to have an inner circumference engageable with an outer circumference of the positioned portion 100b of the driving force member 100 to position the driving force member 100, and the positioning portion 16 does not receive the driving force transmitted from the driving force member 100. By adopting the matching structure that the inner circumference is jointed with the outer circumference, the positioning contact area is increased, and the positioning stability is improved.

Process cartridge mounting process

First, the process cartridge 50 is mounted into the electrophotographic image forming apparatus in the mounting direction substantially perpendicular to the photosensitive drum rotation axis B, the driving force member 100 is in the first position before the process cartridge 50 contacts the driving force member 100, the regulating portion 15 of the process cartridge 50 passes through the first opening 101a of the cover portion 101 and urges the driving force member 100 as the process cartridge 50 is further inserted, so that the driving force member 100 is gradually moved from the inclined state of the first position to the righted state of the second position, and further, at the time of insertion, the developing roller gear teeth 21a whose tooth shape is configured in a spiral shape mesh with the driving force member gear teeth 100a whose tooth shape is also configured in a spiral shape exposed through the second opening 101B of the cover portion 101, and the driving force member 100 is gradually moved from the retracted position of the first position to the extended position of the second position by the pulling force F2 generated by the meshing, and finally the regulating portion 15 is out of contact with the driving force member 100, and in this process, the positioned portion 100b of the driving force member 100 engages with the positioned portion 16 of the housing 30 to finally position the driving force member 100 while the driving force member 100 is in the second position, and at the same time, the process cartridge 50 is also positioned by a positioning means (not shown) within the electrophotographic image forming apparatus, so that the relative positions of the process cartridge 50 and the driving force member 100 are maintained, the developing roller gear teeth 25a are prevented from being disengaged from the driving member gear teeth 100a, and thus, the process cartridge 50 is properly mounted in the electrophotographic image forming apparatus.

Driving force transmission process of processing box

When the process cartridge 50 is mounted and starts to operate, first, the driving force member gear teeth 100a of the driving force member 100 in the electrophotographic image forming apparatus engage with the developing roller gear teeth 21a of the developing roller gear 21 of the process cartridge 50, the driving force member 100 transmits the driving force received from the motor to the developing roller gear 21, the developing roller gear 21 rotates the developing roller 25, the developing roller gear 21 transmits the driving force to the photosensitive drum gear 31 engaging with the developing roller gear 21, the photosensitive drum gear 31 rotates the photosensitive drum 35, and transmits the driving force to the first intermediate transmission gear 22 also engaging with the developing roller gear 21, the first intermediate transmission gear 22 transmits the received driving force to the second intermediate transmission gear 23 engaging with the first intermediate transmission gear 22, the second intermediate transmission gear 23 transmits the received driving force to the agitating frame gear 24 engaging with the second intermediate transmission gear 23, the agitator gear 24 rotates the agitator.

To summarize, the developing roller gear 21 is engaged with the driving force member 100 to receive the driving force and rotate the developing roller 25, the developing roller gear 21 is directly engaged with the photosensitive drum gear 31 to rotate the photosensitive drum 35, and the developing roller gear 21 is engaged with the agitator gear 24 through a plurality of intermediate transmission gears to rotate the agitator, so that the developing roller gear 21 can drive the photosensitive drum gear 31 and the agitator gear 24 simultaneously; that is, when the process cartridge 50 is mounted in the electrophotographic image forming apparatus, the developing roller gear 21 can be simultaneously engaged with the driving force member 100, the photosensitive drum gear 35, and the intermediate transmission gear, and by adopting the above-described structure, it is achieved that the developing roller gear 21 simultaneously drives the photosensitive drum 35 and the agitating frame to rotate while driving the developing roller 25 to rotate by the driving force transmission, and the transmission structure of the process cartridge 50 is greatly simplified.

The beneficial effects of the utility model

On the one hand, the utility model discloses in adopted single driven technical scheme, it just can drive developer roll, sensitization drum, stirring frame rotation just to rely on the developer roll gear to receive the drive power in the electrophotographic image forming device promptly to handle the box, compares in prior art, has simplified the transmission structure who handles the box, has reduced the installation meshing precision of handling the box and driving the power component, has reduced the installation simultaneously and has interfered.

On the other hand, by adopting a structure in which the developing roller gear having a smaller addendum circle is engaged with the driving force member having a larger addendum circle, so that the torque of the driving force member is reduced when the driving force is transmitted, the electrophotographic image forming apparatus requires only a small torque to drive the rotating member in the process cartridge, and the mechanical strength requirement of the driving force member is reduced after the torque of the driving force member is reduced.

The above examples are only intended to illustrate the technical solution of the present invention, but not to limit it; although the present invention has been described in detail with reference to the foregoing embodiments, it will be understood by those of ordinary skill in the art that: the technical solutions described in the foregoing embodiments may still be modified, or some technical features may be equivalently replaced; and such modifications or substitutions do not depart from the spirit and scope of the corresponding technical solutions of the embodiments of the present invention.

Claims (7)

1. A process cartridge detachably mountable to an electrophotographic image forming apparatus having a driving force member, comprising:

a housing configured to accommodate a developer;

a developing roller;

a photosensitive drum rotatable about a photosensitive drum rotation axis extending in an axial direction thereof;

a power receiving part that can receive a driving force of the driving force member;

characterized in that it further comprises a regulating portion provided on one side in the longitudinal direction of the housing, the regulating portion urging the driving force member to a position to engage with the power receiving part which can receive the driving force from the driving force member and can drive the developing roller and the photosensitive drum to rotate when the process cartridge is mounted to the electrophotographic image forming apparatus.

2. A process cartridge according to claim 1, further comprising a positioning portion provided on one side in a longitudinal direction of said casing, said positioning portion being provided coaxially with said photosensitive drum.

3. A process cartridge according to claim 2, wherein said positioning portion is configured to have an inner circumference, and said driving force member is configured to have an outer circumference, and said inner circumference is engageable with said outer circumference.

4. A process cartridge according to claim 1, wherein said power receiving member is configured as a developing roller gear mounted at an axial end of said developing roller and adapted to drive said developing roller to rotate.

5. A process cartridge according to claim 4, further comprising a photosensitive drum gear mounted at an axial end of said photosensitive drum, said photosensitive drum gear being for driving said photosensitive drum to rotate, said developing roller gear being in direct engagement with said photosensitive drum gear.

6. A process cartridge according to claim 4, further comprising an agitating frame and an agitating frame gear mounted at an axial end of said agitating frame for driving said agitating frame to rotate, said process cartridge further comprising an intermediate transmission gear through which said agitating frame gear is engaged with said developing roller gear.

7. A process cartridge according to claim 6, further comprising a photosensitive drum gear mounted at an axial end of said photosensitive drum for driving said photosensitive drum to rotate, said developing roller gear being simultaneously engaged with said driving force member, said photosensitive drum gear, said intermediate transmission gear when said process cartridge is mounted in said electrophotographic image forming apparatus.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120345471.1U CN214375854U (en) | 2021-02-07 | 2021-02-07 | Processing box |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202120345471.1U CN214375854U (en) | 2021-02-07 | 2021-02-07 | Processing box |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN214375854U true CN214375854U (en) | 2021-10-08 |

Family

ID=77965294

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202120345471.1U Active CN214375854U (en) | 2021-02-07 | 2021-02-07 | Processing box |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN214375854U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023134646A1 (en) * | 2022-01-12 | 2023-07-20 | 江西亿铂电子科技有限公司 | Process cartridge |

-

2021

- 2021-02-07 CN CN202120345471.1U patent/CN214375854U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023134646A1 (en) * | 2022-01-12 | 2023-07-20 | 江西亿铂电子科技有限公司 | Process cartridge |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100288971B1 (en) | Process cartridge and electrophotographic image forming apparatus | |

| EP2631717B1 (en) | Image forming apparatus and toner case | |

| EP2343607B1 (en) | Developing cartridge | |

| EP2711782B1 (en) | Image forming apparatus, toner case and drive transmission mechanism | |

| KR970066741A (en) | Processing cartridge and electrophotographic image forming apparatus | |

| EP0251693A1 (en) | Process cartridge and image forming apparatus using same | |

| KR970066740A (en) | Processing cartridge and electrophotographic image forming apparatus | |

| WO2012095009A1 (en) | Photosensitive drum drive assembly, photosensitive drum and process cartridge | |

| CN214375854U (en) | Processing box | |

| CN211015028U (en) | Processing box | |

| EP2667262B1 (en) | Toner case and image forming apparatus | |

| CN110874043A (en) | Processing box | |

| EP0822467B1 (en) | Toner container, process cartridge, and image forming apparatus | |

| CN221551077U (en) | Developing box | |

| CN115268241A (en) | Process cartridge, image forming system, and process cartridge loading method and working method | |

| CN110376858B (en) | Process cartridge, process cartridge mounting method, and electrophotographic image forming apparatus | |

| CN113156789A (en) | Driving force transmission assembly, rotating part, toner cartridge and electronic imaging equipment | |

| CN217787606U (en) | Processing box | |

| CN106933078B (en) | Developing cartridge | |

| CN218974786U (en) | Processing box | |

| JP2012177854A (en) | Cartridge for image forming apparatus, and image forming apparatus | |

| CN217238613U (en) | Processing box | |

| CN217443735U (en) | Processing box | |

| CN217238603U (en) | Processing box | |

| CN218068582U (en) | Processing box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |