CN211070587U - Pneumatic motor type flexible spray gun for liquid coating - Google Patents

Pneumatic motor type flexible spray gun for liquid coating Download PDFInfo

- Publication number

- CN211070587U CN211070587U CN201921650375.7U CN201921650375U CN211070587U CN 211070587 U CN211070587 U CN 211070587U CN 201921650375 U CN201921650375 U CN 201921650375U CN 211070587 U CN211070587 U CN 211070587U

- Authority

- CN

- China

- Prior art keywords

- barrel

- pneumatic motor

- liquid coating

- motor

- spray gun

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Nozzles (AREA)

Abstract

The utility model relates to a flexible spray gun of pneumatic motor formula liquid coating, including pneumatic motor shower nozzle, barrel and righting mechanism, the one end installation pneumatic motor shower nozzle of barrel, outside liquid coating supply apparatus is connected to the other end, righting mechanism one end be connected with pneumatic motor shower nozzle and barrel respectively, the other end supports in the inner wall of treating the spraying pipe fitting, compare with prior art, the utility model has the advantages of be applicable to different pipe diameters return bends and spraying high quality.

Description

Technical Field

The utility model relates to a pipeline undercoating technique especially relates to a flexible spray gun of pneumatic motor formula liquid coating.

Background

With the development of economic technology, higher requirements are put on corrosion prevention of pipelines, and the aim of long-acting protection is to be achieved in a severe environment, and the most basic condition is to increase the thickness of the corrosion prevention layer.

The coating in the pipeline is corroded by corrosive media, physical dissolution and swelling can be generated, the corrosive media permeate and diffuse in the coating, the coating is caused to generate bubbling, stripping and cracking, the corrosive media permeate the surface of the protected metal, the corrosive media can react with the metal to generate corrosion products, and the coating is caused to foam and strip and loses the anticorrosion effect. Such damage is most likely to occur with conventional thin coatings. From theory and experiments, it is proved that the time for the medium to penetrate to reach the interface of the coating and the metal matrix is proportional to the square of the thickness of the coating and inversely proportional to the diffusion coefficient of the medium. The thickness of a dry film of the decorative paint is only 80-150 mu m, the thickness of the coating in the anticorrosion industry is generally more than 200-300 mu m, the thickness of a heavy anticorrosion coating is more than 400-1000 mu m, and the thick coating provides a long-acting service life for anticorrosion engineering.

The viscosity of various heavy anti-corrosion liquid coatings is very high, the high-rotation-speed pneumatic motor spray head is generally required to be arranged, the uniform atomization of the heavy anti-corrosion liquid coatings can be realized, the high-quality spraying is realized, the high-rotation-speed pneumatic motor spray head must be always kept at the central position of a pipe fitting in the spraying process, therefore, the coating construction for the liquid coatings at home and abroad is basically aimed at the inner coating of a straight pipe line although the coating construction is applied for many years, the inner coating of a bent pipe used in many places such as a ground pipeline is difficult to realize in the spraying moving process, the pneumatic motor spray head is still kept at the central position of the pipe fitting while rotating at a high speed, and the research and the application of the inner coating of the bent pipe are relatively lacked.

Chinese utility model CN201520846513.4 discloses a heavy-calibre return bend undercoating coating equipment, including walking dolly and actuating mechanism, the coating adsorbs the storehouse, dust collector and spraying device, spraying device's rotation type spray gun sets up on the walking dolly, the walking dolly includes automobile body and gyro wheel, the equipartition is equipped with anti wheel of overturning on the gyro wheel circumference, the axis of anti wheel of overturning all is perpendicular with the axis of gyro wheel, the utility model discloses but utilize anti wheel of overturning on the gyro wheel automatically regulated walking dolly self balance at the inside walking in-process of return bend, the walking dolly utilizes spraying device to realize the coating spraying of return bend inner wall at the operation in-process, but this walking dolly can only be applicable to the pipe fitting of large pipe diameter, and can't accomplish heavy anticorrosive high viscosity liquid coating's atomizing, the anticorrosive effect of spraying is poor in hand and to the pipe diameter adaptability of pipe fitting.

SUMMERY OF THE UTILITY MODEL

The utility model aims at providing a pneumatic motor formula liquid coating flexible spray gun in order to overcome the defect that above-mentioned prior art exists.

The purpose of the utility model can be realized through the following technical scheme:

the utility model provides a flexible spray gun of pneumatic motor formula liquid coating, includes pneumatic motor shower nozzle, barrel and righting mechanism, the one end installation pneumatic motor shower nozzle of barrel, outside liquid coating supply apparatus is connected to the other end, righting mechanism one end be connected with pneumatic motor shower nozzle and barrel respectively, the other end supports in the inner wall of treating the spraying pipe fitting.

Further, the barrel be double-deck flexible barrel, including inlayer hose and outer hose, inlayer hose coaxial setting in outer hose, inlayer hose and outer hose between form annular transfer passage, inlayer hose carry liquid coating, annular transfer passage carry compressed air, carry compressed air and liquid coating simultaneously in a barrel, compact structure is simple, prevents that many conveyer pipes from removing phenomenons such as produced winding in return bend inside.

Further, the pneumatic motor shower nozzle including the shower nozzle, pneumatic motor and the connecting portion that connect gradually, the connecting portion in set up the first through-hole of being connected with the cooperation of inlayer hose and the second through-hole that sets up around first through-hole circumference, the second through-hole set up with annular transfer passage cooperation, pneumatic motor installs on connecting portion, and connect the second through-hole, the shower nozzle sets up at the pneumatic motor head, and the mid portion is equipped with hollow material chamber, the intercommunication has still evenly been seted up along the circumferencial direction to the shower nozzle a plurality of pores in material chamber still draw forth from first through-hole and pass pneumatic motor connects the material pipe in material chamber drives the shower nozzle high-speed rotation through pneumatic motor, and liquid coating throws out the atomizing through the pore because of the effect of centrifugal force, and the adhesion forms the liquid coating in the pipe fitting is inside.

Furthermore, the outer surface of the pneumatic motor is also provided with a louver, and compressed air flows into the motor through the second through hole and is exhausted from the louver to drive the pneumatic motor to rotate at a high speed.

Further, this spray gun still includes the combination joint of being connected with the barrel other end, the combination joint including mutually perpendicular set up and connect outside air feeder and feeding device's air inlet and feed inlet respectively, the air inlet set up in the side that the combination connects to communicate with the annular channel, the feed inlet set up in the port that the combination connects to communicate with the inlayer hose, guaranteed to connect double-deck barrel and absolute sealing performance simultaneously.

Further, righting the mechanism include the motor centralizer be connected with the pneumatic motor shower nozzle and the barrel centralizer be connected with the barrel, wherein, the motor centralizer include with the solid fixed ring that connecting portion cooperation was cup jointed to the fixed ring of, and a plurality of one end sets up on solid fixed ring and can follow the jack catch that its center pin that centers on drawn in or expanded, ensure the centering performance of shower nozzle, guarantee that the pneumatic motor shower nozzle keeps the central point at the pipe fitting all the time in the spraying process, guarantee the homogeneity of coating.

Further preferably, the jack catch be the claw formula flexure strip that one end was fixed on solid fixed ring, the strong point between its and the pipe fitting inner wall is located the shower nozzle rear, possesses certain compression elasticity scope, can adapt to the pipe fitting spraying of multiple specification pipe diameter.

Furthermore, the barrel centralizer comprises a pipe clamping part and a roller support, the pipe clamping part is sleeved on the outer side of the barrel, one end of the roller support is arranged on the pipe clamping part, a roller is rotatably arranged at the other end of the roller support, the roller can contact the inner wall of the pipe fitting and move along the inner wall of the pipe fitting to centralize the barrel, and the middle position of the barrel in the pipe fitting is controlled to move.

Still further preferably, the roller support sets up a plurality ofly to evenly distributed is on the circumference of pipe card portion, guarantees the stability of shower nozzle spraying walking in-process, roller support thread tightening set up in pipe card portion, can adjust centering size and clearance.

Still further preferably, the plurality of barrel centralizers are arranged along the barrel in sequence, and the plurality of barrel centralizers are used in combination, so that the spraying process is more stable.

Compared with the prior art, the utility model has the advantages of it is following:

1) the pneumatic motor spray head is directly arranged at the port of the flexible gun tube, so that the pneumatic motor spray head can reach a part needing spraying through the interior of the bent tube, meanwhile, the motor centralizer and the gun tube centralizer are arranged, the pneumatic motor spray head is guaranteed to be kept at the central position of a pipe fitting in the spraying process, and the gun tube centralizer is provided with the roller wheel support, so that the flexible gun tube can flexibly and conveniently move in the bent tube, and high-quality spraying is realized;

2) the pneumatic motor sprayer and the flexible gun barrel are small in diameter and can extend into a pipeline with a small pipe diameter, meanwhile, a plurality of claw-type elastic pieces are arranged on the motor centralizer and have a certain compression elastic range, the roller support of the gun barrel centralizer is installed through threads, the roller support can adjust centering size and gap through threads, the pneumatic motor sprayer can be suitable for spraying of pipe fittings with various pipe diameters, and the practicability is high;

3) the flexible gun barrel adopts a double-layer structure, coating and air can be simultaneously conveyed by utilizing one pipeline, the flexible gun barrel is directly connected with a pneumatic motor spray head and is more suitable for various shapes of bent pipes, and a combined joint which is matched and connected with the double-layer structure of the gun barrel ensures that the double-layer gun barrel is simultaneously connected and absolute sealing performance is ensured;

4) the driving motor in the pneumatic motor nozzle rotates at a high speed, the rotating speed can reach 20000 revolutions per minute, and even if the solid content of the heavy anti-corrosion liquid coating is more than 60%, the pneumatic motor nozzle rotating at a high speed can be used for completing good uniform atomization to perform spraying operation, so that the anti-corrosion effect after the spraying is finished is ensured.

Drawings

FIG. 1 is a schematic structural view of the spray gun of the present invention;

FIG. 2 is a schematic view of a barrel configuration;

FIG. 3 is a side view of a pneumatic motor spray head;

FIG. 4 is a schematic perspective view of a pneumatic motor spray head;

FIG. 5 is a schematic view of a connection portion;

FIG. 6 is a schematic view of the connection of the pneumatic motor spray head and the motor centralizer;

FIG. 7 is a side perspective view of the motor centralizer;

FIG. 8 is a perspective view of the motor centralizer;

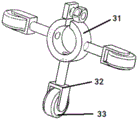

FIG. 9 is a schematic view of a barrel centralizer;

fig. 10 is a schematic structural view of the combination joint.

Wherein: 1. pneumatic motor shower nozzle, 2, motor centralizer, 3, barrel centralizer, 4, barrel, 5, built-up joint, 11, shower nozzle, 12, pneumatic motor, 13, connecting portion, 111, pore, 121, shutter window, 131, first through-hole, 132, second through-hole, 21, solid fixed ring, 22, jack catch, 31, pipe strap portion, 32, gyro wheel support, 33, gyro wheel, 41, inlayer hose, 42, skin hose, 51, air inlet, 52, feed inlet.

Detailed Description

The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

Example (b):

as shown in fig. 1, the utility model provides a flexible spray gun of pneumatic motor formula liquid coating stretches into different pipe diameters and different curvature radius's return bend, carries out liquid coating's undercoating operation, the utility model discloses a spray gun is applicable to the liquid coating of multiple viscosity, accomplishes the liquid spraying of return bend after the sandblast. In this embodiment, this flexible spray gun of pneumatic motor formula liquid coating includes a pneumatic motor shower nozzle 1, one set of righting mechanism, double-deck flexible barrel 4 and combination interface, pneumatic motor shower nozzle 1 is installed to the one end of barrel 4, the other end and combination interface connection, input compressed air and liquid coating, righting mechanism includes a motor centralizer 2 and a plurality of barrel centralizer 3, motor centralizer 2 is used for with pneumatic motor shower nozzle 1 steady support central point in the pipe fitting, barrel centralizer 3 is used for supporting flexible barrel 4 and moves along the pipe fitting inner wall through gyro wheel 33. The spray gun can be freely bent and centered according to the bending curvature of the bent pipe to realize bent pipe spraying, and the pneumatic motor 12 rotating at high speed in the pneumatic motor spray head 1 can uniformly atomize various coatings. During the use, stretch into the return bend inside with the spray gun completely earlier, then open shower nozzle 11, retreat gradually through gyro wheel 33 on the barrel centralizer 3, accomplish the spraying of whole return bend inner wall at the in-process of retreating, the spraying is respond well, and the quality is reliable and stable.

As shown in fig. 2, the gun barrel 4 is a double-layer flexible gun barrel 4, and includes an inner hose 41 and an outer hose 42, the inner hose 41 is coaxially disposed in the outer hose 42, and an annular conveying passage is formed between the inner hose 41 and the outer hose 42 for conveying compressed air, the inner hose 41 is used for conveying liquid paint, the compressed air and the liquid paint are simultaneously conveyed to the pneumatic motor nozzle 1 through the double-layer flexible gun barrel 4, stainless steel braided metal hoses used for both the inner layer and the outer layer of the gun barrel 4 are used, the outer hose 42 is a sextuple pipe, the inner hose 41 is a binary pipe, the structure is compact, the performance is good, the hose can be bent at will according to the bending degree of the pipe, the stainless steel material of the outer hose 42 is wear-resistant and durable, the inner hose 41 is made of polytetrafluoroethylene and corrosion-resistant, and.

As shown in fig. 3, 4 and 5, in the present embodiment, the air motor shower head 1 includes a shower head 11, an air motor 12 and a connection portion 13 connected in sequence, wherein, the nozzle 11 is fixedly connected with the pneumatic motor 12, the pneumatic motor 12 is rotatably connected with the connecting part 13, the connecting part 13 is connected with the outer layer hose 42 in a matching way, a baffle is arranged between the connecting part 13 and the pneumatic motor 12, the baffle is provided with a first through hole 131 connected with the inner layer hose 41 in a matching way and second through holes 132 uniformly arranged around the circumference of the first through hole 131, the second through holes 132 are arranged in a matching way with the annular conveying channel to convey compressed air, the pneumatic motor 12 is communicated with the annular conveying channel through the second through holes 132, and the louver 121 is inclined along the outer circumference so that the compressed air flows into the motor through the second through hole 132 and is discharged from the louver 121, thereby driving the air motor 12 to rotate at a high speed. The spray head 11 is provided with a material cavity, two circles of fine holes 111 communicated with the material cavity are uniformly formed in the circumferential direction, liquid coating flows to the spray head 11 from a middle thin tube (namely a material tube) of the pneumatic motor 12, the pneumatic motor 12 rotating at a high speed drives the spray head 11 fixedly connected with the pneumatic motor to rotate, the liquid coating is thrown out and atomized through the fine holes 111 under the action of centrifugal force, and the liquid coating is adhered to the inside of a pipe fitting to form a liquid coating. The maximum rotating speed of the pneumatic motor 12 is 20000 revolutions per minute, and even if the solid content of the heavy anti-corrosion liquid coating is more than 60%, the heavy anti-corrosion liquid coating can still be well and uniformly atomized for spraying operation.

As shown in fig. 6, 7 and 8, the structure of the motor centralizer 2 is schematically illustrated, the pneumatic motor spray head 1 must be always kept at the central position of the pipe during the spraying process to ensure the uniformity of the coating, and the length of 150cm at the front end of the pneumatic motor spray head 1 is a rotating body, so that a centralizer support cannot be fixedly installed, and therefore, the motor centralizer 2 needs to be fixed at the connecting part 13 of the pneumatic motor spray head 1.

The motor centralizer 2 includes solid fixed ring 21 and a plurality of jack catch 22, jack catch 22 can be claw formula flexure strip, also can be for one end setting on solid fixed ring and can follow the rigid jack catch that its center pin that centers on draws in or expand, adopt claw formula flexure strip can make the motor centralizer possess certain compression elasticity scope, can adapt to the pipe fitting spraying of multiple specification pipe diameter, the one end of jack catch 22 is fixed to be set up in solid fixed ring 21, the other end supports forward in the pipe fitting inner wall to one side, the strong point between jack catch 22 and the pipe fitting inner wall sets up in shower nozzle 11 rear, ensure the centering performance of shower nozzle 11, guarantee that pneumatic motor shower nozzle 1 remains the central point at the pipe fitting throughout in the spraying process, guarantee the homogeneity of coating.

As shown in fig. 9, the barrel centralizer 3 comprises a pipe clamping part 31 and a roller bracket 32, and the barrel centralizer 3 is designed according to the size of the barrel 4 and is matched with the motor centralizer 2 for use, so that various performances of the pneumatic motor sprayer 1 in the spraying process and the stability of the pneumatic motor sprayer 1 in the spraying walking process are further ensured. Pipe card portion 31 is the ring that upper portion was equipped with the breach, it winds in the barrel 4 outside through the screw fixation ring in breach department, and is reliable and stable, the left side of pipe card portion 31, right side and below are installed roller bracket 32 respectively, roller bracket 32's one end is passed through the screw and is set up on pipe card portion 31, can adjust centering size and clearance, the other end is equipped with gyro wheel 33, gyro wheel 33 moves along the pipe fitting inner wall, right barrel 4, and control barrel 4 intermediate position in the pipe fitting removes, can be according to the length of pipe fitting during the use, 3 jointly uses of a plurality of barrel centralizers, make the spraying process more stable.

As shown in fig. 10, the combination joint 5 is connected to the other end of the barrel 4, and includes an air inlet 51 and an air inlet 52 which are vertically arranged, and simultaneously connects the inner hose 41 and the outer hose 42, the air inlet 51 is arranged at the side of the combination joint 5 and is communicated with the annular channel for conveying compressed air, and the air inlet 52 is arranged at the end of the combination joint 5 and is communicated with the inner hose 41 for conveying liquid paint, thereby ensuring simultaneous connection of the double-layered barrel 4 and absolute sealing performance.

In the above embodiment, for example, the pneumatic motor 12 may also adopt other structures commonly used in the art for realizing the rotary connection with the connecting portion and the rotation driven by the compressed air. And the rest of the functional components, if not specifically stated, are all conventional components in the art for realizing the corresponding functions.

While the invention has been described with reference to specific embodiments, the invention is not limited thereto, and those skilled in the art can easily conceive of various equivalent modifications or substitutions within the technical scope of the invention. Therefore, the protection scope of the present invention shall be subject to the protection scope of the claims.

Claims (10)

1. The utility model provides a flexible spray gun of pneumatic motor formula liquid coating, its characterized in that includes pneumatic motor shower nozzle (1), barrel (4) and rights mechanism, the one end installation pneumatic motor shower nozzle (1) of barrel (4), outside liquid coating supply apparatus is connected to the other end, right mechanism one end be connected with pneumatic motor shower nozzle (1) and barrel (4) respectively, the other end supports in the inner wall of waiting to spray the pipe fitting.

2. An air motor type flexible spray gun for liquid coating material according to claim 1 characterized in that said gun barrel (4) is a double layer flexible gun barrel (4) comprising an inner layer hose (41) and an outer layer hose (42), said inner layer hose (41) being coaxially disposed within said outer layer hose (42), said inner layer hose (41) and said outer layer hose (42) forming an annular delivery passage therebetween, said inner layer hose (41) delivering liquid coating material, said annular delivery passage delivering compressed air.

3. An air motor liquid coating material flexible spray gun as claimed in claim 2, the pneumatic motor nozzle (1) comprises a nozzle (11), a pneumatic motor (12) and a connecting part (13) which are connected in sequence, a first through hole (131) which is matched and connected with the inner layer hose (41) and a second through hole (132) which is arranged around the circumference of the first through hole (131) are arranged in the connecting part (13), the second through hole (132) is matched with the annular conveying channel, the pneumatic motor (12) is arranged on the connecting part (13), and is connected with the second through hole (132), the spray head (11) is arranged at the head part of the pneumatic motor (12), and the middle part is provided with a hollow material cavity, the nozzle is further uniformly provided with a plurality of fine holes (111) communicated with the material cavity along the circumferential direction, and a material pipe which penetrates through the pneumatic motor (12) and is connected with the material cavity is further led out from the first through hole (131).

4. An air motor type flexible spray gun for liquid coating material according to claim 3 characterized in that said air motor (12) is further provided with louvers (121) on its outer surface.

5. An air motor type flexible spray gun for liquid coating material according to claim 2, characterized in that it further comprises a combination joint (5) connected to the other end of the gun barrel (4), said combination joint (5) comprising an air inlet (51) and a feed inlet (52) arranged perpendicular to each other and connected to an external air supply device and a supply device, respectively, said air inlet (51) being arranged at the side of the combination joint (5) and communicating with the annular passage, said feed inlet (52) being arranged at the end of the combination joint (5) and communicating with the inner hose (41).

6. A pneumatic motor-type flexible spray gun for liquid coating material according to claim 1, characterized in that said centering mechanism comprises a motor centralizer (2) connected to the pneumatic motor nozzle (1) and a barrel centralizer (3) connected to the barrel (4), wherein said motor centralizer (2) comprises a fixed ring (21) fitted to the connection portion (13), and a plurality of jaws (22) having one end arranged on the fixed ring (21) and capable of being closed or opened along the central axis around which it is wound.

7. An air motor type flexible spray gun for liquid coating material according to claim 6 characterized in that said claw (22) is a claw type elastic piece with one end fixed on the fixed ring (21), and the supporting point between the claw type elastic piece and the inner wall of the pipe fitting is located at the rear of the spray head.

8. A pneumatic motor-type flexible spray gun for liquid coating material according to claim 6 wherein said barrel centralizer (3) comprises a tube-engaging portion (31) and a roller support (32), said tube-engaging portion (31) being fitted around the outside of the barrel (4), said roller support (32) having one end mounted to the tube-engaging portion (31) and the other end rotatably mounted with a roller (33), said roller (33) being adapted to contact and move along the inside wall of the tube.

9. An air motor type flexible spray gun for liquid coating material according to claim 8, characterized in that said roller bracket (32) is provided in plurality and uniformly distributed on the circumference of the pipe clamp portion (31), and said roller bracket (32) is screw-fixed on the pipe clamp portion (31).

10. An air-powered motor-driven flexible spray gun for liquid coating materials as claimed in claim 8, characterized in that said barrel centralizer (3) is provided in a plurality in succession along the barrel (4).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921650375.7U CN211070587U (en) | 2019-09-30 | 2019-09-30 | Pneumatic motor type flexible spray gun for liquid coating |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921650375.7U CN211070587U (en) | 2019-09-30 | 2019-09-30 | Pneumatic motor type flexible spray gun for liquid coating |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN211070587U true CN211070587U (en) | 2020-07-24 |

Family

ID=71633250

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921650375.7U Active CN211070587U (en) | 2019-09-30 | 2019-09-30 | Pneumatic motor type flexible spray gun for liquid coating |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN211070587U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113245114A (en) * | 2021-05-27 | 2021-08-13 | 上海恩耀机电有限公司 | Die inner wall spraying system of die casting equipment |

| CN117181499A (en) * | 2023-11-07 | 2023-12-08 | 山东建华阀门制造有限公司 | Automatic paint spraying equipment for valve inner surface anti-corrosion treatment |

-

2019

- 2019-09-30 CN CN201921650375.7U patent/CN211070587U/en active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113245114A (en) * | 2021-05-27 | 2021-08-13 | 上海恩耀机电有限公司 | Die inner wall spraying system of die casting equipment |

| CN117181499A (en) * | 2023-11-07 | 2023-12-08 | 山东建华阀门制造有限公司 | Automatic paint spraying equipment for valve inner surface anti-corrosion treatment |

| CN117181499B (en) * | 2023-11-07 | 2024-02-27 | 山东建华阀门制造有限公司 | Automatic paint spraying equipment for valve inner surface anti-corrosion treatment |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN211070587U (en) | Pneumatic motor type flexible spray gun for liquid coating | |

| CN110560303B (en) | Pipe diameter self-matching type pipeline inner wall atomizing and spraying device | |

| US20210308700A1 (en) | Tool for holding a spray painting instrument for painting an internal surface of a pipe | |

| US4337723A (en) | Pipe interior surface coating device | |

| US3606862A (en) | Pipe lining apparatus | |

| CN101893153B (en) | Bend antiseptic finish processing device | |

| JPS6240075B2 (en) | ||

| US2859728A (en) | Spray nozzle | |

| CN106925476B (en) | A kind of pipeline inside and outside coating all-in-one machine | |

| CN210994940U (en) | Aluminum alloy pipeline inner wall spraying device | |

| CN105834043A (en) | Inner hole thermal spraying device and method | |

| CN113600389B (en) | Robot spraying apparatus for producing | |

| CN104989078B (en) | Orientation feed paint for wall rotary broom | |

| CN207929455U (en) | A kind of pipeline spray equipment | |

| CN104858112B (en) | Orientation feed top coat rotary broom | |

| CN201795228U (en) | Anti-corrosion bent pipe processing equipment | |

| CN209849152U (en) | Liquid coating spraying device for machining inner wall of bent pipe | |

| CN209138952U (en) | The outer surface rotary spraying polyureas device of the long flexible cable of bridge | |

| CN208527115U (en) | A kind of pipe coating device | |

| CN112354708A (en) | Pipeline inner wall spraying device | |

| CN110605669A (en) | Multi-station flexible rotary sand blasting device | |

| CN218690820U (en) | Steel pipe inner wall spraying device | |

| CN205472035U (en) | Automatic pipe feeding mechanism and use this pipe feeding mechanism's intraductal spraying device | |

| CN210819159U (en) | Multi-station flexible rotary sand blasting device | |

| CN212092920U (en) | Spraying device of pipeline anticorrosive paint |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20211215 Address after: 200941 No. 669 Lok Lok Road, Pu Pu Industrial Park, Shanghai, Baoshan District Patentee after: SHANGHAI TUBE-COTE PETROLEUM PIPE COATING Co.,Ltd. Address before: 200941 No. 669 Lok Lok Road, Pu Pu Industrial Park, Shanghai, Baoshan District Patentee before: SHANGHAI TUBE-COTE PETROLEUM PIPE COATING Co.,Ltd. Patentee before: Shanghai Hailong petroleum pipe Research Institute |