CN211426798U - Integrated beam splitting scanning unit - Google Patents

Integrated beam splitting scanning unit Download PDFInfo

- Publication number

- CN211426798U CN211426798U CN201921630308.9U CN201921630308U CN211426798U CN 211426798 U CN211426798 U CN 211426798U CN 201921630308 U CN201921630308 U CN 201921630308U CN 211426798 U CN211426798 U CN 211426798U

- Authority

- CN

- China

- Prior art keywords

- light

- transparent substrate

- scanning unit

- light source

- sub

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000758 substrate Substances 0.000 claims abstract description 79

- 239000004973 liquid crystal related substance Substances 0.000 claims abstract description 22

- 230000010354 integration Effects 0.000 abstract description 4

- 238000005259 measurement Methods 0.000 description 26

- 230000003287 optical effect Effects 0.000 description 25

- 238000010586 diagram Methods 0.000 description 19

- 239000010410 layer Substances 0.000 description 19

- 238000012545 processing Methods 0.000 description 16

- 238000003491 array Methods 0.000 description 11

- 238000000034 method Methods 0.000 description 11

- 239000004065 semiconductor Substances 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 5

- 230000008901 benefit Effects 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 3

- 238000005286 illumination Methods 0.000 description 3

- 230000001788 irregular Effects 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 230000000007 visual effect Effects 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 2

- 238000003384 imaging method Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000010076 replication Effects 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000003708 edge detection Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 239000002346 layers by function Substances 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000011218 segmentation Effects 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 238000000638 solvent extraction Methods 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 230000001360 synchronised effect Effects 0.000 description 1

- 230000026676 system process Effects 0.000 description 1

Images

Landscapes

- Optical Radar Systems And Details Thereof (AREA)

Abstract

The utility model discloses an integrated beam splitting scanning unit, include: a first transparent substrate and a second transparent substrate; the liquid crystal layer is arranged between the first transparent substrate and the second transparent substrate and used for deflecting incident light beams to realize scanning; and the beam splitting unit is arranged on the first transparent substrate and/or the second transparent substrate and is used for splitting the incident light beam. The device volume is reduced by reasonably arranging the beam splitting unit and the scanning unit, and high integration is realized.

Description

Technical Field

The utility model relates to a computer technology field especially relates to an integrated beam splitting scanning unit.

Background

The Time of Flight principle (Time of Flight) and the structured light principle are utilized to measure the distance of the target so as to obtain a depth image containing the depth value of the target, and further, the functions of three-dimensional reconstruction, face recognition, man-machine interaction and the like can be realized based on the depth image, and related distance measuring systems are widely applied to the fields of consumer electronics, unmanned driving, AR/VR and the like.

Distance measuring systems based on the time-of-flight principle and the structured light principle generally include a light beam emitter and a light beam collector. A light source in the emitter emits a beam of light toward the target space to provide illumination, and a collector receives the beam of light reflected back by the target. Wherein the time-of-flight distance measuring system calculates the distance of the target object by calculating the time required for the beam to be received from the transmission to the reflection; the structured light distance measuring system processes the reflected light beam pattern and calculates the distance of the target object by using a trigonometry method.

No matter which principle scheme is adopted, the distance measurement system faces some problems to be solved urgently at present, and the most central problems are the problem of measurement resolution, the problem of power consumption and the problem of size.

The measurement resolution is often influenced by the light beam emitted by the emitter, and the denser the emitted light beam is, the resolution is often higher, but the dense light beam has higher requirements on the arrangement density of the light sources and the design requirements of related optical devices, and the dense light beam also means higher power consumption. The difficult problem of power consumption is also influenced by the emitter, and the higher the emitter emits light beam power, the higher the light beam density is, the higher the power consumption is, further, the more widely application of the measurement system in more fields is limited. Secondly, the problem of the volume is often caused by complicated devices in the emitter or collector, for example, the emitter usually includes a light source and some optical elements such as refraction and diffraction, which results in a large volume and is not easy to integrate.

The above background disclosure is only for the purpose of assisting understanding of the inventive concept and technical solutions of the present invention, which do not necessarily belong to the prior art of the present patent application, and should not be used for evaluating the novelty and inventive step of the present application without explicit evidence that the above contents have been disclosed at the filing date of the present patent application.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide an integrated beam splitting scanning unit to solve at least one among the above-mentioned background art problem.

In order to achieve the above object, the embodiment of the present invention provides a technical solution that:

an integrated beam splitting scanning unit comprising: a first transparent substrate and a second transparent substrate; the liquid crystal layer is arranged between the first transparent substrate and the second transparent substrate and used for deflecting incident light beams to realize scanning; and the beam splitting unit is arranged on the first transparent substrate and/or the second transparent substrate and is used for splitting the incident light beam.

In some embodiments, further comprising positive and negative electrode layers disposed between the first transparent substrate and the second transparent substrate.

In some embodiments, further comprising a support disposed between the first transparent substrate and the second transparent substrate.

In some embodiments, the beam splitting unit comprises microstructures formed on the first and/or second transparent substrates, the microstructures comprising one or a combination of diffraction gratings, binary gratings, super surface structures.

In some embodiments, the microstructures are formed on an inner surface of the first and/or second transparent substrate.

In some embodiments, the positive and negative electrode layers are disposed on both sides of the liquid crystal layer.

In some embodiments, the support is mounted around the liquid crystal layer.

The utility model discloses technical scheme's beneficial effect is:

the utility model discloses a with the reasonable setting of beam splitting unit and scanning unit in order to reduce the equipment volume, realize high integration, solved among the prior art often complicated device lead to the great difficult integrated problem of volume.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings needed to be used in the description of the embodiments or the prior art will be briefly introduced below, and it is obvious that the drawings in the following description are only some embodiments of the present invention, and it is obvious for those skilled in the art that other drawings can be obtained according to the drawings without inventive exercise.

FIG. 1 is a schematic diagram of a time-of-flight distance measurement system according to one embodiment of the present creation.

Fig. 2 is a schematic diagram of a transmitter according to a first embodiment of the present creation.

FIG. 3 is a schematic diagram of a projection pattern according to a first embodiment of the present disclosure.

Fig. 4 is a schematic diagram of a transmitter according to a second embodiment of the present creation.

Fig. 5 is a schematic diagram of a transmitter according to a third embodiment of the present creation.

FIG. 6 is a schematic diagram of a projection pattern according to a second embodiment of the present invention.

FIG. 7 is a schematic diagram of an integrated beam splitting scanning unit according to one embodiment of the present creation.

FIG. 8 is a schematic diagram of an array light source and its sparse projection pattern according to an embodiment of the present creation.

FIG. 9 is a schematic diagram of an array light source and its dense projection pattern according to an embodiment of the present creation.

Detailed Description

In order to make the technical problems, technical solutions and advantageous effects to be solved by the embodiments of the present disclosure more clearly understood, the present disclosure is further described in detail below with reference to the accompanying drawings and the embodiments. It should be understood that the specific embodiments described herein are merely illustrative of the present authoring and are not intended to be limiting.

It will be understood that when an element is referred to as being "secured to" or "disposed on" another element, it can be directly on the other element or be indirectly on the other element. When an element is referred to as being "connected to" another element, it can be directly connected to the other element or be indirectly connected to the other element. The connection may be for fixation or for circuit connection.

It is to be understood that the terms "length," "width," "upper," "lower," "front," "rear," "left," "right," "vertical," "horizontal," "top," "bottom," "inner," "outer," and the like are used in an orientation or positional relationship indicated in the drawings for convenience in describing the embodiments of the present invention and to simplify the description, and are not intended to indicate or imply that the referenced device or element must have a particular orientation, be constructed and operated in a particular orientation, and are not to be construed as limiting the present disclosure.

Furthermore, the terms "first", "second" and "first" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance or implicitly indicating the number of technical features indicated. Thus, a feature defined as "first" or "second" may explicitly or implicitly include one or more of that feature. In the description of the present embodiments, "a plurality" means two or more unless specifically limited otherwise.

The present creation provides a time-of-flight distance measurement system with higher resolution and/or larger field of view.

FIG. 1 is a schematic diagram of a time-of-flight distance measurement system according to one embodiment of the present disclosure. The distance measuring system 10 comprises a transmitter 11, a collector 12 and a processing circuit 13; emitter 11 provides a transmitted light beam 30 into the target space to illuminate object 20 in the space, wherein at least part of transmitted light beam 30 is reflected by object 20 to form a reflected light beam 40, and at least part of the light signals (photons) of reflected light beam 40 are collected by collector 12. Processing circuitry 13 is coupled to emitter 11 and collector 12, and synchronizes the trigger signals of emitter 11 and collector 12 to calculate the time required for the light beam to be emitted from emitter 11 and received by collector 12, i.e. the time of flight t between emitted light beam 30 and reflected light beam 40, and further, the distance D of the corresponding point on the object can be calculated by the following formula:

D=c·t/2 (1)

where c is the speed of light.

The emitter 11 includes a light source 111, an optical element 112. The light source 111 may be a light source such as a Light Emitting Diode (LED), an Edge Emitting Laser (EEL), a Vertical Cavity Surface Emitting Laser (VCSEL), or an array light source composed of a plurality of light sources. Preferably, the array light source 111 is a VCSEL array light source chip formed by generating a plurality of VCSEL light sources on a single semiconductor substrate. The light beam emitted by the light source 111 may be visible light, infrared light, ultraviolet light, or the like. The light source 111 emits light beams outwards under the control of the processing circuit 13, for example, in one embodiment, the light source 111 emits pulsed light beams under the control of the processing circuit 13 at a certain frequency (pulse period), which can be used in Direct time of flight (Direct TOF) measurement, the frequency is set according to a measurement distance, for example, the frequency can be set to 1MHz-100MHz, and the measurement distance is several meters to several hundred meters. It will be appreciated that the light source 111 may be controlled to emit the associated light beam, either as part of the processing circuitry 13 or independently of sub-circuits present in the processing circuitry 13, such as a pulse signal generator.

The optical element 112 receives the pulsed light beam from the light source 111, optically modulates the pulsed light beam, such as by diffraction, refraction, reflection, etc., and then emits the modulated light beam, such as a focused light beam, a flood light beam, a structured light beam, etc., into the space. The optical elements 112 may be in the form of one or more combinations of lenses, diffractive optical elements, super surface (Metasurface) optical elements, masks, mirrors, MEMS mirrors, and the like.

The processing circuit 13 may be a stand-alone dedicated circuit, such as a dedicated SOC chip, an FPGA chip, an ASIC chip, etc., or may comprise a general-purpose processing circuit, for example, when the depth camera is integrated into an intelligent terminal, such as a mobile phone, a television, a computer, etc., the processing circuit in the terminal may be at least a part of the processing circuit 13.

In some embodiments, the distance measuring system 10 may further include a color camera, an infrared camera, an IMU, etc., and a combination of these devices may implement more various functions, such as 3D texture modeling, infrared face recognition, SLAM, etc.

In some embodiments, emitter 11 and collector 12 may be arranged coaxially, i.e. they are implemented by an optical device with reflection and transmission functions, such as a half-mirror.

In the conventional distance measuring system, the emitter 11 is arranged to emit a flood light beam with a certain field angle, which has the advantages of performing a full-range illumination coverage on a measured object, enabling each pixel in the collector 12 to receive the reflected light beam at the same time, and enabling the resolution of the depth image output by the measuring system to be influenced by the resolution of the pixel unit of the collector 12, and the disadvantage is that the power consumption of the emitter 11 is high, and in addition, the interference between adjacent pixels of the collector 11 during synchronous measurement may be caused. In the present invention, therefore, the emitter 11 is arranged to emit the structured light beam outwards, i.e. only a partial area is illuminated in space, and the advantage of using the structured light beam is that the illumination is more concentrated and thus the signal-to-noise ratio is improved, and the disadvantage is that the resolution is lower, and in some cases the disadvantage of insufficient field angle is also present.

Fig. 2 is a schematic diagram of a transmitter according to a first embodiment of the present creation. The emitter comprises a light source unit, a beam splitting unit 204 and a scanning unit 205, the light source unit is used for emitting a first light beam, the beam splitting unit 204 is used for receiving and splitting the first light beam to form a second light beam with a larger number of light beams, the scanning unit 205 is used for receiving and deflecting the second light beam at a certain angle and then emitting a third light beam outwards, a plurality of third light beams are formed after deflection for a plurality of times, and the comprehensive projection pattern light beam formed by the third light beams has higher density and/or larger field angle than the second light beam.

The light source unit includes a substrate 201 and one or more sub-light sources 202 disposed on the single substrate 201 (or a multi-substrate), the sub-light sources 202 being arranged in a pattern on the substrate. The substrate 201 may be a semiconductor substrate, a metal substrate, etc., and the sub-light sources 202 may be light emitting diodes, edge emitting laser emitters, vertical cavity surface laser emitters (VCSELs), etc., and preferably, the light source unit includes a semiconductor substrate and an array VCSEL chip composed of a plurality of VCSEL sub-light sources disposed on the semiconductor substrate. The sub-light sources are used to emit light beams of any desired wavelength, such as visible light, infrared light, ultraviolet light, and the like. The light source unit emits light under modulation driving of a driving circuit (which may be part of the processing circuit 13), such as amplitude modulation, phase modulation, frequency modulation, pulse modulation, or the like. The sub-light sources 202 may also emit light in groups or in whole under the control of the driving circuit, for example, the sub-light source 202 includes a first sub-light source array 201, a second sub-light source array 202, and the like, the first sub-light source array 201 emits light under the control of the first driving circuit, and the second sub-light source array 202 emits light under the control of the second driving circuit. The arrangement pattern of the sub light sources 202 may be a one-dimensional arrangement pattern, a two-dimensional arrangement pattern, a regular arrangement pattern, an irregular arrangement pattern, or a combination of a regular pattern and an irregular pattern. For ease of analysis, an example is given only schematically in fig. 2, which includes a 3 x 3 regular array of sub-sources.

In one embodiment, the light source unit further includes one or more optical elements such as a lens (or a lens group), a micro-lens array, etc., for example, a lens (or a lens group or a combination of a lens group and a micro-lens array) 203 is disposed between the sub-light source 202 and the beam splitting unit 204, and the lens 203 is used for refracting the light beam emitted by the sub-light source to generate focusing, collimating or diverging effect (forming a focused, collimated or diverging first light beam) so as to meet the modulation requirement of the subsequent optical elements.

The beam splitting unit 204 receives a first light beam emitted from a light source and duplicates and splits the first light beam to form a second light beam with a larger number of light beams, in one embodiment, the beam splitting unit 204 duplicates and splits the first light beam to form a second light beam with a higher array density (in the case of a plurality of sub-light sources), in one embodiment, the beam splitting unit 204 duplicates and splits the first light beam to form a second light beam with a larger field angle, such as the embodiment shown in FIG. 3, in one embodiment, the beam splitting unit 204 duplicates and splits the first light beam to form a second light beam with a higher array density and a larger field angle, the beam splitting unit 204 can be one or a combination of more of diffraction optical elements, gratings, optical masks, Metasurface (metasface) optical elements and any optical elements capable of splitting, and for convenience of analysis, the field angle of the second light beam is assumed to be α, and the angular offset of two adjacent sub-light beams in the second light beam is β, and it is noted that if the second light beam is a spatial light beam, both α and β include two directional components (α and α) of the second light beamx,αy)、(βx,βy)。

After receiving the second light beam from the beam splitting unit 204, the scanning unit 205 deflects and scans the second light beam and emits a third light beam outward. The scanning unit 205 may scan each sub-beam of the incident second light beamThe light beam is deflected in one or two dimensions by diffraction, refraction, reflection, etc., for example, in at least one direction by a certain angle theta (theta)x,θy) Thereby forming a third beam. Fig. 2 schematically shows the second beam deflected by the scanning unit 205 by two angles in sequence along one direction, wherein the first and third beams 206 can be regarded as being formed by deflecting by 0 degrees; the second and third light beams 207 are formed by the scanning unit 205 deflecting the second light beam by a smaller angle theta, which is smaller than the angle between two adjacent sub-beams in the second light beam, i.e. theta<β, the measurement resolution of the measurement system can be improved by the higher density of the combined projection pattern beam formed by the at least two third beams formed after at least two scans relative to the second beam without the scanning unit 205. the detailed description is provided with reference to fig. 3. the scanning unit 205 can be one or more of a liquid crystal spatial light modulator, an acousto-optic modulator, a MEMS galvanometer, a rotating prism pair, a single prism + motor, a reflective two-dimensional OPA device, a liquid crystal super surface device (LC-metaspace), etc. for example, when the scanning unit 205 is a liquid crystal spatial light modulator, the deflection angle of the incident beam can be controlled by adjusting the grating period of the arrangement of the liquid crystal molecules.

FIG. 3 is a schematic diagram of a projection pattern according to a first embodiment of the present disclosure. Based on the emitter 11 shown in fig. 2, in one embodiment, the projection pattern formed by the third light beam emitted by the emitter 11 to the target is as shown in fig. 3. In the present embodiment, the beam splitting unit 204 performs a replication beam splitting on the first light beam to form a second light beam with a larger field angle, wherein the replication is 3 × 3, that is, 3 × 3 times of the first light beam emitted by the sub-light sources regularly arranged in a 3 × 3 array is performed to form a second light beam pattern 301 with a large field angle formed by 9 first light beam patterns 302, and the second light beam pattern 301 includes 81 sub-light beams 303, which are 9 × 9, and are indicated by solid hollow circles in the figure. Assuming that the scanning unit 205 deflects the second light beam, the first deflection is 0 degrees, and the formed first and third light beam patterns are the array spot patterns formed by the solid line hollow circles 303 in fig. 3; subsequently, the scanning unit 205 deflects the second light beam again, for example, in the vertical direction in fig. 3, by an angle smaller than the angle between two adjacent sub-light beams in the second light beam, so that a second third light beam pattern composed of the dashed space circles 304 in fig. 3 can be generated. Since the deflection angle is small, the deflection angle in this embodiment is exactly half of the two adjacent sub-beams in the second beam, i.e. θ equals β/2, the dashed hollow circle 304 will fall between the two solid hollow circles 303, and the integrated scanning pattern formed by the plurality of third beams after a plurality of scans will have a higher density. The scanning direction may be in a single direction or in multiple directions.

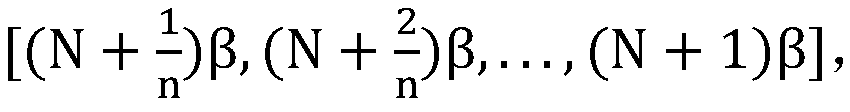

In fact, in the embodiment shown in fig. 2 and 3, the scanning unit 205 also increases the angle of view by deflecting the beam direction, but the increased angle of view is very small relative to the angle of view of the second beam formed by the beam splitting unit 204. It can be understood that the density and the angle of field of the projection pattern can be effectively adjusted by reasonably setting the deflection angle. In one embodiment, the deflection angles θ may be sequentially set toWith n scans, the scan angle is increased successivelyThereby increasing the overall projected pattern density by a factor of n. In one embodiment, the deflection angles θ may be sequentially set to It is thus possible to increase both the density of the projected pattern and the field of view, i.e. the field of view is increased by N β and the density of the intermediate portion overlap region is increased by a factor of N in one embodiment the deflection angle is set to exceed the field of view of the second beam by α, when only the field of view of the projected pattern is increased, as shown in fig. 5.

Fig. 5 is a schematic diagram of a transmitter according to a third embodiment of the present creation. The main components of the emitter are similar to the embodiment shown in fig. 2, and include a light source unit composed of a substrate 501, a sub-light source 502 and a lens 503, as well as a beam splitting unit 504 and a scanning unit 505. Different from the embodiment shown in fig. 2, the deflection angle of the scanning unit 505 for deflecting the incident second light beam is relatively large, that is, θ ≧ α, for example, the first third light beam pattern formed by deflecting 0 degrees for the first time is 506, the second third light beam pattern 507 is formed after deflecting α in a certain direction for the second time, the field angle of the integrated projection pattern formed by the first and second third light beam patterns is increased by 2 times along the deflection direction, and the density of the projection pattern is not changed.

In some embodiments, the scanning unit 505 can deflect in multiple directions to form a projection pattern with a larger field angle, such as the projection pattern diagram shown in fig. 6 according to the second embodiment of the present invention. In this embodiment, the light source unit includes a regular array composed of 3 × 3 sub-light sources, the beam splitting unit performs 3 × 3 copying beam splitting on the regular array of sub-light sources to form a 9 × 9 arranged second light beam, the scanning unit deflects 3 times along the horizontal and vertical directions, the deflection angle of each time is slightly larger than α (to avoid overlapping of light beams at adjacent boundaries), for example, a deflection sequence shown by an arrow in fig. 6, a plurality of third light beams 602, 603, 604, and 605 can be finally formed, the plurality of third light beams jointly form a projection pattern 601, and the viewing angle is improved by 2 times along two directions after multiple deflections. It is understood that the number of deflections in each direction and the sequence of deflections may be set according to actual needs, and are not limited herein.

Fig. 4 is a schematic diagram of a transmitter according to a second embodiment of the present creation. The emitter includes light source unit, scanning unit 404 and beam splitting unit 405, and light source unit is used for launching first light beam, and scanning unit 404 is used for receiving and outwards launching the second light beam after deflecting first light beam, and beam splitting unit 405 is used for receiving and forming the third light beam that the light beam quantity is more after splitting to the second light beam. After being deflected for a plurality of times by the scanning unit 404, a plurality of second light beams are formed, and accordingly, the plurality of second light beams are also split by the beam splitting unit to form a plurality of corresponding third light beams, and the combined projection pattern light beams formed by the third light beams have higher density and/or larger field angle than the second light beams.

The light source unit includes a substrate 401 and one or more sub-light sources 402 disposed on the single substrate 401 (or a multi-substrate), the sub-light sources 402 being arranged in a pattern on the substrate. The substrate 401 may be a semiconductor substrate, a metal substrate, etc., and the sub-light sources 402 may be light emitting diodes, edge emitting laser emitters, vertical cavity surface laser emitters (VCSELs), etc., and preferably, the light source unit includes a semiconductor substrate and an array VCSEL chip composed of a plurality of VCSEL sub-light sources disposed on the semiconductor substrate. The sub-light sources are used to emit light beams of any desired wavelength, such as visible light, infrared light, ultraviolet light, and the like. The light source unit emits light under modulation driving of a driving circuit (which may be part of the processing circuit 13), such as continuous wave modulation, pulse modulation, or the like. The sub-light sources 402 may also emit light in groups or in whole under the control of the driving circuit, for example, the sub-light source 402 includes a first sub-light source array 401, a second sub-light source array 402, and the like, the first sub-light source array 401 emits light under the control of the first driving circuit, and the second sub-light source array 402 emits light under the control of the second driving circuit. The arrangement of the sub light sources 402 may be a one-dimensional arrangement, a two-dimensional arrangement, a regular arrangement, or an irregular arrangement.

In one embodiment, the light source unit further includes one or more optical elements such as a lens (or a lens group), a micro lens array, and the like, for example, a lens (or a lens group) 403 is disposed between the sub-light source 402 and the scanning unit 404, and the lens 403 is used for refracting the light beam emitted from the light source to generate a converging or focusing effect so as to meet the modulation requirement of the subsequent optical elements.

The scanning unit 404 receives a first light beam from the light source, and deflects and scans the first light beam to form a second light beam. The scanning unit 404 may perform one-dimensional deflection or two-dimensional deflection on each sub-beam of the incident second light beam by diffraction, refraction, reflection, or the like, for example, a certain angle along at least one direction, so as to form the second light beam.

The beam splitting unit 405 receives the second light beam emitted from the scanning unit 404 and performs replica beam splitting on the second light beam to form a third light beam having a larger number of light beams. In one embodiment, beam splitting unit 405 performs a replicated split of the second beam to form a third beam with a higher packing density; in one embodiment, the beam splitting unit 405 performs replicated beam splitting on the second beam to form a third beam with a larger field angle; in one embodiment, the beam splitting unit 405 performs a replicated beam splitting on the second light beam to form a third light beam with higher arrangement density and larger field angle. The beam splitting unit 405 may be any optical device capable of splitting beams, such as a diffractive optical element, an optical mask, a super surface (Metasurface) optical element, and the like. Similarly to the embodiment shown in fig. 2, by setting the relationship between the deflection angle θ and the angle of view α of the third beam and the angular offset between the adjacent sub-beams as β, a comprehensive projection pattern with a higher density and a larger angle of view can be formed.

In the embodiment shown in fig. 4, a schematic diagram is schematically shown in which the scanning unit 404 deflects the first light beam by two angles in one direction, wherein the first and second light beams can be regarded as being formed by 0 degree deflection (a solid line between the scanning unit 404 and the beam splitting unit 405 in the figure); the second and second light beams are formed by the scanning unit 404 deflecting the first light beam by a small angle θ (shown as a dotted line between the scanning unit 404 and the beam splitting unit 405). The angle θ is smaller than an included angle θ < β between two adjacent sub-beams in the third beam, so that a comprehensive projection pattern formed by at least two third beams 406 and 407 formed after at least two scans has a higher density than a projection pattern corresponding to the third beam without the scanning unit 404, thereby improving the measurement resolution of the measurement system.

In one embodiment, the deflection angles θ may be sequentially set toWith n scans, the scan angle is increased successivelyThereby increasing the overall projected pattern density by a factor of n. In one embodiment, the deflection angles θ may be sequentially set toIn one embodiment, the deflection angle is set to exceed the viewing angle of the second beam by α, which only increases the viewing angle of the projection pattern, as also shown in FIG. 5, where 504 in FIG. 5 is the scanning unit and 505 is the beam splitting unit, similar to the previous analysis, thereby also forming the large field of view projection pattern as shown in FIG. 6.

It can be understood that, in the embodiments shown in fig. 2 and fig. 4, the beam splitting unit and the scanning unit are respectively provided in opposite arrangement to achieve similar functions, in some embodiments, a first beam splitting unit and a second beam splitting unit may be respectively arranged before and after the scanning unit to achieve more complex functions, or a first scanning unit and a second scanning unit may be respectively arranged before and after the beam splitting unit, and similarly, the number and relative position arrangement relationship of the beam splitting unit and the scanning unit may be reasonably set according to actual needs. All falling within the scope of protection of the present invention.

In the above embodiments, the beam splitting unit and the scanning unit are configured reasonably in function to form high-density and/or large-field projection. However, the need to integrate multiple optics into a single emitter creates undoubted manufacturing challenges. To address this problem, the present inventor also provides an integrated beam splitting scanning unit.

FIG. 7 is a schematic diagram of an integrated beam splitting scanning unit according to one embodiment of the present creation. The integrated beam splitting scanning unit can be used in the emitters in the embodiments shown in fig. 1-6, and can also be used in any other desired device. The integrated beam splitting and scanning unit is used for receiving the first light beam, splitting and scanning the light beam to form a third light beam. The integrated beam splitting scanning unit includes a first transparent substrate 701, a second transparent substrate 702, a liquid crystal layer 703, and a beam splitting unit 704 disposed on the first transparent substrate and/or the second transparent substrate. The liquid crystal layer 703 is used to deflect an incident light beam to realize scanning, and the beam splitting unit 704 is used to split the incident light beam. The first transparent substrate 701 and the second transparent substrate 702 may be disposed in parallel and opposite to each other. The liquid crystal layer 703 is installed between the first transparent substrate 701 and the second transparent substrate 702, and the substrates may function to protect the liquid crystal layer. In addition, other functional layers, such as positive and negative electrode layers, can be added in the liquid crystal layer between the two substrates according to requirements, and the positive and negative electrode layers are arranged on two sides of the liquid crystal layer; a polarizing layer or the like may be added to the outer surface or the inner surface of the substrate.

In one embodiment, the integrated beam splitting scanning unit includes a support 705 disposed between the first transparent substrate 701 and the second transparent substrate 702, the support 705 being disposed around the liquid crystal layer to protect the liquid crystal layer while functioning to support the first transparent substrate 701 and the second transparent substrate 702. The support may be made of any material, such as a semiconductor material, an adhesive, etc.

In one embodiment, the beam splitting unit 704 includes one or a combination of diffractive optical elements such as a diffraction grating and a binary grating, and a super surface (Metasurface) optical element, that is, a diffractive optical microstructure and a super surface structure are formed on the surface of a transparent substrate by means of photolithography, etching, and the like, so that high integration of the beam splitting unit and the scanning unit is achieved. The diffractive optical microstructure, the super surface structure, may be formed on a single surface or both surfaces of the first transparent substrate 701 and/or the second transparent substrate according to actual needs. Preferably, the diffractive optical microstructure is formed on an inner surface of a single transparent substrate, which can be effectively protected.

The present creation also provides a method of manufacturing an integrated beam splitting scanning unit, comprising the steps of:

providing a liquid crystal layer for deflecting an incident beam to realize scanning;

providing a first transparent substrate and a second transparent substrate, and generating a beam splitting unit on a single surface or two surfaces of the first transparent substrate and/or the second transparent substrate;

the liquid crystal layer is mounted between the first transparent substrate and the second transparent substrate.

For the integrated beam splitting scanning unit comprising a support, the step of mounting the support between the first transparent substrate and the second transparent substrate and at the periphery of the liquid crystal layer is further included.

For the emitter which deflects the light beam through the scanning unit to realize the large field of view projection (as shown in fig. 5, the positions of the beam splitting unit and the scanning unit are not limited, that is, the beam splitting unit can be arranged in front of or behind the scanning unit), the invention also provides a dynamic distance measuring system based on the emitter of the grouped array light source. The light source of the emitter in the system comprises an array light source, the sub light sources in the array light source are divided into a plurality of sub light source arrays, each sub light source array can be independently controlled in a grouping mode, in the aspect of spatial arrangement, the sub light source arrays can be arranged in a partitioning mode, namely each sub light source array has an independent spatial partition, the sub light source arrays can also be arranged in a crossing mode, and namely the sub light sources in different sub light source arrays are staggered in the spatial arrangement. At least one sub-light source should be included in the sub-light source array. It can be understood that when the sub-light source arrays are independently turned on, corresponding projection patterns are formed, the density of the projection patterns is related to the density and the number of the sub-light source arrays, the greater the density of the projection patterns corresponding to the sub-light source arrays with more dense arrangement is, and the greater the density of the projection patterns corresponding to the sub-light source arrays with more number is turned on. Based on the large-field-of-view projection scheme (shown in fig. 5) of the grouped array light source, the processing circuit in the measurement system can implement the following dynamic distance measurement method, which specifically includes the following steps:

s1, starting at least one first sub light source array, and forming a sparse projection pattern with a first field of view by using the scanning unit;

fig. 8 is a schematic diagram of an array light source and its sparse projection pattern according to an embodiment of the present creation. The light source in the emitter comprises a light source array 801 comprising a plurality of sub-light source arrays, such as a first sub-light source array (shown as open circles in fig. 8) and a second sub-light source array (shown as filled circles in fig. 8). First, the first sub-light source array is turned on, and the beam splitting unit and the scanning unit in the transmitter respectively split and scan (or scan first and split second) the light beam emitted by the first sub-light source array, and finally the light beam is emitted in the projection pattern 802 shown on the right side in fig. 8 and is incident into the first view field region containing the target 804. Here, the beam splitting unit is schematically shown to perform 2 × 2 replicated beam splitting on the incident beam, and the scanning unit sequentially performs 3 × 3 scanning on the incident beam to expand the field of view by 3 times in the horizontal and vertical directions, respectively.

S2, obtaining a first depth image with a first resolution, and identifying a region where a target is located; the collector collects the light signals reflected back by the target from the sparse projection pattern beam and is further computed by the processing circuitry to obtain a first depth image of a first resolution corresponding to the sparse projection pattern, and theoretically the depth value of each blob 803 can be obtained, so the depth values of the blobs will constitute the first depth image. The target in the field of view can be identified based on the depth image, for example, a pixel region where the target is located can be identified by any suitable means such as a threshold segmentation method, an edge detection method, a feature identification method, and the like.

S3, starting at least one second sub-light source array, forming a dense projection pattern with a second field of view by using the scanning unit, and calculating a second depth image with a second resolution; because the target is identified and the pixel region where the target is located in the previous step, generally speaking, the movement of the target is not too large, meanwhile, the interval between two adjacent measurements is very short, and it can be considered that the target position is unchanged within the time of the two adjacent measurements, therefore, during the measurement, the scanning unit can only form the projection pattern of the second field of view, which is smaller than the first field of view, containing the target region, and simultaneously can turn on more sub-light source arrays than in the step S1 to form a dense projection pattern with a higher relative light beam arrangement density, and based on the dense projection pattern, the collector can obtain effective data containing more spots of the target to calculate a depth image with a higher resolution, so as to realize high-resolution measurement of only the target region. It is to be understood that the resolution generally refers to the number of pixels of the effective depth values, and the resolution is higher for a larger number of pixels of the effective depth values, so that the second resolution is higher than the first resolution. For example, fig. 9 is a schematic diagram of an array light source and its dense projection pattern according to an embodiment of the present invention. In the embodiment, the first array light source and the second array light source are turned on simultaneously, that is, the first sub light source array and the second sub light source array are turned on synchronously, the scanning unit only forms the projection pattern of the 2 × 2 visual field composed of the four sub visual fields 902, 903, 904 and 905 containing the target, and compared with the embodiment shown in fig. 8, the visual field is reduced, but the density of the projection pattern is increased, thereby realizing the measurement with higher resolution at lower power consumption. It can be understood that, if the light source unit includes a plurality of sub light source arrays with different arrangement densities, for example, the arrangement density of the first sub light source array is smaller than that of the second sub light source array, in this step, only the second sub light source array may be turned on, and the effect of projecting the dense projection pattern may also be achieved.

It is understood that the above embodiments are described by taking a time-of-flight distance measurement system as an example, but the related transmitter and dynamic distance measurement scheme can be applied to other measurement systems such as a structured light three-dimensional measurement system.

It will be appreciated that when the distance measuring system of the present invention is embedded in a device or hardware, corresponding structural or component changes may be made to adapt to the needs, and the nature of the system still adopts the distance measuring system of the present invention, and therefore should be considered as the scope of the present invention. The above is a further detailed description of the present creation with reference to specific/preferred embodiments, and it is not to be considered that the present creation is embodied in a limited manner to these descriptions. It will be apparent to those skilled in the art to which the present invention pertains that numerous alternatives and modifications may be made to the described embodiments without departing from the spirit of the present invention, and such alternatives and modifications are to be considered as within the scope of the present invention. In the description herein, references to the description of the term "one embodiment," "some embodiments," "preferred embodiments," "an example," "a specific example," or "some examples" or the like are intended to mean that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one embodiment or example of the invention.

In this specification, the schematic representations of the terms used above are not necessarily intended to refer to the same embodiment or example. Furthermore, the particular features, structures, materials, or characteristics described may be combined in any suitable manner in any one or more embodiments or examples. Furthermore, various embodiments or examples and features of different embodiments or examples described in this specification can be combined and combined by one skilled in the art without contradiction. Although embodiments of the present invention and their advantages have been described in detail, it should be understood that various changes, substitutions and alterations can be made herein without departing from the scope of the invention as defined by the appended claims.

Moreover, the scope of the present application is not intended to be limited to the particular embodiments of the process, machine, manufacture, composition of matter, means, methods and steps described in the specification. One of ordinary skill in the art will readily appreciate that the above-disclosed, presently existing or later to be developed, processes, machines, manufacture, compositions of matter, means, methods, or steps, that perform substantially the same function or achieve substantially the same result as the corresponding embodiments described herein may be utilized. Accordingly, the appended claims are intended to include within their scope such processes, machines, manufacture, compositions of matter, means, methods, or steps.

Claims (7)

1. An integrated beam splitting scanning unit, comprising:

a first transparent substrate and a second transparent substrate;

the liquid crystal layer is arranged between the first transparent substrate and the second transparent substrate and used for deflecting incident light beams to realize scanning;

and the beam splitting unit is arranged on the first transparent substrate and/or the second transparent substrate and is used for splitting the incident light beam.

2. The integrated beam-splitting scanning unit of claim 1, further comprising positive and negative electrode layers; wherein the positive and negative electrode layers are disposed between the first transparent substrate and the second transparent substrate.

3. The integrated beam-splitting scanning unit of claim 1, further comprising a support disposed between the first transparent substrate and the second transparent substrate.

4. The integrated beam-splitting scanning unit of claim 1, wherein the beam-splitting unit comprises microstructures formed on the first transparent substrate and/or the second transparent substrate, the microstructures comprising one or more combinations of diffraction gratings, binary gratings, and super-surface structures.

5. The integrated beam-splitting scanning unit of claim 4, wherein said microstructure is formed on an inner surface of said first transparent substrate and/or second transparent substrate.

6. The integrated beam-splitting scanning unit of claim 2, wherein said positive and negative electrode layers are disposed on either side of said liquid crystal layer.

7. The integrated beam-splitting scanning unit of claim 3, wherein said support is mounted around said liquid crystal layer.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921630308.9U CN211426798U (en) | 2019-09-27 | 2019-09-27 | Integrated beam splitting scanning unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921630308.9U CN211426798U (en) | 2019-09-27 | 2019-09-27 | Integrated beam splitting scanning unit |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN211426798U true CN211426798U (en) | 2020-09-04 |

Family

ID=72287644

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921630308.9U Active CN211426798U (en) | 2019-09-27 | 2019-09-27 | Integrated beam splitting scanning unit |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN211426798U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110658529A (en) * | 2019-09-27 | 2020-01-07 | 深圳奥锐达科技有限公司 | Integrated beam splitting scanning unit and manufacturing method thereof |

-

2019

- 2019-09-27 CN CN201921630308.9U patent/CN211426798U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110658529A (en) * | 2019-09-27 | 2020-01-07 | 深圳奥锐达科技有限公司 | Integrated beam splitting scanning unit and manufacturing method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110824490B (en) | Dynamic distance measuring system and method | |

| CN111025317B (en) | Adjustable depth measuring device and measuring method | |

| CN110658529A (en) | Integrated beam splitting scanning unit and manufacturing method thereof | |

| WO2022021797A1 (en) | Distance measurement system and distance measurement method | |

| CN110716190A (en) | Transmitter and distance measurement system | |

| CN110596721B (en) | Flight time distance measuring system and method of double-shared TDC circuit | |

| CN110596722B (en) | System and method for measuring flight time distance with adjustable histogram | |

| CN110716189A (en) | Transmitter and distance measurement system | |

| WO2021072802A1 (en) | Distance measurement system and method | |

| US11435446B2 (en) | LIDAR signal acquisition | |

| WO2021212915A1 (en) | Laser distance measuring device and method | |

| CN110596723B (en) | Dynamic histogram drawing flight time distance measuring method and measuring system | |

| CN111123289B (en) | Depth measuring device and measuring method | |

| CN109343070A (en) | Time flight depth camera | |

| CN105143820A (en) | Depth scanning with multiple emitters | |

| CN110780312B (en) | Adjustable distance measuring system and method | |

| CN111175769B (en) | Off-axis scanning distance measuring system | |

| CN110244318B (en) | 3D imaging method based on asynchronous ToF discrete point cloud | |

| CN212135134U (en) | 3D imaging device based on time flight | |

| CN211148917U (en) | Distance measuring system | |

| WO2020221188A1 (en) | Synchronous tof discrete point cloud-based 3d imaging apparatus, and electronic device | |

| CN111427230A (en) | Imaging method based on time flight and 3D imaging device | |

| CN109283508A (en) | Flight time calculation method | |

| CN211148903U (en) | Transmitter and distance measurement system | |

| CN110441785A (en) | Time flying distance measuring system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |