CN201354907Y - Pipe junction - Google Patents

Pipe junction Download PDFInfo

- Publication number

- CN201354907Y CN201354907Y CNU2009200510009U CN200920051000U CN201354907Y CN 201354907 Y CN201354907 Y CN 201354907Y CN U2009200510009 U CNU2009200510009 U CN U2009200510009U CN 200920051000 U CN200920051000 U CN 200920051000U CN 201354907 Y CN201354907 Y CN 201354907Y

- Authority

- CN

- China

- Prior art keywords

- hole

- gear ring

- macropore

- elasticity

- ring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Quick-Acting Or Multi-Walled Pipe Joints (AREA)

Abstract

A pipe junction comprises a junction body (1) with a through hole, wherein a locating step for locating a connected pipe is arranged in the middle of the through hole, an end port of the through hole is a step hole which is small inside and big outside, the small hole is adapted with the outer diameter of the connected pipe (2), a rubber gasket ring-shaped groove is arranged on the inner wall of the small hole and is provided with a sealing rubber ring (3), the inner end of the big hole is provided with an elastic locking gear ring (4), and the elastic locking gear ring (4) is provided with a locking mechanism and is provided with an opening mechanism of the elastic locking gear ring outside. The pipe junction has few components, compact structure, simple manufacture technique and low cost, can be made of raw materials such as iron or aluminum alloy, plastic and the like, can not damage the pipe junction on the surface layer when in manufacture and assembly, and has reliable connection and rapid installation and disassembly.

Description

Technical field

The utility model relates to a kind of pipe joint, especially relates to a kind of quick coupling made from iron or aluminum alloy, plastics.

Background technique

Pipeline connection generally passing through pipe joint, thereby existing a kind of pipe joint that adopts the internal tooth clamp ring to replace screw thread connection locking tubing, as Chinese utility model patent communique disclosed " a kind of direct-push type multiunit tube joint ", the patent No. is ZL00235720.8, publication number is CN2428674, relate to aluminium-plastic composite pipe or PEX pipe, be characterized in: be made up of pipe fitting, O-ring seals, awl seat, resilience gear ring, movable tapered sleeve and fixed cover, O-ring seals, awl seat, resilience gear ring, movable tapered sleeve and fixed cover are inclusive in the pipe fitting body opening successively.In aluminium-plastic composite pipe that connects or the direct patchhole of PEX tubing, also realize sealing by the elastic force of 15-20 uniform in resilience gear ring hole internal tooth and the extending amount card jail tubing of seal ring, when the activity compression tapered sleeve, can take out the connected tube material.

But this technological scheme has following deficiency: the one, and component are more, and structure is comparatively complicated, causes manufacture cost higher; The 2nd, can only be with copper material or stainless steel manufacturing.This is because if make with other materials, such scheme is difficult to solve etch-proof problem, for pipe joint, as everyone knows, corrosion protection is a very important point, so pipe joint or adopt copper material, stainless steel manufacturing, for example irony or aluminum alloy are made pipe joint and then must be carried out the corrosion protection surface treatment with other materials.

Can there be very big problem if make with plastics or iron, aluminum alloy in the pipe joint of such scheme on technology.This is because this pipe joint all parts except that pipe fitting all are inclusive in the pipe fitting, the mode that contains is port roll extrusion or the punching press bag mouth with pipe fitting, otherwise the parts of the inside will be fixed and come off out, and roll extrusion or punching press bag mouth are last procedures, just any processing can't have been carried out afterwards, if carry out the material that preservative treatment will destroy the inside again, influence structure, appearance can not seal or can't lock the problem of pipeline, if doing preservative treatment earlier wraps and mouthful will destroy anticorrosive coat, pipe joint can corrosion and damage influence water quality, and can't in the end wrap mouth with the plastic production pipe joint.

Also have, as Chinese utility model patent communique on July 4th, 2007 disclosed " water or steam pipe connection set " (CN1324258C), with model utility communique disclosed utility model patent on October 17th, 2007 " pipe joint that is used for liquid and gas " (CN200961762Y), except that there being the many structures of component equally is the high deficiency of complicated cost, main is that these two kinds of pipe joints all adopt threaded connector (plug sleeve or outer collar, outer blind nut) fixes the component of locking pipe joint inside, because water pipe can produce vibration under current variation or pump valve effect, being threaded, it is loosening to produce, and can produce the risk that gets loose after using in the time of long.

The model utility content

At the deficiencies in the prior art part, primary technical problem to be solved in the utility model, it is low just to provide few, the simple and compact for structure cost of a kind of component, and makes the pipe joint that can not destroy anticorrosive coat when assembling.

On the basis of the above, even if this pipe joint can not produce the phenomenon that gets loose yet under the situation of long-time vibration, and for convenience detach.

Solve the problems of the technologies described above, the utility model can be realized by following technological scheme:

A kind of pipe joint, comprise the joint body that has through hole, be useful on the positioning step of connected tube location in the middle of the through hole, it is characterized in that: described through hole port is inner small and outside big shoulder hole, aperture adapts to the connected tube external diameter, on the aperture inwall, have the cushion rubber annular groove O-ring seal is housed, elasticity locking gear ring is equipped with in the macropore inner end, elasticity locking gear ring is a ring-type, be evenly equipped with in the inside edge of ring body and a plurality ofly stretch out and with anchor ring the latch of same angle is arranged to the ring heart, the locking gear ring is provided with locking framework outward.

The locking framework of described elasticity locking gear ring is:

The landolsring of ring body for not sealing of A, annular resilient locking gear ring has the radial ringed groove corresponding to elasticity locking gear ring on the macropore inner end inwall of joint body port shoulder hole;

Have radial ringed groove on the macropore inner end inwall of B, joint body port shoulder hole, be provided with circlip;

The outer end of C, joint body port shoulder hole is tapped hole and is furnished with blind nut, has the axial bore corresponding to connected tube in the middle of the blind nut, and blind nut is hexagonal blind nut or the cylindrical blind nut that is evenly equipped with radial groove on the exterior edge face;

Have radial ringed groove on the macropore inner end inwall of D, joint body port shoulder hole, be evenly equipped with at least 3 axial notches that are communicated with radial ringed groove from external port on the macropore inwall; Be furnished with the spinner lid, middle axial bore, the excircle that has corresponding to connected tube of spinner lid is provided with the fixedly projection corresponding to the macropore axial notch, and fixedly projection may be stuck in the radial ringed groove of macropore inner end inwall; Also have a spinner cover lock mandrel on the described macropore port inner wall to groove, on spinner lid excircle, have the spiral cover locking axial notch of a correspondence, be furnished with locking and transplant a cutting;

Have radial ringed groove on the macropore inner end inwall of E, joint body port shoulder hole, be evenly equipped with at least 3 axial notches that are communicated with radial ringed groove from external port on the macropore inwall; Be furnished with the elasticity buckle closure, middle axial bore, the excircle that has corresponding to connected tube of elasticity buckle closure is provided with the elastic projection corresponding to the macropore axial notch, and elastic projection may be stuck in the radial ringed groove of macropore inner end inwall.

Wherein:

Can have the hole on the ring body on the breach both sides of the described annular resilient of A point locking gear ring, conveniently will lock gear ring with needle-nose pliers and clamp and put port into; Described big outer end of hole can be furnished with sealing cover, prevents that dust from entering;

The described circlip of B point is an open type, conveniently is pressed into; Big outer end of hole can be furnished with sealing cover equally.

On above-mentioned A, B basis, the utility model can also be done further improvement:

Be provided with elasticity locking gear ring opening mechanism, it can be:

The big outer end of hole of a, joint body port shoulder hole is internal thread and is furnished with one and opens blind nut, open the axial bore, the appearance that have corresponding to connected tube in the middle of the blind nut and have the ladder cylindrical shape, inner external diameter is less than the circlip internal diameter, the outer end has outside thread on the big footpath, and outermost end is hexagonal blind nut or the cylindrical blind nut that is evenly equipped with radial groove on the exterior edge face;

The big outer end of hole of b, joint body port shoulder hole is furnished with one and opens gland, open the axial bore, the appearance that have corresponding to connected tube in the middle of the gland and have the profile of ladder cylinder, inner external diameter is less than the circlip internal diameter, and the outer end is provided with outer bulge loop in the middle of the big footpath; Have the radial ringed groove of twice on the inwall of macropore inner end, be provided with inside and outside two circlips, outer back-up ring is used to open the retaining of gland;

The big outer end of hole of c, joint body port shoulder hole is furnished with one and opens gland, open the axial bore, the appearance that have corresponding to connected tube in the middle of the gland and have the profile of ladder cylinder, inner external diameter is less than the circlip internal diameter, and the outer end is provided with outer bulge loop in the middle of the big footpath; Have radial ringed groove on the inwall of macropore inner end, is furnished with the elasticity buckle closure, have axial bore in the middle of the elasticity buckle closure corresponding to connected tube, elasticity buckle closure excircle is provided with the elastic projection corresponding to the macropore axial notch, elastic projection may be stuck in the radial ringed groove of macropore inner end inwall, and this elasticity buckle closure is used to open the retaining of gland.

Described joint body can be lead directly to, elbow, threeway or cross fitting body.

Above-mentioned joint body material is irony or aluminum alloy, plastics.

The assembling of pipe joint of the present utility model:

Very simple for the pipe joint of opening elasticity locking gear ring, as long as the O-ring seal of packing into, elasticity locking gear ring is pressed into opening elasticity locking gear ring and gets final product.

As long as, be pressed into circlip for the same O-ring seal of packing into of the pipe joint that adopts circlip, elasticity locking gear ring.

For big outer end of hole is internal thread and the pipe joint of being furnished with blind nut, also be pack into successively O-ring seal, elasticity locking gear ring, tighten blind nut again.

For the pipe joint of being furnished with the spinner lid, O-ring seal, the elasticity of packing into successively locking gear ring, the axial notch of again projection of spinner lid being aimed at joint body port macropore inserts and enters after the end falls radial ringed groove on the inwall of macropore inner end, twist the certain angle of spinner lid then, make the macropore locking axial notch of spiral cover lock shaft on groove alignment macropore port inner wall on the spinner lid excircle, insert a locking at last and transplant a cutting spinner lid and joint body stuck.

The pipe joint that is provided with elasticity locking gear ring opening mechanism also can similarly be installed, and this does not give unnecessary details.

With pipe joint connecting tube of the present utility model the time, as long as the port of connected pipe end along this joint inserted, being connected invagination latch that pipe end locks gear ring with elasticity presses and to open, then to insert and arrive to positioning step, the invagination latch is stuck in outside the connected tube or just in time falls in the outer groove of connected tube at this moment, so just can prevent that connected tube from withdrawing from pipe joint.

When needs dismounting connected tube, blind nut is back-outed, or after extracting locking cutting back-out spinner lid, just can be taken out elasticity locking gear ring, extract connected tube.

The invagination latch pressure of elasticity being locked gear ring with special-purpose instrument of perhaps back-outing behind the sealing cover is in addition extracted connected tube after opening.

For the invagination latch of can be directly elasticity being locked gear ring with gland that gland is arranged press open after, extract connected tube.

Beneficial effect: pipe joint of the present utility model, the few compact structure manufacturing process of component is simply with low cost, can use iron or raw material such as aluminum alloy, plastics to make, and can not destroy the pipe joint on top layer when making assembling, connect reliably, but the quick mounting dismounting.

Description of drawings

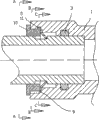

Fig. 1 is the utility model embodiment one a structure cross-sectional schematic;

Fig. 2 is that embodiment's 1 used elasticity is locked the gear ring structure cross-sectional schematic;

Fig. 3 is the left view of Fig. 2;

Fig. 4 is embodiment 1 a joint body structure cross-sectional schematic;

Fig. 5 is the used circlip structural representation of embodiment 1;

Fig. 6 is the used sealing cover structure cross-sectional schematic of embodiment 1;

Fig. 7 is the utility model embodiment two a structure cross-sectional schematic;

Fig. 8 is that embodiment's two used elasticity are locked the gear ring structure cross-sectional schematic;

Fig. 9 is the left view of Fig. 8;

Figure 10 is the utility model embodiment three a structure cross-sectional schematic;

Figure 11 is the used blind nut structure cross-sectional schematic of embodiment three;

Figure 12 is the left view of Figure 11;

Figure 13 is the utility model embodiment four a structure cross-sectional schematic (along the D-D line of Figure 16);

Figure 14 is the A-A line cross-sectional schematic (when the spinner lid does not screw) along Figure 13;

Figure 15 is the B-B line cross-sectional schematic along Figure 13;

Figure 16 is the C-C line cross-sectional schematic along Figure 13;

Figure 17 is embodiment four a joint body structure cross-sectional schematic;

Figure 18 is that schematic representation is looked on the left side of Figure 17;

Figure 19 is embodiment four a spinner lid structure cross-sectional schematic;

Figure 20 is the cross-sectional schematic of Figure 19;

Figure 21 is that schematic representation is looked on the right side of Figure 19;

Figure 22 is the schematic representation of Figure 14 after the spinner lid screws and insert the locking cutting;

Figure 23 is the utility model embodiment five a structure cross-sectional schematic;

Figure 24 is embodiment five a joint body structure cross-sectional schematic;

Figure 25 is embodiment five a locking gear ring elasticity buckle closure structure cross-sectional schematic;

Figure 26 is that schematic representation is looked on the left side of Figure 25;

Figure 27 is embodiment six a structure cross-sectional schematic;

Figure 28 is that schematic representation is looked on a unlatching blind nut structure left side of embodiment six;

Figure 29 is embodiment seven a structure cross-sectional schematic;

Figure 30 is embodiment seven a unlatching blind nut structure cross-sectional schematic;

Figure 31 is embodiment eight a structure cross-sectional schematic;

Figure 32 is embodiment eight a unlatching blind nut structure cross-sectional schematic;

Figure 33 is that schematic representation is looked on the left side of Figure 32.

Among the figure: 1-joint body, 2-connected tube, 3-O-ring seal, 4-elasticity locking gear ring, 41-ring body, 42-latch, 43-elasticity locking gear ring breach, the radial ringed groove of 5-, 6-circlip, 7-sealing cover, the 8-blind nut, the 9-axial notch, 10-spinner lid, 11-spinner lid is projection fixedly, 12-locking gear ring elasticity buckle closure, 13-elasticity buckle closure elastic projection, 14-body locking axial notch, 15-spinner cover lock mandrel is to groove, 16-locks cutting, 17-opens blind nut, and 18-opens gland, 19-gland elasticity buckle closure.

Embodiment

Extremely shown in Figure 6 as Fig. 1, pipe joint embodiment one of the present utility model, comprise the joint body 1 (Fig. 4) that has through hole, be useful on the positioning step of connected tube location in the middle of the through hole, the through hole port is three grades of inner small and outside big shoulder holes, aperture adapts to the external diameter of connected tube 2, on the aperture inwall, have the cushion rubber annular groove O-ring seal 3 is housed, elasticity locking gear ring 4 is installed in the macropore inner end of outermost end, be bearing on the step of intermediate hole, elasticity locking gear ring is ring-type (Fig. 2,3), be evenly equipped with in the inside edge of ring body 41 and a plurality ofly stretch out to the ring heart, and the latch 42 of same angle is arranged with anchor ring, the locking gear ring is provided with locking framework outward, the locking framework of present embodiment is: have radial ringed groove 5 on the macropore inner end inwall of described joint body port shoulder hole, be provided with circlip 6 (Fig. 5), so can lock locking gear ring 4.

Also can on annular resilient is locked the ring body on breach both sides of gear ring, can have the hole, conveniently will lock gear ring with needle-nose pliers and clamp and put port into.

In the left port of joint body 1, also add and be stamped sealing cover 7 (Fig. 6), prevent that foreign material from entering.Certainly the both sides port is all added a cover.

The pipe shaft of connected tube 2 has annular groove in appearance, makes things convenient for elasticity locking gear ring latch to block.

Fig. 7 is to pipe joint embodiment two shown in Figure 9, be that with embodiment's one difference locking framework is: the landolsring of ring body 41 for not sealing of annular resilient locking gear ring 4, have radial ringed groove 5 on the macropore inner end inwall of joint body 1 two ends shoulder hole, so directly annular resilient is locked gear ring 4 and be stuck in the groove corresponding to elasticity locking gear ring 4.Also have, big outer end of hole can be furnished with sealing cover 7 (not drawing among the figure) equally.

Figure 10 is to pipe joint embodiment three shown in Figure 12, be that with embodiment's one difference locking framework is: the macropore of the outermost end of joint body 1 two ends shoulder hole is tapped hole and is furnished with blind nut 8, have axial bore in the middle of the blind nut 8 corresponding to connected tube 2, blind nut 8 is that ladder is cylindrical, be evenly equipped with radial groove on the big end end face, conveniently twist, small end is shaped on outside thread.Certainly big end also can be made the hexagonal blind nut.

Figure 13 is to pipe joint embodiment four shown in Figure 22, be that with embodiment's one difference locking framework is: have radial ringed groove 5 on the macropore inner end inwall of the outermost end of joint body 1 two ends shoulder hole, and be evenly equipped with 4 axial notches 9 (Figure 13,17,18) that are communicated with radial ringed groove 5 from external port; Are furnished with spinner lid 10 (Figure 19,20,21), have axial bore, excircles corresponding to connected tube in the middle of the spinner lid 10 and be provided with corresponding to four of macropore axial notch 9 fixing projections 11, fixedly projection 11 may be stuck in the radial ringed groove 5 of macropore inner end inwall; On body macropore port inner wall, also have body locking axial notch 14, on spinner lid excircle, have the spiral cover locking axial notch 15 of a correspondence, be furnished with locking cutting 16 (Figure 22).

Figure 23 is to pipe joint embodiment five shown in Figure 26, be that with embodiment's one difference being provided with locking framework is: have radial ringed groove 5 on the macropore inner end inwall of joint body 1 two ends shoulder hole, is furnished with elasticity buckle closure 12, elasticity buckle closure 12 middle axial bore, the excircles that have corresponding to connected tube are provided with the elastic projection 13 corresponding to the macropore axial notch, elastic projection 13 may be stuck in the radial ringed groove of macropore inner end inwall, the front end of elastic projection 13 is the inclined-plane, conveniently is pressed into.

Figure 27 is to pipe joint embodiment six shown in Figure 28, be to be provided with elasticity locking gear ring opening mechanism with embodiment's one difference, its structure is: the macropore of the outermost end of joint body port shoulder hole is interior threaded hole and is furnished with one and opens blind nut 17, open the axial bore, the appearance that have corresponding to connected tube in the middle of the blind nut 17 and have the ladder cylindrical shape, inner external diameter is less than the circlip internal diameter, the outer end has outside thread on the big footpath, is evenly equipped with radial groove on the outermost end end face, conveniently twists.

Figure 29 is to pipe joint embodiment seven shown in Figure 30, be that with embodiment's six differences elasticity locking gear ring opening mechanism structure is: the big outer end of hole of joint body port shoulder hole is furnished with one and opens gland 18, open the axial bore, the appearance that have corresponding to connected tube in the middle of the gland and have the profile of ladder cylinder, inner external diameter is less than the circlip internal diameter, and the outer end is provided with outer bulge loop in the middle of the big footpath; Have the radial ringed groove of twice on the inwall of macropore inner end, be provided with inside and outside two circlips 6, outer back-up ring is used to open the retaining of gland.

Figure 31 is to pipe joint embodiment eight shown in Figure 33, the big outer end of hole of joint body port shoulder hole is furnished with one and opens gland 18, open the middle axial bore that has corresponding to connected tube of gland, appearance has the profile of ladder cylinder, inner external diameter is less than the circlip internal diameter, the outer end is provided with outer bulge loop in the middle of the big footpath, have the radial ringed groove of twice on the inwall of macropore inner end, have only the groove of the inside to be furnished with back-up ring locking gear ring, other has gland elasticity buckle closure 19, have axial bore in the middle of the gland elasticity buckle closure corresponding to connected tube, elasticity buckle closure excircle is provided with the elastic projection 13 corresponding to the macropore axial notch, elastic projection may be stuck in the radial ringed groove of outside of macropore inner end inwall, and this elasticity buckle closure is used to open the retaining of gland.

Above-mentioned joint body can be lead directly to, elbow, threeway or cross fitting body, material is irony or aluminum alloy, plastics.

Claims (10)

1, a kind of pipe joint, comprise the joint body (1) that has through hole, be useful on the positioning step of connected tube location in the middle of the through hole, it is characterized in that: described through hole port is inner small and outside big shoulder hole, aperture adapts to connected tube (2) external diameter, on the aperture inwall, have the cushion rubber annular groove O-ring seal (3) is housed, elasticity locking gear ring (4) is equipped with in the macropore inner end, elasticity locking gear ring is a ring-type, be evenly equipped with in the inside edge of ring body (41) and a plurality ofly stretch out to the ring heart, and with anchor ring the latch (42) of same angle is arranged, the outer locking framework that is provided with of elasticity locking gear ring (4).

2, pipe joint according to claim 1, it is characterized in that: described locking framework is: the landolsring of the ring body (41) of annular resilient locking gear ring (4) for not sealing has the radial ringed groove (5) corresponding to elasticity locking gear ring (4) on the macropore inner end inwall of joint body (1) port shoulder hole.

3, pipe joint according to claim 1 is characterized in that: described locking framework is: have radial ringed groove (5) on the macropore inner end inwall of joint body (1) port shoulder hole, be provided with circlip (6).

4, pipe joint according to claim 1, it is characterized in that: described locking framework is: the outermost end of joint body (1) port shoulder hole is tapped hole and is furnished with blind nut (8), have the axial bore corresponding to connected tube (2) in the middle of the blind nut (8), blind nut (8) is hexagonal blind nut or the cylindrical blind nut that is evenly equipped with radial groove on the exterior edge face.

5, pipe joint according to claim 1, it is characterized in that: described locking framework is: have radial ringed groove (5) on the macropore inner end inwall of joint body (1) port shoulder hole, and be evenly equipped with at least 3 axial notches (9) that are communicated with radial ringed groove (5) from external port; Be furnished with spinner lid (10), middle axial bore, the excircle that has corresponding to connected tube of spinner lid is provided with the fixedly projection (11) corresponding to aforementioned axial groove (9), and fixedly projection may be stuck in the aforementioned radial ringed groove (5); Also have body locking axial notch (14) on the described macropore port inner wall, on spinner lid excircle, have the spiral cover locking axial notch (15) of a correspondence, be furnished with locking cutting (16).

6, pipe joint according to claim 1, it is characterized in that: described locking framework is: have radial ringed groove (5) on the macropore inner end inwall of joint body (1) port shoulder hole, is furnished with locking gear ring elasticity buckle closure (12), have axial bore in the middle of the elasticity buckle closure corresponding to connected tube, elasticity buckle closure excircle is provided with the elastic projection (13) corresponding to the macropore axial notch, and elastic projection may be stuck in the radial ringed groove (5) of macropore inner end inwall.

7, according to claim 2 or 3 described pipe joints, it is characterized in that: be provided with elasticity locking gear ring opening mechanism: the outer end of joint body (1) port shoulder hole is tapped hole and is furnished with one and opens blind nut (17), open the axial bore, the appearance that have corresponding to connected tube in the middle of the blind nut and have the ladder cylindrical shape, inner external diameter is less than the circlip internal diameter, have outside thread on the cylindrical of outer end, outermost end is hexagonal or is evenly equipped with radial groove on the exterior edge face.

8, according to claim 2 or 3 described pipe joints, it is characterized in that: be provided with elasticity locking gear ring opening mechanism: the big outer end of hole of joint body (1) port shoulder hole is furnished with one and opens gland (18), open the axial bore, the appearance that have corresponding to connected tube in the middle of the gland and have the profile of ladder cylinder, inner external diameter is less than the circlip internal diameter, and the outer end is provided with outer bulge loop in the middle of the big footpath; Have the radial ringed groove of twice (5) on the inwall of macropore inner end, be provided with inside and outside two circlips (6), outer back-up ring is used to open the retaining of gland.

9, according to claim 2 or 3 described pipe joints, it is characterized in that: be provided with elasticity locking gear ring opening mechanism: the big outer end of hole of joint body (1) port shoulder hole is furnished with one and opens gland (18), open the axial bore, the appearance that have corresponding to connected tube in the middle of the gland and have the profile of ladder cylinder, inner external diameter is less than the circlip internal diameter, and the outer end is provided with outer bulge loop in the middle of the big footpath; Have radial ringed groove on the inwall of macropore inner end, is furnished with gland elasticity buckle closure (19), middle axial bore, the excircle that has corresponding to connected tube of gland elasticity buckle closure is provided with the elastic projection (13) corresponding to the macropore axial notch, and elastic projection may be stuck in the radial ringed groove of macropore inner end inwall.

10, pipe joint according to claim 9 is characterized in that: described joint body material is irony or aluminum alloy, plastics.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2009200510009U CN201354907Y (en) | 2009-02-06 | 2009-02-06 | Pipe junction |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2009200510009U CN201354907Y (en) | 2009-02-06 | 2009-02-06 | Pipe junction |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201354907Y true CN201354907Y (en) | 2009-12-02 |

Family

ID=41411248

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNU2009200510009U Expired - Fee Related CN201354907Y (en) | 2009-02-06 | 2009-02-06 | Pipe junction |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201354907Y (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102261531A (en) * | 2010-05-28 | 2011-11-30 | 上海大众燃气有限公司 | Gas screwed loose joint |

| CN102562029A (en) * | 2011-12-11 | 2012-07-11 | 贵州航天凯山石油仪器有限公司 | Method for protecting ultrasonic transducer from rotary installation and ultrasonic transducer fastening structure |

| CN102620078A (en) * | 2012-02-06 | 2012-08-01 | 王仕才 | Insert-type self-locking fast tube joint and disassembling tool matched with same |

| CN108103728A (en) * | 2018-01-23 | 2018-06-01 | 合肥品卓汽车零部件有限公司 | A kind of roller washing machine gas chamber connecting tube |

| CN108412741A (en) * | 2017-02-09 | 2018-08-17 | 佛山市顺德区美的饮水机制造有限公司 | Diaphragm pump and water treatment facilities |

| CN109163123A (en) * | 2018-10-29 | 2019-01-08 | 镇江市鑫浩塑胶有限公司 | A kind of integral type butterfly valve check-valves loose joint structure |

| CN110953420A (en) * | 2019-12-19 | 2020-04-03 | 宜宾三江机械有限责任公司 | Threaded conduit flexible joint |

| JP2020094604A (en) * | 2018-12-10 | 2020-06-18 | 株式会社ブリヂストン | Pipe joint and locking member |

-

2009

- 2009-02-06 CN CNU2009200510009U patent/CN201354907Y/en not_active Expired - Fee Related

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102261531A (en) * | 2010-05-28 | 2011-11-30 | 上海大众燃气有限公司 | Gas screwed loose joint |

| CN102562029A (en) * | 2011-12-11 | 2012-07-11 | 贵州航天凯山石油仪器有限公司 | Method for protecting ultrasonic transducer from rotary installation and ultrasonic transducer fastening structure |

| CN102562029B (en) * | 2011-12-11 | 2015-09-09 | 贵州航天凯山石油仪器有限公司 | Ultrasonic transducer is avoided to rotate method and the ultrasonic transducer fastening structure of installation |

| CN102620078A (en) * | 2012-02-06 | 2012-08-01 | 王仕才 | Insert-type self-locking fast tube joint and disassembling tool matched with same |

| CN108412741A (en) * | 2017-02-09 | 2018-08-17 | 佛山市顺德区美的饮水机制造有限公司 | Diaphragm pump and water treatment facilities |

| CN108103728A (en) * | 2018-01-23 | 2018-06-01 | 合肥品卓汽车零部件有限公司 | A kind of roller washing machine gas chamber connecting tube |

| CN109163123A (en) * | 2018-10-29 | 2019-01-08 | 镇江市鑫浩塑胶有限公司 | A kind of integral type butterfly valve check-valves loose joint structure |

| JP2020094604A (en) * | 2018-12-10 | 2020-06-18 | 株式会社ブリヂストン | Pipe joint and locking member |

| WO2020121871A1 (en) * | 2018-12-10 | 2020-06-18 | 株式会社ブリヂストン | Pipe joint and core material for pipe joint |

| JP7290937B2 (en) | 2018-12-10 | 2023-06-14 | 株式会社ブリヂストン | Pipe joints and core materials for pipe joints |

| CN110953420A (en) * | 2019-12-19 | 2020-04-03 | 宜宾三江机械有限责任公司 | Threaded conduit flexible joint |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101482209A (en) | Connector of pipe | |

| CN201354907Y (en) | Pipe junction | |

| US10663094B2 (en) | Fitting to connect water pipes | |

| US20100102550A1 (en) | Tube fitting | |

| CN201297462Y (en) | A soft metal sealing structure for pipeline connection | |

| CN201462256U (en) | Pipeline sealing device | |

| CN201246554Y (en) | Corrugated tube joint | |

| CN102434677A (en) | Stop valve for air conditioner | |

| CN201152423Y (en) | Joint for water pipe | |

| CN201902729U (en) | Seal connecting pair with straight-pipe rolled external thread column | |

| CN202252558U (en) | Sealing joint | |

| CN202756804U (en) | Rapid connecting plug | |

| CN206320439U (en) | A kind of fast-connection pipeline | |

| CN201277401Y (en) | Pipe connector | |

| CN206598420U (en) | A kind of plug for mold cooling system | |

| CN203641720U (en) | Pipeline connecting piece | |

| CN202612910U (en) | Movable connector for air pipe of wagon | |

| CN201363496Y (en) | Metal hard seal pipe joint | |

| CN201021741Y (en) | Pipe connector | |

| CN203780991U (en) | Sealing oil drum | |

| CN214579456U (en) | Pipeline sealing structure suitable for less oil equipment | |

| CN215414170U (en) | Pressure gauge with adjustable installation | |

| CN205678319U (en) | Quick connector | |

| CN205896421U (en) | water inlet and outlet structure of water tank and water tank | |

| CN218063777U (en) | Elastic sealing metal ferrule type pipe joint |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20091202 Termination date: 20110206 |