CN202472249U - Toner cartridge - Google Patents

Toner cartridge Download PDFInfo

- Publication number

- CN202472249U CN202472249U CN2012200965792U CN201220096579U CN202472249U CN 202472249 U CN202472249 U CN 202472249U CN 2012200965792 U CN2012200965792 U CN 2012200965792U CN 201220096579 U CN201220096579 U CN 201220096579U CN 202472249 U CN202472249 U CN 202472249U

- Authority

- CN

- China

- Prior art keywords

- counting tooth

- gear end

- tooth

- counting

- toner cartridge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Electrophotography Configuration And Component (AREA)

Abstract

The utility model discloses a toner cartridge, and aims at providing a toner cartridge with a simple structure and a capability of being successfully recycled without dismantling a gear end cover. The toner cartridge comprises a counting tooth (7), a toner cartridge main body (9) and a gear end cover (5) matched with the side part of the toner cartridge main body (9), wherein the counting tooth (7) is arranged on the outer side of the gear end cover (5), the inner side of the counting tooth (7) is in transmission connection with a transmission mechanism inside the toner cartridge main body (9), at least one clamping pin (8) is arranged at the top of the counting tooth (7), the bottom of the counting tooth (7) is cylindrical, no interference rotation exists between the bottom of the counting tooth (7) and the inner side of the gear end cover (5), a limit block (6) used for locating the clamping pin (8) is arranged on the outer side of the gear end cover (5), and the limit block (6) can enable the counting tooth (7) to stop in a correct position during rotation. The utility model can be widely applied to the field of toner cartridges.

Description

Technical field

The utility model relates to a kind of cartridge.

Background technology

Powder box installation back printer is recognized machine has dual mode, and the one, recognize machine through chip counter, the 2nd, recognize machine through counting tooth counting.Wherein, counting tooth counting is recognized the machine process and is: after newly powder box was packed printer into, the rotation of printer driver gear was rotated through the counting of the gear set drive on powder box tooth, and the card base on counting tooth top is dialed the counter switch of printer; Only less than the half-turn profile of tooth, blocked by the inner position-limit foot of gear end cap after the counting tooth half turn, thereby be parked in a fixed position on the counting tooth, the counter switch of a card base jack-up printer on counting tooth top; Printer is recognized the machine completion, and the machinery panel green light is bright, and is ready.When the printer powder box exhausted serviceable life, the machinery panel amber light was bright, and the prompting powder box life-span is most, can not continue to print again, and this moment, powder box must take out regeneration from printer, added carbon dust, and made the counting tooth reset to initial position; Or count tooth counting quota and turn to stuck position, need powder box be taken out regeneration equally.

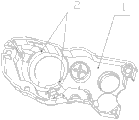

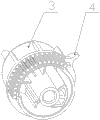

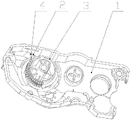

Yet the cartridge under the prior art; Like Fig. 1, Fig. 2, shown in Figure 3; Because the technology shortcoming is perfect, the powder box that the life-span is used up is because the location card base 4 that gear end cap 1 inner spacing card base 2 will be counted on the tooth 3 blocks, and the counting tooth can not rotate for 3 this moments; The staff can only take gear end cap 1 apart and could will count tooth 3 initial position is installed back, and powder box could reproductive success.In addition, present powder box capacity can suitably increase, however the counting tooth of cartridge count down to one regularly can be stuck automatically, at this moment also must take out powder box regeneration, can more fully utilize the carbon dust in the powder box.Therefore, the powder box regenerative process all must be according to this job step each time, and the staff that this process of dismounting cartridge is generally also only known cartridge just can operate, and is extremely not convenient, obviously increases many troubles to related work.

The utility model content

The utility model technical matters to be solved is the deficiency that overcomes prior art, provide a kind of simple in structure, need not to take apart the cartridge that the gear end cap just can make the powder box reproductive success.

The technical scheme that the utility model adopted is: the utility model comprise counting tooth, powder box main body, with the adaptive gear end cap of said powder box main body sidepiece; Said counting tooth is located at the said gear end cap outside; The inboard gear train with said powder box body interior of said counting tooth is in transmission connection; The top of said counting tooth is provided with at least one card base; The bottom of said counting tooth is cylindrical shape and does not have interference rotation with the inboard of said gear end cap, and the outside of said gear end cap is provided with the limited block that is used to locate said card base.

Preferably, said limited block is made as ramped shaped, is convenient to said card base and crosses said limited block.

The beneficial effect of the utility model is: because the utility model has been cancelled the location card base of counting tooth bottom on the basis of existing technology; Therefore rotatablely moving of counting tooth can not be limited in gear end cap inboard; And withstand the printer switch in order to make the counting tooth when recognizing the machine rotation, stop at the fixed position; Be provided with a limited block in the outside of gear end cap, stop at the tram when making the counting tooth recognize the machine rotation.The cartridge of this structure need not be taken the gear end cap apart in the time of will making powder box regeneration, directly will count tooth and be rotated counterclockwise, and makes it cross limited block, gets back to initial position the counting tooth is resetted, and powder box is the ability reproductive success just; Said limited block is made as ramped shaped, and operability is stronger.

Description of drawings

Fig. 1 is the inboard structural representation of prior art lower gear end cap;

Fig. 2 is the structural representation of counting tooth under the prior art;

Fig. 3 counts tooth by the structural representation of gear end cap inner side limiting-position under the prior art;

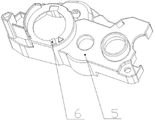

Fig. 4 is the structural representation in the utility model gear end cap outside;

Fig. 5 is the structural representation of the utility model counting tooth;

Fig. 6 is that the utility model counting tooth is by the spacing structural representation in the gear end cap outside.

Embodiment

Like Fig. 4, Fig. 5, shown in Figure 6; The utility model relates to a kind of improved cartridge structure that under prior art, is optimized; It comprises powder box main body 9, with the adaptive gear end cap 5 of said powder box main body 9 sidepieces, said counting tooth 7 is located at the outside of said gear end cap 5, the gear trains of the inboard of said counting tooth 7 and said powder box main body 9 inside are in transmission connection; During the printer action, said gear train drives said counting tooth 7 and rotates; The said counting tooth 7 relatively counting tooth of prior art has reduced the location card base, surveys not have when rotatablely moving and in the said gear end cap 5 and interferes; The outside of said counting tooth 7 is provided with three card bases 8; Be provided with the limited block 6 that is used to locate said card base 8 in the outside of said gear end cap 5; Said limited block 6 can make said card base 8 when said counting tooth 7 is recognized the machine rotation, stop on the correct position, thereby makes the powder box reproductive success of printer.When printer because of powder box in the not enough or said counting tooth 7 of carbon dust when reaching stuck position and quitting work; Only need the said counting tooth 7 moving suitable distance of layback outward; Be rotated counterclockwise and make it to cross said limited block 6 in said counting tooth 7 then; Getting back to initial position makes said counting tooth 7 reset the powder box reproductive success.Said limited block 6 is made as ramped shaped, is convenient to said counting tooth 7 and crosses said limited block 6, accomplish homing action.The great advantage of the cartridge of this structure need not to take apart said gear end cap 5 exactly just can make the powder box reproductive success, convenient to use, workable.

In sum, the utility model can be widely used in the cartridge field.

Claims (2)

1. cartridge; Comprise counting tooth (7), powder box main body (9), with the adaptive gear end cap (5) of said powder box main body (9) sidepiece; Said counting tooth (7) is located at the outside of said gear end cap (5); The inner gear train of the inboard of said counting tooth (7) and said powder box main body (9) is in transmission connection; The top of said counting tooth (7) is provided with at least one card base (8), it is characterized in that: the bottom of said counting tooth (7) is cylindrical shape and does not have interference rotation with the inboard of said gear end cap (5), and the outside of said gear end cap (5) is provided with the limited block (6) that is used to locate said card base (8).

2. a kind of cartridge according to claim 1 is characterized in that: said limited block (6) is made as ramped shaped.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200965792U CN202472249U (en) | 2012-03-15 | 2012-03-15 | Toner cartridge |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200965792U CN202472249U (en) | 2012-03-15 | 2012-03-15 | Toner cartridge |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202472249U true CN202472249U (en) | 2012-10-03 |

Family

ID=46920393

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200965792U Expired - Lifetime CN202472249U (en) | 2012-03-15 | 2012-03-15 | Toner cartridge |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202472249U (en) |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9207567B2 (en) | 2010-08-31 | 2015-12-08 | Brother Kogyo Kabushiki Kaisha | Cap configuration for a toner cartridge |

| US9594329B2 (en) | 2014-03-31 | 2017-03-14 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9599929B2 (en) | 2010-03-31 | 2017-03-21 | Brother Kogyo Kabushiki Kaisha | Cartridge and image forming apparatus |

| US9599953B2 (en) | 2014-03-31 | 2017-03-21 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9599954B2 (en) | 2014-03-31 | 2017-03-21 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9605734B2 (en) | 2013-06-28 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Cartridge provided with movable detected body |

| US9606504B2 (en) | 2013-09-20 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Image forming device |

| US9606473B2 (en) | 2014-03-31 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Cartridge having detected member |

| US9606503B2 (en) | 2014-03-31 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9612569B2 (en) | 2014-03-31 | 2017-04-04 | Brother Kogyo Kabushiki Kaisha | Cartridge with multiple rotary members |

| US9612548B2 (en) | 2011-11-24 | 2017-04-04 | Brother Kogyo Labushiki Kaisha | Cartridge provided with pivotable member for new product detection |

| US9612553B2 (en) | 2013-10-31 | 2017-04-04 | Brother Kogyo Kabushiki Kaisha | Cartridge having agitator and rotary member with detected portion |

| US9618879B2 (en) | 2014-01-06 | 2017-04-11 | Brother Kogyo Kabushiki Kaisha | Developing cartridge |

| US9639026B2 (en) | 2014-03-31 | 2017-05-02 | Brother Kogyo Kabushiki Kaisha | Cartridge with transmission gear and toothless gear |

| US9714696B2 (en) | 2013-06-28 | 2017-07-25 | Brother Kogyo Kabushiki Kaisha | Cartridge provided with body for new product detection |

-

2012

- 2012-03-15 CN CN2012200965792U patent/CN202472249U/en not_active Expired - Lifetime

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9599929B2 (en) | 2010-03-31 | 2017-03-21 | Brother Kogyo Kabushiki Kaisha | Cartridge and image forming apparatus |

| US9612552B2 (en) | 2010-03-31 | 2017-04-04 | Brother Kogyo Kabushiki Kaisha | Cartridge and image forming apparatus |

| US9207567B2 (en) | 2010-08-31 | 2015-12-08 | Brother Kogyo Kabushiki Kaisha | Cap configuration for a toner cartridge |

| US9612551B2 (en) | 2010-08-31 | 2017-04-04 | Brother Kogyo Kabushiki Kaisha | Cap configuration for a toner cartridge |

| US9612548B2 (en) | 2011-11-24 | 2017-04-04 | Brother Kogyo Labushiki Kaisha | Cartridge provided with pivotable member for new product detection |

| US9714696B2 (en) | 2013-06-28 | 2017-07-25 | Brother Kogyo Kabushiki Kaisha | Cartridge provided with body for new product detection |

| US9605734B2 (en) | 2013-06-28 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Cartridge provided with movable detected body |

| US9606504B2 (en) | 2013-09-20 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Image forming device |

| US9612553B2 (en) | 2013-10-31 | 2017-04-04 | Brother Kogyo Kabushiki Kaisha | Cartridge having agitator and rotary member with detected portion |

| US9618879B2 (en) | 2014-01-06 | 2017-04-11 | Brother Kogyo Kabushiki Kaisha | Developing cartridge |

| US9599954B2 (en) | 2014-03-31 | 2017-03-21 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9612569B2 (en) | 2014-03-31 | 2017-04-04 | Brother Kogyo Kabushiki Kaisha | Cartridge with multiple rotary members |

| US9606503B2 (en) | 2014-03-31 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9606473B2 (en) | 2014-03-31 | 2017-03-28 | Brother Kogyo Kabushiki Kaisha | Cartridge having detected member |

| US9599953B2 (en) | 2014-03-31 | 2017-03-21 | Brother Kogyo Kabushiki Kaisha | Cartridge |

| US9639026B2 (en) | 2014-03-31 | 2017-05-02 | Brother Kogyo Kabushiki Kaisha | Cartridge with transmission gear and toothless gear |

| US9594329B2 (en) | 2014-03-31 | 2017-03-14 | Brother Kogyo Kabushiki Kaisha | Cartridge |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202472249U (en) | Toner cartridge | |

| CN203673223U (en) | Developing cartridge counting gear | |

| CN103465006A (en) | Independent automatic electrode cap replacement unit | |

| CN206456559U (en) | A kind of protective cover of unmanned plane propeller | |

| CN204009375U (en) | A kind of handle box and the image processing system that comprises this handle box | |

| CN107380464B (en) | Unmanned aerial vehicle battery rotation type changes structure | |

| CN103760755B (en) | Delevoping cartridge counting gear | |

| CN104308714A (en) | Polishing machine for producing empty capsules | |

| CN205419019U (en) | Accurate fixed position rotation carousel of unmanned on duty intelligence | |

| CN204807911U (en) | Developing box | |

| CN206126035U (en) | Novel bottle lid go -no -go mode mechanism | |

| CN201761967U (en) | Single paper sampling device for automatic die cutting and foilstamping press | |

| CN207780505U (en) | A kind of useless powder collecting device of printer toner cartridge | |

| CN209534771U (en) | A kind of charging pile with automatic winding function | |

| CN206426656U (en) | Combined ink external memory device for multicolour offset press | |

| CN208343662U (en) | A kind of direct plate maker for avoiding printing plate from deviating | |

| CN203004553U (en) | Ribbon cartridge used for label printing device | |

| CN208993317U (en) | It is a kind of can convenient changing colour band electric field verify with verify ink ribbon cartridge for printer | |

| CN216661935U (en) | Degradable cutlery box automatic feeding machine | |

| CN208172505U (en) | Reset structure of counting gear on toner cartridge | |

| CN204955770U (en) | Gear units resets | |

| CN215283884U (en) | Automatic conveying device in environment-friendly carton printing device | |

| CN205680167U (en) | A kind of coin-out control device of coin exchanger | |

| CN204908565U (en) | Bookshelf for business administration | |

| CN103523422A (en) | Vehicle-mounted garbage can provided with suckers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20121003 |