CN210016058U - Lamp strip connector and corresponding lamp strip assembly - Google Patents

Lamp strip connector and corresponding lamp strip assembly Download PDFInfo

- Publication number

- CN210016058U CN210016058U CN201920595577.XU CN201920595577U CN210016058U CN 210016058 U CN210016058 U CN 210016058U CN 201920595577 U CN201920595577 U CN 201920595577U CN 210016058 U CN210016058 U CN 210016058U

- Authority

- CN

- China

- Prior art keywords

- pin

- assembly

- contact

- plug assembly

- strip

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Coupling Device And Connection With Printed Circuit (AREA)

Abstract

Embodiments of the present disclosure relate to a lamp strip connector and a lamp strip assembly including the same. This lamp strip connector includes: a male plug assembly, comprising: a circuit module including a circuit board, a pin contact and a line contact; a female plug assembly comprising an outer casing and an inner core disposed within the outer casing, one end of the outer casing being connected to a power supply input, the other end being provided with a first cavity allowing at least a portion of the male plug assembly to be inserted therein, and a pin assembly adapted to be disposed between the male plug assembly and the female plug assembly and comprising a pin; and in the state that the male plug assembly and the female plug assembly are electrically plugged, the pin contact piece is suitable for being electrically connected with an electric jack terminal in the inner core through the pin in the first cavity. The lamp strip connector can provide a safe and reliable electric connection mode, and pins are prevented from being directly inserted into the wire holes of the lamp strip.

Description

Technical Field

Embodiments of the present disclosure relate to the field of lighting, and more particularly, to a strip connector and a strip assembly including the same.

Background

At present, the high-voltage lamp strip is small in overall current, long in manufacturable length and capable of meeting the requirement of long-distance decorative lighting without a complex series connection process, so that the high-voltage lamp strip is widely applied to household troffer lighting and other decorative lighting.

However, the connection mode of the high-voltage lamp strip and the rectification end output in the market is to directly insert a contact pin into a wire hole of the lamp strip and a female copper terminal of the rectification output end, and the electric connection mode of the contact pin does not meet the requirement of a binding post in the lamp standard. In fact, the connection mode that the contact pin is directly inserted into the wire hole of the lamp strip is disadvantageous because the soft rubber of the lamp strip can become soft due to the action of heat in the use process, so that the electric connection of the contact pin can become loose, contact failure can be caused, and then poor electrification of the lamp strip is caused. In addition, poor contact can also easily lead to undesirable heating and create a fire hazard. In addition, in the operation mode of directly inserting the contact pin into the lamp strip wire guide hole, the contact pin is easy to be inserted in a biased manner when being inserted into the lamp strip wire guide hole, so that the contact area between the contact pin and the wire becomes uneven, the contact pin may need to be pulled out and then repeatedly inserted, and the operation is difficult to be satisfactory.

For example, CN103672779A proposes a light strip connection assembly. The lamp strip connecting component comprises a male plug and a female plug which can be butted with each other, wherein the male plug is provided with a bulge, the female plug is provided with a hole corresponding to the bulge, and the lamp strip connecting component still adopts an electric connection mode that a contact pin is connected with a wire hole of a flexible LED lamp strip in an inserting mode.

SUMMERY OF THE UTILITY MODEL

It is an object of the present disclosure to provide a strip connector that at least overcomes or alleviates one or more of the technical problems of the prior art, such as electrical connection.

According to a first aspect of the present disclosure, there is provided a light strip connector. This lamp strip connector includes: a male plug assembly, comprising: a circuit module comprising a circuit board, a pin contact and a wire contact, the pin contact and the wire contact being electrically connected to each other and both mounted on the circuit board, the wire contact being arranged to fasten and electrically connect the connection terminals of the light strip; a female plug assembly comprising an outer casing and an inner core disposed within the outer casing, one end of the outer casing being connected to a power supply input, the other end being provided with a first cavity allowing at least a portion of the male plug assembly to be inserted therein, and a pin assembly adapted to be disposed between the male plug assembly and the female plug assembly and comprising a pin; wherein in a state where the male and female plug assemblies are electrically plugged, the pin contact is adapted to electrically connect with an electrical receptacle terminal on the core via the pin within the first cavity.

Through the lamp strip connector of the present disclosure, a safe and reliable electrical connection mode can be provided. The electric connection mode avoids the direct insertion of the contact pin into the wire hole of the lamp strip, and meets the requirements of relevant binding posts in the lamp standard. In addition, the lamp strip connector adopts a plug-in structure of the male plug assembly and the female plug assembly, and can quickly realize electric plug-in from the male plug assembly to the female plug assembly.

In some embodiments, the pin contacts may be electrically connected to the line contacts via conductive traces on the circuit board. In such embodiments, the electrical connection of the pin contacts and the wire contacts may be accomplished in dependence upon conductive traces, which may conserve the use of electrical wiring.

In some embodiments, the male plug assembly further comprises a guide block comprising a first end and a second end, the first end being provided with a second cavity allowing at least a portion of the light strip to be inserted therein, the second end being provided with a slot for mounting the circuit board. In such embodiments, the guide block may be configured to securely hold and guide the circuit board such that a user may conveniently effect electrical mating from the male plug assembly to the female plug assembly.

In some embodiments, the guide block further comprises a through hole communicating the first end and the second end, the wire connection terminal of the light strip being adapted to extend from the first end of the guide block through the through hole to the second end for secure electrical connection with the wire contact. In such embodiments, the guide block may effectively guide the electrical connection of the wire terminals of the light strip to the wire contacts.

In some embodiments, one end of the pin assembly is securely and electrically connected to the inner core, and the other end of the pin is exposed in the first cavity, so that the other end of the pin is adapted to be electrically plugged with the pin contact in a state where the male and female plug assemblies are electrically connected. In these embodiments, the pins on the pin assembly can be conveniently electrically connected with both the male assembly and the female assembly.

In some embodiments, the male plug assembly further comprises a junction box, the circuit module is adapted to be received in the junction box, and the wire terminals of the light strip are adapted to electrically connect with the wire contacts in the circuit module. In these embodiments, the terminal box is configured to effectively and securely fix the circuit board and facilitate electrical connection of the entire male plug assembly to the female plug assembly.

In some embodiments, the pin assembly further includes a retention block for retaining the pin, the retention block adapted to be mounted within the junction box, the pin having one end adapted to electrically mate with the pin contact within the junction box and another end adapted to electrically mate with an electrical receptacle terminal on the core. In these embodiments, not only the circuit module but also a part of the pin assembly can be reliably fixed within the junction box, and one end of the pin assembly can be reliably electrically plugged with the pin contact on the circuit module.

In some embodiments, the wire contact includes a post, a contact dome, and a screw, the post including a first post hole into which a portion of the contact dome and a connection terminal of the light strip are inserted, and a second post hole through which an end of the screw passes, the first post hole and the second post hole communicating with each other, the second post hole being provided to allow the end of the screw to pass through to reach the first post hole, and the connection terminal is pressed via the contact dome. In such embodiments, the wiring terminals of the light strip may be securely and securely fastened to the wire contacts, thereby achieving a reliable electrical connection between the light strip and the strip connector.

In some embodiments, the contact spring is a U-shaped spring, the U-shaped spring comprises a first arm and a second arm which are U-shaped with respect to each other, the second arm is provided with an opening adapted to align with the second post hole, the first arm is inserted into the first post hole in a state where the screw is mounted in place, one end of the screw passes through the opening of the U-shaped spring, the second post hole and reaches the first post hole in sequence, and the connection terminal of the light strip is pressed via the first arm. In these embodiments, a reliable compression electrical connection to the wire terminals may be achieved by means of a U-shaped spring.

According to a first aspect of the present disclosure, there is provided a light strip assembly, characterized by comprising a light strip connector according to the various embodiments of the aforementioned first aspect.

It should be understood that the statements herein reciting aspects are not intended to limit the critical or essential features of the embodiments of the present disclosure, nor are they intended to limit the scope of the present disclosure. Other features of the embodiments of the present disclosure will become readily apparent from the following description.

Drawings

The above and other features, advantages and aspects of various embodiments of the present disclosure will become more apparent by referring to the following detailed description when taken in conjunction with the accompanying drawings. In the drawings, like or similar reference characters designate like or similar elements, and wherein:

fig. 1 shows a schematic view of a connection structure of a light strip assembly comprising a light strip connector according to a first embodiment of the present disclosure and a light strip;

FIG. 2 shows a schematic view of the connector of the strip of lamps of FIG. 1;

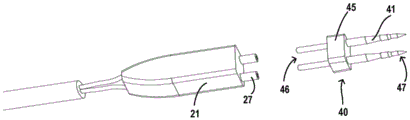

FIG. 3 is a schematic view showing a connection structure of a female plug assembly and a male pin assembly in the connector for lamp strip shown in FIG. 2;

FIG. 4 is a schematic view showing a guide block of a male plug assembly in the strip connector of FIG. 2

FIG. 5 is an exploded view of the circuit module of the male plug assembly of the light strip connector of FIG. 2;

FIG. 6 shows a schematic view of the back side of the circuit board in the circuit module shown in FIG. 5;

FIG. 7 is an exploded schematic view of the line contacts in the circuit module shown in FIG. 5;

fig. 8 is a schematic view showing a connection structure of a guide block and a circuit module in the connector for lamp string shown in fig. 2;

fig. 9 shows a schematic view of the connection of the guide block to the light strip in the light strip connector shown in fig. 2;

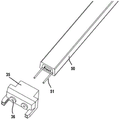

fig. 10 shows a schematic view of a connection structure of a light strip assembly comprising a light strip connector according to a second embodiment of the present disclosure and a light strip;

FIG. 11 shows a detailed structural schematic diagram of the light strip connector shown in FIG. 10; and

fig. 12 shows an overall schematic view of an assembled light strip connector and light strip according to the first and second embodiments of the present disclosure.

Detailed Description

Embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. While certain embodiments of the present disclosure are shown in the drawings, it is to be understood that the present disclosure may be embodied in various forms and should not be construed as limited to the embodiments set forth herein, but rather are provided for a more thorough and complete understanding of the present disclosure. It should be understood that the drawings and embodiments of the disclosure are for illustration purposes only and are not intended to limit the scope of the disclosure.

Embodiments of the present disclosure provide a strip connector, one of its objectives is to at least avoid direct electrical plugging of a contact pin with a flexible LED strip. For this reason, the lamp area connector of this disclosure includes public plug subassembly and female plug subassembly, and wherein the one end in lamp area can be fastened and be connected to public plug subassembly through the binding post in lamp area, and then public plug subassembly can carry out the electricity grafting with female plug subassembly through the contact pin on the contact pin subassembly. In particular, one end of the female plug assembly may be provided with a first cavity allowing at least a portion of the male plug assembly to be inserted therein, and the pin assembly may be secured to either the male plug assembly or the female plug assembly. The connection mode of the male plug assembly and the wiring terminal of the lamp strip avoids direct electric plug connection of the contact pin and the flexible LED lamp strip, the safety of the lamp strip connector is effectively improved, and meanwhile, the design of the male plug assembly and the female plug assembly enables connection among the lamp strip connector, the rectification output end and the flexible LED lamp strip to be simple.

Fig. 1 shows a schematic connection structure of a lamp strip assembly 100 comprising a lamp strip connector and a lamp strip according to a first embodiment of the present disclosure.

As shown in fig. 1, the light strip assembly 100 may comprise a light strip 50 and a light strip connector 10 that may adapt the light strip 50 to a power supply input, wherein the light strip 50 is adapted to emit illumination light of a desired color.

In some embodiments, the light strip 50 may be flexible and have a predetermined length to meet the predetermined length of decorative lighting requirements of the application. However, in other embodiments, a flexible light strip 50 is not required.

The function of the strip connector 10 is to connect the strip 50 to a power supply input. In some embodiments, the power input may be, for example, a rectified output (not labeled) such as the rectifier 12, so that the light strip 50 may be connected to a power source such as alternating current. However, this is not a limitation, and in other embodiments, the power supply input may be a dc power supply that does not include a rectified output.

In embodiments comprising a rectifier 12, the input of the rectifier 12 may for example be connected to an electrical plug 11 adapted to be plugged directly into an electrical supply socket, such as a mains supply, to receive a supply current, such as alternating current. The structure and function of the rectifier 12 and the electrical plug 11 are well known and will not be described in detail here.

The strip connector 10 of the first embodiment of the present disclosure may mainly include a male plug assembly 30, a female plug assembly 20, and a pin assembly 40 interposed between the male plug assembly 30 and the female plug assembly 20.

The detailed structures of the male plug assembly 30, the female plug assembly 20, and the pin assembly 40 in the strip connector 10 according to the first embodiment of the present disclosure and the connection manner of the male plug assembly, the female plug assembly 20, and the pin assembly 40 to the strip 50 will be further described below with reference to fig. 2 to 9.

As can be seen in connection with fig. 1 and 2, the female plug assembly 20 may generally include an outer sleeve 22 and an inner core 21, e.g., overmolded within the outer sleeve 22, which may further include, e.g., an inner sleeve (not labeled) and an electrical receptacle terminal 27 overmolded at least partially therein, wherein one end of the electrical receptacle terminal 27 may be electrically connected to a power input such as an output (not labeled) of the rectifier 12 and the other end may be electrically plugged with a pin 41, which will be described later. By way of example only, the electrical receptacle terminals 27 may be, for example, hollow round copper terminals.

In some embodiments, the wires leading from the power supply input (such as the output of the rectifier 12) may include at least two conductive cores, the inner sleeve (not labeled) functioning to: the stripped at least two conductive cores are separated and the electrical receptacle terminal 27 is secured.

One end 23 of the outer sleeve 22 may for example be connected to a power supply input such as a rectified output of the rectifier 12, and the other end 24 may be provided with a first cavity 25 allowing at least a portion of the male plug assembly 30 to be inserted therein.

The pin assembly 40 may be disposed between the male assembly 30 and the female assembly 20 and functions as an electrical plug between the male assembly 30 and the female assembly 20. As shown in fig. 3, the pin assembly 40 may include a pin 41 and a fixing block 45 for supporting and fixing the pin 41.

The pin 41 may include a first end 46 and an opposite second end 47, wherein the first end 46 may be securely electrically plugged into an electrical receptacle terminal 27 (e.g., a hollow round copper terminal) on the core 21, and the second end 47 may be exposed within the first cavity 25, such that the second ends 47 of the pin 41 and the male assembly 30 are electrically plugged into each other when the male assembly 30 is subsequently plugged into the female assembly 20, thereby electrically connecting the male assembly 30 to the female assembly 20.

Although in the above description, the pin assembly 40 exists independently of the male and female assemblies 30 and 20. However, this is not a limitation and pin assembly 40 may also be present as part of male assembly 30 or female assembly 20 in other embodiments without departing from the spirit of the present invention.

The male plug assembly 30 may include a circuit module 31. For this purpose, fig. 5 further shows an exploded schematic diagram of the circuit module 31. As shown in fig. 5, the circuit module 31 may include a circuit board 32, pin contacts 34, and line contacts 33, wherein the pin contacts 34 and the line contacts 33 may be both mounted on a first surface 321 of the circuit board 32 and electrically connected to each other. The wire contact 33 functions to secure and electrically connect the wire terminals 51 of the light strip 50 (see fig. 1), while the pin contact 34 functions to securely electrically mate with the pin 41 of the pin assembly 40. For example only, the pin contacts 34 may be formed from a clipped metal dome.

In order to achieve the fixing of the pin contacts 34 and the line contacts 33 on the circuit board 32, the pin contacts 34 can be fastened, for example, on mounting holes 324 of the circuit board 32, and the line contacts 33 can be fastened, for example, on mounting holes 325 of the circuit board 32.

In some embodiments, as shown in fig. 6, the pin contacts 34 may be electrically connected to the line contacts 33 via conductive traces 323 on the second surface 322 of the circuit board 32, thereby achieving an electrical connection between the pin contacts 34 and the line contacts 33. However, this is not a limitation, and it will be appreciated that in other embodiments, the conductive traces 323 may be disposed on the first surface 321 of the circuit board 32. It will be appreciated that the conductive traces 323 may save the use of electrical wiring; in still other embodiments, the pin contacts 34 may be electrically connected to the line contacts 33 in a manner such as electrical wiring.

As previously described, the wire contact 33 functions to secure and electrically connect the wire terminals 51 of the light strip 50, fig. 7 further illustrating an exploded view of the wire contact 33; fig. 8 shows a schematic cross-sectional view of the electrical connection of the wire contact 33 to the wire terminal 51 of the light strip 50.

As can be seen in fig. 7 and 8, the wire contact 33 may include a post 333, a contact spring 332, and a screw 331.

The post 333 may include a first post hole 335 and a second post hole 337 communicating with each other, wherein the first post hole 335 functions to allow insertion of a portion of the contact spring 332, and the second post hole 337 functions to allow insertion of the screw 331. In some embodiments, the first post hole 335 and the second post hole 337 may be perpendicular to each other such that the screw 331, when tightened into the second post hole 335, may substantially vertically abut the contact spring 332 within the first post hole 335.

In some embodiments, the contact spring 332 may be a U-shaped spring, which may include a first arm 336 and a second arm 338 that are generally U-shaped relative to each other, wherein the second arm 338 is provided with an aperture 334 adapted to align with the second post 337. In a state where the first arm 336 of the contact spring 332 is inserted into the first post hole 335, the opening 334 of the second wall 338 may be aligned with the second post hole 337 of the post 333, which may facilitate both the opening 334 of the screw 331 and the second post hole 337.

When mounted, one end of the screw 331 may sequentially pass through the opening 334 of the U-shaped dome, the second post hole 337 of the post 333, and reach the first post hole 335, and may press the connection terminal 51 of the light strip 50 via the first arm 336, thereby achieving a firm electrical connection between the wire contact 33 and the connection terminal 51 of the light strip 50. The electrical connection between the wire contact 33 and the connection terminal 51 of the light strip 50 avoids a direct electrical plug of a pin with a wire guide of the light strip.

Referring back to fig. 1 and 2, to facilitate electrical mating of the male plug assembly 30 to the female plug assembly 20, in some embodiments, the male plug assembly 30 may further include a guide block 35 that functions to secure the circuit board of the circuit module 31 and guide the electrical mating of the male plug assembly 30 into the first cavity 35 of the female plug assembly 20.

Fig. 4 further illustrates a detailed structural schematic of the guide block 35 which may be adapted to mount the circuit board 32.

As can be seen in connection with fig. 2 and 4, the guide block 35 may comprise a first end 39 and a second end 38, wherein the first end 39 is provided with a second cavity 351 (see fig. 8) allowing an end (not labeled) of the light strip 50 to be inserted therein, and the second end 38 is provided with a slot 37 for mounting the circuit board 32. Further, the guide block 35 is also provided with a through hole 36 communicating the first end 39 and the second end 38. The through hole 36 is provided so that the wire connection terminal 51 of the light strip 50 conveniently passes in from the first end 39 of the guide block 35 and out from the second end 38 of the guide block 35 for making electrical connection with the wire contact 33 as described above. It will be appreciated that the design of the guide block 35 may securely protect the end (not labeled) of the light strip 50, the wire terminals 51 and the wire contacts 33, which may effectively improve the reliability of the electrical connection of the light strip 50 to the wire contacts 31 and avoid the electrical connection being adversely affected by potential bending of the flexible light strip 50.

To facilitate insertion of the circuit board 32 mounted on the guide block 35 into the first cavity 35 of the female assembly 20, as shown in fig. 2, in some embodiments, the inner side wall of the first cavity 25 of the female assembly 20 may also be provided with a slot 251 corresponding to a side edge of the circuit board 32.

Having described the detailed structure of the strip connector 10 according to the first embodiment of the present disclosure in detail above, the electrical connection process between the male plug assembly 30, the female plug assembly 20 and the strip 50 in the strip connector 10 is briefly described as follows:

first, the connection terminals 51 of the light strip 50 may be exposed, and the connection terminals 51 may be passed through the through-holes 36 of the guide block 35. At this time, an end (not labeled) of the light strip 50 may protrude into the second cavity 351 of the guide block 35 (see fig. 8 and 9);

next, the circuit board 32 of the circuit module 31 is inserted into the insertion slot 37 of the guide block 35, and the connection terminals 51 are fastened to the wire contacts 33 of the circuit module 31, thereby achieving a secure electrical connection of the connection terminals 51 of the light strip 50 to the wire contacts 33 on the circuit board 32 (see fig. 8). At this time, the circuit module 31 together with the guide block 35 may constitute the male plug assembly 30.

Finally, the male plug assembly 30 is inserted into the female plug assembly 20 (see fig. 2, 8 and 12). In the plugged state, electrical connection of both the male and female plug assemblies 30, 20 can be achieved via the male pins 41 secured within the first cavity 25 of the female plug assembly 20, while the male plug assembly 30 can be inserted and concealed integrally into the first cavity 25 of the female plug assembly 20 (see fig. 12), which further improves the security of the electrical plug connection between the male and female plug assemblies 30, 20.

Although the male plug assembly 30 including the guide block 35 is described above with emphasis, it will be understood that the guide block 35 is provided only for plugging the circuit board 32 of the auxiliary circuit module 31 into the female plug assembly 20, and the guide block 35 is not necessarily provided. In other embodiments, the use of the guide block 35 may also be omitted.

The above description of the lamp string connector of the first embodiment of the present disclosure is made. It will be understood that the strip connector according to the first embodiment of the present disclosure can effectively avoid direct electrical insertion of a contact pin into a wire hole of a strip, and meet the requirements of a terminal in a lamp standard, and at the same time, the strip connector according to the first embodiment of the present disclosure is reliable in electrical connection with the strip and the rectification output end, and high in safety. In addition, the installation of lamp strip connector is simple convenient.

Fig. 10 shows a schematic view of a connection structure of a light strip assembly 100' comprising a light strip connector according to a second embodiment of the present disclosure and a light strip; fig. 11 shows a detailed structural diagram of the strip connector shown in fig. 10. Note that: for the sake of brevity and clarity, like parts of the second embodiment to those of the first embodiment have been given like reference numerals.

As shown in fig. 10 and 11, a strip connector 10 'of a second embodiment of the present disclosure may include a female plug assembly 20 and a male plug assembly 30', wherein the female plug assembly 20 may have the same structure as the female plug assembly described in the first embodiment, and will not be described again.

The male plug assembly 30 'may include a junction box 60' and a circuit module 31 'adapted to be mounted within the junction box 60'.

The circuit module 31 ' may include a circuit board 32 ', pin contacts 34, and line contacts 33, wherein the pin contacts 34 and the line contacts 33 are mounted on the circuit board 32 ', and their structures and electrical connection methods to each other may be the same as those of the pin contacts and the line contacts described in the previous first embodiment, and thus will not be described again.

The circuit board 32' differs from the circuit board 32 in the description of the first embodiment earlier in that: the circuit board 32 'may also be provided with positioning holes 37' adapted to position or secure the circuit board 32 'within the junction box 60'.

In some embodiments, the positioning holes 37 ' may be provided, for example, at locations on the circuit board 32 ' between the pin contacts 34 and the wire contacts 33, which function to mate with positioning posts 67 ' within the junction box 60 ' to be described later to position the circuit board 32 '. However, this is not a limitation, and in other embodiments, the positioning holes 37 'may be disposed at other locations on the circuit board 32'.

In some embodiments, an opening 38 ' may also be provided between the two line contacts 33 on the circuit board 32 ', the opening 38 ' serving to allow a partition wall 68 ' of a junction box 60 ', to be described later, to be inserted therethrough to separate the two line contacts 33.

Junction box 60 'may include an upper cover 63' and a lower cover 64 ', wherein upper cover 63' and lower cover 64 'may collectively form a cavity (not labeled) adapted to receive circuit board 32' and/or pin assembly 40.

The circuit board 32 ' may be positioned adjacent the first end 62 ' of the junction box 60 ' to facilitate electrical connection of the wire terminals 51 of the light strip 50 at the first end 62 ' with the wire contacts 33 disposed on the circuit board 32 ', but at the same time, space may be reserved within the first end 62 ' of the junction box 60 ' for insertion of an end portion (not labeled) of the light strip 50. In this case, when making the electrical connection of the wire connection terminal 51 to the wire contact 33, the end of the light strip 50 may be at least partially inserted into the first end 62 'of the junction box 60', whereby it may be ensured that the wire connection terminal 51 as a whole is electrically connected to the wire contact 33 within the junction box 60 ', which improves the reliability of the electrical connection of the wire connection terminal 51 at this first end 62'.

The pin assembly 40 may be positioned adjacent the second end 61 'of the junction box 60' and may have one end 46 of the pin 41 extending from the second end 61 'of the junction box 60' such that the one end 46 of the pin 41 may be electrically mated with the female assembly 20.

In some embodiments, the upper cover 63 'may be attached to the lower cover 64' and may pivot about one side edge of the lower cover 64 ', thereby facilitating the snap-fitting of the upper cover 63' to the lower cover 64 'to form a cavity adapted to receive the circuit board 32'. It will be appreciated, however, that this is not a limitation and in other embodiments, the junction box 60 'may not have an upper cover 63' or the upper cover 63 'may be provided separately from the lower cover 64'.

In some embodiments, the lower cover 64 'may have a cavity that receives or mounts the circuit board 32'. However, this is not limiting and in other embodiments, the function of housing or mounting the circuit board 32 'may be performed by the cover 63'.

In embodiments such as where the circuit board 32 ' is received or mounted in the lower cover 64 ', the lower cover 64 ' may be provided with positioning posts 67 ' and a partition wall 68 ', such as for positioning or securing the circuit board 32 ', wherein the positioning posts 67 ' may be adapted to pass through positioning holes 37 ' provided on the circuit board 32 ' to position the circuit board 32 ' in the lower cover 64 '; while the partition wall 68 'may pass through the opening 38' in the circuit board 32 'to separate the two line contacts 33 provided on the circuit board 32', which may effectively avoid a short circuit of both line contacts 33.

In addition to mounting the circuit board 32 ', in some embodiments, the lower cover 62' may also be provided with a space adapted to receive or mount or secure the pin assembly 40. As an example, the lower cover 62 ' may, for example, have a receiving groove 65 ', the receiving groove 65 ' being adapted to receive or mount the fixing block 45 of the pin assembly 40.

In a state where the fixing block 45 is mounted in the receiving groove 65 ', one end 47 of the pin 41 of the pin assembly 40 can be electrically inserted into the pin contact 34 in the terminal block 60'; the other end 46 may extend out of the junction box 60' for electrical mating with the electrical receptacle terminals 27 of the core 21 in the female assembly 20.

Having described the detailed structure of the strip connector 10 ' according to the second embodiment of the present disclosure in detail above, the electrical connection process between the male plug assembly 30 ', the female plug assembly 20 and the strip 50 in the strip connector 10 ' is briefly described as follows:

first, the wire terminals 51 of the light strip 50 may be exposed, and the circuit module 31 'and the pin assembly 40 are mounted in the junction box 60'. At this time, one end 47 of the pin 41 of the pin assembly 40 is electrically plugged with the pin contact 34 in the circuit module 31 'in the terminal block 60', and the other end 46 is exposed from the second end 61 'of the terminal block 60';

next, the connection terminals 51 of the lamp strip 50 are securely and electrically connected to the wire contacts 33 in the circuit module 31 ', and then the upper cover 63 ' is snapped onto the lower cover 64 ';

finally, the terminal block 60' with the pin assembly 40 attached thereto is inserted into the first cavity 25 of the female plug assembly 20 (see fig. 12). In the plugged state, the male plug assembly 30 ' can be electrically connected to the female plug assembly 20 via the pins 41 of the pin assembly 40, while the entire male plug assembly 30 ' can be completely plugged into the first cavity 25 of the female plug assembly 20 (see fig. 12), which also improves the safety of the electrical plug connection between the male plug assembly 30 ' and the female plug assembly 20.

While the above description focuses on a junction box 60 ' adapted to receive both the circuit board 32 ' and the pin assembly 40, it will be appreciated that the junction box 60 ' functions as: electrical mating between the auxiliary circuit board 32 'and the pin assembly 40, and electrical mating of the auxiliary male assembly 30' to the female assembly 20. Thus, it will be appreciated that the arrangement and configuration of the terminal block 60 ' described above is not required, and in other embodiments, the terminal block 60 ' may be designed to receive only one of the circuit board 32 ' and the pin assembly 40; in still other embodiments, junction box 60' may be omitted.

The above description of the connector for lamp string according to the second embodiment of the present disclosure. It will be understood that the strip connector according to the second embodiment of the present disclosure may also effectively avoid direct electrical insertion of the contact pin into the wire hole of the strip, and meet the requirements of the terminal in the lamp standard, and meanwhile, the electrical connection between the strip connector according to the second embodiment of the present disclosure and the strip and the rectifying output end is also relatively reliable and high in safety. In addition, the installation of the lamp strip connector is convenient.

While the invention has been illustrated and described in detail in the drawings and foregoing description, such illustration and description are to be considered illustrative or exemplary and not restrictive; the present invention is not limited to the disclosed embodiments. Other variations to the disclosed embodiments can be understood and effected by those skilled in the art in practicing the claimed invention, from a study of the drawings, the disclosure, and the appended claims.

In the claims, the word "comprising" does not exclude other elements, and the indefinite article "a" or "an" does not exclude a plurality. A single element or other unit may fulfill the functions of several items recited in the claims. The mere fact that certain features are recited in mutually different embodiments or in dependent claims does not indicate that a combination of these features cannot be used to advantage. The scope of protection of the present application covers any possible combination of features recited in the various embodiments or in the dependent claims, without departing from the spirit and scope of the application.

Any reference signs in the claims shall not be construed as limiting the scope of the invention.

Claims (10)

1. A light strip connector (10, 10'), comprising:

a male plug assembly (30, 30') comprising:

a circuit module (31, 31 ') comprising a circuit board (32, 32 '), a pin contact (34) and a line contact (33), the pin contact (34) and the line contact (33) being electrically connected to each other and both mounted on the circuit board (32, 32 '), the line contact (33) being arranged to fasten and electrically connect a connection terminal (51) of a light strip (50);

a female plug assembly (20) comprising an outer casing (22) and an inner core (21) arranged within the outer casing (22), one end (23) of the outer casing (22) being connected to a power supply input, the other end (24) being provided with a first cavity (25) allowing at least a portion of the male plug assembly (30, 30') to be inserted therein, and

a pin assembly (40) adapted to be arranged between the male assembly (30, 30') and the female assembly (20) and comprising a pin (41);

wherein in a state of electrical plugging of the male plug assembly (30, 30') and the female plug assembly (20), the pin contact (34) is adapted to make an electrical connection with an electrical receptacle terminal (27) on the core (21) via the pin (41) within the first cavity (25).

2. The strip connector (10, 10') according to claim 1,

the pin contacts (34) are electrically connected to the line contacts (33) via conductive traces (323) on the circuit boards (32, 32').

3. The strip connector (10, 10 ') according to claim 1, wherein the male plug assembly (30, 30') further comprises a guide block (35),

the guide block (35) comprises a first end (39) and a second end (38), the first end (39) being provided with a second cavity (351) allowing at least a portion of the light strip (50) to be inserted therein, the second end (38) being provided with a slot (37) for mounting the circuit board (32).

4. A strip connector (10, 10') according to claim 3, wherein said guide block (35) further comprises a through hole (36) communicating said first end (39) and said second end (38), said strip terminal (51) being adapted to extend from said first end (39) of said guide block (35) through said through hole (36) to said second end (38) for making a secure electrical connection with said wire contact (33).

5. The strip connector (10, 10') according to claim 3, wherein one end (46) of the pin (41) of the pin assembly (40) is securely and electrically connected to the electrical receptacle terminal (27) on the core (21), and the other end (46) of the pin (41) is exposed within the first cavity (25) such that the other end (47) of the pin (41) is adapted to be electrically plugged with the pin contact (34) in a state where the male and female assemblies (30, 20) are electrically connected.

6. The strip connector (10, 10 ') of claim 1, wherein the male plug assembly (30 ') further comprises a junction box (60 '),

the circuit module (31 ') is adapted to be received in the junction box (60 '), the wire terminals (51) of the light strip being adapted to be electrically connected with the wire contacts (33) in the circuit module (31 ').

7. The strip connector (10, 10 ') according to claim 6, wherein said pin assembly (40) further comprises a fixing block (45) for fixing said pins (41), said fixing block (45) being adapted to be mounted in said junction box (60'),

one end (47) of the pin (41) is adapted to electrically plug with the pin contact (34) in the terminal block (60'), and the other end (46) is adapted to electrically plug with the electrical receptacle terminal (27) on the core (21).

8. Strip connector (10, 10') according to any one of claims 1-7, wherein the wire contact (33) comprises a terminal post (333), a contact spring (332) and a screw (331),

the contact post (333) includes a first post hole (335) into which a portion of the contact spring (332) and the connection terminal (51) of the lamp strip (50) are inserted, and a second post hole (337) through which one end of the screw (331) passes, the first post hole (335) and the second post hole (337) communicating with each other,

the second post hole (337) is provided to be adapted to pass one end of the screw (331) therethrough to reach the first post hole (335), and press the terminal (51) via the contact spring (332).

9. The strip connector (10, 10') according to claim 8, wherein the contact spring (332) is a U-shaped spring comprising a first arm (336) and a second arm (338) having a U-shape with respect to each other, the second arm (338) being provided with an opening (334) adapted to be aligned with the second post hole (337),

in a state that the screw 331 is mounted in place, the first arm 336 is inserted into the first post hole 335, one end of the screw 331 passes through the opening hole 334 of the U-shaped dome, the second post hole 337 and reaches the first post hole 335 in order, and presses the connection terminal 51 of the lamp strip 50 via the first arm 336.

10. A light strip assembly (100, 100 ') characterized by comprising a light strip connector (10, 10') according to any one of claims 1-9.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920595577.XU CN210016058U (en) | 2019-04-26 | 2019-04-26 | Lamp strip connector and corresponding lamp strip assembly |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201920595577.XU CN210016058U (en) | 2019-04-26 | 2019-04-26 | Lamp strip connector and corresponding lamp strip assembly |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210016058U true CN210016058U (en) | 2020-02-04 |

Family

ID=69316080

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201920595577.XU Active CN210016058U (en) | 2019-04-26 | 2019-04-26 | Lamp strip connector and corresponding lamp strip assembly |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210016058U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111543771A (en) * | 2020-06-09 | 2020-08-18 | 东莞市觅智实业有限公司 | LED lamp vanity mirror |

-

2019

- 2019-04-26 CN CN201920595577.XU patent/CN210016058U/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111543771A (en) * | 2020-06-09 | 2020-08-18 | 东莞市觅智实业有限公司 | LED lamp vanity mirror |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7794283B2 (en) | Socket, plug, and adaptor combination with waterproof arrangement | |

| US7429186B2 (en) | Flexible high-power LED lighting system | |

| US9912081B2 (en) | Lighted electrical connector housing | |

| US20220329026A1 (en) | Serially-connectable device for electrical cable | |

| US8536820B2 (en) | Modular electric socket assembly and assembly method thereof | |

| KR101782652B1 (en) | Light emitting diode interconnection system | |

| CN210016058U (en) | Lamp strip connector and corresponding lamp strip assembly | |

| US7766681B1 (en) | Waterproof electric plug or receptacle for LED light string | |

| CN116191086B (en) | Connector assembly | |

| CN211265744U (en) | Connecting device | |

| CN210052872U (en) | Wire series connection structure | |

| CN209461740U (en) | A kind of male end connector and female end connector | |

| KR100982429B1 (en) | Light control device having ground plate | |

| CN112467430A (en) | Wire series connection structure | |

| CN219106637U (en) | Energy storage connector socket | |

| CN212725670U (en) | Multicore elbow connector that possesses integral type terminal of bending | |

| CN219371531U (en) | Improved structure of connector lock catch pulling force | |

| CN219696847U (en) | Male connector and electronic equipment comprising same | |

| CN215722835U (en) | Ceiling lamp | |

| KR101389564B1 (en) | Led bulb using socket connector | |

| CN219696746U (en) | Connector assembly and electronic equipment | |

| CN116014484B (en) | Connector assembly and electronic equipment | |

| CN220102904U (en) | LED lamp plug-in type interface structure and LED lamp tube | |

| CN217903581U (en) | HM subassembly water joint convenient to install | |

| CN211088679U (en) | Power supply connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |