CN210463643U - CO2 double-stage frequency conversion air source heat pump hot water unit - Google Patents

CO2 double-stage frequency conversion air source heat pump hot water unit Download PDFInfo

- Publication number

- CN210463643U CN210463643U CN201920794052.9U CN201920794052U CN210463643U CN 210463643 U CN210463643 U CN 210463643U CN 201920794052 U CN201920794052 U CN 201920794052U CN 210463643 U CN210463643 U CN 210463643U

- Authority

- CN

- China

- Prior art keywords

- hot water

- frequency conversion

- frequency

- compressor

- heat pump

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Heat-Pump Type And Storage Water Heaters (AREA)

Abstract

The utility model discloses a CO2 doublestage frequency conversion air source heat pump hot water unit, it includes the rack, rack inside is fixed with variable frequency controller and frequency conversion driver, variable frequency controller and frequency conversion driver and CO2 frequency conversion compressor connect, CO2 frequency conversion compressor's front end and vapour and liquid separator are connected, its rear end and four-way reversing valve are connected, four-way reversing valve respectively with condenser and vapour and liquid separator and outside heat exchanger connection, outside heat exchanger is close to axial fan and sets up, outside heat exchanger rear end and combination valve body are connected to an organic whole, the bottom and the condenser of combination valve body are connected to an organic whole; the left end and the right end of the combined valve body are connected with the reservoir and the filter to form a circulation loop. The utility model provides a heat pump prepare high temperature hot water's a difficult problem, it is significant to high temperature hot water heating and life high temperature hot water provide.

Description

Technical Field

The utility model relates to a central air conditioning and domestic freezing, heating and hot water system specifically say to a CO2 doublestage variable frequency air source heat pump hot water unit.

Background

Energy conservation and environmental protection are the key points for realizing sustainable development. The air conditioning field is used as a large-capacity user, and the energy consumption of the air conditioning field accounts for about 70 percent of the total energy consumption of the building, so the energy-saving significance is very great. On the basis of the sustainable development theory, the key of how the air conditioning system is suitable for efficient energy-saving operation under low load and energy-saving selection and matching of equipment in system design becomes air conditioning energy, which has very important significance for saving energy, reducing operation cost, protecting environment and promoting national economic development. However, the refrigeration and hot water modes of the existing central air conditioner and household refrigeration, heating and hot water system are single, which wastes electric energy seriously in the practical application process, and derives the damage effect of refrigerant to the ozone layer, generates greenhouse gas effect and other problems of damaging the environment.

Aiming at the defects in the prior art, as technical personnel in the industry, how to improve and design a hot water unit through technology, the technical problem that the technical personnel in the prior art needs to solve urgently is that the refrigerating and heating with high efficiency, low energy consumption and no pollution can be carried out through a novel refrigerant.

Disclosure of Invention

An object of the utility model is to provide a hot water unit realizes high-efficient heating through adopting new structure and through using CO2 as the refrigerant, and this kind of heating mode can effectual improvement heating effect simultaneously to the use of refrigerant can realize nontoxic, consume energy low and the environmental protection.

In order to realize the purpose, the utility model discloses a technical scheme as follows: a CO2 double-stage variable-frequency air source heat pump hot water unit comprises a cabinet, wherein a variable-frequency controller and a variable-frequency driver are fixed inside the cabinet, the variable-frequency controller and the variable-frequency driver are connected with a CO2 variable-frequency compressor, the front end of the CO2 variable-frequency compressor is connected with a gas-liquid separator, the rear end of the CO2 variable-frequency compressor is connected with a four-way reversing valve, the four-way reversing valve is respectively connected with a condenser, the gas-liquid separator and an outer heat exchanger, the outer heat exchanger is arranged close to an axial flow fan, the rear end of the outer heat exchanger is connected with a combined; the left end and the right end of the combined valve body are connected with the reservoir and the filter to form a circulation loop.

The CO2 frequency conversion compressor is one or more CO2 and compressor double-stage compression double-rotor frequency conversion compressors or CO2 and compressor double-stage compression screw frequency conversion compressors which are used together, a double-stage compression cavity is arranged in the CO2 frequency conversion compressor, and the double-stage compression cavity is connected into a whole in a series connection mode.

The combined valve body comprises two one-way valves and two expansion valves, wherein a series branch is formed by one-way valve and one expansion valve, and the two series branches are connected in parallel to form the combined valve body.

The expansion valve adopts a high-pressure-resistant thermostatic expansion valve or an electronic expansion valve.

The CO2 double-stage variable frequency air source heat pump hot water unit is characterized in that the condenser adopts a high-pressure resistant brazed plate heat exchanger or a shell-and-tube heat exchanger or a sleeve-type heat exchanger; the outer side heat exchanger adopts a high-pressure-resistant finned heat exchanger.

According to the CO2 double-stage frequency conversion air source heat pump hot water unit, a frequency conversion driver adopts a direct current frequency conversion compressor drive controller or a special frequency converter for a fan pump, wherein the direct current frequency conversion compressor drive controller or the special frequency converter is specially used for alternating current single-phase 220V input.

The CO2 double-stage frequency conversion air source heat pump hot water unit is characterized in that a frequency conversion controller is controlled according to the following control logic:

heating frequency limit control

Limiting different upper frequency limits according to different working conditions, and obtaining a table below the segmentation interval;

high exhaust frequency limiting: when the exhaust temperature reaches the high exhaust limit frequency point, the CO2 inverter compressor does not increase the frequency any more.

In order to realize the frequency reduction protection control of the CO2 frequency conversion compressor, when the current of the CO2 frequency conversion compressor reaches an over-current frequency reduction point, the CO2 frequency conversion compressor starts to reduce the frequency until the current of the CO2 frequency conversion compressor is less than the over-current frequency reduction point to 0.5A, and the frequency reduction is stopped.

The utility model has the advantages that:

1. refrigerants such as R22, R410A, R134A, etc. which have the disadvantage of either ozone depletion potential > 0, or high global warming potential, or flammability, or toxicity, are commonly used in the prior art. In contrast, CO2 refrigerant is a safe refrigerant with the advantages of being non-toxic, non-flammable, having an ozone depletion potential of 0, and having a global warming potential of 1.

2, the maximum hot water temperature can only reach 65 ℃ by using heat pump units of refrigerants such as R22, R410A, R134A and the like in the prior art. Compared with the CO2 double-stage variable-frequency air source heat pump hot water unit, the temperature of the highest hot water prepared by the CO2 double-stage variable-frequency air source heat pump hot water unit can reach 95 ℃, the problem that the heat pump prepares high-temperature hot water is solved, and the CO2 double-stage variable-frequency air source heat pump hot water unit has great significance for high-temperature hot water heating and high-temperature domestic.

3, when the heat pump units using refrigerants such as R22, R410A, R134A and the like are generally adopted to prepare hot water in the prior art, the heat pump units can only operate in the environment with the lowest ambient temperature of more than 10 ℃ below zero. Compared with the prior art, when the CO2 double-stage variable-frequency air source heat pump hot water unit is used for preparing hot water, the lowest ambient temperature can reach-25 ℃, the problem that the heat pump in most northern areas prepares high-temperature hot water is solved, and the device has great environmental protection significance for heating in northern winter, providing domestic hot water, replacing a coal-fired boiler and eliminating haze.

4, when the hot water is prepared by the heat pump units of the refrigerants such as R22, R410A, R134A and the like in the prior art, the energy efficiency ratio of the air conditioning unit can only reach 1.5 at the lowest ambient temperature. Compared with the prior art, when the CO2 double-stage variable-frequency air source heat pump hot water unit is used for preparing hot water, the hot water at 70-95 ℃ is prepared at the lowest ambient temperature of-25 ℃, the energy efficiency ratio of the air conditioning unit can be as low as 2.3, and the energy efficiency ratio of the air conditioning unit at other ambient temperatures can be as high as 4.5.

5, the CO2 double-stage frequency conversion air source heat pump hot water unit adopts the frequency conversion control technology, so that the frequency of the compressor is changed along with the change of the load, and the energy is saved by more than 30 percent compared with the compressor unit with a fixed frequency in use.

6, the CO2 double-stage variable-frequency air source heat pump hot water unit adopts the same CO2 variable-frequency compressor double-stage compression variable-frequency compressor, and has simpler structure, smaller and compact unit size and lower cost compared with a non-same CO2 variable-frequency compressor double-stage compression variable-frequency compressor, so that the industrialized mass production and the use in actual engineering become easy.

Drawings

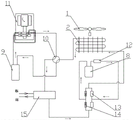

Fig. 1 is a schematic view of the structure of the present invention;

FIG. 2 is a schematic side view of the present invention;

fig. 3 is a schematic bottom view of the present invention;

FIG. 4 is a schematic view of the internal working principle of the present invention in a refrigerating state;

FIG. 5 is a schematic view of the internal working principle of the utility model in the heating state;

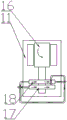

FIG. 6 is a schematic view of the working principle of the compressor of the present invention;

reference numerals: the system comprises a 1-axial flow fan, a 2-outer side heat exchanger, a 3-cabinet, a 4-control cabinet, a 5-variable frequency driver, a 6-variable frequency controller, a 7-condenser, an 8-liquid storage device, a 9-gas-liquid separator, a 10-four-way reversing valve, a 11-CO2 variable frequency compressor, a 12-filter, a 13-expansion valve, a 14-one-way valve, a 15-condenser, a 16-motor rotor, a 17-first-stage compression cavity and an 18-second-stage compression cavity.

Detailed Description

In order to make the objects, technical solutions and advantages of the present invention more clearly understood, the present invention is further described in detail below with reference to the accompanying drawings. It should be understood that the detailed description and specific examples, while indicating the invention, are given by way of illustration only.

A CO2 double-stage variable-frequency air source heat pump hot water unit is shown in the attached drawing and comprises a cabinet 3, wherein a variable-frequency controller 6 and a variable-frequency driver 5 are fixed inside the cabinet 3, the variable-frequency controller 6 and the variable-frequency driver 5 are connected with a CO2 variable-frequency compressor 11, the front end of the CO2 variable-frequency compressor 11 is connected with a gas-liquid separator, the rear end of the CO2 variable-frequency compressor 11 is connected with a four-way reversing valve 10, the four-way reversing valve 10 is respectively connected with a condenser 15, the gas-liquid separator 9 and an outer side heat exchanger 2, the outer side heat exchanger 2 is arranged close to an axial flow fan 1, the rear end of the outer side heat exchanger 2; the left end and the right end of the combined valve body are connected with the liquid reservoir 8 and the filter 12 to form a circulation loop; the combined valve body comprises two one-way valves 14 and two expansion valves 13, wherein a series branch is formed by one-way valve 14 and one expansion valve 13, and the two series branches are connected in parallel to form the combined valve body.

Further, the CO2 inverter compressor is one or more CO2 and compressor two-stage compression dual-rotor inverter compressors or CO2 and compressor two-stage compression screw inverter compressors, as shown in fig. 6, a first-stage compression cavity 17 and a second-stage compression cavity 18 are arranged inside the CO2 inverter compressor, the first-stage compression cavity 17 and the second-stage compression cavity 18 are connected into a whole in a series connection mode, and are connected into a whole through a motor rotor 16, and when the CO2 inverter compressor works, under the driving operation of a motor, double inverter compression can be realized.

Because the CO2 frequency conversion compressor has higher working pressure, the expansion valve 13 adopts a high pressure resistant thermostatic expansion valve or an electronic expansion valve, and the electronic expansion valve is preferably selected under the frequency conversion setting.

When the CO2 double-stage variable frequency air source heat pump hot water unit runs, the condenser adopts a high-pressure-resistant brazed plate heat exchanger or a shell-and-tube heat exchanger or a sleeve-type heat exchanger; the outer side heat exchanger 2 adopts a high-pressure-resistant finned heat exchanger.

In the CO2 double-stage frequency conversion air source heat pump hot water unit, the frequency conversion driver 5 adopts a direct current frequency conversion compressor drive controller or a special frequency converter for a fan pump, which is specially used for alternating current single-phase 220V input.

The CO2 double-stage frequency conversion air source heat pump hot water unit is characterized in that a frequency conversion controller is controlled according to the following control logic:

example 1:

as shown in fig. 4, in the cooling mode:

when the control temperature is larger than or equal to the refrigeration setting + loading deviation, the relay of the CO2 inverter compressor 11 outputs, and the inverter driver 5 adjusts the CO2 inverter compressor 11 to start frequency rising through the inverter controller 6;

when the control temperature is less than or equal to the refrigeration set value, the variable frequency driver 5 adjusts the CO2 variable frequency compressor 11 to start to reduce the frequency through the variable frequency controller 6;

and when the control temperature is less than or equal to the refrigeration setting-unloading deviation, the relay of the CO2 inverter compressor 11 stops outputting.

The variable frequency controller 6 and the variable frequency driver 5 are connected with the CO2 variable frequency compressor 11, through the control of the variable frequency controller 6 and the variable frequency driver 5, the CO2 variable frequency compressor 11 enters the outer side heat exchanger 2 through the four-way reversing valve 10 after being internally compressed, after heat exchange is carried out under the action of the axial flow fan 1, the rear end of the outer side heat exchanger 2 and the one-way valve 14 on the combined valve body enter the liquid storage device 8, enter the condenser 15 through the expansion valve 13 after passing through the liquid storage device 8 and the filter 12, then enter the gas-liquid separator 9 through the four-way reversing valve 10 and then enter the CO2 variable frequency compressor 11 for secondary circulation, and therefore the refrigeration process is achieved.

Example 2:

as shown in fig. 5, in the heating mode:

the frequency adjusting range in the heating mode is as follows: lower frequency limit to upper frequency limit 8;

when the control temperature is less than or equal to the heating setting-loading deviation, the relay of the CO2 inverter compressor 11 outputs, and the inverter driver 5 adjusts the CO2 inverter compressor 11 to start frequency increasing through the inverter controller 6

When the control temperature is larger than or equal to the heating set value, the variable frequency driver 5 adjusts the CO2 variable frequency compressor 11 to start to reduce the frequency through the variable frequency controller 6;

and when the control temperature is larger than or equal to the heating setting and the unloading deviation, the relay of the CO2 inverter compressor 11 stops outputting.

The variable frequency controller 6 and the variable frequency driver 5 are connected with the CO2 variable frequency compressor 11, through the control of the variable frequency controller 6 and the variable frequency driver 5, the CO2 variable frequency compressor 11 is compressed inside, enters the condenser 15 through the four-way reversing valve 10, enters the one-way valve 14 through the condenser 15, enters the liquid storage device 8, enters the outer side heat exchanger 2 through the expansion valve 13 after passing through the liquid storage device 8 and the filter 12, exchanges heat through the action of the axial flow fan 1, enters the gas-liquid separator 9 through the four-way reversing valve 10, and then enters the CO2 variable frequency compressor 11 for secondary circulation, so that the heating process is realized.

When the heating process is carried out, in order to ensure the stability of the heating process, the heating frequency limit is controlled by the following control modes:

limiting different upper frequency limits according to different working conditions, and obtaining a table below the segmentation interval;

Claims (6)

1. the utility model provides a CO2 doublestage frequency conversion air source heat pump hot water unit, includes the rack, and rack inside is fixed with variable frequency controller and frequency conversion driver, its characterized in that: the variable frequency controller and the variable frequency driver are connected with the CO2 variable frequency compressor, the front end of the CO2 variable frequency compressor is connected with the gas-liquid separator, the rear end of the CO2 variable frequency compressor is connected with the four-way reversing valve, the four-way reversing valve is respectively connected with the condenser, the gas-liquid separator and the outer side heat exchanger, the outer side heat exchanger is arranged close to the axial flow fan, the rear end of the outer side heat exchanger is connected with the combined valve body into a whole, and the bottom of the combined valve body is; the left end and the right end of the combined valve body are connected with the reservoir and the filter to form a circulation loop.

2. The CO2 two-stage variable frequency air source heat pump hot water unit as claimed in claim 1, wherein: the CO2 frequency conversion compressor is one or more CO2 and compressor double-stage compression double-rotor frequency conversion compressors or CO2 and compressor double-stage compression screw frequency conversion compressors which are used together, a double-stage compression cavity is arranged in the CO2 frequency conversion compressor, and the double-stage compression cavity is connected into a whole in a series connection mode.

3. The CO2 two-stage variable frequency air source heat pump hot water unit as claimed in claim 1, wherein: the combined valve body comprises two one-way valves and two expansion valves, wherein a series branch is formed by one-way valve and one expansion valve, and the two series branches are connected in parallel to form the combined valve body.

4. The CO2 two-stage variable frequency air source heat pump hot water unit as claimed in claim 3, wherein: the expansion valve adopts a high-pressure-resistant thermostatic expansion valve or an electronic expansion valve.

5. The CO2 two-stage variable frequency air source heat pump hot water unit as claimed in claim 1, wherein: the CO2 double-stage variable frequency air source heat pump hot water unit is characterized in that the condenser adopts a high-pressure resistant brazed plate heat exchanger or a shell-and-tube heat exchanger or a sleeve-type heat exchanger; the outer side heat exchanger adopts a high-pressure-resistant finned heat exchanger.

6. The CO2 two-stage variable frequency air source heat pump hot water unit as claimed in claim 1, wherein: according to the CO2 double-stage frequency conversion air source heat pump hot water unit, a frequency conversion driver adopts a direct current frequency conversion compressor drive controller or a special frequency converter for a fan pump, wherein the direct current frequency conversion compressor drive controller or the special frequency converter is specially used for alternating current single-phase 220V input.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920794052.9U CN210463643U (en) | 2019-05-30 | 2019-05-30 | CO2 double-stage frequency conversion air source heat pump hot water unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920794052.9U CN210463643U (en) | 2019-05-30 | 2019-05-30 | CO2 double-stage frequency conversion air source heat pump hot water unit |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210463643U true CN210463643U (en) | 2020-05-05 |

Family

ID=70438945

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201920794052.9U Active CN210463643U (en) | 2019-05-30 | 2019-05-30 | CO2 double-stage frequency conversion air source heat pump hot water unit |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210463643U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110332725A (en) * | 2019-05-30 | 2019-10-15 | 武晓宁 | CO2 twin-stage frequency conversion air friction drag |

| WO2021223529A1 (en) * | 2020-05-25 | 2021-11-11 | 青岛海尔空调电子有限公司 | Heat pump system |

-

2019

- 2019-05-30 CN CN201920794052.9U patent/CN210463643U/en active Active

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110332725A (en) * | 2019-05-30 | 2019-10-15 | 武晓宁 | CO2 twin-stage frequency conversion air friction drag |

| WO2021223529A1 (en) * | 2020-05-25 | 2021-11-11 | 青岛海尔空调电子有限公司 | Heat pump system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN104154609B (en) | Dual-system heat pump roof unit | |

| CN102748900B (en) | Heat pump, heat pump air conditioner and heat pump water heating unit sequentially using single/double stage compression | |

| CN210463643U (en) | CO2 double-stage frequency conversion air source heat pump hot water unit | |

| CN102759159B (en) | A kind of heat pipe hot pump composite system | |

| CN201177411Y (en) | Water-cooling/ wind cooling -type integral heat pump units | |

| CN201945082U (en) | Integrative industrial water chiller unit | |

| CN213687347U (en) | Evaporative cold air source heat pump adopting variable-frequency variable-internal-volume-ratio compressor | |

| CN203501363U (en) | Double-effect heat pump air conditioning unit | |

| CN111076421A (en) | Direct current frequency conversion overlapping hot water unit | |

| CN206683135U (en) | A kind of ice-chilling air conditioning system | |

| CN204987326U (en) | Heat pipe air conditioner integral type heat transfer system | |

| CN214332912U (en) | Cascade air source high-temperature heat pump cooling and heating unit | |

| CN204100637U (en) | A kind of twice decompression carbon dioxide household electric refrigerator | |

| CN210399579U (en) | Refrigerating and heating water system, air conditioning unit and heat pump unit | |

| CN107726657A (en) | A kind of superposition type air-cooled heat pump water chiller-heater units | |

| CN203413820U (en) | Water heating unit of double-source high-temperature heat pump | |

| CN203413821U (en) | Water heating unit of air source high temperature heat pump | |

| CN110332725A (en) | CO2 twin-stage frequency conversion air friction drag | |

| CN207035543U (en) | Refrigerating plant and heat pump assembly | |

| CN205227930U (en) | Serial -type two -stage thermal -arrest heat pump | |

| CN201779788U (en) | Separated variable-capacity module system substituting air-source variable-frequency multi-connected unit | |

| CN201259350Y (en) | Heating and cooling air conditioner and sanitary hot water integrated modular refrigerating unit | |

| CN112762532A (en) | Water source heat pump groundwater formula vortex internal conversion heat recovery unit | |

| CN205957531U (en) | Refrigerating system of supplementary water -cooling unit in area | |

| CN205227932U (en) | Short circuit tonifying qi heat pump suitable for low temperature environment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |