CN212274285U - Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system - Google Patents

Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system Download PDFInfo

- Publication number

- CN212274285U CN212274285U CN202021207262.2U CN202021207262U CN212274285U CN 212274285 U CN212274285 U CN 212274285U CN 202021207262 U CN202021207262 U CN 202021207262U CN 212274285 U CN212274285 U CN 212274285U

- Authority

- CN

- China

- Prior art keywords

- vacuum glass

- heat

- straight

- solar vacuum

- pipe

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/40—Solar thermal energy, e.g. solar towers

- Y02E10/44—Heat exchange systems

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/40—Solar thermal energy, e.g. solar towers

- Y02E10/47—Mountings or tracking

Landscapes

- Thermal Insulation (AREA)

Abstract

The application relates to a snakelike solar vacuum glass tube pressure-bearing heat collector and a heat collector system, relating to the technical field of heat collectors, wherein the heat collector comprises two header bodies and a plurality of straight-through solar vacuum glass heat collecting tubes arranged between the two header bodies, a plurality of through holes are arranged on the two header bodies along the distribution direction of the straight-through solar vacuum glass heat collecting tubes, and two ends of the straight-through solar vacuum glass heat collecting tubes are respectively penetrated through the corresponding through holes on the two header bodies; a heat-conducting metal straight pipe is arranged in each straight-through solar vacuum glass heat-collecting pipe in a penetrating way; elastic straight pipe brackets are arranged between the straight-through solar vacuum glass heat collecting pipes and the corresponding heat conducting metal straight pipes, and connecting pipe fittings for connecting all the heat conducting metal straight pipes into an S-shaped serpentine pipeline are connected between the heat conducting metal straight pipes at the head parts of the two adjacent straight-through solar vacuum glass heat collecting pipes. The present application has the effect of being able to control the upper limit of the temperature of the heat transfer medium within a controllable time range.

Description

Technical Field

The application relates to the technical field of heat collectors, in particular to a snakelike solar vacuum glass tube pressure-bearing heat collector and a heat collector system.

Background

The principle of the solar vacuum glass tube heat collector is as follows: the solar energy can be converted into heat energy by irradiating the outer glass tube of the solar vacuum glass tube to the heat absorption coating on the outer surface of the inner glass tube of the solar vacuum glass tube, and then the heat transfer fluid in the inner glass tube is heated.

The solar vacuum glass tube of the solar vacuum glass tube pressure-bearing heat collector which is common in the market adopts a structure that an inlet and an outlet are the same interface, namely a single-port blind tube type structure, and the shape of the solar vacuum glass tube pressure-bearing heat collector is like a slender thermos flask liner. The heating principle of the solar vacuum glass tube is that when the solar vacuum glass tube is irradiated by sunlight, photons strike a heat absorption coating on the solar vacuum glass tube, solar energy is converted into heat energy, water in the solar vacuum glass tube absorbs heat from the coating, the water temperature rises, the density is reduced, hot water moves upwards, and cold water with high specific gravity falls, so that the hot water is always positioned at the upper part, namely in a water tank.

However, the above prior art solutions have the following drawbacks: because the length of the solar vacuum glass tube of the single-port blind tube type structure is limited, when the solar vacuum glass tube pressure-bearing heat collector is required to heat the liquid medium to a higher temperature, a longer time is required, and the defect that the temperature rising speed of the heated medium is slow is caused.

SUMMERY OF THE UTILITY MODEL

In order to improve the problem that the heating medium speed of the existing solar vacuum glass tube pressure-bearing heat collector is slow, the application provides a snakelike solar vacuum glass tube pressure-bearing heat collector and a heat collector system.

First aspect, the application provides a snakelike solar energy vacuum glass tube pressure-bearing heat collector, adopts following technical scheme:

a snakelike solar vacuum glass tube pressure-bearing heat collector is characterized by comprising two header bodies which are symmetrically arranged and a plurality of straight-through solar vacuum glass heat collecting tubes which are arranged between the two header bodies, wherein the straight-through solar vacuum glass heat collecting tubes are parallel to each other and are sequentially arranged along a straight line direction;

a plurality of through holes matched with the outer diameters of the end parts of the straight-through type solar vacuum glass heat collecting tubes are formed in the two header bodies along the distribution direction of the straight-through type solar vacuum glass heat collecting tubes, and the two ends of the straight-through type solar vacuum glass heat collecting tubes are respectively arranged on the two header bodies in a penetrating mode through the corresponding through holes;

a heat-conducting metal straight pipe penetrates through each straight-through type solar vacuum glass heat collecting pipe, the length of each heat-conducting metal straight pipe is greater than that of each straight-through type solar vacuum glass heat collecting pipe, and two ends of each heat-conducting metal straight pipe extend out of the corresponding straight-through type solar vacuum glass heat collecting pipes;

an elastic straight pipe bracket is arranged between each straight-through type solar vacuum glass heat collecting pipe and the corresponding heat conducting metal straight pipe, and a connecting pipe fitting for connecting all the heat conducting metal straight pipes into an S-shaped serpentine pipeline is connected between the heat conducting metal straight pipes at the head parts of the two adjacent straight-through type solar vacuum glass heat collecting pipes.

Through adopting above-mentioned technical scheme, on the one hand, S-shaped snakelike medium circulation pipeline has the advantage that the pipeline is long compared in the solar vacuum glass pipe of single port blind tube structure, can let the heat-transfer medium in the pipeline rise to ultimate temperature or expected temperature in the short time, realizes the superimposed effect of temperature. In addition, the temperature rise time and temperature rise temperature of the medium in the pipeline are controllable, and the flow rate of the medium in the pipeline can be controlled. On the other hand, compared with a traditional heat collector with a zigzag needle-shaped metal tube structure, the S-shaped snake-shaped medium circulation pipeline has less winding bends and the calibers of the S-shaped snake-shaped medium circulation pipeline and the straight-through solar vacuum glass heat collection tube tend to be consistent, so that compared with the traditional zigzag needle-shaped metal tube structure, the S-shaped snake-shaped medium circulation pipeline has larger medium capacity and smaller resistance, and is beneficial to leading the heat absorbed and converted by the straight-through solar vacuum glass heat collection tube to be fully taken away, thereby being beneficial to avoiding heat waste. Specifically, the heating process of water or the liquid medium comprises the steps that after water or the heated liquid medium flows in from an inlet of an S-shaped snake-shaped pipeline, the water or the heated liquid medium is continuously heated step by step through an S-shaped snake-shaped medium circulation pipeline with the caliber being consistent with that of the straight-through solar vacuum glass heat collecting pipe, and the straight-through solar vacuum glass heat collecting pipe has excellent photo-thermal conversion performance and heat insulation performance, so that the temperature of the water or the heated liquid medium is continuously increased, and a higher temperature can be reached in a short time.

The present application may be further configured in a preferred example to: the heat-conducting metal straight pipe is an aluminum pipe.

By adopting the technical scheme, the aluminum pipe has better heat conduction performance, photons impact the heat absorption coating after the straight-through solar vacuum glass heat collection pipe is irradiated by sunlight, solar energy is converted into heat energy, the aluminum pipe absorbs heat from the coating and transfers the heat to water or other liquid media circulating in the aluminum pipe, and the temperature of the water or the liquid media is increased. The heat transfer function is guaranteed, and meanwhile, the material cost is reduced compared with a copper pipe of a traditional square-needle-shaped metal pipe structure.

The present application may be further configured in a preferred example to: the elastic straight pipe bracket is a hollow aluminum plate and is C-shaped.

By adopting the technical scheme, a certain space for deformation of the elastic straight pipe bracket is formed between the heat-conducting metal straight pipe and the straight-through type solar vacuum glass heat collecting pipe, and assembly between the heat-conducting metal straight pipe and the straight-through type solar vacuum glass heat collecting pipe is facilitated. And because the elastic straight pipe bracket is a hollow aluminum plate, the heat transfer is more facilitated, and the heating speed of a heat transfer medium is ensured.

The present application may be further configured in a preferred example to: and a dustproof fixed silica gel ring is arranged between the outer wall of the end part of the straight-through solar vacuum glass heat collecting tube (2) extending into the through hole and the inner wall of the corresponding through hole.

By adopting the technical scheme, on one hand, the sealing performance between the straight-through solar vacuum glass heat collecting tube and the header body is improved, and the dust-proof function is achieved. On the other hand, the friction force of the dustproof silica gel fixing ring and the contact part of the straight-through type solar vacuum glass heat collecting pipe is facilitated, and the purpose of fixing and positioning the straight-through type solar vacuum glass heat collecting pipe is achieved.

The present application may be further configured in a preferred example to: the inner wall of the dustproof silica gel fixing ring (12) is provided with convex lines.

By adopting the technical scheme, the friction force of the dustproof fixed silica gel ring and the contact part of the straight-through solar vacuum glass heat collecting pipe is further increased, so that the positioning effect of the straight-through solar vacuum glass heat collecting pipe is better.

The present application may be further configured in a preferred example to: the connecting pipe fitting is a semicircular elbow and comprises an inner layer connecting pipe and an outer layer heat-insulating pipe coated outside the inner layer connecting pipe; the two ends of the outer layer heat-insulating pipe are respectively sleeved at the end parts of the corresponding straight-through solar vacuum glass heat-collecting pipes, and the two ends of the inner layer connecting pipe are respectively sleeved at the end parts of the corresponding heat-conducting metal straight pipes.

Through adopting above-mentioned technical scheme, semicircular elbow makes whole snakelike medium circulation pipeline's turn be the arc, does benefit to and reduces the resistance that rivers flowed to the impulse pressure that snakelike medium circulation pipeline received has also been reduced. In addition, the connecting pipe fitting is arranged to be of a double-layer structure, so that the communication between the heat conducting metal straight pipes is guaranteed, the heat preservation effect can be achieved, and the heat in the heat transfer medium is prevented from being dissipated from the connecting pipe fitting.

The present application may be further configured in a preferred example to: the outer wall of the connecting pipe fitting is provided with a connecting lug capable of abutting against the outer wall of the header body, and the connecting lug is provided with a through hole for a screw to pass through.

By adopting the technical scheme, the connection stability between the connecting pipe fitting and the heat-conducting metal straight pipe and the straight-through solar vacuum glass heat collecting pipe can be ensured.

In a second aspect, the present application provides a heat collector system, which adopts the following technical solution:

a heat collector system comprises a plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors according to the technical scheme, and the snakelike solar vacuum glass tube pressure-bearing heat collectors are sequentially connected in series.

Through adopting above-mentioned technical scheme, a plurality of snakelike solar energy vacuum glass tube pressure-bearing heat collectors establish ties easily and use and connect to form longer snakelike medium circulation pipeline, can be applicable to some fields that need the large tracts of land series connection use heat collector such as central heating or well high temperature heating, have enlarged the application range of snakelike solar energy vacuum glass tube pressure-bearing heat collector.

The present application may be further configured in a preferred example to: one end of a serpentine pipeline of the serpentine solar vacuum glass tube pressure-bearing heat collector is an inlet, and the other end of the serpentine pipeline is an outlet; the inlet and the outlet of the snakelike solar vacuum glass tube pressure-bearing heat collector are both positioned on the same header body;

the inlet of the first snakelike solar vacuum glass tube pressure-bearing heat collector and the outlet of the last snakelike solar vacuum glass tube pressure-bearing heat collector in the plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors connected in series are both connected with the clamping sleeve elbows, and the inlets and the outlets of the other adjacent snakelike solar vacuum glass tube pressure-bearing heat collectors are communicated through the connecting pipe fittings.

Through adopting above-mentioned technical scheme, be convenient for establish ties the use with a plurality of snakelike solar energy vacuum glass tube pressure-bearing heat collectors, when establishing ties a plurality of snakelike solar energy vacuum glass tube pressure-bearing heat collectors's of operation moreover, can link together two adjacent snakelike solar energy vacuum glass tube pressure-bearing heat collectors through connecting the pipe fitting to greatly reduced the manufacturing cost of operating cost and accessory.

The present application may be further configured in a preferred example to: two adjacent headers of snakelike solar vacuum glass tube pressure collector's equidirectional one end are a set of, and two headers in each set of header are all overlapped jointly on being the tip that sets up in opposite directions and are equipped with the joint cover.

Through adopting above-mentioned technical scheme, can improve the connection steadiness between the adjacent header body, make the position of adjacent header body more accurate that can correspond moreover, more do benefit to the installation of the connection pipe fitting of adjacent header body butt joint department.

In summary, the present application includes at least one of the following beneficial technical effects:

1. through the arrangement of the header body, the perforation, the straight-through solar vacuum glass heat collecting tube, the heat conducting metal straight tubes and the elastic straight tube bracket, the adjacent heat conducting metal straight tubes are connected through the connecting tube fitting, so that all the heat conducting metal straight tubes form an S-shaped serpentine pipeline; on one hand, the heat transfer medium in the pipeline can be raised to the limit temperature or the expected temperature in a short time, and the effect of temperature superposition is realized; on the other hand, the S-shaped serpentine pipeline has less winding bending compared with a heat collector with a traditional square-needle-shaped metal tube structure, and the calibers of the S-shaped serpentine pipeline and the straight-through solar vacuum glass heat collecting tube tend to be consistent, so that the medium capacity of the S-shaped serpentine pipeline is larger than that of the pipeline with the traditional square-needle-shaped metal tube structure, and the straight-through solar vacuum glass heat collecting tube can fully take away the heat absorbed and converted;

2. through the arrangement of the dustproof fixed silica gel ring and the connecting lugs, the connection stability between the straight-through solar vacuum glass heat collecting tube and the header body is improved, and the connection stability between the connecting tube and the heat conducting metal straight tube as well as between the straight-through solar vacuum glass heat collecting tube is also improved.

Drawings

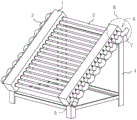

FIG. 1 is a schematic view of the overall structure of a serpentine solar vacuum glass tube pressure collector according to an embodiment of the present application;

FIG. 2 is a schematic structural diagram of a straight-through solar vacuum glass heat collecting tube according to an embodiment of the present application;

FIG. 3 is a cross-sectional view of a serpentine solar evacuated glass tube load collector of an embodiment of the present application;

FIG. 4 is an enlarged view of portion A of FIG. 3;

FIG. 5 is a perspective view of a serpentine solar evacuated glass tube load collector according to an embodiment of the present application;

FIG. 6 is an enlarged view of portion B of FIG. 5;

FIG. 7 is a schematic illustration of the construction of one of the collector systems of the embodiments of the present application;

FIG. 8 is a schematic structural view of another collector system according to an embodiment of the present application.

In the figure, 1, a header body; 11. perforating; 12. fixing a silica gel ring in a dustproof manner; 13. a relief pattern; 2. a straight-through solar vacuum glass heat collecting tube; 21. a heat-conducting metal straight pipe; 22. an elastic straight tube bracket; 3. connecting pipe fittings; 31. an inner layer connecting pipe; 32. an outer layer heat preservation pipe; 33. connecting lugs; 34. a through hole; 35. a hole of abdication; 4. a support; 5. an inlet; 6. an outlet; 7. cutting the elbow; 8. a clamping sleeve; 91. a medium inlet pipe; 92. and a medium outlet pipe.

Detailed Description

The present application is described in further detail below with reference to the attached drawings.

The straight-through solar vacuum glass heat collecting tube is composed of an inner concentric glass tube and an outer concentric glass tube, selective absorption wax with high absorption rate and low emissivity is deposited on the outer surface or the inner surface of the inner tube to form a heat absorption coating, high vacuum is pumped between an inner tube interlayer and an outer tube interlayer, two ends of the whole straight-through solar vacuum glass heat collecting tube are arranged in an opening mode, and the straight-through solar vacuum glass heat collecting tube has excellent photo-thermal conversion performance and heat preservation performance as a traditional single-opening blind tube type solar vacuum tube. After the straight-through solar vacuum glass heat collecting tube is irradiated by sunlight, photons impact the heat absorption coating, solar energy is converted into heat energy, a medium flowing from the inner part of the inner tube or a medium in a medium flowing pipeline penetrating the inner tube absorbs heat from the coating, and the water temperature is increased.

The embodiment of the application discloses snakelike solar vacuum glass tube pressure-bearing heat collector. Referring to fig. 1, the snakelike solar vacuum glass tube pressure-bearing heat collector comprises two header bodies 1 which are symmetrically arranged and a plurality of straight-through solar vacuum glass heat collecting tubes 2 which are arranged between the two header bodies 1, wherein the two header bodies 1 are both in a strip shape, and the plurality of straight-through solar vacuum glass heat collecting tubes 2 are mutually parallel and are sequentially arranged along the length direction of the header bodies 1.

Referring to fig. 2, a heat conducting metal straight tube 21 penetrates through each straight-through solar vacuum glass heat collecting tube 2, the length of the heat conducting metal straight tube 21 is greater than that of the straight-through solar vacuum glass heat collecting tube 2, and two ends of the heat conducting metal straight tube extend out of the corresponding straight-through solar vacuum glass heat collecting tube 2. In order to improve the heat absorption performance of the heat-conducting metal straight pipe 21 and reduce the material cost, the heat-conducting metal straight pipe 21 is made of an aluminum pipe, and a liquid medium is stored and flows through the aluminum pipe. Elastic straight pipe brackets 22 are arranged between each straight-through solar vacuum glass heat collecting pipe 2 and the corresponding heat conducting metal straight pipe 21, each elastic straight pipe bracket 22 is a C-shaped hollow aluminum plate, each aluminum plate is arranged along the length direction of the straight-through solar vacuum glass heat collecting pipe 2, and the two ends of each aluminum plate are open, and the aluminum plates are arranged in a hollow structure, so that the elastic straight pipe brackets 22 have certain deformation capacity, can be easily arranged between the straight-through solar vacuum glass heat collecting pipes 2 and the heat conducting metal straight pipes 21 and can support the heat conducting metal straight pipes 21.

Referring to fig. 3 and 4, a plurality of through holes 11 are formed in the two header bodies 1 along the distribution direction of the straight-through solar vacuum glass heat collecting tubes 2, the number of the through holes 11 in each header body 1 is equal to the number of the straight-through solar vacuum glass heat collecting tubes 2 between the two header bodies 1, and the through holes 11 in one header body 1 are arranged in one-to-one correspondence with the through holes 11 in the other header body 1. The through holes 11 are matched with the outer diameters of the end parts of the straight-through type solar vacuum glass heat collecting tubes 2, two ends of the straight-through type solar vacuum glass heat collecting tubes 2 are respectively arranged in the corresponding through holes 11 on the two header bodies 1 in a penetrating mode, and the two end parts of the straight-through type solar vacuum glass heat collecting tubes 2 are located on the outer sides of the header bodies 1.

Referring to fig. 2 and 4, in order to ensure the sealing performance and the fastening performance of the connection between the straight-through solar vacuum glass heat collecting tube 2 and the header body 1, a dustproof fixing silica gel ring 12 is arranged between the outer wall of the end part of the straight-through solar vacuum glass heat collecting tube 2 extending into the through hole 11 and the inner wall of the corresponding through hole 11. The inner wall of the dustproof fixed silica gel ring 12 is provided with the convex patterns 13, and the friction force between the dustproof fixed silica gel ring 12 and the straight-through solar vacuum glass heat collecting tube 2 can be increased through the convex patterns 13, so that the positioning effect of the straight-through solar vacuum glass heat collecting tube 2 is improved.

Referring to fig. 3 and 4, a connecting pipe fitting 3 for connecting all the heat conducting metal straight pipes 21 into an S-shaped serpentine pipeline is connected between the heat conducting metal straight pipes 21 at the head parts of two adjacent straight-through solar vacuum glass heat collecting pipes 2, and the connecting pipe fitting 3 adopts a semicircular elbow. Specifically, the connecting pipe fitting 3 comprises an inner layer connecting pipe 31 and an outer layer heat preservation pipe 32 coated outside the inner layer connecting pipe; the outer layer heat preservation pipe 32 is made of heat preservation plastic materials such as polyurethane heat preservation pipes, and two ends of the outer layer heat preservation pipe are respectively provided with a abdicating hole 35 for inserting the end part of the straight-through solar vacuum glass heat collection pipe 2; the inner layer connecting pipe 31 is also made of an aluminum pipe, and two ends of the inner layer connecting pipe are respectively sleeved on the ends of the corresponding heat conducting metal straight pipes 21.

Referring to fig. 5, the snakelike solar vacuum glass tube pressure-bearing heat collector can be fixedly provided with a support 4 at the bottom in practical application, so that the snakelike solar vacuum glass tube pressure-bearing heat collector is integrally arranged in an inclined manner to face the sunlight. With reference to fig. 4, one end of the bottom-most heat-conducting metal straight tube 21 is an inlet 5, one end of the top-most heat-conducting metal straight tube 21 is an outlet 6, and the ends of the other adjacent heat-conducting metal straight tubes 21 are connected by the connecting pipe fitting 3, so that the heat-conducting metal straight tubes 21 are connected to form an S-shaped serpentine medium circulation pipeline. The end parts of the heat-conducting metal straight pipes 21 which are arranged as the inlet 5 and the outlet 6 are connected with the right-angle clamping sleeve elbows 7, and the clamping sleeve elbows 7 are of double-layer structures as well as the connecting pipe fittings 3 except the shapes.

Referring to fig. 6, the outer walls of the connecting pipe fitting 3 and the ferrule elbow 7 are both provided with a connecting lug 33, and the connecting lug 33 is provided with a through hole 34 for a screw to pass through. After the connecting pipe fitting 3 and the ferrule elbow 7 are connected with the end part of the corresponding straight-through solar vacuum glass heat collecting pipe 2, the connecting lug 33 abuts against the side wall of the outer side of the corresponding header body 1, and at the moment, the screw penetrates through the through hole 34 to be connected with the header body 1, so that the straight-through solar vacuum glass heat collecting pipe 2 can be firmly fixed, and the connection stability between the straight-through solar vacuum glass heat collecting pipe 2 and the header body 1 is improved.

The application embodiment of the snakelike solar vacuum glass tube pressure-bearing heat collector has the following implementation principle:

the heated liquid medium flows in from the ferrule elbow 7 at the inlet 5 and is continuously heated step by step through the S-shaped snake-shaped medium circulation pipeline, and the temperature of the heated liquid medium can be continuously increased because the straight-through solar vacuum glass heat collecting tube 2 has excellent photo-thermal conversion performance and heat preservation performance. In practical application, the liquid temperature can be quickly raised or raised to an extremely high temperature by adjusting the flow rate of the liquid, and in addition, it should be noted that, under the same illumination condition, the slower the flow rate of the liquid, the longer the time existing in the S-shaped serpentine medium circulation pipeline, so that more heat can be absorbed, and finally the temperature to which the liquid is raised is higher. Simultaneously, form S-shaped snakelike medium circulation pipeline through the aluminium pipe difficult to corrode, can guarantee that quality of water is clean, the aluminium pipe pressure-resistant ability is strong moreover for whole snakelike medium circulation pipeline can bear higher water pressure, possesses the ability of pressure-bearing operation.

The embodiment of the application also discloses a heat collector system. Referring to fig. 7, the collector system comprises a medium inlet pipe 91, a medium outlet pipe 92 and a plurality of serpentine solar vacuum glass tube pressure collectors arranged side by side. Specifically, the cutting ferrule elbow 7 of 5 departments of the import of a plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors that set up side by side all advances a tub 91 with the medium and is connected, and the cutting ferrule elbow 7 of 6 departments of the export of a plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors that set up side by side all is connected with medium exit tube 92, has formed the parallelly connected structure of a plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors.

The implementation principle of the above heat collector system in the embodiment of the present application is as follows:

the heated liquid medium in the medium inlet pipe 91 can flow in from the ferrule elbows 7 at the inlets 5 of the plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors arranged side by side, and in each snakelike solar vacuum glass tube pressure-bearing heat collector, the liquid medium can be continuously heated step by step through the S-shaped snakelike medium circulation pipeline with the caliber approximately consistent with the caliber of the straight-through solar vacuum glass heat collecting tube 2, and finally the liquid medium is gathered and flows out from the medium outlet pipe 92. Because the straight-through type solar vacuum glass heat collecting tube 2 has excellent photo-thermal conversion performance and heat preservation performance, and the aluminum tube also has excellent heat conduction performance, the temperature of water or heated liquid medium in a snakelike medium circulation pipeline can be continuously raised, and the rapid heating for increasing the liquid capacity can be realized by arranging a plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors side by side, so that the heating efficiency is further accelerated. Moreover, compared with the traditional heat collector with a clip-shaped metal tube structure, the single-block heat collector has less winding bending, so that the liquid resistance is lower, the multi-block parallel large-area use in the central heating field or the medium-high temperature field is facilitated, and the application range of the snake-shaped solar vacuum glass tube pressure-bearing heat collector is enlarged.

The embodiment of the application also discloses another heat collector system. Referring to fig. 8, the heat collector system comprises a plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors which are sequentially arranged along the length direction of a header body 1 and are connected in series. Specifically, import 5 and the export 6 of snakelike solar energy vacuum glass tube pressure-bearing heat collector all are located same header 1, and two cutting ferrule elbows 7 are connected respectively at the import 5 of the first snakelike solar energy vacuum glass tube pressure-bearing heat collector and the export 6 of last snakelike solar energy vacuum glass tube pressure-bearing heat collector in a plurality of snakelike solar energy vacuum glass tube pressure-bearing heat collectors of establishing ties, and the import 5 and the export 6 of remaining adjacent snakelike solar energy vacuum glass tube pressure-bearing heat collector all connect through connecting pipe fitting 3.

Referring to fig. 8, two header bodies 1 of the equidirectional one end of two adjacent snakelike solar vacuum glass tube pressure collectors are a set of, and for improving the connection steadiness between two adjacent snakelike solar vacuum glass tube pressure collectors, two header bodies 1 in each set of header body 1 are all together overlapped and are equipped with joint sleeve 8 on the tip that sets up in opposite directions, and joint sleeve 8 is cyclic annular and tightly overlaps and establish the tip that corresponds header body 1.

The implementation principle of the above another heat collector system in the embodiment of the present application is as follows:

by redesigning the structure of the heat collector system and the connection mode between the heat collectors, the heated liquid medium flows in from the ferrule elbow 7 at the inlet 5 of the heat collector system, and can be continuously heated step by step through the S-shaped snake-shaped medium circulation pipeline with the caliber approximately consistent with that of the straight-through solar vacuum glass heat collecting tube 2. Because the straight-through solar vacuum glass heat collecting tube 2 has excellent photo-thermal conversion performance and heat preservation performance, and the aluminum tube also has excellent heat conduction performance, the temperature of the heated liquid medium in the snakelike medium circulation pipeline can be continuously raised, and compared with the traditional heat collector with a zigzag needle-shaped metal tube structure, the solar vacuum heat collecting tube has the advantages of higher temperature rise, higher heat exchange efficiency and more sufficient heat exchange.

Moreover, compared with the traditional heat collector with a clip-shaped metal tube structure, the single-block heat collector has the advantages that the winding bend is less, so that the liquid resistance is lower, the large-area serial connection of multiple blocks and multiple groups in series connection in the field of central heating or in the field of medium and high temperature is facilitated, and the application range of the snake-shaped solar vacuum glass tube pressure-bearing heat collector is enlarged.

The above embodiments are preferred embodiments of the present application, and the protection scope of the present application is not limited by the above embodiments, so: all equivalent changes made according to the structure, shape and principle of the present application shall be covered by the protection scope of the present application.

Claims (10)

1. A snakelike solar vacuum glass tube pressure-bearing heat collector is characterized by comprising two header bodies (1) which are symmetrically arranged and a plurality of straight-through solar vacuum glass heat collecting tubes (2) which are arranged between the two header bodies (1), wherein the straight-through solar vacuum glass heat collecting tubes (2) are mutually parallel and are sequentially arranged along a straight line direction;

a plurality of through holes (11) matched with the outer diameters of the end parts of the straight-through type solar vacuum glass heat collecting tubes (2) are formed in the two header bodies (1) along the distribution direction of the straight-through type solar vacuum glass heat collecting tubes (2), and the two ends of the straight-through type solar vacuum glass heat collecting tubes (2) are respectively arranged on the corresponding through holes (11) in the two header bodies (1) in a penetrating manner;

a heat-conducting metal straight pipe (21) penetrates through each straight-through type solar vacuum glass heat collecting pipe (2), the length of each heat-conducting metal straight pipe (21) is greater than that of each straight-through type solar vacuum glass heat collecting pipe (2), and two ends of each heat-conducting metal straight pipe extend out of the corresponding straight-through type solar vacuum glass heat collecting pipes (2);

elastic straight pipe brackets (22) are arranged between each straight-through solar vacuum glass heat collecting pipe (2) and the corresponding heat conducting metal straight pipe (21), and a connecting pipe fitting (3) for connecting all the heat conducting metal straight pipes (21) into an S-shaped serpentine pipeline is connected between the heat conducting metal straight pipes (21) at the head parts of the two adjacent straight-through solar vacuum glass heat collecting pipes (2).

2. The serpentine solar vacuum glass tube pressure collector according to claim 1, wherein the straight heat conducting metal tube (21) is an aluminum tube.

3. The serpentine solar vacuum glass tube pressure collector according to claim 1, wherein the elastic straight tube bracket (22) is a hollow aluminum plate and is C-shaped.

4. The snakelike solar vacuum glass tube pressure-bearing heat collector according to claim 1, wherein a dustproof fixing silica gel ring (12) is arranged between the outer wall of the end part of the straight-through solar vacuum glass heat collecting tube (2) extending into the through hole (11) and the inner wall of the corresponding through hole (11).

5. The snakelike solar vacuum glass tube pressure-bearing heat collector according to claim 4, wherein the inner wall of the dustproof fixing silicone ring (12) is provided with a convex pattern (13).

6. The serpentine solar vacuum glass tube pressure collector according to claim 1, wherein the connecting tube member (3) is a semicircular elbow, and the connecting tube member (3) comprises an inner connecting tube (31) and an outer insulating tube (32) wrapped outside the inner connecting tube; two ends of the outer layer heat preservation pipe (32) are respectively sleeved at the end parts of the corresponding straight-through solar vacuum glass heat collection pipes (2), and two ends of the inner layer connecting pipe (31) are respectively sleeved at the end parts of the corresponding heat conduction metal straight pipes (21).

7. The snakelike solar vacuum glass tube pressure-bearing heat collector according to claim 6, wherein the outer wall of the connecting pipe (3) is provided with a connecting lug (33) capable of abutting against the outer wall of the header body (1), and the connecting lug (33) is provided with a through hole (34) for a screw to pass through.

8. A heat collector system comprising a plurality of serpentine solar evacuated glass tube pressure collector defined in any one of claims 1 to 7 connected in series.

9. The heat collector system according to claim 8 wherein the serpentine tube of the serpentine solar evacuated glass tube pressure collector has an inlet (5) at one end and an outlet (6) at the other end; the inlet (5) and the outlet (6) of the snakelike solar vacuum glass tube pressure-bearing heat collector are both positioned on the same header body (1);

the inlet (5) of the first snakelike solar vacuum glass tube pressure-bearing heat collector and the outlet (6) of the last snakelike solar vacuum glass tube pressure-bearing heat collector in the plurality of snakelike solar vacuum glass tube pressure-bearing heat collectors connected in series are both connected with a clamping sleeve elbow (7), and the inlets (5) and the outlets (6) of the rest adjacent snakelike solar vacuum glass tube pressure-bearing heat collectors are communicated through the connecting pipe fitting (3).

10. The heat collector system according to claim 9, wherein two header bodies (1) at one end of the adjacent two serpentine solar vacuum glass tube pressure collectors in the same direction are in a group, and clamping sleeves (8) are sleeved on the end parts of the two header bodies (1) in each group of header bodies (1) which are arranged in opposite directions.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021207262.2U CN212274285U (en) | 2020-06-24 | 2020-06-24 | Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021207262.2U CN212274285U (en) | 2020-06-24 | 2020-06-24 | Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212274285U true CN212274285U (en) | 2021-01-01 |

Family

ID=73881786

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021207262.2U Active CN212274285U (en) | 2020-06-24 | 2020-06-24 | Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212274285U (en) |

-

2020

- 2020-06-24 CN CN202021207262.2U patent/CN212274285U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8347877B2 (en) | Solar energy collecting system and method | |

| CN201215399Y (en) | U-type tubular solar heat collector | |

| CN101825348A (en) | Focusing flat plate solar heat collector | |

| CN212274285U (en) | Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system | |

| CN101936608B (en) | Two-stage heat pipe type solar air heater | |

| CN201724447U (en) | Microchannel parallel flow heat collecting module for solar heating | |

| CN111609563A (en) | Snakelike solar vacuum glass tube pressure-bearing heat collector and heat collector system | |

| CN208794752U (en) | A kind of Bulk coat high efficiency plate solar thermal collector | |

| CN210688783U (en) | Novel heat absorber assembly for tower type photo-thermal power generation | |

| CN102788433B (en) | Solar thermal collector and water heater | |

| CN200968733Y (en) | Wall hanging type solar energy water heater | |

| CN208282422U (en) | A kind of evacuated collector tube of card slot type heat shock resistance | |

| CN203148066U (en) | Novel micro heat pipe array flat-plate water-free solar collector and novel micro heat pipe array water heater | |

| CN103075820B (en) | Novel micro heat pipe array flat-plate solar anhydrous heat collector and water heater | |

| CN215809384U (en) | Solar heat collecting pipe and solar heat collector thereof | |

| CN214841736U (en) | Novel solar heat collector | |

| CN101118095B (en) | Double-layer glass vacuum metal pipe type solar heat-collector | |

| CN202013029U (en) | Heat transfer device for heat pipe type solar heat collector | |

| CN201050897Y (en) | Solar heat-collecting tube | |

| WO2009000129A1 (en) | A solar vacuum heat-collecting tube | |

| CN220038789U (en) | Flat-plate solar heat collector and heat-absorbing plate core | |

| CN205191941U (en) | Cavity absorber based on linear fei nieer solar collector | |

| CN216716605U (en) | Loop type flat-plate solar collector with heat collection fins | |

| CN110375442A (en) | A kind of high temperature solar cavate heat pipe central receiver | |

| CN202158674U (en) | Concentrator of flat tube type solar water heater |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |