CN210706677U - Surface pattern pressing equipment for aluminum profile machining - Google Patents

Surface pattern pressing equipment for aluminum profile machining Download PDFInfo

- Publication number

- CN210706677U CN210706677U CN201921188034.2U CN201921188034U CN210706677U CN 210706677 U CN210706677 U CN 210706677U CN 201921188034 U CN201921188034 U CN 201921188034U CN 210706677 U CN210706677 U CN 210706677U

- Authority

- CN

- China

- Prior art keywords

- fixed mounting

- push rod

- electric push

- fixedly mounted

- slide rail

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

Abstract

The utility model discloses a surface decorative pattern pressing equipment is used in aluminium alloy processing, including last mounting panel, work platform and base, the top fixed mounting of base has damper, damper's top fixed mounting has work platform, the all fixed mounting in both sides at work platform top has the support column, the top fixed mounting of support column has last mounting panel, one side fixed mounting at last mounting panel top has second electric putter, the intermediate position department of going up the mounting panel has seted up the opening, second electric putter's output fixed mounting has first electric putter, first electric putter's output fixed mounting has the casing, the inside fixed mounting of casing has the motor, the output movable mounting of motor has the decorative pattern mould. The utility model discloses a be provided with a series of structures and make this device can effectually adjust the decorative pattern mould in the use, and be convenient for change the decorative pattern mould, optimize the use.

Description

Technical Field

The utility model relates to an aluminium alloy processing technology field specifically is an aluminium alloy processing is with surperficial decorative pattern suppression equipment.

Background

Along with the continuous development of the times, the aluminum profile is very widely applied to the life of people, the types of the aluminum profiles are gradually increased, the surface of the aluminum profile needs to be subjected to pattern pressing when the aluminum profile is processed, the aluminum profile needs to be applied to surface pattern pressing equipment for aluminum profile processing when the pattern pressing is carried out, the aluminum profile is not convenient to adjust when the surface pattern pressing equipment for aluminum profile processing is used, and a mold for pressing patterns is not convenient to replace, so that the surface pattern pressing equipment for aluminum profile processing is urgently needed to solve the existing problems.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide an aluminium alloy processing is with surperficial decorative pattern pressing equipment to solve the problem that proposes in the above-mentioned background art.

In order to achieve the above object, the utility model provides a following technical scheme: a surface pattern pressing device for processing aluminum profiles comprises an upper mounting plate, a working platform and a base, the top of the base is fixedly provided with a damping mechanism, the top of the damping mechanism is fixedly provided with a working platform, the two sides of the top of the working platform are both fixedly provided with supporting columns, the top of each supporting column is fixedly provided with an upper mounting plate, a second electric push rod is fixedly arranged on one side of the top of the upper mounting plate, an opening is arranged at the middle position of the upper mounting plate, the output end of the second electric push rod is fixedly provided with a first electric push rod, the output end of the first electric push rod is fixedly provided with a casing, a motor is fixedly arranged in the shell, a pattern die is movably arranged at the output end of the motor, a power plug is fixedly mounted on one side of the upper mounting plate, and a controller is fixedly mounted on one side of a support column at one end of the power plug.

Preferably, the both ends at work platform top all fixed mounting have third electric putter, the all fixed mounting of third electric putter's output has the limiting plate, first slide rail has all been seted up to the inside both sides of work platform, the bottom fixed mounting of limiting plate has the first slider of using with first slide rail mutually supporting.

Preferably, the both sides inside the opening are all fixed mounting have the third slide rail, the both sides of first electric putter are all fixed mounting have the third slider of mutually supporting the use with the third slide rail.

Preferably, the output end of the motor is fixedly provided with a connecting sleeve, the top of the pattern die is fixedly provided with a connecting piece, and the connecting sleeve is movably connected with the connecting piece through threads.

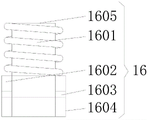

Preferably, damper includes spring, second slide rail, second slider, loop bar and movable rod, the inside both sides fixed mounting of loop bar has the second slide rail, the inside movable mounting of loop bar has the movable rod, the both sides fixed mounting of movable rod bottom has the second slider that uses with the second slide rail is mutually supported, the outside cover at movable rod top is equipped with the spring.

Preferably, the output end of the power plug is electrically connected with the input end of the controller, and the output end of the controller is electrically connected with the input ends of the first electric push rod, the second electric push rod, the third electric push rod and the motor respectively.

Compared with the prior art, the beneficial effects of the utility model are that: when the surface pattern pressing equipment for aluminum profile machining is used, the motor can drive the pattern die to rotate, the angle of a required pressed pattern can be adjusted, then the first electric push rod is pushed by the second electric push rod, the third sliding blocks at two ends of the first electric push rod can slide on the third sliding rails at two ends of the opening, the position of the pattern die in the horizontal direction is adjusted, so that a plurality of patterns can be pressed on an aluminum profile, then the utility model has the damping function through the damping mechanism, when the pattern on the surface of the aluminum profile is pressed, the working platform can press the movable rod in the damping mechanism, the second sliding blocks at two sides of the movable rod can slide in the second sliding rails, the spring can be compressed at the same time, the spring can generate a reverse acting force to damp the utility model, and then the limiting plate can be driven to move through the third electric push rod, the limiting plate can drive first slider and move in first slide rail, then the limiting plate can fix spacingly to the aluminium alloy, avoids the condition that the aluminium alloy shifted to appear when pressing aluminium alloy surface decorative pattern, rotates through the decorative pattern mould at last, and under the effect of screw thread, the connecting piece on the decorative pattern mould can be followed the link and sheathe in the separation to the staff of being convenient for changes the decorative pattern mould, so that the decorative pattern of difference to the aluminium alloy suppression.

Drawings

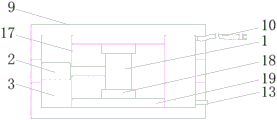

Fig. 1 is a schematic structural view of the present invention;

fig. 2 is a front view of the present invention;

fig. 3 is a top view of the present invention;

fig. 4 is an enlarged view of the structure at a in fig. 1 according to the present invention;

fig. 5 is a schematic structural view of the damping mechanism of the present invention.

In the figure: 1. a first electric push rod; 2. a second electric push rod; 3. an upper mounting plate; 4. a support pillar; 5. a pattern mold; 6. a limiting plate; 7. a third electric push rod; 8. a working platform; 9. a base; 10. a power plug; 11. a housing; 12. a motor; 13. a controller; 14. a first slider; 15. a first slide rail; 16. a damping mechanism; 1601. a spring; 1602. a second slide rail; 1603. a second slider; 1604. a loop bar; 1605. a movable rod; 17. an opening; 18. a third slider; 19. a third slide rail; 20. connecting sleeves; 21. a connecting member; 22. and (4) threading.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

In the description of the present invention, it should be noted that the terms "upper", "lower", "inner", "outer", "front end", "rear end", "both ends", "one end", "the other end" and the like indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, and are only for convenience of description and simplification of description, but do not indicate or imply that the device or element to which the reference is made must have a specific orientation, be constructed in a specific orientation, and be operated, and thus, should not be construed as limiting the present invention. Furthermore, the terms "first" and "second" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance.

In the description of the present invention, it is to be noted that, unless otherwise explicitly specified or limited, the terms "mounted," "disposed," "connected," and the like are to be construed broadly, and for example, "connected" may be either fixedly connected or detachably connected, or integrally connected; can be mechanically or electrically connected; they may be connected directly or indirectly through intervening media, or they may be interconnected between two elements. The specific meaning of the above terms in the present invention can be understood in specific cases to those skilled in the art.

Referring to fig. 1-5, the present invention provides an embodiment: a surface pattern pressing device for processing aluminum profiles comprises an upper mounting plate 3, a working platform 8 and a base 9, wherein a damping mechanism 16 is fixedly mounted at the top of the base 9, when a pattern mold 5 presses patterns, the damping mechanism 16 can be pressed down, then the damping mechanism 16 can buffer and damp the aluminum profile, the working platform 8 is fixedly mounted at the top of the damping mechanism 16, supporting columns 4 are fixedly mounted at both sides of the top of the working platform 8, an upper mounting plate 3 is fixedly mounted at the top of the supporting columns 4, a second electric push rod 2 is fixedly mounted at one side of the top of the upper mounting plate 3, the type of the second electric push rod 2 can be NKLA24, the aluminum profile pressing device belongs to the prior art, an opening 17 is formed in the middle position of the upper mounting plate 3, a first electric push rod 1 is fixedly mounted at the output end of the second electric push rod 2, and the type of the first electric push rod 1 can, belongs to the prior art, the second electric push rod 2 can drive the first electric push rod 1 to move horizontally in the opening 17, thereby adjusting the pattern mold 5 horizontally, when the pattern pressing is needed, the worker can utilize the first electric push rod 1 to drive the pattern mold 5 to press down, thereby performing the pattern pressing, the output end of the first electric push rod 1 is fixedly provided with a casing 11, a motor 12 is fixedly arranged in the casing 11, the model of the motor 12 can be Y90S-2, which belongs to the prior art, the output end of the motor 12 is movably provided with the pattern mold 5, the motor 12 can drive the pattern mold 5 to rotate, thereby adjusting the angle of the pattern mold 5, when the pattern mold 5 needs to be replaced, only the pattern mold 5 needs to rotate, thereby the pattern mold 5 can be detached and replaced, go up one side fixed mounting of mounting panel 3 and have power plug 10, have controller 13 through 4 one sides fixed mounting of support column of power plug 10 one end, this controller 13's model can be MAM-330, belongs to prior art, and the staff can be right through controller 13 the utility model discloses control.

Further, the both ends of 8 tops of work platform all fixed mounting have third electric putter 7, this third electric putter 7's model can be NKLA24, belong to prior art, the equal fixed mounting of output of third electric putter 7 has limiting plate 6, first slide rail 15 has all been seted up to the inside both sides of work platform 8, the bottom fixed mounting of limiting plate 6 has the first slider 14 of mutually supporting the use with first slide rail 15, third electric putter 7 can promote limiting plate 6 and move, first slider 14 of limiting plate 6 bottom can move in first slide rail 15, then limiting plate 6 can carry out spacing fixed to it according to the specification of aluminium alloy, avoid when the decorative pattern suppression, the condition that the aluminium alloy shifted appears.

Furthermore, both sides inside the opening 17 are fixedly provided with third slide rails 19, both sides of the first electric push rod 1 are fixedly provided with third slide blocks 18 which are matched with the third slide rails 19 for use, when the pattern mold 5 is adjusted in the horizontal direction, the third slide blocks 18 on both sides of the first electric push rod 1 can slide in the third slide rails 19, so that the stability of the pattern mold 5 in the horizontal direction is ensured.

Further, a connecting sleeve 20 is fixedly mounted at the output end of the motor 12, a connecting piece 21 is fixedly mounted at the top of the pattern mold 5, the connecting sleeve 20 is movably connected with the connecting piece 21 through a thread 22, and when the pattern mold 5 rotates, the connecting sleeve 20 and the connecting piece 21 can be detached under the action of the thread 22.

Further, damper 16 includes spring 1601, second slide rail 1602, second slider 1603, loop bar 1604 and movable rod 1605, the inside both sides fixed mounting of loop bar 1604 has second slide rail 1602, the inside movable mounting of loop bar 1604 has movable rod 1605, the both sides fixed mounting of movable rod 1605 bottom has the second slider 1603 of mutually supporting the use with second slide rail 1602, the outside cover at movable rod 1605 top is equipped with spring 1601, when carrying out the decorative pattern suppression, movable rod 1605 can be pushed down, the second slider 1603 of movable rod 1605 both sides can slide in the inside second slide rail 1602 of loop bar 1604, spring 1601 can be compressed simultaneously, then spring 1601 can produce a reverse effort, thereby the shock attenuation has been cushioned when the decorative pattern suppression.

Further, the output end of the power plug 10 is electrically connected to the input end of the controller 13, and the output end of the controller 13 is electrically connected to the input ends of the first electric push rod 1, the second electric push rod 2, the third electric push rod 7 and the motor 12, respectively.

The working principle is as follows: the worker uses the power plug 10 to carry out external power supply, then the worker can place the aluminum profile on the working platform 8, then the worker can use the controller 13 to open the third electric push rod 7, the output end of the third electric push rod 7 can drive the limiting plate 6 to move, the first slide block 14 at the bottom of the limiting plate 6 can slide in the first slide rail 15 inside the working platform 8, so that the aluminum profile is limited and fixed by the limiting plate 6, then the worker can use the controller 13 to open the second electric push rod 2, the second electric push rod 2 can drive the first electric push rod 1 to move in the opening 17, the third slide blocks 18 at two sides of the first electric push rod 1 can slide in the third slide rail 19 in the opening 17, thereby adjusting the pattern mold 5 to a horizontal position to be used, and then the worker can use the controller 13 to open the motor 12, the motor 12 drives the pattern mold 5 to rotate, the pattern mold 5 is adjusted to a required angle, then a worker opens the first electric push rod 1 by using the controller 13, the pattern mold 5 performs pattern pressing work on the surface of the aluminum profile, and then when the pattern pressing work is required to be performed continuously, the pattern mold 5 can be adjusted to be in a horizontal position by using the second electric push rod 2 again, so that the pattern pressing work can be performed continuously, and when the pattern pressing work is performed on the surface of the aluminum profile, the working platform 8 can press down the movable rod 1605 in the damping mechanism 16, the second slide block 1603 at the bottom of the movable rod 1605 can slide in the second slide rail 1602 in the sleeve rod 1604, meanwhile, the spring 1601 at the top of the movable rod 1605 can be compressed, meanwhile, the spring 1601 can generate a reverse acting force, so that the function of buffering and damping can be performed on the surface of the aluminum profile, when different pattern molds 5 are required to be used, the staff can rotate the decorative pattern mould 5, make the connecting piece 21 at the top of decorative pattern mould 5 separate from adapter sleeve 20 under the effect of screw thread 22 to be convenient for the staff to change decorative pattern mould 5.

It is obvious to a person skilled in the art that the invention is not restricted to details of the above-described exemplary embodiments, but that it can be implemented in other specific forms without departing from the spirit or essential characteristics of the invention. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein. Any reference sign in a claim should not be construed as limiting the claim concerned.

Claims (6)

1. The utility model provides an aluminium alloy processing is with surperficial decorative pattern pressing equipment, includes mounting panel (3), work platform (8) and base (9), its characterized in that: the damping mechanism (16) is fixedly mounted at the top of the base (9), the working platform (8) is fixedly mounted at the top of the damping mechanism (16), support columns (4) are fixedly mounted at both sides of the top of the working platform (8), an upper mounting plate (3) is fixedly mounted at the top of the support columns (4), a second electric push rod (2) is fixedly mounted at one side of the top of the upper mounting plate (3), an opening (17) is formed in the middle position of the upper mounting plate (3), a first electric push rod (1) is fixedly mounted at the output end of the second electric push rod (2), a casing (11) is fixedly mounted at the output end of the first electric push rod (1), a motor (12) is fixedly mounted inside the casing (11), a pattern die (5) is movably mounted at the output end of the motor (12), a power plug (10) is fixedly mounted at one side of the upper mounting plate (3), and a controller (13) is fixedly installed on one side of the support column (4) at one end of the power plug (10).

2. The surface pattern pressing equipment for processing the aluminum profile as claimed in claim 1, is characterized in that: all fixed mounting at the both ends at work platform (8) top has third electric putter (7), the all fixed mounting of output of third electric putter (7) has limiting plate (6), first slide rail (15) have all been seted up to the inside both sides of work platform (8), the bottom fixed mounting of limiting plate (6) has first slider (14) of mutually supporting the use with first slide rail (15).

3. The surface pattern pressing equipment for processing the aluminum profile as claimed in claim 1, is characterized in that: the inside both sides of opening (17) all fixed mounting have third slide rail (19), the both sides of first electric putter (1) all fixed mounting have third slider (18) of mutually supporting the use with third slide rail (19).

4. The surface pattern pressing equipment for processing the aluminum profile as claimed in claim 1, is characterized in that: the output end of the motor (12) is fixedly provided with a connecting sleeve (20), the top of the pattern die (5) is fixedly provided with a connecting piece (21), and the connecting sleeve (20) is movably connected with the connecting piece (21) through threads (22).

5. The surface pattern pressing equipment for processing the aluminum profile as claimed in claim 1, is characterized in that: damper (16) include spring (1601), second slide rail (1602), second slider (1603), loop bar (1604) and movable rod (1605), the inside both sides fixed mounting of loop bar (1604) has second slide rail (1602), the inside movable mounting of loop bar (1604) has movable rod (1605), the both sides fixed mounting of movable rod (1605) bottom has second slider (1603) of mutually supporting the use with second slide rail (1602), the outside cover at movable rod (1605) top is equipped with spring (1601).

6. The surface pattern pressing equipment for processing the aluminum profile as claimed in claim 1, is characterized in that: the output end of the power plug (10) is electrically connected with the input end of the controller (13), and the output end of the controller (13) is electrically connected with the input ends of the first electric push rod (1), the second electric push rod (2), the third electric push rod (7) and the motor (12) respectively.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921188034.2U CN210706677U (en) | 2019-07-25 | 2019-07-25 | Surface pattern pressing equipment for aluminum profile machining |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921188034.2U CN210706677U (en) | 2019-07-25 | 2019-07-25 | Surface pattern pressing equipment for aluminum profile machining |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210706677U true CN210706677U (en) | 2020-06-09 |

Family

ID=70958423

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921188034.2U Expired - Fee Related CN210706677U (en) | 2019-07-25 | 2019-07-25 | Surface pattern pressing equipment for aluminum profile machining |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210706677U (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113071048A (en) * | 2021-04-01 | 2021-07-06 | 重庆同力塑料制品有限公司 | EPS foamed plastic forming device for inner package of household appliance |

| CN113878302A (en) * | 2021-09-14 | 2022-01-04 | 兴发铝业(成都)有限公司 | Surface pattern pressing equipment for aluminum profile machining |

| CN115157422A (en) * | 2022-05-24 | 2022-10-11 | 怀宁县鑫之港新型建材有限公司 | Surface grain pressing device for processing sintered bricks |

-

2019

- 2019-07-25 CN CN201921188034.2U patent/CN210706677U/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113071048A (en) * | 2021-04-01 | 2021-07-06 | 重庆同力塑料制品有限公司 | EPS foamed plastic forming device for inner package of household appliance |

| CN113878302A (en) * | 2021-09-14 | 2022-01-04 | 兴发铝业(成都)有限公司 | Surface pattern pressing equipment for aluminum profile machining |

| CN115157422A (en) * | 2022-05-24 | 2022-10-11 | 怀宁县鑫之港新型建材有限公司 | Surface grain pressing device for processing sintered bricks |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN210706677U (en) | Surface pattern pressing equipment for aluminum profile machining | |

| CN111496020A (en) | Bending machine convenient for adjusting bending angle | |

| CN211757778U (en) | Bending machine convenient for adjusting bending angle | |

| CN211032760U (en) | Variable center console for unmanned automobile | |

| CN211101361U (en) | Stamping mechanism of metal piece forging device | |

| CN215145190U (en) | Structure divides strip machine is dismantled with drive roller to aluminum plate production and processing | |

| CN208538459U (en) | A kind of LED display single point detection device | |

| CN206810859U (en) | A kind of screwdown gear of rolling mill | |

| CN211475387U (en) | Combined display screen for monitoring room | |

| CN214724250U (en) | Tunnel wall surface detection robot with anti-collision device | |

| CN211135072U (en) | Bending device is used in aluminium alloy processing | |

| CN211969231U (en) | Fixed slide way of automobile electric seat | |

| CN208613569U (en) | A kind of shell jig with guide function | |

| CN215617991U (en) | Tool storage device for maintenance of sleeper production equipment | |

| CN112485710A (en) | Power equipment predicts with easy to detach's circuit short circuit alarm device | |

| CN215072992U (en) | Bluetooth gateway indoor positioning implementation device | |

| CN212254620U (en) | Air conditioner load prediction device based on multi-factor chaotic support vector machine | |

| CN214290259U (en) | Stamping forming equipment for automobile hardware machined parts | |

| CN210231584U (en) | Rocking arm bores for auto parts production | |

| CN216729162U (en) | Structure of sliding plate for fixing upper and lower die seats of hollow heading machine | |

| CN212577324U (en) | Hardware processing die convenient to maintain | |

| CN214771621U (en) | Adjustable multifunctional clamp for machining | |

| CN219998626U (en) | Connector bracket for new energy automobile battery | |

| CN215619931U (en) | Stable tetrafluoro board leveling device | |

| CN212123939U (en) | EPS mould apparatus for producing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20200609 Termination date: 20210725 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |