CN213989330U - Plasma generator, plasma generating system and hair comb - Google Patents

Plasma generator, plasma generating system and hair comb Download PDFInfo

- Publication number

- CN213989330U CN213989330U CN202023170497.1U CN202023170497U CN213989330U CN 213989330 U CN213989330 U CN 213989330U CN 202023170497 U CN202023170497 U CN 202023170497U CN 213989330 U CN213989330 U CN 213989330U

- Authority

- CN

- China

- Prior art keywords

- charging

- plasma generator

- plasma

- isolation

- seat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Electrotherapy Devices (AREA)

Abstract

The utility model discloses a plasma generator, a plasma generating system and a hair comb, wherein, the plasma generator comprises a shell, a plasma generating component and a battery, the plasma generating component is arranged on the shell; the battery is arranged in the shell and is electrically connected with the plasma generating assembly; the shell is provided with a charging end, the charging end is provided with a switch key for connecting or disconnecting the battery and the plasma generation assembly and a first charging contact electrically connected with the battery, so that the plasma generator is connected with the charging seat in an inserting mode, and when the first charging contact is electrically connected with the charging seat, the charging seat can shield the switch key. The plasma generator can reduce the probability of mistakenly triggering the switch key when the plasma generator is not used or is charged.

Description

Technical Field

The utility model relates to the technical field of medical equipment, in particular to plasma generator, plasma generating system and hair comb.

Background

Hair diseases are frequently encountered clinically, and are frequently manifested by alopecia, baldness, dry hair and white hair. With the increasing beauty consciousness of people, people put higher demands on hair health. Relevant researches show that the plasma acts on the scalp, can improve the absorption rate of scalp tissues to drugs, and can play a role in sterilization and inflammation diminishing, so that the secretion of sebaceous gland oil is effectively relieved, the symptoms such as scalp pruritus and the like are reduced, and the health condition of the scalp is improved. However, when the plasma generator in the related art is not used or is charged, the switch button is easily triggered by mistake, so that the plasma generator is turned on, and the safety of the plasma generator needs to be improved. For example, if the switch button is inadvertently triggered to turn on the plasma generator, air between the eyes and the plasma generator is ionized to generate plasma, which impacts the eyes and damages the eyes if the plasma generator is close to the eyes of the user.

SUMMERY OF THE UTILITY MODEL

The utility model aims to provide a plasma generator aims at reducing the probability that plasma generator mistriggered the trigger switch button when not using or when charging.

To achieve the above object, the present invention provides a plasma generator, including:

a housing;

the plasma generating assembly is arranged on the shell; and

the battery is arranged in the shell and is electrically connected with the plasma generation assembly;

the shell is provided with a charging end, and the charging end is provided with a switch key for connecting or disconnecting the battery and the plasma generation assembly and a first charging contact electrically connected with the battery, so that the plasma generator is connected with a charging seat in an inserting mode, and the charging seat can shield the switch key when the first charging contact is electrically connected with the charging seat.

In one embodiment, the switch button and the first charging contact are both located on an end face of the charging end.

In an embodiment, the charging end is provided with an avoiding hole, and the first charging contact is accommodated in the avoiding hole.

In one embodiment, the housing includes a handle portion and a working portion connected to each other, the battery is located in the handle portion, the plasma generation assembly is located on the working portion, and the charging end is an end of the handle portion away from the working portion.

In one embodiment, the handle portion has an elliptical or circular cross-section.

In one embodiment, the plasma generating assembly comprises a mounting seat, a working electrode and an isolating cap, wherein the isolating cap is made of an insulating material;

the working part is provided with an opening, the mounting seat seals the opening, the mounting seat is provided with a mounting through hole, the working electrode is provided with an inserting part and an outer convex part connected with the inserting part, the inserting part is inserted into the mounting through hole, one end of the inserting part, far away from the outer convex part, is electrically connected with the battery, the outer convex part is positioned outside the mounting through hole and positioned on one side, far away from the shell, of the mounting seat, the isolation cap is provided with an open end, and the isolation cap is sleeved outside the outer convex part through the open end.

In one embodiment, an end surface of the open end abuts against the mounting seat; and/or

The open end and the mounting seat are fixed in a sealing mode through glue surrounding the open end for one circle.

In one embodiment, the isolation cap is made of ceramic or teflon, and the mounting seat is made of polycarbonate; and/or

The installation through holes, the working electrodes and the isolation caps are multiple and are arranged in a one-to-one correspondence mode.

The utility model discloses still provide a plasma generating system, include:

the above plasma generator; and

the charging seat is provided with a fixed cavity, a second charging contact is arranged on the inner wall of the fixed cavity, an exposed charging interface is arranged on the charging seat, and the charging interface is electrically connected with the second charging contact;

the charging end of the plasma generator can be contained in the fixed cavity, and the first charging contact can be abutted against the second charging contact.

The utility model also provides a hair-growing comb, which comprises the plasma generator or the plasma generating system;

when the plasma generating assembly comprises the mounting seat, the working electrode and the isolation cap, each comb tooth of the hair growing comb comprises the inserting part and the isolation cap.

In the plasma generator, the housing has a charging end, and the switch button and the first charging contact are located at the charging end. Therefore, when the charging end of the shell of the plasma generator is inserted into the charging seat, the first charging contact of the charging end is electrically connected with the second charging contact in the charging seat, and at the moment, the charging seat electrically connected with the power supply can charge the first battery. The switch key and the first charging contact are both located at the charging end, so that the charging seat can shield the switch key when the plasma generator is charged and when the plasma generator is not needed to be used, the plasma generator can be prevented from being started due to misoperation of the switch key, the probability that the switch key is triggered by mistake when the plasma generator is not used or is charged is reduced, and the safety of the plasma generator is improved.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings needed to be used in the description of the embodiments or the prior art will be briefly described below, it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to the structures shown in the drawings without creative efforts.

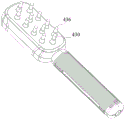

Fig. 1 is a schematic perspective view of a plasma generator according to an embodiment of the present invention;

FIG. 2 is a schematic perspective view of the plasma generator shown in FIG. 1 from another perspective;

FIG. 3 is an enlarged view of a portion of FIG. 1 at A;

FIG. 4 is a partially exploded view of the plasma generator shown in FIG. 1;

FIG. 5 is a partially exploded view from another perspective of the plasma generator shown in FIG. 1;

FIG. 6 is a schematic cross-sectional view of the plasma generator shown in FIG. 1;

fig. 7 is a partial enlarged view at B in fig. 6;

FIG. 8 is a schematic perspective cross-sectional view of the mount of FIG. 1;

fig. 9 is a partial enlarged view at C in fig. 8;

fig. 10 is a schematic structural view of a plasma generator according to another embodiment of the present invention;

fig. 11 is a schematic structural diagram of a plasma generator according to another embodiment of the present invention;

fig. 12 is a schematic structural view of a plasma generator according to another embodiment of the present invention;

fig. 13 is a schematic perspective view of a plasma generator according to another embodiment of the present invention;

FIG. 14 is a schematic cross-sectional view of an isolation cap of the plasma generator of FIG. 13;

fig. 15 is a schematic perspective exploded view of a plasma generator according to another embodiment of the present invention;

FIG. 16 is a block schematic diagram of a plasma generator corresponding to FIG. 15;

fig. 17 is a schematic perspective view of a charging seat according to an embodiment of the present invention;

FIG. 18 is a top view of the charging dock of FIG. 17;

FIG. 19 is an exploded perspective view of the charging dock of FIG. 17;

FIG. 20 is a cross-sectional view of the charging dock of FIG. 17;

fig. 21 is a schematic cross-sectional view of a charging stand according to another embodiment of the present invention.

The reference numbers illustrate:

the objects, features and advantages of the present invention will be further described with reference to the accompanying drawings.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative efforts belong to the protection scope of the present invention.

It should be noted that if directional indications (such as up, down, left, right, front, and back … …) are involved in the embodiment of the present invention, the directional indications are only used to explain the relative position relationship between the components, the motion situation, etc. in a specific posture, and if the specific posture is changed, the directional indications are changed accordingly.

In addition, if there is a description relating to "first", "second", etc. in the embodiments of the present invention, the description of "first", "second", etc. is for descriptive purposes only and is not to be construed as indicating or implying relative importance or implicitly indicating the number of technical features indicated. Thus, a feature defined as "first" or "second" may explicitly or implicitly include at least one such feature. In addition, if appearing throughout the text, "and/or" is meant to include three juxtaposed aspects, taking "A and/or B" as an example, including either the A aspect, or the B aspect, or both A and B satisfied aspects. In addition, the technical solutions in the embodiments may be combined with each other, but it must be based on the realization of those skilled in the art, and when the technical solutions are contradictory or cannot be realized, the combination of the technical solutions should not be considered to exist, and is not within the protection scope of the present invention.

The utility model provides a plasma generating system.

In the embodiment of the present invention, as shown in fig. 1 and 14, the plasma generation system includes a plasma generator 10 and a charging base 20 cooperating with the plasma generator 10. The charging stand 20 serves to support the plasma generator 10 and to charge the plasma generator 10.

When the plasma generator 10 is not needed, the plasma generator 10 can be inserted into the charging base 20, so that the plasma generator 10 can be stably placed on a table top or the like, the plasma generator 10 is prevented from rolling off from the table top or the like, and when the plasma generator 10 needs to be charged, the charging base 20 electrically connected with the power supply can charge the plasma generator 10. When the plasma generator 10 is required to be used, the plasma generator 10 may be removed from the charging stand 20.

In use of the plasma generator 10, when the plasma generator 10 is in close proximity to the scalp of a user, the plasma generator 10 may ionize the air between the scalp of the user and the plasma generator 10, generating a plasma. The plasma acts on scalp of user to improve scalp health.

In the present embodiment, as shown in fig. 1 to 4, the plasma generator 10 includes a housing 300, a plasma generating assembly 400, and a first battery 500. The plasma generating assembly 400 is provided on the housing 300. The first battery 500 is provided in the case 300.

The housing 300 is provided with a switch button 302a and a first charging contact 302 b.

The switch button 302a is used to connect or disconnect the plasma generating assembly 400 and the first battery 500. The plasma generator 10 may be operated when the plasma generating assembly 400 is in conduction with the first cell 500, and the plasma generator 10 may be not operated when the plasma generating assembly 400 is disconnected from the first cell 500.

The first charging contact 302b is electrically connected to the first battery 500, and when the first battery 500 is conducted to the power supply through the first charging contact 302b, the power supply can charge the first battery 500.

In the present embodiment, the housing 300 has a charging terminal 302. The switch button 302a and the first charging contact 302b are located at the charging terminal 302. In this way, when the charging terminal 302 of the housing 300 of the plasma generator 10 is inserted into the charging dock 20, the first charging contact 302b of the charging terminal 302 is electrically connected to the second charging contact 212 of the charging dock 20, and at this time, the charging dock 20 electrically connected to the power supply can charge the first battery 500. Since the switch button 302a and the first charging contact 302b are both located at the charging terminal 302, when the plasma generator 10 is charged and when the plasma generator 10 is not needed, the charging base 20 can shield the switch button 302a, thereby preventing the plasma generator 10 from being turned on due to the misoperation of the switch button 302a, and improving the safety of the plasma generator 10. For example, when the switch button 302a is inadvertently triggered during charging to turn on the plasma generator 10, if the plasma generator 10 is close to the eyes of the user, the air between the eyes and the plasma generator 10 is ionized, and the generated plasma may impact the eyes, thereby causing the eyes to be injured.

In the present embodiment, the switch button 302a and the first charging contact 302b are both located on the end surface of the charging terminal 202. Thus, it is more convenient to shield the switch button 302a during charging. It is understood that in other embodiments, at least one of the switch button 302a and the first charging contact 302b may also be on the circumferential wall of the charging terminal 202.

In the embodiment, the charging terminal 302 is provided with an avoiding hole 3022. The first charging contact 302b is received in the relief hole 3022. Thus, the protruding first charging contact 302b can be prevented from being damaged by scraping.

In this embodiment, the housing 300 includes a handle portion 310 and a working portion 320 connected together. First battery 500 is located within handle portion 310. The plasma generation assembly 400 is located on the working portion 320. Charging terminal 302 is the end of handle portion 310 remote from working portion 320.

In this embodiment, handle portion 310 is oval in cross-section. Thus, the holding by the user is more convenient. In other embodiments, handle portion 310 may be circular, square, etc. in cross-section.

In the present embodiment, in the arrangement direction of the handle portion 310 and the working portion 320, the width of the working portion 320 is equal to or greater than the width of the handle portion 310.

In this embodiment, as shown in fig. 4-9, plasma generation assembly 400 includes a mount 410, a working electrode 420, and an isolation cap 430. The working portion 320 has an opening 320 a. The mount 410 closes the opening 320 a. The mounting base 410 is opened with a mounting through hole 410 a. The working electrode 420 has a socket 422 and an outer protrusion 424 connected to the socket 422. The insertion part 422 is inserted into the mounting through hole 410 a. An end of the mating part 422 distal to the male part 424 is for electrical connection to a power source. In the present embodiment, the power source is the first battery 500. It is understood that in other embodiments, when the first battery 500 is omitted, the working electrode 420 can be powered by the mains power, and in this case, the power is the mains power. The outer protrusion 424 is located outside the mounting through-hole 410 a. The isolation cap 430 has an open end 432, and the isolation cap 430 is sleeved outside the outer protrusion 424 through the open end 432.

By providing the opening 320a, it is very convenient to assemble the mounting socket 410 on the working portion 320 and to electrically connect the socket 422 of the working electrode 420 with a power source. By providing the mounting through-hole 410a, it is very convenient to assemble the socket 422 of the working electrode 420 on the mounting seat 410. The external protrusion 424 of the working electrode 420 is positioned outside the mounting through hole 410a, so that the external protrusion 424 of the working electrode 420 protrudes out of the mounting base 410, thereby facilitating the working electrode 420 to be closer to the scalp of the user, etc., for example, facilitating the isolation cap 430 and the external protrusion 424 of the working electrode 420 to constitute comb teeth for combing hair. The isolation cap 430 can isolate the protruding portion 424 of the working electrode 420, so as to prevent the working electrode 420 from damaging the scalp of the user.

In this embodiment, the mounting seat 410 is detachably connected to the working portion 320. Thus, the assembly and disassembly are very convenient. Specifically, in the present embodiment, the mounting seat 410 and the working portion 320 are fastened by a snap.

In order to further improve the isolation effect of the working electrode 420, in the present embodiment, as shown in fig. 4 to 11, the mounting seat 410 is an isolation seat 410. The isolation seat 410 is further formed with an installation groove 410b surrounding the installation through hole 410a for one circle. The male protrusion 424 and the mounting groove 410b are located on the same side of the spacer 410. The isolation cap 430 is sleeved outside the outer protrusion 424 through the opening end 432, and the opening end 432 is inserted into the mounting groove 410 b. Since the isolation cap 430 is sleeved outside the outer protrusion 424 through the open end 432, when the working electrode 420 works, the ionization energy emitted from the working electrode 420 may leak through the open end 432. And through setting up mounting groove 410b, open end 432 is pegged graft in mounting groove 410b to for two-layer isolation layer inside and outside forming in open end 432 department, and then can effectively avoid the ionization that working electrode 420 emitted to leak outward through open end 432, further improve working electrode 420's isolation effect, make plasma generator 10 have higher security.

In some embodiments, as shown in fig. 12, an end surface of the open end 432 interferes with the isolation seat 410. In some embodiments, open end 432 and isolation seat 410 are sealingly secured by glue 432a around open end 432. In some embodiments, an end surface of the open end 432 abuts against the isolation seat 410, and the open end 432 and the isolation seat 410 are sealed and fixed by glue 432a surrounding the open end 432. Thus, the ionization emitted from the working electrode 420 can be prevented from leaking out through the open end 432 to a certain extent, and the isolation effect of the working electrode 420 is further improved, so that the plasma generator 10 has higher safety.

In the present embodiment, as shown in fig. 4-9, isolation seat 410 includes a mounting plate 412 and an isolation boss 414. Mounting plate 412 closes opening 320 a. An isolation protrusion 414 protrudes from the side of the mounting plate 412 away from the opening 320 a. The mounting through-hole 410a penetrates the mounting plate 412 and the isolating protrusion 414. The mounting groove 410b is located at an end of the isolating protrusion 414 away from the mounting plate 412. By providing the isolation protrusion 414, it is more convenient for the outer protrusion 424 of the working electrode 420 to protrude out of the isolation seat 410, and thus it is more convenient for the working electrode 420 to be close to the scalp of the user, for example, it is more convenient for the isolation cap 430 and the outer protrusion 424 of the working electrode 420 to form comb teeth for combing hair.

In the present embodiment, the material of the mounting plate 412 is the same as the material of the isolation protrusion 414. I.e., mounting plate 412 is a spacer plate. In this manner, isolation of working electrode 420 is facilitated. It is understood that in other embodiments, the material of the mounting plate 412 may be different from the material of the isolation protrusion 414.

In the present embodiment, the isolation seat 410 is made of polycarbonate. Not only has the isolation effect, but also has the characteristic of better light transmission.

In this embodiment, the mounting plate 412 is integrally formed with the isolation protrusion 414. Thus, the manufacturing is convenient.

In this embodiment, the isolation bump 414 has an inner isolation tube 4142. The mounting through-hole 410a includes a hollow cavity of the inner isolation tube 4142. The mounting groove 410b surrounds the inner isolation tube 4142. One end of the inner isolation tube 4142 near the outer protrusion 424 protrudes out of the mounting groove 410 b. In this way, it is more convenient for the outer protrusion 424 of the working electrode 420 to protrude out of the isolation seat 410, and thus it is more convenient for the working electrode 420 to be close to the scalp and the like of the user, for example, it is more convenient for the isolation cap 430 and the outer protrusion 424 of the working electrode 420 to constitute comb teeth for combing hair. And while ensuring that the working electrode 420 has a better isolation effect, the mass and volume of the isolation protrusion 414 can be smaller, which is more beneficial to obtaining the plasma generator 10 with smaller weight and volume.

In some embodiments, as shown in FIG. 11, isolation seat 410 has an inner isolation tube 4142. The inner isolation tube 4142 has a mounting through-hole 410 a. The mounting groove 410b surrounds the inner isolation tube 4142. Wherein, one end of the inner isolation tube 4142 near the outer protrusion 424 is protruded out of the mounting groove 410 b. In this way, it is more convenient for the outer protrusion 424 of the working electrode 420 to protrude out of the isolation seat 410, so that the working electrode 420 is more convenient to be close to the scalp of the user, for example, it is more convenient for the isolation cap 430 and the outer protrusion 424 of the working electrode 420 to form comb teeth for combing hair.

In the present embodiment, as shown in fig. 4 to 9, the outer diameter of the isolation protrusion 414 is gradually reduced in the arrangement direction of the mounting plate 412 to the isolation protrusion 414. Therefore, the ionization energy emitted by the working electrode 420 is prevented from leaking outside through the opening end 432, the isolation effect of the working electrode 420 is further improved, the plasma generator 10 has higher safety, and meanwhile, the mass and the volume of the isolation protrusion 414 are smaller, so that the plasma generator 10 with smaller weight and volume is more beneficial to obtaining.

In the present embodiment, the mounting through hole 410a has an insertion section 410c and a transition section 410d connected with each other, the inner diameter of the transition section 410d is larger than that of the insertion section 410c, and the transition section 410d is closer to the mounting plate 412 than the insertion section 410 c. An end of the insertion part 422 near the male part 424 is inserted into the insertion section 410 c. Thus, the working electrode 420 can be conveniently inserted into the mounting through hole 410a, and the working electrode 420 can be conveniently electrically connected with a power supply at the side where the transition section 410d is located.

In this embodiment, the socket 422 is a clearance fit with the socket section 410 c. When the plasma generator 10 is manufactured, after the working electrode 420 is inserted into the installation through hole 410a, glue may be dispensed between the working electrode 420 and the inner wall of the installation through hole 410a to firmly fix the working electrode 420.

In this embodiment, the outer diameter of male portion 424 is greater than the outer diameter of female portion 422. In this manner, the protruding portion 424 is positioned outside the mounting through-hole 410a, thereby facilitating the positioning and assembly of the working electrode 420 and the mounting through-hole 410 a.

In this embodiment, the isolation cap 430 is a clearance fit with the male protrusion 424. In this manner, insertion of the male portion 424 into the isolation cap 430 is greatly facilitated. When the plasma generator 10 is manufactured, after the working electrode 420 is inserted into the isolation cap 430, glue may be dispensed between the working electrode 420 and the inner wall of the isolation cap 430 to firmly fix the working electrode 420.

In the present embodiment, the open end 432 of the insulation cap 430 is in clearance fit with the inner circumferential wall of the mounting groove 410 b. Thus, it is very convenient for the open end 432 to be inserted into the mounting groove 410 b. When the plasma generator 10 is manufactured, after the open end 432 is inserted into the mounting groove 410b, glue may be dispensed between the open end 432 and the inner peripheral wall of the mounting groove 410b to firmly fix the isolation cap 430.

In the present embodiment, the end surface of the open end 432 contacts (including interferes with) the groove bottom of the mounting groove 410 b. Thus, the ionization energy emitted from the working electrode 420 can be better isolated.

In this embodiment, the diameter of the male protrusion 424 is 2.8mm to 3.6 mm. In this manner, the ionization discharge of the convex portion 424 of the working electrode 420 is greatly facilitated. The diameter of the convex portion 424 may be 2.9mm, 3.0mm, 3.1mm, 3.2mm, 3.3mm, 3.4mm, or 3.5 mm.

In this embodiment, the outer diameter of the isolation cap 430 is 4.0mm to 5.0mm, and the wall thickness of the isolation cap 430 is 0.3mm to 1.5 mm. Thus, the outer protrusion 424 of the working electrode 420 is very convenient for isolating the discharge. Wherein, the outer diameter of the isolation cap 430 may be 4.1mm, 4.2mm, 4.3mm, 4.4mm, 4.5mm, 4.6mm, 4.7mm, 4.8mm, or 4.9 mm. The wall thickness of the isolation cap 430 may be 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.1mm, 1.2mm, 1.3mm, or 1.4 mm.

Specifically, in the present embodiment, the diameter of the male portion 424 is 3.2mm, the outer diameter of the separation cap 430 is 4.5mm, and the wall thickness of the separation cap 430 is 0.6 mm.

In this embodiment, the end of the isolation cap 430 distal to the open end 432 is a flattened end 434. As such, the end of the isolation cap 430 distal from the open end 432 may be made to have a relatively large ionization end surface, thereby facilitating ionization of air between the end of the isolation cap 430 distal from the open end 432 and the scalp of the user.

In some embodiments, as shown in fig. 13 and 14, the end of the isolation cap 430 distal to the open end 432 is a rounded end 436. In some embodiments, the end face of the rounded tip 436 includes a convex radiused working surface 4362. In some embodiments, the end surface of rounded tip 436 includes a concave rounded working surface. The convex arc-shaped working surface 436 can prevent the end surface of the round head end 436 from scratching the scalp of the user. The scalp of the user is approximately arc-shaped, and the concave arc working surface can make the end surface of the round head end 436 approximately same as the scalp of the user in shape, so that the distance between the end surface of the round head end 436 and the scalp of the user can be approximately same everywhere, and air between the end surface of the round head end 436 and the scalp of the user can be ionized more uniformly.

In the present embodiment, the isolation cap 430 is made of an insulating material. Specifically, in the present embodiment, the isolation cap 430 is made of ceramic. More specifically, in the present embodiment, the material of the isolation cap 430 is zirconia or alumina. In other embodiments, the isolation cap 430 may also be made of teflon.

In this embodiment, as shown in fig. 4 to 9, the installation through holes 410a, the installation grooves 410b, the working electrodes 420, and the isolation caps 430 are all provided in a plurality and are arranged in a one-to-one correspondence. That is, the plurality of isolation protrusions 414, the working electrode 420, and the isolation cap 430 are all provided in a one-to-one correspondence. In this manner, the plasma generator 10 can be made to have a large ionization area.

In the present embodiment, a plurality of the insulative caps 430 are spaced apart from each other. The plurality of isolation protrusions 414 are spaced apart from each other.

In the present embodiment, the isolation seat 410 includes a mounting portion 416 and a light-transmitting portion 418 connected to each other. The mounting through-hole 410a and the mounting groove 410b are located on the mounting portion 416. In the present embodiment, the mounting plate 412 includes a mounting portion 416, and the light-transmitting portion 418 includes the isolation protrusion 414 and a portion of the mounting plate 412 corresponding to the isolation protrusion 414.

The plasma generator 10 also includes a light treatment assembly 600 located within the housing 300. The light treatment assembly 600 includes a first light source 610. In the present embodiment, the first light source 610 is a laser light source. The first light source 610 is located at a side of the isolation seat 410 away from the isolation cap 430, and is disposed corresponding to the light-transmitting portion 416. Thus, the light emitted from the first light source 610 can irradiate the scalp of the user through the light-transmitting portion 416 to irradiate the scalp of the user, so as to stimulate cells, activate hair root cells, promote blood circulation, and further promote hair growth, thereby preventing alopecia and baldness.

In the present embodiment, the number of the first light sources 610 is multiple, and the multiple first light sources 610 are distributed at the gaps of the multiple isolation caps 430 and at the same time distributed at the gaps of the multiple isolation protrusions 414. Thus, the shielding of the first light source 610 by the isolation cap 430 and the isolation protrusion 414 may be reduced.

In the present embodiment, the light-transmitting portion 418 has a position corresponding to the first light source 610 with a position-avoiding groove 4182. Therefore, the protruded first light source 610 can be avoided, and the light of the first light source 610 can be better transmitted out of the isolation seat 410.

In this embodiment, the plasma generator 10 further includes a vibrating massage assembly 700 located within the housing 300. The vibratory massage assembly 700 is used to drive the isolation seat 410 to vibrate. As such, when the working electrode 420 does not operate, the isolation cap 430 may be brought into contact with the scalp of the user while the vibration massage assembly 700 is turned on, so that the isolation seat 410 vibrates, thereby performing a vibration massage on the scalp of the user.

In this embodiment, the vibration massage assembly 700, the first light source 610 and the working electrode 420 are electrically connected to the first battery 500, and the first battery 500 supplies power to the vibration massage assembly 700, the first light source 610 and the working electrode 420.

In the present embodiment, the plasma generator 10 further includes a transformer 800 and a circuit board 900 located in the housing 300. The transformer 800, the vibration massage assembly 700 and the first light source 610 are electrically connected to the first battery 500 through the circuit board 900, and the transformer 800 is electrically connected to the insertion part 422 of the working electrode 420 through the circuit board 900. The transformer 800 may increase the voltage of the first battery 500 to provide a high voltage to the working electrode 420, thereby enabling the working electrode 420 to ionize air between the scalp of the user and the isolation cap 430 while in operation.

In the present embodiment, the circuit boards 900 are two, namely a first circuit board 900a and a second circuit board 900 b. The isolation seat 410, the first circuit board 900a and the second circuit board 900b are sequentially arranged, and the first circuit board 900a is electrically connected with the second circuit board 900 b. The working electrode 420 and the first light source 610 are electrically connected to the first circuit board 900a, and the first battery 500, the vibration massage assembly 700, and the transformer 800 are electrically connected to the second circuit board 900 b. Two circuit boards 900 are provided to facilitate electrical connection of the components to the first battery 500.

In the present embodiment, the first circuit board 900a is exposed from the opening 320 a. The first circuit board 900a is formed with a plug hole 910 corresponding to the plug portion 422. The insertion part 422 is inserted into the insertion hole 910, so that the working electrode 420 is electrically connected to the first circuit board 900 a. Thus, it is very convenient for the working electrode 420 to be electrically connected to the first circuit board 900 a.

In the present embodiment, the housing 300 includes a first housing 330 and a second housing 340. The first housing 330 and the second housing 340 are arranged along the direction of the isolation seat 410, the first circuit board 900a and the second circuit board 900b, and are detachably connected. The first housing 330 and the second housing 340 enclose a cavity for accommodating the first battery 500, the light therapy component 600, the vibration massage component 700, the transformer 800 and the circuit board 900. The opening 320a is located on the first housing 330.

In the present embodiment, as shown in fig. 4 to 9, a conductive member 350 is provided on the handle portion 310 of the housing 300. Conductive member 350 is electrically connected to plasma generating assembly 400. Specifically, in the present embodiment, the conductive member 350 is electrically connected to the negative electrode of the first battery 500. Thus, when the plasma generating assembly 400 (working electrode 420) is close to the scalp of the user, and the plasma generating assembly 400 (working electrode 420) operates, the plasma generating assembly 400 (working electrode 420) ionizes air between the scalp of the user and the plasma generating assembly 400 (working electrode 420 and/or isolation cap 430) to generate plasma, and at this time, when the user touches the conductive member 350, a loop is formed among the plasma generating assembly 400 (working electrode 420 and/or isolation cap 430), the plasma, the human body, the conductive member 350 and the plasma generating assembly 400 (working electrode 420), so that energy of ionization energy output by the working electrode 420 can be improved.

In the present embodiment, the conductive member 350 has an elongated shape. The length direction of the conductive member 350 is the same as that of the handle part 310. In this way, a user can touch the conductive member 350 even at different positions of the handle portion 310, thereby facilitating the user's use.

In the present embodiment, the conductive member 350 is a long metal sheet, such as a metal copper sheet.

In the present embodiment, the conductive member 350 is located at a junction position of the first housing 330 and the second housing 340, that is, at a connection position of the first housing 330 and the second housing 340. In this way, the conductive member 350 is electrically connected to the first battery 500.

In some embodiments, there are a plurality of conductive members 350, and the plurality of conductive members 350 are conducted with each other. Wherein at least one conductive member 350 is electrically connected to the plasma generating assembly 400. A plurality of conductive elements 350 are provided to facilitate user access to the conductive elements 350.

In some embodiments, as shown in fig. 15 and 16, the conductive member 350 includes a first conductive member 350a and a second conductive member 350b that are insulated from each other, and the first conductive member 350a and the second conductive member 350b can be conducted by a user holding the handle portion 310.

The plasma generator 10 also includes a detection module 360. The detecting module 360 is configured to detect whether the first conductive member 350a and the second conductive member 350b are conducted, wherein when the first conductive member 350a and the second conductive member 350b are conducted, the plasma generating assembly 400 operates, and when the first conductive member 350a and the second conductive member 350b are not conducted, the plasma generating assembly 400 does not operate. That is, before the plasma generating assembly 400 operates, the detecting module 360 detects whether the first conductive member 350a and the second conductive member 350b are conducted by the user holding the handle portion 310, that is, the detecting module 360 detects whether the user simultaneously contacts the first conductive member 350a and the second conductive member 350b, and the plasma generating assembly 400 operates after the user simultaneously contacts the first conductive member 350a and the second conductive member 350 b. Therefore, the plasma generation assembly 400 can be prevented from working mistakenly, and the user experience is improved.

The cradle 20 is described in detail below.

In the present embodiment, as shown in fig. 17-20, the charging stand 20 includes a charging base 210 and a fixing cover 220. The charging base 210 has a second charging contact 212. The fixing cover 220 is disposed on the charging base 210. The fixing cover 220 has a fixing cavity 220a for receiving the charging terminal 202 of the plasma generator 10 (to be fixed). When the charging terminal 202 of the plasma generator 10 (to-be-fixed member) is accommodated in the fixing cavity 220a, the charging stand 20 stably supports the plasma generator 10 (to-be-fixed member), and the first charging contact 302b of the charging terminal 202 of the plasma generator 10 (to-be-fixed member) abuts against the second charging contact 212 of the charging base 210. Thus, the charging base 20 can effectively protect the plasma generator 10 (to-be-fixed member) by preventing the plasma generator 10 (to-be-fixed member) from rolling off from a desktop or the like, and the charging base 20 electrically connected to the power supply can also charge the plasma generator 10 (to-be-fixed member).

In this embodiment, the charging base 210 is provided with an exposed charging interface 214, and the charging interface 214 is electrically connected to the second charging contact 212. The charging interface 214 is used for electrically connecting with a power supply. In this embodiment, the charging interface 214 is a USB interface.

In this embodiment, 1/4-2/3 times the length of the handle 310 can be accommodated in the charging dock 20, i.e., the depth of the fixing cavity 220a of the charging dock 20 is approximately 1/4-2/3 times the length of the handle 310. Thus, the charging stand 20 can stably support the plasma generator 10 (to be fixed).

In the present embodiment, the outer diameter of the fixing cover 220 is gradually reduced in the arrangement direction of the charging base 210 to the fixing cover 220. Therefore, the charging base 20 can stably support the plasma generator 10 (to be fixed), and the user can conveniently identify the insertion end of the charging base 20, so that the fool-proof effect is achieved.

In the present embodiment, the shape of the fixing cavity 220a is the same as that of the charging terminal 202 of the plasma generator 10 (to-be-fixed). Thus, the charging stand 20 can stably support the plasma generator 10 (to be fixed). In the present embodiment, the shape of the fixing cavity 220a and the shape of the charging end 202 of the plasma generator 10 (to be fixed) are both oval, circular or square.

In this embodiment, the fixing cover 220 is detachably connected to the charging base 210. Thus, the charging stand 20 can be easily assembled and disassembled.

In this embodiment, the charging base 210 has a bayonet 216, the fixing cover 220 has a latch 222, and the latch 222 is clipped on the bayonet 216, so as to realize the detachable connection between the fixing cover 220 and the charging base 210. It is understood that in other embodiments, the fixing cover 220 and the charging base 210 may be detachably connected by screwing.

In the present embodiment, the charging base 210 has an inward concave bypass groove 218. The shape of the avoiding groove 218 is the same as the end surface shape of the charging end 202 of the plasma generator 10 (to be fixed). Thus, the charging stand 20 can stably support the plasma generator 10 (to be fixed).

In this embodiment, the second charging contact 212 is located at the bottom of the avoidance slot 218. In this way, it is more convenient for the second charging contact 212 to be electrically connected to the charging terminal 202 of the plasma generator 10 (to be fixed).

In some embodiments, as shown in fig. 20, the bayonet 216 is located at the bottom of the recess 218. In some embodiments, as shown in fig. 21, the bayonet 216 is located at the periphery of the escape slot 218.

In the present embodiment, as shown in fig. 17 to 21, the charging stand 20 further includes a second light source 230. The second light source 230 is disposed on the charging base 210 and electrically connected to the charging interface 214. The stationary cover 220 is light transmissive. The light emitted from the second light source 230 can be transmitted through the fixing cover 220. Therefore, when the charging base 210 is electrically connected to the power supply through the charging interface 214, the second light source 230 is turned on, and at this time, the charging base 20 can also function as a lighting device and can be used as a desk lamp. In some embodiments, the cradle 20 further comprises a second battery electrically connected to the second light source 230 to power the second light source 230. So that the second light source 230 can be illuminated by the second light source 230 when the charging base 210 is not electrically connected with the power supply.

In the present embodiment, the charging base 210 includes a bottom plate 210a, a third circuit board 210b, and a base 210c, wherein the base 210c is disposed on the bottom plate 210a, and the third circuit board 210b is sandwiched between the base 210c and the bottom plate 210 a. The second charging contact 212, the second light source 230 and the charging interface 214 are electrically connected to the third circuit board 210b, respectively. Wherein, the fixing cover 220 is detachably connected with the base 210 c. The avoiding groove 218 is located on the seat body 210 c. The second charging contact 212 and the second light source 230 are exposed from one side of the base 210c close to the fixing cover 220. Charging connector 214 is exposed from the peripheral sidewall of housing 210 c.

In this embodiment, the charging base 210 further includes an anti-slip ring 210 d. The anti-slip ring 210d is disposed on a side of the bottom plate 210a away from the seat body 210 c. The anti-slip ring 210d can make the charging base 210 stably stand on a table or the like.

In some embodiments, as shown in FIG. 20, the walls of the fixation lumen 220a are hollow. Thus, on the premise that the charging seat 20 stably supports the plasma generator 10 (to be fixed), the material cost of the charging seat 20 can be reduced.

In some embodiments, as shown in FIG. 21, the walls of the fixation lumen 220a are solid structures. In this way, the charging stand 20 can be made to stably support the plasma generator 10 (to-be-fixed member).

In this embodiment, there is also provided a hair growing comb comprising the plasma generator 10 or the hair growing system. At this time, each comb tooth of the hair-growing comb includes an outer protrusion 424 and an isolation cap 430.

The above is only the optional embodiment of the present invention, and not the scope of the present invention is limited thereby, all the equivalent structure changes made by the contents of the specification and the drawings are utilized under the inventive concept of the present invention, or the direct/indirect application in other related technical fields is included in the patent protection scope of the present invention.

Claims (10)

1. A plasma generator, comprising:

a housing;

the plasma generating assembly is arranged on the shell; and

the battery is arranged in the shell and is electrically connected with the plasma generation assembly;

the shell is provided with a charging end, and the charging end is provided with a switch key for connecting or disconnecting the battery and the plasma generation assembly and a first charging contact electrically connected with the battery, so that the plasma generator is connected with a charging seat in an inserting mode, and the charging seat can shield the switch key when the first charging contact is electrically connected with the charging seat.

2. The plasma generator of claim 1, wherein the switch button and the first charging contact are located on an end face of the charging terminal.

3. The plasma generator of claim 1, wherein the charging end defines an escape aperture, and the first charging contact is received in the escape aperture.

4. The plasma generator of claim 1, wherein the housing comprises a handle portion and a working portion coupled together, the battery being located within the handle portion, the plasma generating assembly being located on the working portion, and the charging end being an end of the handle portion remote from the working portion.

5. The plasma generator of claim 4, wherein the handle portion has an elliptical or circular cross-section.

6. The plasma generator of claim 4, wherein the plasma generating assembly comprises a mounting base, a working electrode and an isolation cap, and the isolation cap is made of an insulating material;

the working part is provided with an opening, the mounting seat seals the opening, the mounting seat is provided with a mounting through hole, the working electrode is provided with an inserting part and an outer convex part connected with the inserting part, the inserting part is inserted into the mounting through hole, one end of the inserting part, far away from the outer convex part, is electrically connected with the battery, the outer convex part is positioned outside the mounting through hole and positioned on one side, far away from the shell, of the mounting seat, the isolation cap is provided with an open end, and the isolation cap is sleeved outside the outer convex part through the open end.

7. The plasma generator of claim 6, wherein an end surface of the open end abuts the mount; and/or

The open end and the mounting seat are fixed in a sealing mode through glue surrounding the open end for one circle.

8. The plasma generator of claim 6, wherein the isolation cap is made of ceramic or teflon, and the mounting base is made of polycarbonate; and/or

The installation through holes, the working electrodes and the isolation caps are multiple and are arranged in a one-to-one correspondence mode.

9. A plasma generation system, comprising:

the plasma generator of any one of claims 1-8; and

the charging seat is provided with a fixed cavity, a second charging contact is arranged on the inner wall of the fixed cavity, an exposed charging interface is arranged on the charging seat, and the charging interface is electrically connected with the second charging contact;

the charging end of the plasma generator can be contained in the fixed cavity, and the first charging contact can be abutted against the second charging contact.

10. A hair comb comprising a plasma generator according to any one of claims 1 to 8 or a plasma generating system according to claim 9;

when the plasma generating assembly comprises the mounting seat, the working electrode and the isolation cap, each comb tooth of the hair growing comb comprises the inserting part and the isolation cap.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202023170497.1U CN213989330U (en) | 2020-12-24 | 2020-12-24 | Plasma generator, plasma generating system and hair comb |

| PCT/CN2021/075333 WO2022134279A1 (en) | 2020-12-24 | 2021-02-04 | Plasma generation assembly, hair growth comb, and charging base |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202023170497.1U CN213989330U (en) | 2020-12-24 | 2020-12-24 | Plasma generator, plasma generating system and hair comb |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN213989330U true CN213989330U (en) | 2021-08-17 |

Family

ID=77248016

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202023170497.1U Active CN213989330U (en) | 2020-12-24 | 2020-12-24 | Plasma generator, plasma generating system and hair comb |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN213989330U (en) |

-

2020

- 2020-12-24 CN CN202023170497.1U patent/CN213989330U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3226151U (en) | Beauty device head and beauty device | |

| KR20180043015A (en) | galvanic massager | |

| CN214154933U (en) | Plasma generating assembly, plasma generator and hair comb | |

| CN213076032U (en) | Portable sterilizing electric toothbrush | |

| CN111132439A (en) | Multi-position low-temperature plasma handle | |

| CN213989330U (en) | Plasma generator, plasma generating system and hair comb | |

| CN215195045U (en) | Plasma generator and hair comb | |

| CN213989506U (en) | Charging seat, plasma generation system and hair comb | |

| CN112543544A (en) | Plasma generating assembly, plasma generator and hair comb | |

| WO2022134279A1 (en) | Plasma generation assembly, hair growth comb, and charging base | |

| CN211297112U (en) | Multi-position low-temperature plasma handle | |

| CN213312929U (en) | Face cleaning massage leading-in instrument | |

| CN214050181U (en) | Massage assembly of massage appearance and have its massage appearance | |

| CN110002405B (en) | Handheld ozone generator | |

| CN219185620U (en) | Beauty instrument | |

| CN219250884U (en) | Beauty instrument | |

| WO2024066467A1 (en) | Portable beauty instrument and charging base thereof | |

| CN112007268A (en) | Beauty instrument and beauty instrument assembly | |

| CN211067352U (en) | Beauty instrument | |

| CN112023261A (en) | Massage assembly of massage appearance and have its massage appearance | |

| CN110664604A (en) | Detachable plasma beauty instrument | |

| CN216823746U (en) | Electric toothbrush with light wave | |

| CN219231231U (en) | Beauty instrument and base device thereof | |

| CN221332464U (en) | Permeation promoting instrument | |

| KR102462466B1 (en) | Current generating device and current generation system including the sam |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP01 | Change in the name or title of a patent holder | ||

| CP01 | Change in the name or title of a patent holder |

Address after: 518000 3rd floor, block a, building F2, Changfeng Industrial Park, Liuxian 3rd road, 68 Xin'an street, Bao'an District, Shenzhen City, Guangdong Province Patentee after: Shenzhen Peninsula Medical Group Co.,Ltd. Address before: 518000 3rd floor, block a, building F2, Changfeng Industrial Park, Liuxian 3rd road, 68 Xin'an street, Bao'an District, Shenzhen City, Guangdong Province Patentee before: Shenzhen Peninsula Medical Co.,Ltd. |