CN210195811U - Underground single hydraulic prop carrying device - Google Patents

Underground single hydraulic prop carrying device Download PDFInfo

- Publication number

- CN210195811U CN210195811U CN201921166819.XU CN201921166819U CN210195811U CN 210195811 U CN210195811 U CN 210195811U CN 201921166819 U CN201921166819 U CN 201921166819U CN 210195811 U CN210195811 U CN 210195811U

- Authority

- CN

- China

- Prior art keywords

- hydraulic prop

- guide wheel

- plate

- suspension

- bearing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Bridges Or Land Bridges (AREA)

Abstract

The utility model relates to a mining equipment field, in particular to hydraulic prop handling device in pit, it includes: the horizontal hanging rails are hung in the roadway through the hanging piece and are arranged along the extending direction of the roadway, and sliding areas are respectively arranged on the horizontal hanging rails on the two sides of the hanging piece; the suspension bracket comprises a bearing part for bearing the single hydraulic prop, a suspension part arranged on the upper side of the bearing part and two guide wheel assemblies connected with the suspension part, the two guide wheel assemblies are respectively arranged on two sides of the horizontal suspension rail, and each guide wheel assembly comprises a guide wheel arranged in a sliding area in a rolling manner; wherein, there are two to suspend in midair the support and constitute a transport unit, each of transport unit the bearing passes through the bearing hydraulic prop, the utility model discloses not only reduced workman's intensity of labour, still improved the efficiency of hydraulic prop transportation, the effectual problem of having solved existence among the prior art.

Description

Technical Field

The utility model relates to a mining equipment field, in particular to hydraulic prop handling device in pit.

Background

The single hydraulic prop is used more underground as important support equipment in the pit, and particularly in a roadway close to a stope face, because the roadway is influenced by mining, the phenomena of heaving bottom, sinking top plate and the like easily occur, so that a large number of single hydraulic props are needed to be used for advance support in the roadway close to the stope face, and because the working face is continuously propelled, the single hydraulic prop needs to be frequently carried by workers. At present, the single hydraulic prop is carried by manpower, so that the labor intensity of workers is high, and the efficiency is low.

SUMMERY OF THE UTILITY MODEL

In order to solve the technical problem, the utility model provides a hydraulic prop handling device in pit has not only reduced workman's intensity of labour, has still improved the efficiency of hydraulic prop transportation in the pit, the effectual problem of having solved existence among the prior art.

In order to solve the problem, the utility model provides a hydraulic prop handling device in pit, include: the horizontal hanging rails are hung in the roadway through the hanging piece and are arranged along the extending direction of the roadway, and sliding areas are respectively arranged on the horizontal hanging rails on the two sides of the hanging piece; the suspension bracket comprises a bearing part for bearing the single hydraulic prop, a suspension part arranged on the upper side of the bearing part and two guide wheel assemblies connected with the suspension part, the two guide wheel assemblies are respectively arranged on two sides of the horizontal suspension rail, and each guide wheel assembly comprises a guide wheel arranged in a sliding area in a rolling manner; at least two suspension supports form a carrying unit, and all the bearing parts of the carrying unit jointly bear the single hydraulic prop.

Furthermore, the horizontal hanger rail comprises a plurality of rail plates which are connected end to end, and the two adjacent rail plates are connected through bolts.

Furthermore, the guide wheel assembly also comprises a guide wheel frame connected with the guide wheel, the guide wheel frame extends downwards, and a plurality of first through holes are formed in the guide wheel frame at intervals along the vertical direction; the suspension part comprises a connecting arm formed by upwards extending the bearing part, a plurality of second through holes are formed in the connecting arm at intervals in the vertical direction, and the carrying device further comprises a bolt and a nut which are used for connecting the guide wheel frame and the connecting wall.

Furthermore, two sides of the track plate are provided with side rib plates extending upwards.

Furthermore, one end of each track plate is bent downwards and then horizontally extends to form a bottom support part, the adjacent track plates are lapped on the bottom support part, the two adjacent track plates are connected at the bottom support part, and the top surfaces of the two adjacent track plates are coplanar.

Further, the suspension part comprises a steel wire rope fixed on the top wall of the roadway and a steel wire rope buckle arranged at the top of the horizontal suspension rail.

Furthermore, the bearing part comprises a bearing plate horizontally arranged and side plates arranged at two ends of the bearing plate, a storage space of the single hydraulic prop is formed between the two side plates, a bottom plate is arranged on the bearing plate, and a plurality of arc-shaped surfaces are arranged at the top of the bottom plate at intervals.

Furthermore, the suspension bracket further comprises a pressing plate buckled on the bottom supporting plate, the bottom of the pressing plate is provided with an arc-shaped surface matched with the bottom supporting plate, and the pressing plate is connected with the supporting plate through a bolt.

Furthermore, rubber layers are arranged on the lower surface of the pressing plate and the upper surface of the bottom supporting plate.

Furthermore, the carrying device further comprises a connecting rod, and the connecting rod is connected with each suspension bracket in the same carrying unit through bolts.

The beneficial effects of the utility model reside in that, the utility model provides a hydraulic prop handling device in pit through remove the transport unit on horizontal lifting sling in order to transport hydraulic prop, workman's low in labor strength still can once transport a plurality of hydraulic prop, and the removal rate of transport unit is fast, and conveying efficiency is higher, the effectual problem of existing among the prior art of having solved.

Drawings

The accompanying drawings, which are described herein, serve to provide a further understanding of the invention and constitute a part of this specification, and the exemplary embodiments and descriptions thereof are provided for explaining the invention without unduly limiting it. In the drawings:

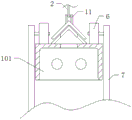

fig. 1 is a schematic structural diagram of an embodiment of the present invention.

Fig. 2 is a schematic structural view of a joint between two adjacent track slabs according to an embodiment of the present invention.

Fig. 3 is a schematic cross-sectional structural view of the track slab according to an embodiment of the present invention.

Fig. 4 is a schematic cross-sectional structural view of the track slab according to an embodiment of the present invention.

Fig. 5 is a schematic structural view of a suspension bracket according to an embodiment of the present invention.

Wherein: 1. horizontal hanger rails; 101. a track plate; 102. a base portion; 2. a wire rope; 3. a suspension bracket; 4. a bearing part; 401. a support plate; 402. a side plate; 5. a connecting arm; 6. a guide wheel; 7. a guide wheel frame; 8. a first through hole; 9. a second through hole; 10. a side rib plate; 11. a steel wire rope is buckled; 12. a bottom pallet; 13. pressing a plate; 14. a rubber layer; 15. a connecting rod.

Detailed Description

In order to more clearly explain the overall concept of the present invention, the following detailed description is given by way of example in conjunction with the accompanying drawings.

It should be noted that in the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention, however, the present invention may be practiced in other ways than those specifically described herein, and thus the scope of the present invention is not limited by the specific embodiments disclosed below.

In addition, in the description of the present invention, it should be understood that the terms "center", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", "bottom", "inner", "outer", "axial", "radial", "circumferential", and the like indicate orientations or positional relationships based on those shown in the drawings, and are only for convenience of description and simplicity of description, and do not indicate or imply that the device or element referred to must have a particular orientation, be constructed and operated in a particular orientation, and therefore should not be construed as limiting the present invention.

In the present invention, unless otherwise expressly stated or limited, the terms "mounted," "connected," and "fixed" are to be construed broadly and may, for example, be fixedly connected, detachably connected, or integrally formed; either directly or indirectly through intervening media, either internally or in any other relationship. However, the direct connection means that the two bodies are not connected to each other by the intermediate structure but connected to each other by the connecting structure to form a whole. The specific meaning of the above terms in the present invention can be understood according to specific situations by those skilled in the art.

In the present application, unless expressly stated or limited otherwise, the first feature may be directly on or directly under the second feature or indirectly via intermediate members. In the description herein, references to the description of the term "one embodiment," "some embodiments," "an example," "a specific example," or "some examples," etc., mean that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one embodiment or example of the invention. In this specification, the schematic representations of the terms used above are not necessarily intended to refer to the same embodiment or example. Furthermore, the particular features, structures, materials, or characteristics described may be combined in any suitable manner in any one or more embodiments or examples.

In the present invention, as shown in fig. 1 to 5, there is provided a downhole individual hydraulic prop handling apparatus, comprising: the horizontal hanger rail 1 is hung in a roadway through a hanging piece and is arranged along the extending direction of the roadway, and sliding areas are respectively arranged on the horizontal hanger rail 1 at two sides of the hanging piece; the suspension bracket 3 comprises a supporting part 4 for supporting the single hydraulic prop, a suspension part arranged on the upper side of the supporting part 4, and two guide wheel 6 assemblies connected with the suspension part, wherein the two guide wheel assemblies are respectively arranged on two sides of the horizontal suspension rail 1, and each guide wheel 6 assembly comprises a guide wheel 6 arranged in a sliding area in a rolling manner; at least two of the suspension supports 3 form a carrying unit, and the supporting parts 4 of the carrying unit jointly support the single hydraulic prop.

The utility model discloses a handling device is when using, through suspending horizontal hanger rail 1 in the tunnel in midair, then suspends support 3 in midair and constitutes a transport unit with two, takes respectively to put on a supporting portion 4 with the both ends of monomer hydraulic prop, then removes whole transport unit, can carry monomer hydraulic prop in the tunnel.

By adopting the carrying device of the utility model, the worker only needs to carry the single hydraulic prop to the bearing part 4 and then pushes the carrying unit, compared with the existing carrying mode, the utility model saves more labor, reduces the labor intensity of the worker, and can carry a plurality of single hydraulic props at one time, thereby having higher efficiency; furthermore, the utility model discloses a set up horizontal hanger rail in the tunnel, can keep 6 subassemblies of guide pulley to have comparatively level and smooth slip region to when removing whole transport unit, it is more laborsaving.

In a preferred embodiment, as shown in fig. 2, further specifically, the horizontal suspension rail 1 includes a plurality of rail plates 101 connected end to end, and two adjacent rail plates 101 are connected by bolts. With this, it is convenient to mount the track plate 101.

In the embodiment shown in fig. 1, more specifically, the guide wheel 6 assembly further includes a guide wheel frame 7 connected to the guide wheel 6, the guide wheel frame 7 extends downward, and a plurality of first through holes 8 are formed in the guide wheel frame 7 at intervals in the vertical direction; the suspension part comprises a connecting arm 5 formed by upwards extending the bearing part 4, a plurality of second through holes 9 are formed in the connecting arm 5 at intervals in the vertical direction, and the carrying device further comprises bolts and nuts used for connecting the guide wheel frame 7 and the connecting wall.

In a preferred embodiment, as shown in fig. 3, two sides of the track plate 101 are provided with side rib plates 10 extending upward. Thereby preventing the guide wheels 6 from being separated from the track plate 101.

In an alternative embodiment, as shown in fig. 4, the top of the track plate 101 may not be provided with the side rib 10, and the bottom of the track plate 101 may be provided with a rib to reinforce the strength of the track plate 101.

In the embodiment shown in fig. 2, a further optimization is that one end of each track plate 101 is bent downward and then extends horizontally to form a base portion 102, adjacent track plates 101 are overlapped on the base portion 102, two adjacent track plates 101 are connected at the base portion 102, and top surfaces of the two adjacent track plates 101 are coplanar. Therefore, after the track plates 101 are connected with each other, the track plates 101 have coplanar top surfaces, so that the guide wheel 6 assembly can roll on a flat plane, and the movement of the carrying unit is more stable and labor-saving, wherein, as shown in fig. 2, bolts are arranged at the middle position of the bottom support part 102 to connect two adjacent track plates 101, so that the bolts can be prevented from interfering with the guide wheel 6 assembly.

Of course, the connection between the track plates 101 may also be in other forms, for example, as shown in fig. 4, a transverse rib plate is arranged at the end of the track plate, a connection hole is formed on the rib plate, and two adjacent rib plates may pass through the connection hole through a bolt to be connected.

Preferably, as shown in fig. 2, the bottom support part 102 is not provided with the lateral rib plate 10.

Further specifically, the suspension member includes a steel wire rope 2 fixed on the top wall of the roadway and a steel wire rope buckle 11 arranged on the top of the horizontal suspension rail 1. As shown in fig. 1, 3 and 4, an angle steel is arranged at the top of the track plate 101, and the steel wire buckle is fixed on the angle steel, so that the strength of the track plate 101 can be increased through the angle steel, and the steel wire buckle 11 can be conveniently installed. In an alternative embodiment, a connection hole may be provided on the track plate 101, and the wire rope 2 is directly bolted in the connection hole.

By adjusting the length of the wire rope 2, the track slab 101 can be leveled.

In a preferred embodiment, as shown in fig. 5, further specifically, the supporting portion 4 includes a horizontally disposed supporting plate 401, and side plates 402 disposed at two ends of the supporting plate 401, a storage space of the single hydraulic prop is formed between the two side plates 402, a bottom supporting plate 12 is disposed on the supporting plate 401, and a plurality of arc-shaped surfaces are disposed at intervals on the top of the bottom supporting plate 12. By providing the bottom bracket plate 12 with an arc-shaped face, the individual hydraulic prop can be prevented from rolling in the horizontal direction.

As shown in fig. 5, the side plate 402 is connected to the connecting arm 5.

The further optimization is that the suspension bracket 3 further comprises a pressing plate 13 buckled on the bottom support plate 12, the bottom of the pressing plate 13 is provided with an arc-shaped surface matched with the bottom support plate 12, and the pressing plate 13 is connected with the support plate 401 through bolts. This enables the platen 13 and the bottom bracket plate 12 to clamp and fix the single hydraulic prop, and prevents the single hydraulic main shaft from being separated from the receiver 4 when the single hydraulic prop is transported.

The further optimization is that the lower surface of the pressure plate 13 and the upper surface of the bottom supporting plate 12 are both provided with rubber layers 14. In this way, the frictional force between the support plate 401, the pressure plate 13, and the hydraulic support cells can be increased, and the stability of fixing to the hydraulic support cells can be further improved.

A further optimization is that, as shown in fig. 1, the carrying device further comprises a connecting rod 15, and the connecting rod 15 is connected with each suspension bracket 3 in the same carrying unit through bolts. Therefore, the stability of the whole carrying unit can be improved, the change of the distance between the two suspension brackets 3 in the carrying process can be prevented, and the single hydraulic prop can be prevented from falling off the suspension brackets 3.

The embodiments in the present specification are described in a progressive manner, and the same and similar parts among the embodiments are referred to each other, and each embodiment focuses on the differences from the other embodiments. In particular, for the system embodiment, since it is substantially similar to the method embodiment, the description is simple, and for the relevant points, reference may be made to the partial description of the method embodiment.

The above description is only an example of the present application and is not intended to limit the present application. Various modifications and changes may occur to those skilled in the art. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present application should be included in the scope of the claims of the present application.

Claims (10)

1. A downhole monoblock hydraulic prop handling device, comprising:

the horizontal hanging rails are hung in the roadway through the hanging piece and are arranged along the extending direction of the roadway, and sliding areas are respectively arranged on the horizontal hanging rails on the two sides of the hanging piece;

the suspension bracket comprises a bearing part for bearing the single hydraulic prop, a suspension part arranged on the upper side of the bearing part and two guide wheel assemblies connected with the suspension part, the two guide wheel assemblies are respectively arranged on two sides of the horizontal suspension rail, and each guide wheel assembly comprises a guide wheel arranged in a sliding area in a rolling manner;

at least two suspension supports form a carrying unit, and all the bearing parts of the carrying unit jointly bear the single hydraulic prop.

2. The downhole hydraulic prop handling device of claim 1, wherein the horizontal hanger rail comprises a plurality of rail plates connected end to end, and two adjacent rail plates are connected by bolts.

3. The apparatus as claimed in claim 2, wherein the guide wheel assembly further comprises a guide wheel frame connected to the guide wheel, the guide wheel frame extending downward, and a plurality of first through holes being formed in the guide wheel frame at intervals in a vertical direction; the suspension part comprises a connecting arm formed by upwards extending the bearing part, a plurality of second through holes are formed in the connecting arm at intervals in the vertical direction, and the carrying device further comprises a bolt and a nut which are used for connecting the guide wheel frame and the connecting arm.

4. The underground hydraulic prop handling device of claim 2, wherein the track plate is provided with side rib plates extending upwards on both sides.

5. The underground hydraulic prop handling device of claim 2, wherein one end of each track plate is bent downward and then horizontally extends to form a base portion, each adjacent track plate is overlapped on the base portion, two adjacent track plates are connected at the base portion, and top surfaces of the two adjacent track plates are coplanar.

6. The downhole individual hydraulic prop handling device of claim 1, wherein the suspension member comprises a wire rope fixed to a roof wall of the roadway, and a wire rope buckle disposed on top of the horizontal hanger rail.

7. The underground single hydraulic prop conveying device according to claim 1, wherein the bearing part comprises a horizontally arranged bearing plate and side plates arranged at two ends of the bearing plate, a single hydraulic prop storage space is formed between the two side plates, a bottom plate is arranged on the bearing plate, and a plurality of arc-shaped surfaces are arranged at intervals at the top of the bottom plate.

8. The downhole individual hydraulic prop handling device of claim 7, wherein the suspension bracket further comprises a pressure plate fastened to the bottom plate, the bottom of the pressure plate has an arc-shaped surface engaged with the bottom plate, and the pressure plate is connected to the support plate by bolts.

9. The downhole monoblock hydraulic prop handling device of claim 8, wherein the lower surface of the pressure plate and the upper surface of the bottom pallet are each provided with a rubber layer.

10. The downhole individual hydraulic prop handling apparatus of claim 1, further comprising a connecting rod, wherein the connecting rod is bolted to each of the suspension brackets in the same handling unit.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921166819.XU CN210195811U (en) | 2019-07-23 | 2019-07-23 | Underground single hydraulic prop carrying device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921166819.XU CN210195811U (en) | 2019-07-23 | 2019-07-23 | Underground single hydraulic prop carrying device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210195811U true CN210195811U (en) | 2020-03-27 |

Family

ID=69867150

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921166819.XU Expired - Fee Related CN210195811U (en) | 2019-07-23 | 2019-07-23 | Underground single hydraulic prop carrying device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210195811U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113638766A (en) * | 2021-09-15 | 2021-11-12 | 山东泰安煤矿机械有限公司 | Hanging type head-on escape channel for long-distance tunneling |

| CN114017081A (en) * | 2021-10-20 | 2022-02-08 | 安徽恒源煤电股份有限公司 | Transfer device of mine stack type support |

-

2019

- 2019-07-23 CN CN201921166819.XU patent/CN210195811U/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113638766A (en) * | 2021-09-15 | 2021-11-12 | 山东泰安煤矿机械有限公司 | Hanging type head-on escape channel for long-distance tunneling |

| CN114017081A (en) * | 2021-10-20 | 2022-02-08 | 安徽恒源煤电股份有限公司 | Transfer device of mine stack type support |

| CN114017081B (en) * | 2021-10-20 | 2023-08-01 | 安徽恒源煤电股份有限公司 | Transfer device of crenelated support for mine |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN210195811U (en) | Underground single hydraulic prop carrying device | |

| CN108657949B (en) | Pneumatic monorail crane installation device and method | |

| CN113335317B (en) | Monorail track roof beam fortune frame mobile device in tunnel | |

| CN102926330B (en) | Installation method of hanging basket suitable for bridge construction | |

| CN219078968U (en) | Auxiliary device for carrying and installing large-scale equipment in building | |

| CN213059894U (en) | Hoisting tool for motor transfer in limited space | |

| CN211872614U (en) | Bridge bottom construction maintenance equipment | |

| CN210505356U (en) | Underground oil drum lifter | |

| CN211168676U (en) | Hanging belt type conveyor | |

| CN110654805A (en) | Hanging belt type conveyor | |

| CN216072775U (en) | Jack moving device | |

| CN214358554U (en) | Conveyor bracket assembly | |

| CN216331714U (en) | Disconnect-type GIL piping lane conveyer | |

| US5228549A (en) | Mobile beltine moving system | |

| CN217971297U (en) | A movable door type frame for belt feeder installation | |

| CN219565076U (en) | Tool for TBM main drive transportation in narrow space under deep coal mine | |

| CN217323268U (en) | Material transferring and lifting system suitable for slope supporting operation | |

| CN209990133U (en) | Reinforced concrete wall sliding formwork device | |

| CN115092630B (en) | Automatic climbing conveying equipment for small-sized precast blocks for slope protection | |

| CN216377189U (en) | Hoisting and transporting trolley | |

| CN220378332U (en) | U-shaped shed conveying device | |

| CN217516531U (en) | Crane lifting device | |

| CN210621485U (en) | Station hoisting system for hoisting corrugated steel web | |

| CN217230172U (en) | Rail moving tool | |

| CN222023497U (en) | Jacking device for leveling H-shaped frame of conveyor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20200327 Termination date: 20210723 |