CN210689438U - Mistake proofing frock for bolt - Google Patents

Mistake proofing frock for bolt Download PDFInfo

- Publication number

- CN210689438U CN210689438U CN201921942906.XU CN201921942906U CN210689438U CN 210689438 U CN210689438 U CN 210689438U CN 201921942906 U CN201921942906 U CN 201921942906U CN 210689438 U CN210689438 U CN 210689438U

- Authority

- CN

- China

- Prior art keywords

- fixing block

- bolt

- semi

- cylinder

- fixed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Pivots And Pivotal Connections (AREA)

Abstract

The utility model discloses a mistake proofing frock for bolt belongs to bolt detection technical field. The novel solar water heater comprises a box body, wherein a fixed shaft is fixedly arranged in the box body. The utility model discloses the main objective is through articulating mechanism, and under the connection respectively of first semicircle post and second semicircle post, make every first arc mouth and every second arc mouth open and shut mutually, when the two closed, be applicable to fixed stud's the thread part that does not, stud's two inequality long thread parts can distinguish this moment, and at the hand wheel, the dwang, the sliding block, the ball, fixed axle and articulating mechanism, detachable fixed establishment's assistance is down, make whole one end that first arc mouth and second arc mouth formed when closed and long thread end and/or short thread end be connected do not take the corresponding end of thread portion to the end, and make the mark, thereby in carrying out mechanical assembly process, avoid appearing the circumstances that the unequal long thread bolt in both sides put upside down, the adjustment time has been shortened, the work efficiency is improved.

Description

Technical Field

The utility model relates to a mistake proofing frock is used to bolt belongs to bolt detection technical field.

Background

There are many kinds of bolts, in which the stud bolt belongs to one kind of bolt, and the stud bolt has two kinds of bolts with equal length threads on both sides and bolts with unequal length threads on both sides.

When using the long thread bolted connection machinery that varies on both sides, along with the increase of production task, when the manual work was placed, can be difficult to avoid putting the both ends of the long thread bolt that varies on both sides and turning over for in carrying out mechanical assembly process, increased the time that the both ends of the long thread bolt that varies on both sides took, reduced work efficiency.

Disclosure of Invention

The utility model discloses the technical problem that will solve lies in: the utility model provides a mistake proofing frock for bolt, it has solved in carrying out mechanical assembly process, and the both ends of the long thread bolt that both sides vary are put anti-reversely, has increased the problem that the both ends of the long thread bolt that varies on both sides take time to adjust.

The utility model discloses the technical problem that will solve takes following technical scheme to realize:

the utility model provides a mistake proofing frock for bolt, includes the box, the inside fixed mounting of box has the fixed axle, the sliding block has been cup jointed through the ball on the fixed axle, the top fixed mounting of sliding block has the connecting plate, a plurality of first arcs mouth has been seted up respectively at the top of connecting plate, the top of box still is equipped with the apron, a plurality ofly and first arc mouth assorted second arc mouth have been seted up to the bottom of apron, just be connected through hinge mechanism between the one end of apron and the connecting plate, it is fixed mutually through detachable fixed establishment between the other end of apron and the connecting plate, the rotation groove has been seted up respectively on the double-phase relative lateral wall in box top, every the inside in rotation groove rotates respectively and is connected with the pivot, hinge mechanism and the equal slip of detachable fixed establishment cup joint in the pivot.

As a preferred example, the hinge mechanism includes a first semi-cylinder, a second semi-cylinder and a hinge, one end of the first semi-cylinder is fixedly connected with one end of the connecting plate, one end of the second semi-cylinder is fixedly connected with the cover plate, the first semi-cylinder and the second semi-cylinder are fixed through the hinge, and the first semi-cylinder is slidably sleeved on one of the rotating shafts.

As a preferred example, the detachable fixing mechanism comprises a first fixing block and a second fixing block, one end of the first fixing block is fixedly connected with the cover plate, the second fixing block is fixedly connected with the connecting plate, jacks are formed in the top of the first fixing block and the top of the second fixing block, the second fixing block is sleeved on another rotating shaft in a sliding mode, and the jacks on the second fixing block are not in contact with the sleeved portion of the rotating shaft and the second fixing block.

As a preferable example, one side of the sliding block is also fixedly connected with a rotating rod, and one end part of the rotating rod penetrates through the extending box body and is fixedly sleeved with a hand wheel.

The utility model has the advantages that: the utility model discloses the main objective is through articulating mechanism, and under the connection respectively of first semicircle post and second semicircle post, make every first arc mouth and every second arc mouth open and shut mutually, when the two closed, be applicable to fixed stud's the thread part that does not, stud's two inequality long thread parts can distinguish this moment, and at the hand wheel, the dwang, the sliding block, the ball, fixed axle and articulating mechanism, detachable fixed establishment's assistance is down, make whole one end that first arc mouth and second arc mouth formed when closed and long thread end and/or short thread end be connected do not take the corresponding end of thread portion to the end, and make the mark, thereby in carrying out mechanical assembly process, avoid appearing the circumstances that the unequal long thread bolt in both sides put upside down, the adjustment time has been shortened, the work efficiency is improved.

Drawings

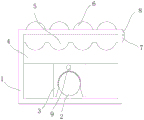

Fig. 1 is a schematic structural view of the present invention;

FIG. 2 is a schematic structural view of portion A of FIG. 1;

FIG. 3 is a schematic structural view of portion B of FIG. 1;

fig. 4 is a front view of the present invention;

fig. 5 is an internal schematic view of the present invention.

In the figure: the box body 1, the fixed axle 2, the sliding block 3, the connecting plate 4, first arc mouth 5, second arc mouth 6, first semicircle post 7, second semicircle post 8, dwang 9, hand wheel 10, rotation groove 11, pivot 12, first fixed block 13, second fixed block 14, apron 15, jack 16.

Detailed Description

In order to make the technical means, the creation features, the achievement purposes and the functions of the present invention easy to understand and understand, the present invention is further explained by combining the following specific drawings.

As shown in fig. 1-5, a mistake proofing frock is used to bolt, including box 1, the inside fixed mounting of box 1 has fixed axle 2, sliding block 3 has been cup jointed through the ball on the fixed axle 2, the top fixed mounting of sliding block 3 has connecting plate 4, a plurality of first arcs 5 have been seted up respectively at the top of connecting plate 4, box 1's top still is equipped with apron 15, a plurality of and first arcs 5 assorted second arcs 6 have been seted up to apron 15's bottom, and be connected through hinge mechanism between the one end of apron 15 and the connecting plate 4, it is fixed mutually through detachable fixed establishment between the other end of apron 15 and the connecting plate, rotation groove 11 has been seted up respectively on the double-phase relative lateral wall in box 1 top, the inside of every rotation groove 11 rotates respectively and is connected with pivot 12, hinge mechanism and detachable fixed establishment all slide and cup joint on pivot 12.

The hinge mechanism comprises a first semi-cylinder 7, a second semi-cylinder 8 and a hinge, one end of the first semi-cylinder 7 is fixedly connected with one end of the connecting plate 4, one end of the second semi-cylinder 8 is fixedly connected with the cover plate 15, the first semi-cylinder 7 and the second semi-cylinder 8 are fixed through the hinge, and the first semi-cylinder 7 is sleeved on one of the rotating shafts 12 in a sliding mode.

The detachable fixing mechanism comprises a first fixing block 13 and a second fixing block 14, one end of the first fixing block 13 is fixedly connected with a cover plate 15, the second fixing block 14 is fixedly connected with a connecting plate, jacks 16 are formed in the top of the first fixing block 13 and the top of the second fixing block 14, the second fixing block 14 is sleeved on the other rotating shaft 12 in a sliding mode, and the jacks 16 on the second fixing block 14 are not in contact with the sleeved portions of the rotating shaft 12 and the second fixing block 14.

One side of the sliding block 3 is also fixedly connected with a rotating rod 9, and one end part of the rotating rod 9 penetrates through the box body 1 and is fixedly sleeved with a hand wheel 10.

The working principle is as follows:

firstly, respectively placing each threaded bolt with unequal length on two sides in a first arc-shaped opening 5 on a connecting plate 4, then, under the assistance of the hinge joint of the second semi-cylinder 8 and the first semi-cylinder 7, the second arc-shaped opening 6 on the cover plate 15 moves towards the first arc-shaped opening 5 provided with the bolts with unequal length at two sides until the bolt with unequal length at two sides is covered by the whole formed by the second arc-shaped opening 6 on the cover plate 15 and the first arc-shaped opening 5, and the first fixing block 13 connected with the cover plate 15 is lapped on the second fixing block 14 connected with the connecting plate 4, the jacks 16 on the first fixing block 13 correspond to the jacks 16 on the second fixing block 14, and at the moment, a bolt is simultaneously inserted into the two jacks 16 until the second arc-shaped opening 6 on the cover plate 15 and the first arc-shaped opening 5 on the connecting plate 4 form a whole body which is sleeved on the threaded bolts with unequal length on two sides;

II, when the non-threaded part on the stud bolt exceeds the range closed by the first arc-shaped opening 5 and the second arc-shaped opening 6, the hand wheel 10 is rotated to drive the rotating rod 9 to rotate, so as to drive the sliding block 3 to move on the fixed shaft 2 under the assistance of the balls, further, the connecting plate 4 is moved, further, the first arc-shaped openings 5 are moved, further, the whole formed by the first semi-cylinder 7 on the connecting plate 4, the second semi-cylinder 14 on the connecting plate 4, the second semi-cylinder 8 on the cover plate 15, the first fixing block 13, the bolt and the hinge respectively slides on the rotating shaft 12 positioned in the two rotating grooves 11, further, the cover plate 15 and the second arc-shaped opening 6 on the cover plate 15 are also moved, and when the whole formed by the first arc-shaped opening 5 on the connecting plate 4 and the second arc-shaped opening 6 on the cover plate 15 when being closed moves to the corresponding non-threaded part end connected with the new threaded end and/or the short threaded end, marking the long thread end and/or the short thread end;

III, the stud bolts with different-length threads are placed on the box body 1 according to the I and the II, and the stud bolts are convenient to take when being assembled.

The basic principles and the main features of the invention and the advantages of the invention have been shown and described above. It should be understood by those skilled in the art that the present invention is not limited to the above embodiments, and that various changes and modifications may be made without departing from the spirit and scope of the invention, and such changes and modifications fall within the scope of the claimed invention. The scope of the invention is defined by the appended claims and equivalents thereof.

Claims (4)

1. The utility model provides a mistake proofing frock for bolt, includes the box, its characterized in that: the inside fixed mounting of box has the fixed axle, the sliding block has been cup jointed through the ball on the fixed axle, the top fixed mounting of sliding block has the connecting plate, a plurality of first arcs mouth have been seted up respectively at the top of connecting plate, the top of box still is equipped with the apron, a plurality ofly and first arcs mouthful assorted second arcs mouth have been seted up to the bottom of apron, just be connected through hinge mechanisms between the one end of apron and the connecting plate, it is fixed mutually through detachable fixed establishment between the other end of apron and the connecting plate, the rotation groove has been seted up respectively on the double-phase relative lateral wall in box top, every the inside in rotation groove rotates respectively and is connected with the pivot, hinge mechanisms and detachable fixed establishment all slide to cup joint in the pivot.

2. The mistake proofing tool for the bolt of claim 1, characterized in that: the hinge mechanism comprises a first semi-cylinder, a second semi-cylinder and a hinge, one end of the first semi-cylinder is fixedly connected with one end of the connecting plate, one end of the second semi-cylinder is fixedly connected with the cover plate, the first semi-cylinder and the second semi-cylinder are fixed through the hinge, and the first semi-cylinder is slidably sleeved on one rotating shaft.

3. The mistake proofing tool for the bolt of claim 1, characterized in that: the detachable fixing mechanism comprises a first fixing block and a second fixing block, one end of the first fixing block is fixedly connected with the cover plate, the second fixing block is fixedly connected with the connecting plate, jacks are formed in the top of the first fixing block and the top of the second fixing block, the second fixing block is sleeved on another rotating shaft in a sliding mode and located in a non-contact mode of the portion, sleeved with the rotating shaft, of the jack on the second fixing block, and the portion, sleeved with the second fixing block, of the rotating shaft is not in contact with the portion, sleeved with the second.

4. The mistake proofing tool for the bolt of claim 1, characterized in that: one side of sliding block still fixedly connected with dwang, the one end tip of dwang runs through and stretches out the box and fixed cover has connect the hand wheel.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921942906.XU CN210689438U (en) | 2019-11-07 | 2019-11-07 | Mistake proofing frock for bolt |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921942906.XU CN210689438U (en) | 2019-11-07 | 2019-11-07 | Mistake proofing frock for bolt |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210689438U true CN210689438U (en) | 2020-06-05 |

Family

ID=70904004

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921942906.XU Active CN210689438U (en) | 2019-11-07 | 2019-11-07 | Mistake proofing frock for bolt |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210689438U (en) |

-

2019

- 2019-11-07 CN CN201921942906.XU patent/CN210689438U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205414822U (en) | Pneumatic rotatory device that shifts of eight stations welding | |

| CN107458495A (en) | Leg travel mechanism and quadruped robot | |

| CN106976073A (en) | A kind of fruits and vegetables sorting manipulator | |

| CN107511703A (en) | A kind of hardware workpiece fixture for processing | |

| CN210689438U (en) | Mistake proofing frock for bolt | |

| CN208051111U (en) | A kind of end socket trimming device | |

| CN204221460U (en) | A kind of multi-functional milling drilling and tapping machining center is with clamping system | |

| CN206048256U (en) | A kind of industrial robot rotates jacking with the adjustable two-stage of multi-angle | |

| CN105392622B (en) | Cuber | |

| CN214417392U (en) | Clamping device for pipe fitting production cold bending machine | |

| CN212601185U (en) | Labyrinth grease lubricating grinding wheel spindle of centerless grinding machine | |

| CN210757788U (en) | Clamping mechanism capable of adjusting direction of clamping jaw | |

| CN210233030U (en) | Convertible double-arm robot | |

| CN206690085U (en) | A kind of fruits and vegetables sorting manipulator | |

| CN209793343U (en) | Glass fiber burr multi-angle processor on polymer surface | |

| CN209865478U (en) | Full-automatic self-cleaning filter device of uncapping | |

| CN108527421A (en) | A kind of multifunctional unit humanoid robot | |

| CN205520397U (en) | Automatic screw up hexagon nut's device | |

| CN107088998A (en) | The rotation contracting brake mechanism of single cylinder-actuated | |

| CN112276608B (en) | Fixed tool for die machining | |

| CN210879046U (en) | Automatic grinding device of outer lane roller slot | |

| CN207273259U (en) | A kind of innovative robot movable arm | |

| CN206832489U (en) | A kind of grain and oil detection seed clamping device | |

| CN206598299U (en) | A kind of new mechanical arm | |

| CN205310283U (en) | Grind quick -witted robot arm |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| PE01 | Entry into force of the registration of the contract for pledge of patent right |

Denomination of utility model: A mistake proof tooling for bolts Effective date of registration: 20221114 Granted publication date: 20200605 Pledgee: Shanghai Rural Commercial Bank Co.,Ltd. Jinshan sub branch Pledgor: SHANGHAI RIVET MANUFACTURE Co.,Ltd. Registration number: Y2022310000322 |

|

| PE01 | Entry into force of the registration of the contract for pledge of patent right |