CN202118823U - Connecting element and backlight device - Google Patents

Connecting element and backlight device Download PDFInfo

- Publication number

- CN202118823U CN202118823U CN2011201912321U CN201120191232U CN202118823U CN 202118823 U CN202118823 U CN 202118823U CN 2011201912321 U CN2011201912321 U CN 2011201912321U CN 201120191232 U CN201120191232 U CN 201120191232U CN 202118823 U CN202118823 U CN 202118823U

- Authority

- CN

- China

- Prior art keywords

- clamping element

- glue frame

- elastic fastening

- hole

- convexity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Connection Of Plates (AREA)

Abstract

The utility model discloses a connecting element and a backlight device. A rubber frame is provided with a first surface, a back plate is provided with a second surface, a protrusion of a clamping element enables an elastic clamping hook to be tightly clamped with the edge of a hole through a corresponding hole, and accordingly the first surface is clamped and fixed with the second surface. Users only need to perform hole-opening treatment on the back plate and do not need to draw or rivet a stud, and no influence on the dimension of a module is caused. In the assembly process of the backlight device, external force is slightly exerted so that the elastic clamping hook is tightly clamped in the hole, and the particular assembly process is not needed.

Description

[technical field]

The utility model relates to the back lighting device field of liquid crystal display, the back lighting device that relates in particular to a kind of Connection Element and adopt this Connection Element.

[background technology]

The framework of liquid crystal display module generally includes preceding frame, glass plate and backlight assembly.Glue frame in the backlight assembly is connected with the mode of backboard through screw or external grab.

Be to adopt the screw mode to connect the connected mode sketch map of glue frame and backboard shown in the accompanying drawing 1; Comprise backboard 11, glue frame 12 and screw 13; On backboard 11 and glue frame 12, have internal thread perforate 110 and 120 respectively; Screw 13 passes perforate 110 and 120, thereby backboard 11 and glue frame 12 are linked together.The screw ways of connecting is a connected mode the most common in the prior art, and shortcoming is that backboard 11 also need be done to take out draws or rivet double-screw bolt, and the use of screw 13 has also increased assembling man-hour when increasing material cost.

Be the connected mode sketch map that adopts external opening shown in the accompanying drawing 2, comprise backboard 21 and glue frame 22, be provided with elastic fastening hook 220 at the side-lower of glue frame 22, the ipsilateral of backboard 21 is provided with the projection 210 corresponding with elastic fastening hook 220.When assembling, grab 220 leans on self elasticity and projection 210 to tighten each other under external force, thereby backboard 21 and glue frame 22 are linked together.The shortcoming of this mode is and will inevitably produces certain influence to the appearance and size of module size that the material that increases a glue frame at least is thick.

[utility model content]

The utility model technical problem to be solved is, a kind of Connection Element and back lighting device are provided, and can neither have influence on the size of module, again can the economical with materials cost and assembling man-hour.

In order to address the above problem, the utility model provides a kind of Connection Element, comprises glue frame and backboard; Said glue frame is provided with first surface; Said backboard is provided with second surface, and said first surface is provided with a plurality of clamping elements, and each clamping element comprises the convexity that protrudes in first surface; Each protruding end is provided with and is a plurality of elastic fastening hooks that outside divergent shape distributes; Said second surface is provided with the hole corresponding with clamping element, and the convexity of said clamping element can tighten through the edge of corresponding hole with elastic fastening hook and hole, thereby first surface and said second surface are fixed.

As optional technical scheme, the convexity of the outstanding first surface of said clamping element is a plurality of support bars perpendicular to first surface, and the end of each support bar is provided with an elastic fastening hook.

As optional technical scheme, the convexity of the outstanding first surface of each clamping element is a support bar, and the end of said support bar is provided with a plurality of elastic fastening hooks.Said support bar is the elastic rod of middle part hollow out.

The utility model further provides a kind of back lighting device; Comprise glue frame, backboard and at least one backlight, said glue frame is provided with first surface, and said backboard is provided with second surface; Said first surface is provided with a plurality of clamping elements; Each clamping element comprises the convexity that protrudes in first surface, and each protruding end is provided with and is a plurality of elastic fastening hooks that outside divergent shape distributes, and said second surface is provided with the hole corresponding with clamping element; The convexity of said clamping element can tighten through the edge of corresponding hole with elastic fastening hook and hole, thereby first surface and said second surface are fixed.

As optional technical scheme, said glue frame is many knockdown glue frames, and said glue frame is provided with said a plurality of clamping element at least two respective side assemblies.

As optional technical scheme, the glue frame that said glue frame is an integrate shaped type, said glue frame is provided with said a plurality of clamping element at least two respective side.

The advantage of the utility model is; Because the first surface at the glue frame is provided with elastic fastening hook, and, therefore only needs to do perforate and handle at backboard because elastic fastening hook is clamped on the inside of the second surface of backboard; Need not to take out and draw or rivet double-screw bolt, can the size of module not exerted an influence.It is inner that above-mentioned back lighting device only needs a little external force can elastic fastening hook be tightened to hole in assembling process, need not special assembling procedure.

[description of drawings]

Accompanying drawing 1 is structural representations of Connection Element in the utility model prior art with accompanying drawing 2.

Accompanying drawing 3 is structural representations of Connection Element in the utility model one specific embodiment.

Accompanying drawing 4 is local enlarged diagrams of the clamping element of Connection Element shown in the accompanying drawing 3.

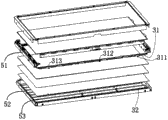

Accompanying drawing 5 is the assembling sketch mapes that adopt the back lighting device of Connection Element shown in the accompanying drawing 3.

Accompanying drawing 6 is structural representations of clamping element in another specific embodiment of the utility model.

Accompanying drawing 7 is structural representations of clamping element in the another specific embodiment of the utility model.

[specific embodiment]

The Connection Element that the utility model is provided below in conjunction with accompanying drawing and adopt the specific embodiment of the back lighting device of this Connection Element to elaborate.

At first combine accompanying drawing to provide first specific embodiment of the utility model.

Accompanying drawing 3 is structural representations of Connection Element in this specific embodiment, comprises opposite first 31 and second surface 32.First surface 31 is provided with three clamping elements, is respectively 311,312 and 313, and is provided with hole 321,322 and 323 in second surface 32 and the corresponding position of these clamping elements.Clamping element 311,312 and 313 can pass corresponding hole 321,322 with 323 and with the edge chucking of hole, thereby first surface 31 and second surface 32 are linked together.In other embodiment, more or clamping element still less also can be set, and the hole of respective number be set according to the position of clamping element.

Specifically, accompanying drawing 4 is enlarged diagrams of clamping element 311 shown in the accompanying drawing 3, and wherein clamping element 311 comprises convexity 3113 and first elastic fastening hook 3111 and second elastic fastening hook 3112 that are arranged on protruding 3113 ends.In this embodiment, protruding 3113 is a support bar.In accompanying drawing 4, protruding 3113 end bilateral symmetry is provided with two elastic fastening hooks 3111 and 3112.Two other clamping element 312 and 313 at accompanying drawing 3 also is identical structure.And in other embodiment, one or more protruding end can also be provided with the elastic fastening hook more than two arbitrarily, for example three or four etc.A plurality of elastic fastening hooks are that the center is outside divergent shape and distributes with the end of convexity that these elastic fastening hooks are set; The embodiment that three elastic fastening hooks for example are set can be that the divergent shape that three grabs are 120 degree angles each other distributes, and the embodiment that four elastic fastening hooks are set can be the distribution of dispersing that four grabs are an angle of 90 degrees each other.This centrosymmetric mode can make elastic fastening hook and hole when chucking and hole between active force be uniform.

Accompanying drawing 5 is the assembling sketch mapes that adopt the back lighting device of Connection Element shown in the accompanying drawing 3; Comprise glue frame 51, backboard 52 and backlight 53; Wherein said glue frame 51 is normally made by the plastic material ejection formation, and said backboard 52 is normally formed by the metal stamping bending.Said glue frame 51 and the backboard 52 common inner spaces that form are with existing assemblies such as ccontaining at least one backlight 53 and at least one blooming pieces.In the utility model, glue frame 51 has first surface 31, and backboard 52 has second surface 32.First surface 31 is provided with three clamping elements; Be respectively 311,312 and 313; And be provided with hole 321~323 (size of hole is too little, can't in accompanying drawing 5, show, particular location sees also accompanying drawing 3) in second surface 32 and these protruding corresponding positions.Glue frame 51 can be many knockdown glue frames, but also can be the glue frame of integrate shaped type.In the present embodiment, glue frame 51 is many knockdown glue frames, and at least wherein is provided with clamping element 311~313 on the two respective side assemblies at glue frame 51.If the glue frame that said glue frame 51 is integrate shaped types, then said glue frame is provided with said a plurality of clamping element 1 at least two respective side.Moreover; Said glue frame 51 also is provided with same clamping element structure (not shown in the accompanying drawing 5) with a side (assembly) that is provided with clamping element 311~313 along relative another side (assembly) edge, and corresponding position also is provided with same hole 321~323 on backboard 52.

When assembling, these clamping elements 311~313 can pass hole 321~323 and the edge of elastic fastening hook and hole is tightened, thereby the glue frame 51 that will have first surface 31 links together with the backboard 52 with second surface 32.From accompanying drawing 5, can it is evident that; Because the first surface 31 at glue frame 51 is provided with the clamping element 311~313 with elastic fastening hook; And because the elastic fastening hook of clamping element 311~313 ends is clamped on the inside of the second surface 32 of backboard 52; Therefore only need to do perforate and handle, draw or rivet double-screw bolt and need not to take out, so the utility model can not exert an influence to the size of module at backboard 52.It is inner that above-mentioned back lighting device only needs a little external force can clamping element 311~313 be tightened to hole in assembling process, need not special assembling procedure or extra screw assembly.

Accompanying drawing 6 is structural representations of clamping element in another specific embodiment of the utility model, comprises two first support bar 6111 and second support bars 6112 perpendicular to first surface.The end that the end of first support bar 6111 has first elastic fastening hook, 6113, the second support bars 6112 has second elastic fastening hook 6114.First elastic fastening hook 6113 and second elastic fastening hook 6114 are 180 degree angles mutually in same plane.In other and accompanying drawing 6 similar embodiments; Clamping element can also have more support bars; For example three or four etc.; Be " article " font each other or sphere of movements for the elephants shape is evenly arranged; The end of each support bar has an elastic fastening hook, can be the divergent shape distribution that three elastic fastening hooks are 120 degree angles each other as far as the embodiment that is provided with three support bars and elastic fastening hook, and can be the distribution of dispersing that four elastic fastening hooks are an angle of 90 degrees each other in the embodiment that four support bars and elastic fastening hook are set.

Accompanying drawing 7 is structural representations of clamping element in the another specific embodiment of the utility model, and bossing is the elastic rod 7113 of a middle part hollow out, is provided with first elastic fastening hook 7111 and second elastic fastening hook 7112 in elastic rod 7113 ends.Adopt the advantage of the elastic rod 7113 of middle part hollow out be to utilize the middle part engraved structure increased clamping element along with the telescopic level of first surface parallel direction, help going in the hole (not shown in the accompanying drawing 7) that first elastic fastening hook 7111 and second elastic fastening hook 7112 more easily snap onto correspondence.Certainly, similar with aforementioned embodiments, the end of elastic rod 7113 can also be provided with the elastic fastening hook more than two certainly, for example three or four etc., and its arrangement mode and advantage see also the narration of front, no longer repeat here.

One of ordinary skill in the art will appreciate that all or part of step in the whole bag of tricks of the foregoing description is to instruct relevant hardware to accomplish through program; This program can be stored in the computer-readable recording medium, and storage medium can comprise: ROM, RAM, disk or CD etc.

More than method, equipment and system that the utility model embodiment is provided carried out detailed introduction; Used concrete example among this paper the principle and the embodiment of the utility model are set forth, the explanation of above embodiment just is used to help to understand the method and the core concept thereof of the utility model; Simultaneously, for one of ordinary skill in the art, according to the thought of the utility model, the part that on the specific embodiment and range of application, all can change, in sum, this description should not be construed as the restriction to the utility model.

Claims (10)

1. a Connection Element comprises glue frame and backboard, it is characterized in that; Comprise: said glue frame is provided with first surface; Said backboard is provided with second surface, and said first surface is provided with a plurality of clamping elements, and each clamping element comprises the convexity that protrudes in first surface; Each protruding end is provided with and is a plurality of elastic fastening hooks that outside divergent shape distributes; Said second surface is provided with the hole corresponding with clamping element, and the convexity of said clamping element can tighten through the edge of corresponding hole with elastic fastening hook and hole, thereby first surface and said second surface are fixed.

2. Connection Element according to claim 1 is characterized in that: the convexity of the outstanding first surface of said clamping element is a plurality of support bars perpendicular to said first surface, and the end of each said support bar is provided with an elastic fastening hook.

3. Connection Element according to claim 1 is characterized in that; The convexity of the outstanding first surface of each said clamping element is a support bar, and the end of said support bar is provided with a plurality of elastic fastening hooks.

4. Connection Element according to claim 3 is characterized in that; Said support bar is the elastic rod of middle part hollow out.

5. back lighting device; Comprise glue frame, backboard and at least one backlight, said glue frame is provided with first surface, and said backboard is provided with second surface; Said first surface is provided with a plurality of clamping elements; Each clamping element comprises the convexity that protrudes in first surface, and each protruding end is provided with and is a plurality of elastic fastening hooks that outside divergent shape distributes, and said second surface is provided with the hole corresponding with clamping element; The convexity of said clamping element can tighten through the edge of corresponding hole with elastic fastening hook and hole, thereby first surface and said second surface are fixed.

6. back lighting device according to claim 5 is characterized in that: the convexity of the outstanding first surface of said clamping element is a plurality of support bars perpendicular to said first surface, and the end of each said support bar is provided with an elastic fastening hook.

7. back lighting device according to claim 5 is characterized in that: the convexity of the outstanding first surface of each said clamping element is a support bar, and the end of said support bar is provided with a plurality of elastic fastening hooks.

8. back lighting device according to claim 7 is characterized in that: said support bar is the elastic rod of middle part hollow out.

9. back lighting device according to claim 5 is characterized in that: said glue frame is many knockdown glue frames, and said glue frame is provided with said a plurality of clamping element at least two respective side assemblies.

10. back lighting device according to claim 5 is characterized in that: the glue frame that said glue frame is an integrate shaped type, said glue frame is provided with said a plurality of clamping element at least two respective side.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011201912321U CN202118823U (en) | 2011-06-07 | 2011-06-07 | Connecting element and backlight device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011201912321U CN202118823U (en) | 2011-06-07 | 2011-06-07 | Connecting element and backlight device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202118823U true CN202118823U (en) | 2012-01-18 |

Family

ID=45459885

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011201912321U Expired - Fee Related CN202118823U (en) | 2011-06-07 | 2011-06-07 | Connecting element and backlight device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202118823U (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102749734A (en) * | 2012-06-19 | 2012-10-24 | 歌尔声学股份有限公司 | Backlight module of LCD (Liquid Crystal Display) device and manufacturing method of backlight module |

| WO2014005346A1 (en) * | 2012-07-04 | 2014-01-09 | 深圳市华星光电技术有限公司 | Backlight module, connecting component, and disassembling method thereof |

| WO2016045145A1 (en) * | 2014-09-28 | 2016-03-31 | 深圳市华星光电技术有限公司 | Backlight module and liquid crystal display device |

| CN109782491A (en) * | 2019-03-29 | 2019-05-21 | 厦门天马微电子有限公司 | A kind of backlight module and display device |

-

2011

- 2011-06-07 CN CN2011201912321U patent/CN202118823U/en not_active Expired - Fee Related

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102749734A (en) * | 2012-06-19 | 2012-10-24 | 歌尔声学股份有限公司 | Backlight module of LCD (Liquid Crystal Display) device and manufacturing method of backlight module |

| WO2014005346A1 (en) * | 2012-07-04 | 2014-01-09 | 深圳市华星光电技术有限公司 | Backlight module, connecting component, and disassembling method thereof |

| WO2016045145A1 (en) * | 2014-09-28 | 2016-03-31 | 深圳市华星光电技术有限公司 | Backlight module and liquid crystal display device |

| CN109782491A (en) * | 2019-03-29 | 2019-05-21 | 厦门天马微电子有限公司 | A kind of backlight module and display device |

| CN109782491B (en) * | 2019-03-29 | 2022-09-13 | 厦门天马微电子有限公司 | Backlight module and display device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101943375A (en) | Connecting assembly and backlight module | |

| CN202118823U (en) | Connecting element and backlight device | |

| CN203461337U (en) | Improved glass shelf | |

| CN103353096B (en) | A kind of splicing backboard of backlight module | |

| US10500461B2 (en) | Foldable rebound net frame | |

| CN210998310U (en) | Fastening clamp assembly for building board machining | |

| CN203595876U (en) | Middle frame of liquid crystal display, liquid crystal display and liquid crystal television | |

| CN203055343U (en) | Caution plate base | |

| CN101630052B (en) | Barrel bearing jig | |

| CN109466856A (en) | Columnar product transfer device | |

| CN204580363U (en) | Magnetic pressure type reading stand | |

| CN202935081U (en) | Detachable drawing board | |

| CN201681549U (en) | Framework of display device | |

| CN201323212Y (en) | Battery combination framework | |

| CN215814680U (en) | Display device for teaching | |

| CN204931060U (en) | A kind of building material product showing stand | |

| CN203563987U (en) | Display table | |

| CN202257498U (en) | Outer framework for electronic whiteboard | |

| CN211418070U (en) | Electronic blackboard transports mount | |

| CN201765408U (en) | Fixing structure for LCD (liquid crystal display) screen | |

| CN210930457U (en) | Sofa frame with freely adjustable backrest | |

| CN204650091U (en) | Display | |

| CN2724005Y (en) | PCB plate test clamp | |

| CN205669776U (en) | A kind of bindiny mechanism of novel multiple-unit body splicing | |

| CN213370763U (en) | Book shelf |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| DD01 | Delivery of document by public notice |

Addressee: Zhang Shuhong Document name: Notification to Pay the Fees |

|

| DD01 | Delivery of document by public notice |

Addressee: Zhang Shuhong Document name: Notification of Termination of Patent Right |

|

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120118 Termination date: 20120607 |