CN201329566Y - Chain pipe wrench - Google Patents

Chain pipe wrench Download PDFInfo

- Publication number

- CN201329566Y CN201329566Y CNU2008201304610U CN200820130461U CN201329566Y CN 201329566 Y CN201329566 Y CN 201329566Y CN U2008201304610 U CNU2008201304610 U CN U2008201304610U CN 200820130461 U CN200820130461 U CN 200820130461U CN 201329566 Y CN201329566 Y CN 201329566Y

- Authority

- CN

- China

- Prior art keywords

- chain

- jaw

- shaft

- caliper

- wrench

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Details Of Spanners, Wrenches, And Screw Drivers And Accessories (AREA)

Abstract

The utility model relates to a hand-operated tool for fastening and disassembly, and particularly discloses a chain pipe wrench for holding and swiveling a tubular workpiece. The chain pipe wrench is characterized in that a jaw shaft is arranged between the jaw and the wrench body, the jaw is hinged with the wrench body through the jaw shaft, and the jaw shaft is positioned on one edge between a chain shaft on the jaw and the other end of the jaw, which is distant from serrations, and at the end of the wrench body corresponding to the jaw, which is distant from a chain hook. The utility model can overcome the defects that loosening and slipping of the chain frequently occurs when the chain pipe wrench in the prior art is in use.

Description

Technical field

The utility model relates to a kind of be used for hand-operated tools, especially clamping and the chain wrench that rotates tubular workpiece fastening, dismounting.

Background technology

The chain wrench of the clamping of prior art and rotation round piece, by a caliper with chain hook and pincers handle, one side has the jaw that sawtooth, an end have chain shaft, jaw and caliper are an integral body, one by a plurality of links cross chain link shaft successively hinge connect the chain form, described chain shaft is positioned on the jaw end away from chain hook, one end of described chain is connected by hinge between chain shaft and the jaw, as: the People's Republic of China's disclosed chain wrench of industry standard QB1200-91 just belongs to this structure.

When using chain wrench, closely around the specific tubular workpiece of clamping, simultaneously the chain link shaft of the other end of chain and chain hook relevant position is hung on the chain hook fixingly jaw and chain, firmly rotate then and clamp handle and get final product.But, owing to have certain spacing between the adjacent chain nodal axisn, can not keep jaw and chain closely under the situation around the particular circle workpiece of clamping usually, chain hook is also aimed at a chain link shaft on the respective link just.At this moment adjacent chain link shaft can only be hung on the chain hook, thus cause chain can not clamp around workpiece, that is: the chain phenomenon that " relaxes " appears.In this case, firmly rotate the pincers handle and occur through regular meeting producing between the tubular workpiece of pipe vice and clamping and trackslip, that is: appearance " skidding " phenomenon influences the normal use of pipe vice.

Summary of the invention

The purpose of this utility model provides a kind of chain wrench, and the chain that the chain wrench that it can overcome prior art in use often occurs " relax " and the deficiency of " skidding ".

The utility model is achieved in that it comprises a caliper with chain hook and pincers handle, an one side has sawtooth, one end has the jaw of chain shaft, one by a plurality of links cross chain link shaft successively hinge link the chain form, described chain shaft is positioned on the jaw end away from chain hook, one end of described chain is connected by hinge between chain shaft and the jaw, between jaw and caliper, establish a jaw axle, jaw is connected with the caliper hinge by the jaw axle, described jaw axle between the other end of chain shaft on the jaw and jaw away from one side of sawtooth be positioned on the caliper with the corresponding end of jaw and away from the position of chain hook.

The utility model compared with prior art, owing to have and between jaw and caliper, be provided with a jaw axle, jaw is by jaw axle and the hinged technical characterictic of caliper, when using chain wrench, earlier with jaw and chain ring around tubular workpiece, strain chain again, hang on the chain hook respective link axle fixing, firmly rotate the pincers handle then downwards, at this moment be positioned at chain hook on the caliper and also follow the pincers handle and clockwise rotate with respect to jaw around the jaw axle, chain hook is strained chain thereupon simultaneously, has overcome the phenomenon that chain " relaxes ", thereby can more effectively avoid the generation of " skidding " phenomenon, guarantee the normal use of pipe vice.In addition,, can change the jaw of damage easily, and needn't change whole pipe vice, can fall replacement cost owing to only be connected between jaw and the caliper by the jaw axle.

Description of drawings

Below in conjunction with the drawings and specific embodiments the utility model is described in further detail.Wherein:

Fig. 1 is the structural map of chain wrench in the prior art.

Fig. 2 be among Fig. 1 A to zoomed-in view.

Fig. 3 is the structural map of the utility model chain wrench user mode.

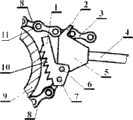

Reference numeral: 1, jaw, 2, chain hook, 3, chain link, 4, the pincers handle, 5, caliper, 6, the jaw axle, 7, chain shaft, 8, chain, 9, tubular workpiece, 10, sawtooth, 11, chain link shaft.

The specific embodiment

Describe with reference to Fig. 3: it comprises a caliper 5 with chain hook 2 and pincers handle 4, an one side has sawtooth 10, one end has the jaw 1 of chain shaft 7, a chain 8 of forming by the connection of chain link shaft 11 hinge successively by a plurality of chain links 3, described chain shaft 7 is positioned on the jaw 1 end away from chain hook 2, one end of described chain 8 is connected by hinge between chain shaft 7 and the jaw 1, between jaw 1 and caliper 5, establish a jaw axle 6, jaw 1 is connected with caliper 5 hinges by jaw axle 6, described jaw axle 6 between the other end of chain shaft 7 on the jaw 1 and jaw 1 away from sawtooth 10 one side be positioned on the caliper 5 and the position of jaw 1 a corresponding end away from chain hook 2.

When using chain wrench, earlier with jaw 1 and chain 8 around tubular workpiece 9, strain chain 8 again, respective link axle 11 is hung on the chain hook 2 fixing, firmly rotate pincers handle 4 then downwards.At this moment the chain hook 2 that is positioned on the caliper 5 is strained chain 8 thereupon, makes chain 8 clamp the tubular workpiece 9 of clamping, makes this workpiece rotation simultaneously.

Claims (1)

1, a kind of chain wrench, it comprises: the caliper (5) with chain hook (2) and pincers handles (4), an one side has sawtooth (10), one end has the jaw (1) of chain shaft (7), a chain (8) that connects to form by chain link shaft (11) hinge successively by a plurality of chain links (3), described chain shaft (7) is positioned at the last end away from chain hook (2) of jaw (1), one end of described chain (8) is connected by hinge between chain shaft (7) and the jaw (1), it is characterized in that: be provided with a jaw axle (6) between jaw (1) and the caliper (5), jaw (1) is connected by hinge between jaw axle (6) and the caliper (5), described jaw axle (6) be positioned at jaw (1) go up between the other end of chain shaft (7) and jaw (1) away from one side of sawtooth (10) be positioned on the caliper (5) and the corresponding end of jaw (1) and away from the position of chain hook (2).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2008201304610U CN201329566Y (en) | 2008-12-12 | 2008-12-12 | Chain pipe wrench |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2008201304610U CN201329566Y (en) | 2008-12-12 | 2008-12-12 | Chain pipe wrench |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201329566Y true CN201329566Y (en) | 2009-10-21 |

Family

ID=41222940

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNU2008201304610U Expired - Fee Related CN201329566Y (en) | 2008-12-12 | 2008-12-12 | Chain pipe wrench |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201329566Y (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104097157A (en) * | 2014-07-17 | 2014-10-15 | 福建省南平市延平区迈玄机械设计有限公司 | Flexible drill rod tongs |

| CN110978108A (en) * | 2019-12-27 | 2020-04-10 | 金华市亚虎工具有限公司 | Sawtooth bracket for cutting machine support |

-

2008

- 2008-12-12 CN CNU2008201304610U patent/CN201329566Y/en not_active Expired - Fee Related

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104097157A (en) * | 2014-07-17 | 2014-10-15 | 福建省南平市延平区迈玄机械设计有限公司 | Flexible drill rod tongs |

| CN104097157B (en) * | 2014-07-17 | 2016-06-15 | 福建省南平市延平区迈玄机械设计有限公司 | flexible free pliers |

| CN110978108A (en) * | 2019-12-27 | 2020-04-10 | 金华市亚虎工具有限公司 | Sawtooth bracket for cutting machine support |

| CN110978108B (en) * | 2019-12-27 | 2024-03-29 | 金华市亚虎工具有限公司 | Sawtooth bracket for cutting machine support |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2008157424A3 (en) | Methods and apparatus for joint disassembly | |

| CN203438157U (en) | Disassembly pincers for quick coupler of automobile oil pipe | |

| WO2010030832A3 (en) | Hand tool articulating apparatus with offset handle | |

| CN201329566Y (en) | Chain pipe wrench | |

| CN201455867U (en) | Friction pipe plier | |

| CN204604195U (en) | Five metals spanner | |

| CN202367624U (en) | Slip joint pliers | |

| CN203510035U (en) | Hexagon socket screw spanner | |

| CN202212905U (en) | Round-head internal hexagonal wrench suit | |

| CN202924694U (en) | Novel crow bar | |

| CN2748227Y (en) | Plench | |

| CN201579731U (en) | Multipurpose speed wrench | |

| CN2633513Y (en) | Semi automatic socket spanner | |

| WO2010079211A3 (en) | Pliers for establishing a sliding-sleeve connection | |

| CN2767063Y (en) | Dual-purpose pipe wrench | |

| CN204748513U (en) | Novel piston ring dismouting pincers | |

| CN203317293U (en) | Spanner | |

| CN2732425Y (en) | Lever-type pipe wrench | |

| CN2723123Y (en) | Simple ratchet spanners | |

| CN203901131U (en) | Multi-purpose plier | |

| CN202428362U (en) | Convenient and practical F-shaped spanner | |

| CN202021574U (en) | Flexible multipurpose pipe tongs | |

| CN2792707Y (en) | Pliers with adjustable bite | |

| CN202207984U (en) | Multipurpose wrench | |

| CN201960500U (en) | Multifunctional rod clamp |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20091021 Termination date: 20100112 |