CN210463644U - Refrigerating system and air conditioner - Google Patents

Refrigerating system and air conditioner Download PDFInfo

- Publication number

- CN210463644U CN210463644U CN201920519028.4U CN201920519028U CN210463644U CN 210463644 U CN210463644 U CN 210463644U CN 201920519028 U CN201920519028 U CN 201920519028U CN 210463644 U CN210463644 U CN 210463644U

- Authority

- CN

- China

- Prior art keywords

- cooling section

- cooling

- control box

- refrigeration system

- electronic control

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Cooling Or The Like Of Electrical Apparatus (AREA)

Abstract

The utility model discloses a refrigerating system and air conditioner, refrigerating system includes: the heat exchanger comprises a first heat exchanger, a second heat exchanger, an electric control box assembly, a first pipeline, a second pipeline and a throttling component group. The first pipeline comprises a first cooling section for cooling the electronic control box assembly; the second pipeline comprises a second cooling section for cooling the electronic control box assembly; one end of the throttling component group is communicated with one end of the first heat exchanger through the first pipeline, and the other end of the throttling component group is communicated with the second heat exchanger through the second pipeline. Under high temperature environment, through setting up first pipeline and second pipeline, can fully dispel the heat to automatically controlled box subassembly, can guarantee that the components and parts in the automatically controlled box subassembly are stable lasting work to can prolong the life of automatically controlled box subassembly.

Description

Technical Field

The utility model belongs to the technical field of life electrical apparatus and specifically relates to a refrigerating system and have this refrigerating system's air conditioner is related to.

Background

In the related art, along with the development of air conditioning technology, the heat productivity of an electric control box assembly of an air conditioner is gradually increased, most of the electric control box assemblies are radiated by radiating fins through air convection, and the electric control box assembly is also radiated by using a refrigerant at the outlet of a condenser. However, the existing refrigerant heat dissipation method does not cool all components of the electronic control box assembly.

Wherein, can be subject to outdoor ambient temperature to great extent through outdoor air convection heat dissipation, the higher the heat dissipation efficiency that the temperature is lower, dispel the heat through condenser export refrigerant, the radiating effect can promote greatly, but the present technical level also is subject to higher high temperature weather, and to some high temperature places, temperature can exceed 60 ℃, even higher. And under the condition that the outdoor environment temperature is higher, the heat dissipation environment of the electric control box assembly is severe, and the heat dissipation effect is poor. The reliability and service life of the components are affected.

SUMMERY OF THE UTILITY MODEL

The application provides a refrigerating system, this refrigerating system can fully dispel the heat to automatically controlled box subassembly, can guarantee that the components and parts in the automatically controlled box subassembly are stable lasting work.

The utility model discloses an air conditioner is further proposed.

According to the utility model discloses a refrigerating system includes: the heat exchanger comprises a first heat exchanger, a second heat exchanger, an electric control box assembly, a first pipeline, a second pipeline and a throttling component group. The first pipeline comprises a first cooling section for cooling the electronic control box assembly; the second pipeline comprises a second cooling section for cooling the electronic control box assembly; one end of the throttling component group is communicated with one end of the first heat exchanger through the first pipeline, and the other end of the throttling component group is communicated with the second heat exchanger through the second pipeline.

According to the utility model discloses a refrigerating system, under high temperature environment, through setting up first pipeline and second pipeline, can fully dispel the heat to automatically controlled box subassembly, can guarantee that the components and parts in the automatically controlled box subassembly stabilize lasting work to can prolong the life of automatically controlled box subassembly.

In some examples of the present invention, the throttling part set includes a first throttling part, a second throttling part and a third pipeline for communicating the first throttling part and the second throttling part, the first pipeline communicates with the first throttling part, the second pipeline communicates with the second throttling part, and the third pipeline includes a third cooling section for cooling the electronic control box assembly.

In some examples of the invention, the third cooling section is disposed through the electronic control box assembly.

The utility model discloses an in some examples, automatically controlled box subassembly includes electrical components and the box body that is enclosed by a plurality of plate bodys, electrical components locates in the box body, the third pipeline is worn to locate in the box body, perhaps the third pipeline be for forming in the inside passageway of plate body.

In some examples of the present invention, the electrical control box assembly includes an electrical component and a box body enclosed by a plurality of plate bodies, the electrical component is disposed in the box body, and the first cooling section and at least one of the second cooling sections are located in the box body.

In some examples of the invention, the electrical component is in contact with the first cooling section or the second cooling section located within the cartridge body.

In some examples of the invention, at least one of the first cooling section and the second cooling section is in contact with an inner wall surface or an outer wall surface of the electronic control box assembly.

In some examples of the invention, at least one of the first cooling section and the second cooling section is an annular cooling tube, the annular cooling tube surrounds the periphery of the electronic control box assembly, and the annular cooling tube contacts with the outer peripheral wall of the electronic control box assembly.

In some examples of the present invention, at least one of the first cooling section and the second cooling section is an annular cooling pipe, the annular cooling pipe is located inside the electronic control box assembly, the annular cooling pipe is along the inner peripheral wall of the electronic control box assembly extends and contacts with the inner peripheral wall of the electronic control box assembly.

In some examples of the present invention, the first cooling section is a straight pipe, a U-shaped pipe, or an S-shaped pipe; or the second cooling section is a straight pipe, a U-shaped pipe or an S-shaped pipe.

In some examples of the invention, the first cooling section has a cross-section that is circular, elliptical, or polygonal; or the cross section of the second cooling section is circular, oval or polygonal.

In some examples of the present invention, a plurality of heat dissipating fins are provided on the first cooling section or the second cooling section.

In some examples of the present invention, the first cooling section or the second cooling section is disposed through the heat dissipating fin.

In some examples of the present invention, the heat dissipating fins are welded to the corresponding first cooling section or the second cooling section.

In some examples of the present invention, a plurality of the heat dissipating fins are spaced apart along a length direction of the corresponding first cooling section or the second cooling section.

In some examples of the present invention, at least one of the first cooling section and the second cooling section has a heat dissipating substrate.

In some examples of the present invention, the heat-dissipating substrate is an aluminum plate.

In some examples of the present invention, the electronic control box assembly includes a heat dissipating fin, a circuit board, an electrical component, and a box body, the circuit board and the electrical component are disposed in the box body, the box body the circuit board and at least one of the electrical component is disposed with the heat dissipating fin.

In some examples of the present invention, the heat dissipating fins are provided on the case body, and the heat dissipating fins are provided on an outer surface of the case body.

In some examples of the present invention, at least one fan is disposed within the electronic control box assembly.

In some examples of the present invention, at least one of the first cooling section and the second cooling section is a copper pipe or an aluminum pipe.

In some examples of the invention, the electrically controlled box assembly comprises a box body, the box body being a thermally conductive box body.

In some examples of the invention, the cartridge is an insulating cartridge.

In some examples of the invention, the electronic control box assembly has a heat-generating end, at least one of the first cooling section and the second cooling section is located in the heat-generating end.

In some examples of the present invention, the electrically controlled box assembly is filled with a thermally conductive layer.

In some examples of the invention, the heat conducting layer is an insulating layer.

In some examples of the present invention, the refrigeration system further comprises a semiconductor refrigeration sheet, wherein the cold end of the semiconductor refrigeration sheet is used for heat dissipation of the electronic control box assembly.

In some examples of the present invention, the semiconductor refrigeration sheet is disposed outside the electric control box assembly, and the semiconductor refrigeration sheet contacts with the outer peripheral wall of the electric control box assembly.

In some examples of the present invention, the semiconductor refrigeration sheet is disposed in the electronic control box assembly, the electronic control box assembly includes a heat dissipating fin, a circuit board, an electrical component and a box body, the circuit board and the electrical component are disposed in the box body, the box body the circuit board and at least one of the electrical component and the semiconductor refrigeration sheet contact.

In some examples of the present invention, the refrigeration system is an R290 refrigerant platform.

According to the utility model discloses an air conditioner includes: the heat exchanger comprises a first heat exchanger, a second heat exchanger, an electric control box assembly, a first pipeline, a second pipeline and a throttling component group. The first pipeline comprises a first cooling section for cooling the electronic control box assembly; the second pipeline comprises a second cooling section for cooling the electronic control box assembly; one end of the throttling component group is communicated with one end of the first heat exchanger through the first pipeline, and the other end of the throttling component group is communicated with the second heat exchanger through the second pipeline.

Additional aspects and advantages of the invention will be set forth in part in the description which follows and, in part, will be obvious from the description, or may be learned by practice of the invention.

Drawings

The above and/or additional aspects and advantages of the present invention will become apparent and readily appreciated from the following description of the embodiments, taken in conjunction with the accompanying drawings of which:

fig. 1 is a schematic diagram of a refrigeration system according to an embodiment of the present invention;

figure 2 is a schematic diagram of an electronic control box assembly of a refrigeration system according to an embodiment of the present invention;

fig. 3 is a schematic view of a first pipeline of a refrigeration system according to an embodiment of the present invention disposed in a box body;

fig. 4 is a top view of a first pipeline of a refrigeration system according to an embodiment of the present invention disposed within a box;

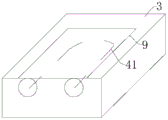

fig. 5 is a schematic view of a cassette of a refrigeration system according to an embodiment of the present invention;

fig. 6 is a schematic view of a fan of a refrigeration system according to an embodiment of the present invention disposed within a box;

fig. 7 is a top view of a fan of a refrigeration system according to an embodiment of the present invention disposed within a cassette body;

fig. 8 is a schematic view of the assembly of the first cooling section and the heat dissipating fins of the refrigeration system according to the embodiment of the present invention;

fig. 9 is a top view of a refrigeration system according to an embodiment of the present invention after assembly of a first cooling section with cooling fins;

fig. 10 is a front view of a refrigeration system according to an embodiment of the present invention after assembly of a first cooling section with cooling fins;

fig. 11 is a schematic view of a heat dissipation substrate disposed in a box body of a refrigeration system according to an embodiment of the present invention;

fig. 12 is a schematic diagram of a structure of a part of the first pipeline of the refrigeration system according to the embodiment of the invention, which is positioned outside the box body.

Reference numerals:

a refrigeration system 10;

a first heat exchanger 1;

a second heat exchanger 2;

an electric control box component 3; a case 31; a fan 32;

a first pipeline 4; a first cooling stage 41;

a second pipeline 5; a second cooling stage 51;

a throttling part group 6; a first throttle member 61; a second throttling member 62;

a third pipeline 7; a third cooling stage 71;

a compressor 20;

a four-way selector valve 30; a first interface D; a second interface E; a third interface S; and a fourth interface C.

Detailed Description

Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the same or similar elements or elements having the same or similar function throughout. The embodiments described below with reference to the drawings are exemplary only for the purpose of explaining the present invention, and should not be construed as limiting the present invention.

A refrigeration system 10 according to an embodiment of the present invention is described below with reference to fig. 1-12.

As shown in fig. 1 to 12, a refrigeration system 10 according to an embodiment of the present invention includes: the heat exchanger comprises a first heat exchanger 1, a second heat exchanger 2, an electronic control box assembly 3, a first pipeline 4, a second pipeline 5 and a throttling component group 6. The first pipeline 4 comprises a first cooling section 41 for cooling the electronic control box assembly 3. The second pipeline 5 comprises a second cooling section 51 for cooling the electronic control box assembly 3. One end of the throttling component group 6 is communicated with one end of the first heat exchanger 1 through the first pipeline 4, and the other end of the throttling component group 6 is communicated with the second heat exchanger 2 through the second pipeline 5.

In some embodiments of the present invention, the electronic control box assembly 3 may include an electrical component and a box 31 surrounded by a plurality of plate bodies, and the electrical component may be disposed in the box 31. At least one of the first cooling section 41 and the second cooling section 51 is a channel formed inside the plate body, and it should be noted that at least one of the first cooling section 41 and the second cooling section 51 is located inside the plate body.

As shown in fig. 1, the refrigeration system 10 may further include: the compressor 20 and the four-way reversing valve 30, the four-way reversing valve 30 has a first port D, a second port E, a third port S and a fourth port C. The first interface D is communicated with the compressor 20, when the refrigeration system 10 refrigerates, the first interface D is communicated with the fourth interface C, the second interface E is communicated with the third interface S, high-temperature and high-pressure gaseous refrigerants discharged by the compressor 20 enter the four-way reversing valve 30, the four-way reversing valve 30 is in a refrigeration mode, the refrigerants enter the first heat exchanger 1 after passing through the four-way reversing valve 30, the high-temperature and high-pressure gaseous refrigerants are condensed, and the refrigerant temperature is reduced. The refrigerant after the temperature reduction gets into first pipeline 4 and second pipeline 5 through first heat exchanger 1, and the lower refrigerant of temperature takes away the heat in automatically controlled box subassembly 3 in first pipeline 4 and second pipeline 5, accomplishes the cooling to the electrical components in automatically controlled box subassembly 3. The refrigerant flow direction in the whole process of the refrigeration system 10 is the compressor 20, the four-way reversing valve 30, the first heat exchanger 1, the first pipeline 4, the throttling component group 6, the second pipeline 5, the second heat exchanger 2 and the compressor 20.

When the refrigeration system 10 heats, the first interface D is communicated with the second interface E, the third interface S is communicated with the fourth interface C, the high-temperature and high-pressure gaseous refrigerant discharged by the compressor 20 enters the four-way reversing valve 30, the four-way reversing valve 30 is in a heating mode, the refrigerant enters the second heat exchanger 2 after passing through the four-way reversing valve 30, and the high-temperature and high-pressure gaseous refrigerant is condensed in the second heat exchanger 2 to complete heating of the indoor air. The temperature of the refrigerant passing through the second heat exchanger 2 is lowered. The refrigerant after the temperature reduction enters the first heat exchanger 1 through the second pipeline 5, the throttling component group 6 and the first pipeline 4, the refrigerant with lower temperature in the first pipeline 4 and the second pipeline 5 can take away the heat productivity in the electric control box assembly 3, and the cooling of electric elements in the electric control box assembly 3 is completed. The refrigerant flow direction in the entire heating process of the refrigeration system 10 is opposite to the refrigerant flow direction in the cooling process of the refrigeration system 10.

Among other things, when the refrigeration system 10 is operating in an extremely hot (i.e., high temperature) environment, such as: the refrigeration system 10 works in an environment of 60-80 ℃, when in refrigeration, the temperature of the first heat exchanger 1 (namely an outdoor unit) is high, the temperature of the external environment is high, and the heat dissipation effect of the electric control box assembly 3 is poor, when in heating, the temperature of the second heat exchanger 2 (namely an indoor unit) is high, the temperature of the external environment is high, and the heat dissipation effect of the electric control box assembly 3 is poor. This application is through arranging first pipeline 4 and second pipeline 5, the refrigerant has in first pipeline 4 and the second pipeline 5, the refrigerant in first pipeline 4 and the second pipeline 5 can carry out the heat exchange with automatically controlled box subassembly 3 simultaneously, the refrigerant in first pipeline 4 and the second pipeline 5 can take away the heat on the automatically controlled box subassembly 3, can fully dispel the heat to automatically controlled box subassembly 3 subassembly, thereby can guarantee that the components and parts in the automatically controlled box subassembly 3 stabilize lasting work, also can guarantee automatically controlled box subassembly 3 and normally work, and then can prolong the life of automatically controlled box subassembly 3.

From this, under high temperature environment, through setting up first pipeline 4 and second pipeline 5, can fully dispel the heat to automatically controlled box subassembly 3, can guarantee that the stable lasting work of components and parts in automatically controlled box subassembly 3 to can prolong the life of automatically controlled box subassembly 3.

In some embodiments of the present invention, as shown in fig. 1, the throttling component set 6 may include a first throttling component 61, a second throttling component 62, and a third pipeline 7 for communicating the first throttling component 61 and the second throttling component 62, and each of the first throttling component 61 and the second throttling component 62 may be any one of a throttle valve and an electronic expansion valve. The first pipe 4 communicates with the first throttling part 61, the second pipe 5 communicates with the second throttling part 62, and the third pipe 7 may include a third cooling section 71 for cooling the control box assembly 3. Wherein, first cooling section 41, second cooling section 51 and third cooling section 71 all have the refrigerant, and first cooling section 41, second cooling section 51 and third cooling section 71 can dispel the heat to automatically controlled box subassembly 3 simultaneously to can lower the temperature to automatically controlled box subassembly 3 better, and then can further guarantee the stable lasting work of components and parts in the automatically controlled box subassembly 3.

In some embodiments of the present invention, the third cooling section 71 can be disposed in the electronic control box assembly 3 in a penetrating manner, wherein the temperature of the refrigerant in the third cooling section 71 is lower than the temperature of the refrigerant in the first cooling section 41 and the second cooling section 51, and after the refrigerant in the throttling element group 6 enters the third cooling section 71, the refrigerant in the third cooling section 71 can cool the air in the box body 31, so as to achieve the purpose of cooling the electrical components in the electronic control box assembly 3.

The utility model discloses an in some embodiments, automatically controlled box subassembly 3 can include electrical components and the box body 31 that is enclosed by a plurality of plate bodys, electrical components locates in the box body 31, third pipeline 7 can wear to locate in the box body 31, perhaps third pipeline 7 is for forming in the inside passageway of plate body, so set up and to arrange third pipeline 7 in box body 31, can make the refrigerant in the third pipeline 7 take away the heat on the electrical components better, thereby can promote the cooling effect to electrical components, and then can make the arrangement mode of third pipeline 7 more reasonable.

In some embodiments of the present invention, the electronic control box assembly 3 may include an electrical component and a box 31 surrounded by a plurality of plate bodies, the electrical component is disposed in the box 31, and at least one of the first cooling section 41 and the second cooling section 51 is located in the box 31, for example: as shown in fig. 1, the first cooling section 41 is located inside the box 31, the second cooling section 51 is located outside the box 31, and the refrigerant in the first cooling section 41 and the second cooling section 51 can sufficiently cool the air in the box 31, so as to prevent the temperature of the electrical component from being too high, and further ensure the operational reliability of the electrical component.

In some embodiments of the present invention, the electrical component is in contact with the first cooling section 41 or the second cooling section 51 located within the box body 31. Wherein, after the low temperature refrigerant that flows passes through first cooling section 41 and second cooling section 51, first cooling section 41 and second cooling section 51 can cool off electrical components, can make electrical components cooling, and simultaneously, first cooling section 41 and second cooling section 51 can cool off the sealed air in box body 31 to can cool off other electrical components that do not contact with first cooling section 41 or second cooling section 51, and then can further guarantee the operational reliability of automatically controlled box subassembly 3.

In some embodiments of the utility model, at least one in first cooling zone 41 and the second cooling zone 51 and the internal wall face or the outer wall face contact of automatically controlled box subassembly 3, that is to say, at least one in first cooling zone 41 and the second cooling zone 51 can contact with the internal wall face of automatically controlled box subassembly 3, at least one in first cooling zone 41 and the second cooling zone 51 also can contact with the outer wall face of automatically controlled box subassembly 3, set up like this and can cool down box body 31, can realize cooling to the electrical components in box body 31.

The utility model discloses an in some embodiments, at least one in first cooling zone 41 and the second cooling zone 51 is annular cooling tube, and annular cooling tube surrounds in automatically controlled box subassembly 3's periphery, and annular cooling tube and automatically controlled box subassembly 3's periphery wall contact moreover, so set up can dispel the heat to automatically controlled box subassembly 3's box body 31 better, can cool off box body 31 fast to can promote the cooling effect to automatically controlled box subassembly 3.

In some embodiments of the present invention, at least one of the first cooling section 41 and the second cooling section 51 is an annular cooling pipe, the annular cooling pipe is located inside the electronic control box assembly 3, the annular cooling pipe extends along the inner peripheral wall of the electronic control box assembly 3, and the annular cooling pipe can contact with the inner peripheral wall of the electronic control box assembly 3, so that the first cooling section 41 and the second cooling section 51 can cool the air inside the box body 31 and the box body 31 at the same time. The cooling effect on the electronic control box assembly 3 can be improved.

In some embodiments of the present invention, the first cooling section 41 may be set to a straight pipe, a U-shaped pipe or an S-shaped pipe, or the second cooling section 51 may be set to a straight pipe, a U-shaped pipe or an S-shaped pipe, so as to increase the length of the first cooling section 41 and the second cooling section 51, and in a unit time, more heat can be taken away by the first cooling section 41 and the second cooling section 51, so as to further improve the cooling effect of the first cooling section 41 and the second cooling section 51, and further ensure the working reliability of the electronic control box assembly 3.

In some embodiments of the present invention, the cross section of the first cooling section 41 may be set to be circular, oval or polygonal, and the cross section of the second cooling section 51 may be set to be circular, oval or polygonal, so that the shapes of the first cooling section 41 and the second cooling section 51 can be more reasonable, the surface areas of the first cooling section 41 and the second cooling section 51 can be increased, and thus the heat dissipation areas of the first cooling section 41 and the second cooling section 51 can be increased.

In some embodiments of the present invention, as shown in fig. 8-10, a plurality of heat dissipation fins 8 may be disposed on the first cooling section 41 or the second cooling section 51. Wherein, radiating fin 8 can be located box body 31, radiating fin 8 and the gaseous contact of box body 31 internal seal, radiating fin 8 can cool off sealed gas, and gas after the cooling then cools off electrical components, so set up the heat radiating area that can increase first cooling section 41, second cooling section 51, can increase first cooling section 41, second cooling section 51's heat transfer capacity to can promote the cooling effect to electrical components.

The utility model discloses a some embodiments, corresponding first cooling section 41 or second cooling section 51 wear to locate radiating fin 8, set up like this and can reduce first cooling section 41, second cooling section 51 and radiating fin 8's whole volume, can reduce the shared space of first cooling section 41, second cooling section 51 and radiating fin 8.

In some embodiments of the present invention, the heat dissipating fin 8 is welded to the corresponding first cooling section 41 or second cooling section 51, and the heat dissipating fin 8 can be reliably assembled to the first cooling section 41 or second cooling section 51 by such a configuration, so that the heat dissipating fin 8 can be prevented from being separated from the first cooling section 41 or second cooling section 51, and the positional stability of the heat dissipating fin 8 can be ensured.

In some embodiments of the present invention, as shown in fig. 8 and 9, the plurality of heat dissipation fins 8 are arranged along the length direction of the corresponding first cooling section 41 or the second cooling section 51 at intervals, so that the plurality of heat dissipation fins 8 can be prevented from being closely attached together, and the surface area of each heat dissipation fin 8 can be ensured to be in contact with the air, so as to ensure the heat dissipation area of the plurality of heat dissipation fins 8, and further ensure the heat dissipation effect of the plurality of heat dissipation fins 8.

In some embodiments of the present invention, as shown in fig. 11, at least one of the first cooling section 41 and the second cooling section 51 has a heat dissipating substrate 9. Wherein, heat dissipation substrate 9 can with the electrical components direct contact in the box body 31 to can cool off the electrical components of contacting with heat dissipation substrate 9, and then can guarantee electrical components's operational reliability better.

The utility model discloses an in some embodiments, heat dissipation base plate 9 can set up to aluminum plate, so set up can promote heat conductivility of heat dissipation base plate 9, can promote heat dissipation base plate 9's cooling capacity to, aluminum plate's quality is light, can reduce heat dissipation base plate 9's weight, thereby can realize heat dissipation base plate 9's lightweight design.

In some embodiments of the present invention, the electronic control box assembly 3 may include: radiating fin 8, the circuit board, electrical components and box body 31, circuit board and electrical components locate in box body 31, at least one among circuit board and the electrical components is equipped with radiating fin 8, wherein, radiating fin 8 has heat dispersion, when radiating fin 8 sets up simultaneously at box body 31, when circuit board and electrical components are gone up, radiating fin 8 can be to box body 31, circuit board and electrical components cool off, can take away the heat on box body 31, circuit board and the electrical components fast, thereby can be better to box body 31, circuit board and electrical components cool down.

The utility model discloses an in some embodiments, can be equipped with radiating fin 8 on box body 31, radiating fin 8 can locate the surface of box body 31, and wherein, radiating fin 8 can carry out the heat exchange with box body 31, and radiating fin 8 can take away the heat on the box body 31 to can reach the work purpose to the box body 31 cooling.

In some embodiments of the present invention, as shown in fig. 6 and 7, at least one fan 32 may be disposed within the electronic control box assembly 3. Wherein, when fan 32 rotated, fan 32 can drive the interior air current of box body 31, can strengthen the heat exchange of gas, electrical components in cooling zone and the box body 31 to can reduce electrical components's temperature more fast, and then can promote the radiating effect to electrical components.

The utility model discloses an in some embodiments, at least one in first cooling zone 41 and the second cooling zone 51 is copper pipe or aluminum pipe, and the thermal conductivity of copper pipe or aluminum pipe is good, so set up the heat conduction effect that can promote first cooling zone 41 and second cooling zone 51, can promote the heat transfer capacity of first cooling zone 41 and second cooling zone 51 to can promote the cooling efficiency of first cooling zone 41 and second cooling zone 51.

In some embodiments of the present invention, the electronic control box assembly 3 may include: box 31, box 31 can be set up to heat conduction box 31, and the setting can promote the heat conductivility of box 31 like this, can make the heat in box 31 transmit to box 31 outside rapidly.

The utility model discloses an in some embodiments, box body 31 can set up to insulating box body 31, so set up and to guarantee that box body 31 has insulating nature, can avoid the electric leakage of automatically controlled box subassembly 3 to can promote the safety in utilization of automatically controlled box subassembly 3.

The utility model discloses an in some embodiments, automatically controlled box subassembly 3 can have the heat-generating end, and the heat-generating end is located to at least one in first cooling zone 41 and the second cooling zone 51, and the setting can cool off the heat-generating end of automatically controlled box subassembly 3 like this, can prevent that the temperature of automatically controlled box subassembly 3 is too high to can avoid automatically controlled box subassembly 3 to catch fire, and then can guarantee the safety in utilization of automatically controlled box subassembly 3.

The utility model discloses an in some embodiments, can fill in the automatically controlled box subassembly 3 has the heat-conducting layer, wherein, the heat-conducting layer can with the electrical components direct contact in the box body 31, also can be spaced apart with the electrical components in the box body 31, the heat-conducting layer can be directly with the air heat transfer to box body 31 in electrical components and/or the box body 31 to can reach the refrigerated working effect to electrical components.

The utility model discloses an in some embodiments, the heat-conducting layer can set up to the insulating layer, so set up and can prevent the electric leakage of automatically controlled box subassembly 3 better, can promote the safety in utilization of automatically controlled box subassembly 3 to can promote user's personal safety.

In some embodiments of the present invention, the refrigeration system 10 may further include: semiconductor refrigeration piece, the cold junction of semiconductor refrigeration piece is used for dispelling the heat to automatically controlled box subassembly 3, and wherein, the refrigeration effect of semiconductor refrigeration piece is good, sets up like this and can promote the cooling effect to automatically controlled box subassembly 3, can guarantee automatically controlled box subassembly 3 normal work better.

The utility model discloses an in some embodiments, the semiconductor refrigeration piece can be located outside automatically controlled box subassembly 3, and the periphery wall contact of semiconductor refrigeration piece and automatically controlled box subassembly 3, wherein, when semiconductor refrigeration piece during operation, the semiconductor refrigeration piece can carry out the heat exchange with automatically controlled box subassembly 3, the semiconductor refrigeration piece can be taken away the heat of automatically controlled box subassembly 3, thereby can further promote the radiating effect to automatically controlled box subassembly 3, and then can further prolong the life of automatically controlled box subassembly 3, also can guarantee the working property of automatically controlled box subassembly 3.

The utility model discloses an in some embodiments, the semiconductor refrigeration piece can be located inside automatically controlled box subassembly 3, and automatically controlled box subassembly 3 can include radiating fin 8, circuit board, electrical components and box body 31, and in box body 31 was located to circuit board and electrical components, at least one and the semiconductor refrigeration piece contact in box body 31, circuit board and the electrical components, for example: semiconductor refrigeration piece can all contact with box body 31, circuit board, electrical components, so set up and to make semiconductor refrigeration piece carry out the heat exchange with box body 31, circuit board and electrical components better, can further promote the cooling effect to box body 31, circuit board and electrical components.

The utility model discloses an in some embodiments, refrigerating system 10 can set up to R290 refrigerant platform, sets up like this and can promote R290 refrigerant platform cooling capacity, can promote the working property of R290 refrigerant platform.

According to the utility model discloses air conditioner includes: the heat exchanger comprises a first heat exchanger 1, a second heat exchanger 2, an electronic control box assembly 3, a first pipeline 4, a second pipeline 5 and a throttling component group 6. The first pipeline 4 comprises a first cooling section 41 used for cooling the electronic control box assembly 3, the second pipeline 5 comprises a second cooling section 51 used for cooling the electronic control box assembly 3, one end of the throttling component group 6 is communicated with one end of the first heat exchanger 1 through the first pipeline 4, and the other end of the throttling component group 6 is communicated with the second heat exchanger 2 through the second pipeline 5. Under high temperature environment, through setting up first pipeline 4 and second pipeline 5, can fully dispel the heat to automatically controlled box subassembly 3 subassembly, can guarantee that the components and parts in automatically controlled box subassembly 3 stabilize lasting work to can prolong the life of automatically controlled box subassembly 3, and then can prolong the life of air conditioner, also can guarantee that the air conditioner normally works.

In the description herein, references to the description of the term "one embodiment," "some embodiments," "an illustrative embodiment," "an example," "a specific example," or "some examples" or the like mean that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one embodiment or example of the present invention. In this specification, the schematic representations of the terms used above do not necessarily refer to the same embodiment or example. Furthermore, the particular features, structures, materials, or characteristics described may be combined in any suitable manner in any one or more embodiments or examples.

While embodiments of the present invention have been shown and described, it will be understood by those of ordinary skill in the art that: various changes, modifications, substitutions and alterations can be made to the embodiments without departing from the principles and spirit of the invention, the scope of which is defined by the claims and their equivalents.

Claims (31)

1. A refrigeration system, comprising:

a first heat exchanger;

a second heat exchanger;

an electronic control box assembly;

the first pipeline comprises a first cooling section for cooling the electronic control box assembly;

the second pipeline comprises a second cooling section for cooling the electronic control box assembly;

one end of the throttling component group is communicated with one end of the first heat exchanger through the first pipeline, and the other end of the throttling component group is communicated with the second heat exchanger through the second pipeline.

2. The refrigeration system of claim 1, wherein the throttling component set includes a first throttling component, a second throttling component, and a third conduit for communicating the first throttling component and the second throttling component, the first conduit communicating with the first throttling component, the second conduit communicating with the second throttling component,

the third pipeline comprises a third cooling section for cooling the electronic control box assembly.

3. The refrigeration system of claim 2, wherein the third cooling section is disposed through the electronic control box assembly.

4. The refrigeration system of claim 2, wherein the electrical control box assembly includes an electrical component and a box body enclosed by a plurality of plate bodies, the electrical component being disposed within the box body,

the third pipeline is arranged in the box body in a penetrating mode, or the third pipeline is a channel formed in the plate body.

5. The refrigeration system of claim 1, wherein the electrical control box assembly comprises an electrical component and a box body enclosed by a plurality of plate bodies, the electrical component being disposed within the box body,

at least one of the first cooling section and the second cooling section is located within the box body.

6. The refrigeration system of claim 5 wherein the electrical component is in contact with the first cooling section or the second cooling section within the cartridge.

7. The refrigeration system of claim 1, wherein at least one of the first cooling section and the second cooling section is in contact with an inner wall surface or an outer wall surface of the electronic control box assembly.

8. The refrigeration system of claim 1, wherein at least one of the first cooling section and the second cooling section is an annular cooling tube, the annular cooling tube surrounds an outer periphery of the electronic control box assembly, and the annular cooling tube contacts an outer peripheral wall of the electronic control box assembly.

9. The refrigeration system of claim 1, wherein at least one of the first cooling section and the second cooling section is an annular cooling tube that is positioned inside the electronic control box assembly and that extends along and contacts an inner peripheral wall of the electronic control box assembly.

10. The refrigeration system of claim 1, wherein the first cooling section is a straight tube, a U-shaped tube, or an S-shaped tube;

or the second cooling section is a straight pipe, a U-shaped pipe or an S-shaped pipe.

11. The refrigeration system of claim 1, wherein the cross-section of the first cooling section is circular, elliptical, or polygonal;

or the cross section of the second cooling section is circular, oval or polygonal.

12. The refrigeration system of claim 1, wherein a plurality of cooling fins are provided on the first cooling section or the second cooling section.

13. The refrigeration system of claim 12, wherein the respective first cooling section or second cooling section is disposed through the heat sink fin.

14. The refrigeration system of claim 12, wherein the heat sink fins are welded to the respective first cooling section or second cooling section.

15. The refrigeration system of claim 12 wherein a plurality of said fins are spaced along the length of the respective first cooling section or second cooling section.

16. The refrigeration system of claim 1 wherein at least one of the first cooling stage and the second cooling stage has a heat sink base.

17. The refrigeration system of claim 16, wherein the heat sink substrate is an aluminum plate.

18. The refrigeration system of claim 1, wherein the electronic control box assembly includes heat fins, a circuit board, electrical components, and a box, the circuit board and the electrical components being disposed within the box, at least one of the box, the circuit board, and the electrical components being provided with the heat fins.

19. The refrigeration system of claim 18, wherein the heat sink fins are disposed on the box and on an outer surface of the box.

20. The refrigerant system as set forth in claim 1, wherein at least one fan is disposed within said electrical control box assembly.

21. The refrigerant system as set forth in claim 1, wherein at least one of said first cooling stage and said second cooling stage is a copper or aluminum tube.

22. The refrigeration system of claim 1, wherein the electrical control box assembly comprises a box that is a thermally conductive box.

23. The refrigeration system of claim 22 wherein the cartridge is an insulating cartridge.

24. The refrigeration system of claim 1, wherein the electronic control box assembly has a heat-generating end, and at least one of the first cooling section and the second cooling section is disposed at the heat-generating end.

25. The refrigeration system of claim 1, wherein the electrical control box assembly is filled with a thermally conductive layer.

26. The refrigerant system as set forth in claim 25, wherein said thermally conductive layer is an insulating layer.

27. The refrigeration system of claim 1, further comprising a semiconductor refrigeration pill, a cold end of the semiconductor refrigeration pill being configured to dissipate heat from the electronic control box assembly.

28. The refrigeration system of claim 27, wherein the semiconductor refrigeration pill is disposed outside the electronic control box assembly and contacts an outer peripheral wall of the electronic control box assembly.

29. The refrigeration system of claim 27, wherein the semiconductor chilling plate is disposed within the electronic control box assembly,

the electronic control box assembly comprises radiating fins, a circuit board, an electrical component and a box body, wherein the circuit board and the electrical component are arranged in the box body, and at least one of the box body, the circuit board and the electrical component is in contact with the semiconductor refrigerating sheet.

30. The refrigerant system as set forth in claim 1, wherein said refrigerant system is an R290 refrigerant platform.

31. An air conditioner, comprising:

a first heat exchanger;

a second heat exchanger;

an electronic control box assembly;

the first pipeline comprises a first cooling section for cooling the electronic control box assembly;

the second pipeline comprises a second cooling section for cooling the electronic control box assembly;

one end of the throttling component group is communicated with one end of the first heat exchanger through the first pipeline, and the other end of the throttling component group is communicated with the second heat exchanger through the second pipeline.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920519028.4U CN210463644U (en) | 2019-04-15 | 2019-04-15 | Refrigerating system and air conditioner |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920519028.4U CN210463644U (en) | 2019-04-15 | 2019-04-15 | Refrigerating system and air conditioner |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210463644U true CN210463644U (en) | 2020-05-05 |

Family

ID=70429784

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201920519028.4U Active CN210463644U (en) | 2019-04-15 | 2019-04-15 | Refrigerating system and air conditioner |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210463644U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109959182A (en) * | 2019-04-15 | 2019-07-02 | 广东美的制冷设备有限公司 | Refrigeration system and air conditioner |

| WO2022166236A1 (en) * | 2020-08-26 | 2022-08-11 | 广东美的暖通设备有限公司 | Heat exchanger, electric control box and air conditioning system |

-

2019

- 2019-04-15 CN CN201920519028.4U patent/CN210463644U/en active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109959182A (en) * | 2019-04-15 | 2019-07-02 | 广东美的制冷设备有限公司 | Refrigeration system and air conditioner |

| CN109959182B (en) * | 2019-04-15 | 2024-06-25 | 广东美的制冷设备有限公司 | Refrigerating system and air conditioner |

| WO2022166236A1 (en) * | 2020-08-26 | 2022-08-11 | 广东美的暖通设备有限公司 | Heat exchanger, electric control box and air conditioning system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109959182B (en) | Refrigerating system and air conditioner | |

| CN104329871B (en) | Semi-conductor refrigeration refrigerator and cold end heat exchanging device thereof | |

| CN101922778B (en) | Semiconductor refrigerating air conditioning device | |

| CN107477770B (en) | Air conditioner and control method thereof | |

| JPH024163A (en) | Cooling device for semiconductor element for power | |

| CN203744424U (en) | Variable-frequency air conditioner control module cooling and variable-frequency air conditioner | |

| CN110044032B (en) | Control method of air conditioner | |

| CN210463644U (en) | Refrigerating system and air conditioner | |

| CN210441468U (en) | Refrigerating system and air conditioner | |

| CN106958962A (en) | Semiconductor defrosting heater and refrigeration plant | |

| CN205878547U (en) | Heat abstractor and transducer air conditioning of air conditioner converter | |

| CN208652889U (en) | Radiating assembly, control module and air conditioner | |

| CN209857252U (en) | Air conditioning system and air conditioning apparatus | |

| CN109959181B (en) | Refrigerating system and air conditioner | |

| CN209877183U (en) | Heat abstractor, air condensing units and air conditioner | |

| TWI411390B (en) | Devices in series for continuous cooling/ heating | |

| CN110044031B (en) | Control method of air conditioning device, electric control box assembly and air conditioning device | |

| CN100450335C (en) | Radiation cooling method for power device of refrigeration device | |

| CN209857250U (en) | Air conditioning system and air conditioning apparatus | |

| CN209857251U (en) | Air conditioning system and air conditioning apparatus | |

| CN215295145U (en) | Radiator and air conditioner | |

| CN209882431U (en) | Heat dissipation component, air condensing units and air conditioner | |

| CN210014481U (en) | Air conditioning device and electric control box assembly of air conditioning device | |

| KR20040061286A (en) | Hybrid heat exchanger having tec and heat pipe | |

| CN111578391A (en) | Radiator and air condensing units |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |