CN203172387U - Balanced suspension system used for heavy commercial vehicle - Google Patents

Balanced suspension system used for heavy commercial vehicle Download PDFInfo

- Publication number

- CN203172387U CN203172387U CN 201320000698 CN201320000698U CN203172387U CN 203172387 U CN203172387 U CN 203172387U CN 201320000698 CN201320000698 CN 201320000698 CN 201320000698 U CN201320000698 U CN 201320000698U CN 203172387 U CN203172387 U CN 203172387U

- Authority

- CN

- China

- Prior art keywords

- type

- suspension system

- weight

- balanced suspension

- heavy

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Vehicle Body Suspensions (AREA)

Abstract

The utility model provides a balanced suspension used for a heavy commercial vehicle. The balanced suspension used for the heavy commercial vehicle adopts a split V-shaped thrust rod support structure, and the structure comprises a split V-shaped thrust rod support (3) and a stamping cross beam (4). Under the condition that unchanging of parameters of designing and installing of a V-shaped thrust rod (5) of the balanced suspension is ensured, and the V-shaped thrust rod support (3) and the stamping cross beam (4) which are optimized in structure and light in weight are used to replace a cast cross beam structure which integrates a thrust rod seat and is thick and large in shape and heavy in weight. According to the balanced suspension used for the heavy commercial vehicle, weight of the finished vehicle can be reduced, manufacturing cost can be reduced, transporting efficiency can be improved, and the balanced suspension used for the heavy commercial vehicle meets requirements for developing of light-weight commercial vehicles.

Description

Technical field

The utility model relates to the heavy motor vehicle suspension system, specifically relates to a kind of equalizing suspension system.

Background technology

Two drive axle heavy type commercial automobile rear suspensions adopt balance suspension more, realize the transmission of propulsive effort between drive axle and vehicle frame by propelling rod.The V-type propelling rod not only can be along the vehicle heading transmission of drive force, can also absorb the drive axle transmission side force, play the effect of Panhard rod, so the V-type propelling rod is widely used in the two drive axle heavy type commercial automobiles at non-mining road traveling.

At present, adopt that the heavy-duty commercial vehicle of V-type propelling rod is general all to be incorporated in the thrust pole seat of vehicle frame end on the casting beam, adopt foundry technique, make that design of part is thick, weight is big, increased complete vehicle weight, thereby caused the conveying efficiency decrease to some degree.

Figure 1 illustrates the structural representation of existing V-type propelling rod 1 and casting beam 2.In this structure, merged thrust pole seat in the casting beam.The foundry technique that adopts when making casting beam causes this casting beam profile thick, makes that the weight of crossbeam is difficult to reduce, cost is higher.

Figure 2 illustrates the structural representation that adopts the crossbeam that foundry technique makes.Owing to adopted foundry technique, the structure of this crossbeam is handed over complicated, and also because foundry technique makes that the volume of crossbeam is bigger, weight is bigger simultaneously.

Obviously, the crossbeam that adopts foundry technique to make in automobile suspension system is unfavorable for the weight of suspension system, can not improve conveying efficiency effectively.

In view of this, the invention provides a kind of novel suspension system and overcome problems of the prior art.

The utility model content

For realizing the lightweight of heavy type commercial automobile, the utility model provides a kind of novel suspension system, and this suspension system can reduce its weight to a great extent under the reliable and stable situation of retention.

For achieving the above object, this kind is used for the equalizing suspension system of heavy type commercial automobile, it is characterized in that described equalizing suspension system adopts split type V-type track bar bracket and punching press crossbeam, and described V-type track bar bracket and punching press crossbeam are respectively fixed on the vehicle frame.

Preferably, an end of V-type propelling rod is inserted in the hole of V-type track bar bracket, and the other end is contained in the hole that is fixed on the drive axle, realize the fixing of V-type propelling rod, and the punching press crossbeam is installed on the vehicle frame, is used for reinforcing vehicle frame.

More preferably, described V-type track bar bracket adopts foundry technique to make.

Suspension system of the present utility model has adopted split type V-type track bar bracket 3, wherein, has replaced casting beam of the prior art with the punching press crossbeam.

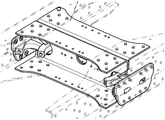

Clearly, the utility model improves existing structure, as shown in Figure 3: split type V-type track bar bracket 3 is separated the function of thrust pole seat from crossbeam, and design independently V-type track bar bracket 3 with the method for foundry goods optimization, replace casting beams to finish the function of reinforcing vehicle frame with punching press crossbeam 4 simultaneously.Fig. 4 is V-type track bar bracket 3 and punching press crossbeam 4 scheme drawings.

As can be seen from Figure 4, independently the structure of V-type track bar bracket 3 wants simple a lot of with respect to the thrust pole seat structure that is incorporated in the casting beam, can use relative less material when adopting foundry technique to make this simple relatively structure, thereby make the weight of V-type track bar bracket lighter, and reduce manufacturing cost.

Improvement effect of the present utility model is exactly: the casting beam that replaces having merged thrust pole seat with V-type track bar bracket 3 and punching press crossbeam 4.New construction can significantly reduce structural weight, reaches heavy type commercial automobile weight-saving purpose, and reduces manufacturing cost simultaneously.

Description of drawings

Fig. 1 is the mounting structure scheme drawing of prior art;

Fig. 2 is the casting beam structural representation that has merged thrust pole seat of the prior art;

Fig. 3 is the mounting structure scheme drawing of split type V-type track bar bracket of the present invention;

Fig. 4 is V-type track bar bracket and punching press crossbeam scheme drawing.

The specific embodiment

By reference to the accompanying drawings heavy type commercial automobile balance suspension of the present utility model is described, this balance suspension has adopted split type V-type track bar bracket structure.

As shown in Figure 4, V-type track bar bracket 3 comprises two V-shaped holes, is used for the end that holds V-type propelling rod 5.When mounted, the end of V-type propelling rod 5 is inserted in the hole of V-type track bar bracket 3, and the other end is contained in (as shown in Figure 3) in the hole that is fixed on the drive axle.Punching press crossbeam 4 is installed on the chassis side rail by bolt, nut, and V-type track bar bracket 3 also is installed on the chassis side rail by bolt, nut.Thereby realize the propelling rod transmission of drive force, absorb side force that drive axle transmits, and play the purpose of Panhard rod effect.The punching press crossbeam is installed on the vehicle frame, can play the effect of reinforcing vehicle frame.

Divide the employing of body structure to make crossbeam can adopt the Sheet Metal Forming Technology manufacturing, be easy to reach the purpose of falling weight.V-type track bar bracket 3 is with after the function of crossbeam is separated, and the method that easily adopts foundry goods to optimize reduces deadweight to greatest extent on the basis that guarantees structural strength.So the employing of split type V-type track bar bracket 3 can significantly reduce the car load deadweight, reduces oil consumption, improve conveying efficiency, and is consistent with heavy-duty commercial vehicle weight-saving development tendency.

Claims (3)

1. equalizing suspension system that is used for heavy type commercial automobile, it is characterized in that, described equalizing suspension system adopts split type V-type track bar bracket (3) and punching press crossbeam (4), and described V-type track bar bracket (3) is respectively fixed on the vehicle frame with punching press crossbeam (4).

2. equalizing suspension system as claimed in claim 1, it is characterized in that: an end of V-type propelling rod (5) is inserted in the hole of V-type track bar bracket (3), the other end is contained in the hole that is fixed on the drive axle, realize the fixing of V-type propelling rod (5), and punching press crossbeam (4) is installed on the vehicle frame, is used for reinforcing vehicle frame.

3. equalizing suspension system as claimed in claim 2 is characterized in that: described V-type track bar bracket (3) adopts foundry technique to make.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201320000698 CN203172387U (en) | 2013-01-04 | 2013-01-04 | Balanced suspension system used for heavy commercial vehicle |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201320000698 CN203172387U (en) | 2013-01-04 | 2013-01-04 | Balanced suspension system used for heavy commercial vehicle |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN203172387U true CN203172387U (en) | 2013-09-04 |

Family

ID=49069134

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201320000698 Expired - Fee Related CN203172387U (en) | 2013-01-04 | 2013-01-04 | Balanced suspension system used for heavy commercial vehicle |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN203172387U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107264204A (en) * | 2017-06-09 | 2017-10-20 | 中国第汽车股份有限公司 | A kind of Novel lightweight V-type track bar bracket |

| CN109229209A (en) * | 2018-09-18 | 2019-01-18 | 东风汽车悬架弹簧有限公司 | A kind of novel commercial vehicle carriage assembly type crossbeam |

-

2013

- 2013-01-04 CN CN 201320000698 patent/CN203172387U/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107264204A (en) * | 2017-06-09 | 2017-10-20 | 中国第汽车股份有限公司 | A kind of Novel lightweight V-type track bar bracket |

| CN109229209A (en) * | 2018-09-18 | 2019-01-18 | 东风汽车悬架弹簧有限公司 | A kind of novel commercial vehicle carriage assembly type crossbeam |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103085595B (en) | Be used in particular for the front axle support of automobile | |

| CN202656818U (en) | Balanced suspension for wide-body mining car | |

| KR101956483B1 (en) | Monorail bogie formed all in one comprise that main frame and guide arm | |

| CN103786788B (en) | A kind of automobile front subframe and corresponding automobile | |

| CN209535205U (en) | Subframe and the automobile for applying it | |

| CN204197030U (en) | A kind of quarry tipper riveted joint vehicle frame | |

| CN210191655U (en) | Semi-floating suspension system for cab of light truck | |

| CN203172387U (en) | Balanced suspension system used for heavy commercial vehicle | |

| CN101549624A (en) | Rubber vehicle suspension device with variable rigidity property | |

| CN202923319U (en) | Front axle of electric wheel dump truck | |

| CN102729756A (en) | Rear suspension system for rear-drive off-road vehicle | |

| CN205871661U (en) | Electric automobile is with back longitudinal wall formula independent suspension structure | |

| CN201395026Y (en) | Air suspension for heavy-duty truck | |

| CN201304877Y (en) | Vehicle rubber suspension device with variable stiffness performance | |

| CN208021562U (en) | A kind of commercial-vehicle cab rear-suspending system | |

| CN202200797U (en) | Frame for adjusting height of automobile body of small-sized electric automobile | |

| CN208021549U (en) | A kind of car modular vehicle frame | |

| CN202743003U (en) | Novel multifunctional push-down support assembly | |

| CN2823017Y (en) | Rear overhang system of coach | |

| CN209833762U (en) | Steering assembly of commercial vehicle | |

| CN203864803U (en) | Double-rear-axle type heavy truck frame | |

| CN202163263U (en) | Plate spring suspension structure with overhanging beam | |

| CN203358265U (en) | Multi-functional front shock absorber support | |

| CN209336425U (en) | A kind of new-energy automobile dual wheel rims drive axle structure | |

| CN201472470U (en) | Carriage assembly with straight longitudinal beam |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20130904 Termination date: 20180104 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |