CN210477349U - Mortar machine with screening function - Google Patents

Mortar machine with screening function Download PDFInfo

- Publication number

- CN210477349U CN210477349U CN201920901721.8U CN201920901721U CN210477349U CN 210477349 U CN210477349 U CN 210477349U CN 201920901721 U CN201920901721 U CN 201920901721U CN 210477349 U CN210477349 U CN 210477349U

- Authority

- CN

- China

- Prior art keywords

- organism

- screen

- side wall

- mortar

- machine body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Combined Means For Separation Of Solids (AREA)

Abstract

The utility model discloses a mortar machine with screening function, including organism, motor and waste material mouth, the organism upper surface rotates and is connected with flip, the inlet pipe link up with the organism is inside, and the left and right sides wall of organism all is provided with the spout, the inside wall of organism is connected with the slider through the spout, and is provided with the spring on the slider, the spring inboard is provided with telescopic connecting rod, and is provided with the backup pad on the spring, the backup pad upper end is provided with the screen cloth, the motor sets up the left side at the organism, the pivot is connected with the bull stick, the puddler rotates to be connected on the interior right side wall of organism, the bottom of organism is inlayed and is had the filter screen, and the lower extreme of filter screen is provided with. This mortar machine with screening function, the screen cloth that sets up are the slope form, and vibrating motor drives the screen cloth and vibrates and screen the sand grain, and qualified size's sand grain passes through the screen cloth, and unqualified size's sand grain rolls down by the screen cloth and follows the waste material mouth roll-off.

Description

Technical Field

The utility model relates to a mortar processing technology field specifically is a mortar machine with screening function.

Background

The mortar machine is a kind of mechanical equipment used for mortar preparation, put sand grain, cement and water into mortar machine and stir and make into mortar, because the sand grain contains the bigger particulate matter, influence the quality of mortar easily when making mortar, so can screen the sand grain before stirring, common mortar machine does not have the screening function, generally screen the sand grain and all accomplish through the manual work use screen cloth, then put into the mortar machine after screening sand grain efficiency too low, be unfavorable for production.

SUMMERY OF THE UTILITY MODEL

An object of the utility model is to provide a mortar machine with screening function to the common mortar machine who proposes in solving above-mentioned background does not have the screening function, and general screening sand grain all uses the screen cloth to accomplish through the manual work, then drops into the sand grain after the screening into the mortar machine in efficiency too low again, is unfavorable for the problem of production.

In order to achieve the above object, the utility model provides a following technical scheme: a mortar machine with a screening function comprises a machine body, a motor and a waste material port, wherein the upper surface of the machine body is rotatably connected with a flip, the upper surface of the flip is provided with a feeding pipe, the feeding pipe is communicated with the inside of the machine body, the left side wall and the right side wall of the machine body are respectively provided with a sliding chute, the inner side wall of the machine body is connected with a sliding block through the sliding chutes, the upper end of the sliding block is provided with a spring, the inner side of the spring is provided with a telescopic connecting rod, the upper end of the spring is provided with a supporting plate, the upper end of the supporting plate is provided with a screen, the upper end of the screen is provided with a vibrating motor, the motor is arranged at the left side of the machine body, the motor is connected with a rotating shaft, the rotating shaft is connected with a rotating rod, the rotating, the waste material mouth sets up on the right side wall of organism, and the waste material mouth sets up between the spout, the interior left side wall of organism is provided with sealed the pad, and sealed the below of pad setting at the spout, the bottom of organism is inlayed and is had the filter screen, and the lower extreme of filter screen is provided with the discharging pipe, and the discharging pipe runs through the bottom of organism simultaneously.

Preferably, the sliding blocks are in sliding connection with the inner side wall of the machine body through the sliding grooves, the sliding blocks and the sliding grooves are in one-to-one correspondence, and the number of the sliding grooves is four.

Preferably, the springs and the supporting plate form a telescopic mechanism, and the number of the springs is four.

Preferably, the screen is arranged in an inclined shape, and the lowest height of the screen is flush with the waste opening.

Preferably, the motor, the rotating shaft, the rotating rod and the stirring rod form a rotating mechanism, and the central point of the rotating shaft, the central point of the rotating rod and the central point of the stirring rod are on the same straight line.

Preferably, the diameter of the screen is greater than the outer diameter of the tapping pipe.

Compared with the prior art, the beneficial effects of the utility model are that: the mortar machine with the screening function has the advantages that,

(1) the arranged screen is inclined, the vibrating motor is arranged on the screen, when sand falls on the screen, the vibrating motor drives the screen to vibrate to screen the sand, the qualified sand passes through the screen, the unqualified sand rolls off from the screen and slides out from the waste port, and the spring arranged below the screen can reduce the influence of vibration generated by the vibrating motor on the machine body;

(2) the screen and the vibrating motor can be taken out of the machine body by moving the sliding block on the sliding chute, and then the interior of the machine body is cleaned, so that mortar is prevented from being stuck on the inner wall of the machine body and corroding the inner wall of the machine body for a long time;

(3) the discharging pipe is provided with the filter screen above, and the filter screen can filter the mortar that stirs once more, and the mortar of qualified consistency passes through the filter screen, and unqualified mortar continues to stay in the filter screen top and evenly stirs, and the quality that the assurance mortar used is to qualified outflow filter screen.

Drawings

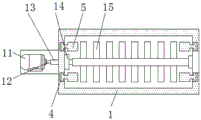

Fig. 1 is a schematic view of the front cross-sectional structure of the present invention;

FIG. 2 is a schematic top view of the cross-sectional structure of the present invention;

fig. 3 is a schematic diagram of the structure viewed from the right side of the present invention.

In the figure: 1. the device comprises a machine body, 2, a turnover cover, 3, a feeding pipe, 4, a sliding chute, 5, a sliding block, 6, a spring, 7, a telescopic connecting rod, 8, a supporting plate, 9, a screen, 10, a vibrating motor, 11, a motor, 12, a rotating shaft, 13, a rotating rod, 14, a sealing gasket, 15, a stirring rod, 16, a waste port, 17, a filter screen, 18 and a discharging pipe.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Referring to fig. 1-3, the present invention provides a technical solution: the utility model provides a mortar machine with screening function, as shown in fig. 1 and fig. 2, 1 upper surface of organism rotates and is connected with flip 2, and flip 2 upper surface is provided with inlet pipe 3, inlet pipe 3 link up with 1 inside of organism mutually, and the left and right sides wall of organism 1 all is provided with spout 4, the inside wall of organism 1 is connected with slider 5 through spout 4, and slider 5 upper end is provided with spring 6, slider 5 is sliding connection through between spout 4 and the 1 inside wall of organism, and slider 5 and spout 4 present the one-to-one relation, spout 4 is provided with four simultaneously, slide in spout 4 through slider 5, can take out screen cloth 9 from organism 1, be convenient for clear up the maintenance to 1 inside of organism.

As shown in fig. 1, spring 6 inboard is provided with telescopic link 7, and the spring 6 upper end is provided with backup pad 8, telescopic machanism is constituteed with backup pad 8 to spring 6, and spring 6 is provided with four, spring 6 can slow down the influence of the vibration that vibrating motor 10 produced to organism 1, 8 upper ends in backup pad are provided with screen cloth 9, and the screen cloth 9 upper end is provided with vibrating motor 10, screen cloth 9 sets up to the slope form, and the minimum height of screen cloth 9 flushes with waste material mouth 16 mutually, screen cloth 9 screens the sand grain, qualified sand grain can pass through screen cloth 9, unqualified sand grain follows waste material mouth 16 roll-off.

As shown in fig. 1 and 2, the motor 11 is disposed on the left side of the machine body 1, and the motor 11 is connected to the rotating shaft 12, the motor 11, the rotating shaft 12, the rotating rod 13 and the stirring rod 15 constitute a rotating mechanism, and a central point of the rotating shaft 12, a central point of the rotating rod 13 and a central point of the stirring rod 15 are on the same straight line, the motor 11 drives the stirring rod 15 to uniformly mix and stir the material through the rotating shaft 12 and the rotating rod 13, the rotating shaft 12 is connected to the rotating rod 13, the rotating rod 13 penetrates through the left side wall of the machine body 1 and the sealing gasket 14 to be connected to the stirring rod 15, the stirring rod 15 is rotatably connected to the inner right side wall of the machine body 1, and the stirring rod 15 is disposed below the.

As shown in fig. 1 and 3, waste opening 16 sets up on the right side wall of organism 1, and waste opening 16 sets up between spout 4, the interior left side wall of organism 1 is provided with sealed 14, and sealed 14 sets up the below at spout 4, the bottom of organism 1 is inlayed and is had filter screen 17, and the lower extreme of filter screen 17 is provided with discharging pipe 18, discharging pipe 18 runs through the bottom of organism 1 simultaneously, the diameter of filter screen 17 is greater than the external diameter of discharging pipe 18, filter screen 17 can filter the mortar that stirs once more, the mortar of qualified consistency passes through filter screen 17, unqualified mortar continues to remain in filter screen 17 top and evenly stirs.

The working principle is as follows: when the mortar machine with the screening function is used, a power supply is switched on, manufacturing materials of mortar are put into the machine body 1 through the feeding pipe 3 one by one, the vibration motor 10 is utilized to drive the screen 9 to carry out vibration screening on the sand, qualified sand falls into the machine body 1 through the screen 9, unqualified sand slides off the screen 9 and slides out of the waste port 16, the spring 6 can reduce the influence of vibration generated by the vibration motor 10 on the machine body 1, the telescopic connecting rod 7 can prevent the transverse deformation of the spring 6, the motor 11 is started, the motor 11 drives the rotating shaft 12 to rotate, the rotating shaft 12 drives the rotating rod 13 to rotate, the rotating rod 13 drives the stirring rod 15 to uniformly stir the materials, the sealing gasket 14 ensures the sealing performance of the machine body 1, after the mortar is stirred, a valve on the discharging pipe 18 is opened, the mortar is discharged, the mortar drops from the discharging pipe 18 into a lower collecting device after the mortar is screened, the filter screen 17 keeps the mortar with unqualified viscosity above, the mortar is continuously stirred under the action of the stirring rod 15 until the mortar is uniformly stirred to be qualified, after the mortar is manufactured, the flip cover 2 is opened, the sliding block 5, the screen 9 and the vibrating motor 10 above the sliding block are taken out from the sliding groove 4 in a sliding mode, the interior of the machine body 1 is cleaned, mortar residues are prevented from being stuck on the inner wall of the machine body 1 and corroding the inner wall of the machine body 1 for a long time, and the content which is not described in detail in the specification belongs to the prior art which is well known by technicians in the field.

The terms "central," "longitudinal," "lateral," "front," "rear," "left," "right," "vertical," "horizontal," "top," "bottom," "inner," "outer," and the like are used in the orientation or positional relationship indicated in the drawings for ease of description, but are not intended to indicate or imply that the device or element so referred to must have a particular orientation, be constructed and operated in a particular orientation, and are not to be considered limiting of the scope of the invention.

Although the present invention has been described in detail with reference to the foregoing embodiments, it will be apparent to those skilled in the art that modifications may be made to the embodiments or portions thereof without departing from the spirit and scope of the invention.

Claims (6)

1. The utility model provides a mortar machine with screening function, includes organism (1), motor (11) and waste material mouth (16), its characterized in that: the machine body (1) upper surface is rotatably connected with a flip cover (2), the upper surface of the flip cover (2) is provided with an inlet pipe (3), the inlet pipe (3) is communicated with the inside of the machine body (1), the left side wall and the right side wall of the machine body (1) are respectively provided with a sliding groove (4), the inner side wall of the machine body (1) is connected with a sliding block (5) through the sliding grooves (4), the upper end of the sliding block (5) is provided with a spring (6), the inner side of the spring (6) is provided with a telescopic connecting rod (7), the upper end of the spring (6) is provided with a supporting plate (8), the upper end of the supporting plate (8) is provided with a screen (9), the upper end of the screen (9) is provided with a vibrating motor (10), the motor (11) is arranged on the left side of the machine body (1), the motor (, and bull stick (13) run through the left side wall of organism (1) and seal up (14) and be connected with puddler (15), puddler (15) rotate to be connected on the interior right side wall of organism (1), and puddler (15) set up the below in spout (4), waste material mouth (16) set up on the right side wall of organism (1), and waste material mouth (16) set up between spout (4), the interior left side wall of organism (1) is provided with sealed pad (14), and sealed pad (14) set up the below in spout (4), the bottom of organism (1) is inlayed and is had filter screen (17), and the lower extreme of filter screen (17) is provided with discharging pipe (18), and discharging pipe (18) run through the bottom of organism (1) simultaneously.

2. A screening-capable mortar machine according to claim 1, characterized in that: the sliding block (5) is connected with the inner side wall of the machine body (1) in a sliding mode through the sliding grooves (4), the sliding block (5) and the sliding grooves (4) are in one-to-one correspondence, and the sliding grooves (4) are four in number.

3. A screening-capable mortar machine according to claim 1, characterized in that: the spring (6) and the support plate (8) form a telescopic mechanism, and four springs (6) are arranged.

4. A screening-capable mortar machine according to claim 1, characterized in that: the screen (9) is arranged to be inclined, and the lowest height of the screen (9) is flush with the waste opening (16).

5. A screening-capable mortar machine according to claim 1, characterized in that: the rotating mechanism is composed of the motor (11), the rotating shaft (12), the rotating rod (13) and the stirring rod (15), and the central point of the rotating shaft (12), the central point of the rotating rod (13) and the central point of the stirring rod (15) are on the same straight line.

6. A screening-capable mortar machine according to claim 1, characterized in that: the diameter of the filter screen (17) is greater than the outer diameter of the discharge pipe (18).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920901721.8U CN210477349U (en) | 2019-06-14 | 2019-06-14 | Mortar machine with screening function |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920901721.8U CN210477349U (en) | 2019-06-14 | 2019-06-14 | Mortar machine with screening function |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210477349U true CN210477349U (en) | 2020-05-08 |

Family

ID=70529383

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201920901721.8U Active CN210477349U (en) | 2019-06-14 | 2019-06-14 | Mortar machine with screening function |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210477349U (en) |

-

2019

- 2019-06-14 CN CN201920901721.8U patent/CN210477349U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN211801518U (en) | High-efficient type material crusher for chemical industry | |

| CN209271552U (en) | A kind of raw material grinding device of the manufacture of cement with screening function | |

| CN213408994U (en) | Interior wall cover face putty powder raw materials sieving mechanism | |

| CN210477349U (en) | Mortar machine with screening function | |

| CN210995295U (en) | Dedicated flour sieving mechanism of flour processing | |

| CN217550370U (en) | Electric automatic disintegrating slag sorting device for gold mine | |

| CN215744752U (en) | Grit screening plant is used in highway engineering construction convenient to use | |

| CN210079279U (en) | Powder raw material mixing device convenient to clean | |

| CN209052810U (en) | A kind of duck's down processing cleaning device that cleaning efficiency can be improved | |

| CN210061674U (en) | Automatic change processing of loudspeaker screen cloth and use raw materials mixing apparatus | |

| CN212882744U (en) | Mining industry processing engineering is with ball mill of automatic branch material formula | |

| CN213914022U (en) | A compounding device for aerated concrete block | |

| CN211888868U (en) | Casting sand screening plant | |

| CN212069723U (en) | Recycling solid waste resource cleaning device | |

| CN2140295Y (en) | Dual-cylinder continuous slurrying machine | |

| CN114367233A (en) | JS polymer cement base water proof coating agitated vessel | |

| CN207808045U (en) | Fitment is with vibrating lime mud agitating unit | |

| CN221432975U (en) | Cement grinding aid feeding device | |

| CN207187897U (en) | A kind of polyester resin sheet stock crushing system | |

| CN214600220U (en) | Screening device for processing refractory castable | |

| CN214345701U (en) | Raw material mixing equipment of glass beverage bottle | |

| CN220919839U (en) | Sand screening device for building construction | |

| CN217967635U (en) | Tower type mortar anti-blocking stirring device | |

| CN221499895U (en) | Filling mechanism with connect material structure | |

| CN220219054U (en) | Recycled concrete preparation facilities |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |